Anyone seen this new rotary engine design? LiquidPiston X engine.

#1

Anyone seen this new rotary engine design? LiquidPiston X engine.

Has anyone seen this new rotary design? Check this out:

The engine above is a diesel. They're claiming up to 50% reduction in diesel fuel consumption while the motor is 75% smaller than similar power output diesels. Gasoline motors are a similar design but lower compression ratio. They're saying about a 20% decrease in fuel consumption and 30% smaller than a similar output traditional gasoline motor. They claim it will be scalable from 1 hp to 1,000 hp. They received $1m in funding from DARPA. Here's a few articles:

Crazy-Efficient Rotary Engine Lands Million-Dollar DARPA Contract

LiquidPiston's Hyper-Efficient Engine: Turning the Rotary Inside Out

Small engine packs a punch | MIT News

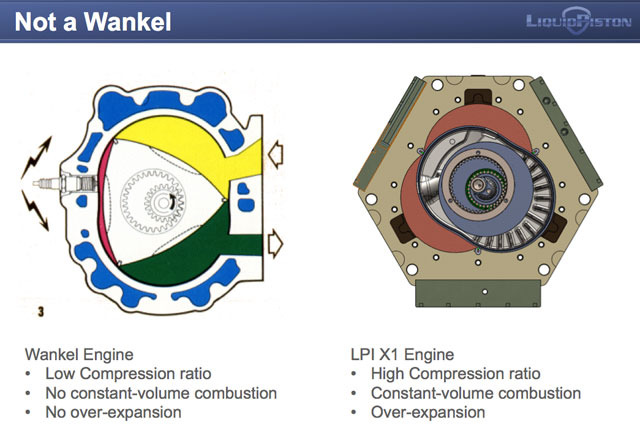

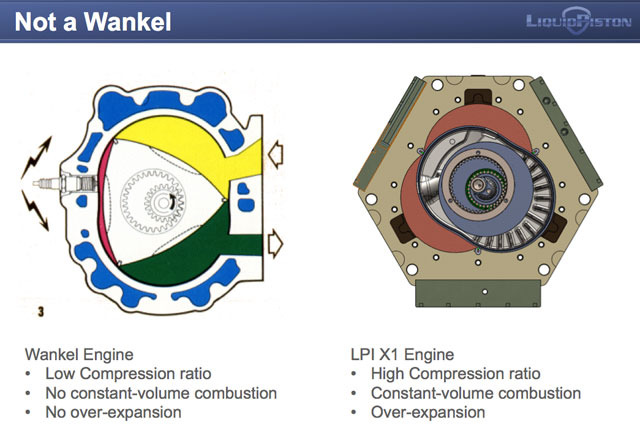

Quick diagram:

In my opinion, its brilliant! They've inverted the idea of the traditional Wankel rotary! No more triangle in oval housing; I like the oval in the

(triple?) triangle housing idea! With 3 combustion chambers within one housing its no wonder the efficiency/size ratio is so high! Unfortunately, it doesn't look like you would be able to "stack" this design, so you're probably "stuck" with only 1 housing, but the one housing is essentially a 3 combustion chamber (cylinder/housing design) in a compact package!

I did a bit of reading about this design and it really is genius. No more apex seals on the edges of the rotor that need to be lubricated with injected/consumed oil; the apex seals in this design are stationary on the housing itself (tips of the combustion chambers from my estimation). This would essentially mean it shouldn't consume nearly as much oil as a Wankel rotary, and consequently, should reduce emissions (a long time sore spot with making rotaries emissions legal).

I'm curious to see how large this engine would be when scaled to around the ~300hp mark. I'm just sayin'.... Interesting that they're only really marketing it towards small appliances & military applications and not cars. I guess it makes sense though, as auto manufacturers are now leaning heavily towards making electric (and possibly hydrogen powered) powered cars as the next wave of transportation. I'm also curious to see how robust this design is; specifically the apex seals, as they've seemingly been one of the primary limiting factors in high HP Wankels. Also curious about the solidity of the intake/exhaust ports as they're within the rotors themselves. It's too bad this design wasn't invented 20+ years ago when the internal combustion engine was still fully reigning supreme... Either way, I really like this concept and it would be interesting to see a major auto manufacturer pick up on it.

Dear Mazda: rotary powered sports cars are in your heritage and you have fairly deep pockets.... I'm just throwing that out there!

The engine above is a diesel. They're claiming up to 50% reduction in diesel fuel consumption while the motor is 75% smaller than similar power output diesels. Gasoline motors are a similar design but lower compression ratio. They're saying about a 20% decrease in fuel consumption and 30% smaller than a similar output traditional gasoline motor. They claim it will be scalable from 1 hp to 1,000 hp. They received $1m in funding from DARPA. Here's a few articles:

Crazy-Efficient Rotary Engine Lands Million-Dollar DARPA Contract

LiquidPiston's Hyper-Efficient Engine: Turning the Rotary Inside Out

Small engine packs a punch | MIT News

Quick diagram:

In my opinion, its brilliant! They've inverted the idea of the traditional Wankel rotary! No more triangle in oval housing; I like the oval in the

(triple?) triangle housing idea! With 3 combustion chambers within one housing its no wonder the efficiency/size ratio is so high! Unfortunately, it doesn't look like you would be able to "stack" this design, so you're probably "stuck" with only 1 housing, but the one housing is essentially a 3 combustion chamber (cylinder/housing design) in a compact package!

I did a bit of reading about this design and it really is genius. No more apex seals on the edges of the rotor that need to be lubricated with injected/consumed oil; the apex seals in this design are stationary on the housing itself (tips of the combustion chambers from my estimation). This would essentially mean it shouldn't consume nearly as much oil as a Wankel rotary, and consequently, should reduce emissions (a long time sore spot with making rotaries emissions legal).

I'm curious to see how large this engine would be when scaled to around the ~300hp mark. I'm just sayin'.... Interesting that they're only really marketing it towards small appliances & military applications and not cars. I guess it makes sense though, as auto manufacturers are now leaning heavily towards making electric (and possibly hydrogen powered) powered cars as the next wave of transportation. I'm also curious to see how robust this design is; specifically the apex seals, as they've seemingly been one of the primary limiting factors in high HP Wankels. Also curious about the solidity of the intake/exhaust ports as they're within the rotors themselves. It's too bad this design wasn't invented 20+ years ago when the internal combustion engine was still fully reigning supreme... Either way, I really like this concept and it would be interesting to see a major auto manufacturer pick up on it.

Dear Mazda: rotary powered sports cars are in your heritage and you have fairly deep pockets.... I'm just throwing that out there!

#3

#6

The constant volume thing is pretty important, it addresses directly why our engines are not fuel efficient : there is a pocket of rich mixture in the trailing portion of the moving combustion chamber that quenches the flame front. It's why we have a second spark plug, to relight the mixture so it doesn't just go out the tail pipe. In this case the combustion volume isn't being asked to move much, so you should get more usable power out of the same amount burned. Hope they can make it happen!

#7

Back to the drawing board guys, the chief engineer doesn't approve.

The constant volume thing is pretty important, it addresses directly why our engines are not fuel efficient : there is a pocket of rich mixture in the trailing portion of the moving combustion chamber that quenches the flame front. It's why we have a second spark plug, to relight the mixture so it doesn't just go out the tail pipe. In this case the combustion volume isn't being asked to move much, so you should get more usable power out of the same amount burned. Hope they can make it happen!

The constant volume thing is pretty important, it addresses directly why our engines are not fuel efficient : there is a pocket of rich mixture in the trailing portion of the moving combustion chamber that quenches the flame front. It's why we have a second spark plug, to relight the mixture so it doesn't just go out the tail pipe. In this case the combustion volume isn't being asked to move much, so you should get more usable power out of the same amount burned. Hope they can make it happen!

#8

Fuel isn't the problem, and more fuel isn't going to solve this. Instead of fuel, picture laundry going through the engine, like a washing machine. As the rotor turns, all the laundry will be at the back of the combustion chamber and, like laundry, it doesn't burn up instantly. There is a flame front that has to travel the length of the chamber, and it gets quenched as it reaches the rich portion at the back, so some of that gas never burns (and what does burn is less useful since it's pushing the rotor backward).

Ideally you want all of the burn to happen at the front of the combustion chamber, and not have any fuel in the back, but to do that your charge air would have to come in through the rotor front of the rotor itself and be already compressed and none of this makes sense.

But if your compression chamber is not moving, the problem is solved.

Ideally you want all of the burn to happen at the front of the combustion chamber, and not have any fuel in the back, but to do that your charge air would have to come in through the rotor front of the rotor itself and be already compressed and none of this makes sense.

But if your compression chamber is not moving, the problem is solved.

#9

Ahh gotcha..... So it's like throwing the dirty laundry in and then When you open the lid and expect to find it clean, BAM it's still dirty. I wish it was as easy as doing laundry, they can just add a smidge of oxy and BAM, no more dirty laundry.

#11

Reviving a dead thread - I just stumbled upon this today, and I get it that it works in theory and after slapping one on a go-kart in practice. I'd like to see if it would have full scale automotive applications but...spinning doritos are still best.

#12

These guys are still around and kicking - and there's a cool new video from the guy that did the Wankel with the transparent front cover.

Hopefully they can find investors/partners to put this into a product, but with "electrification" all the rage these days, I have my doubts,

Hopefully they can find investors/partners to put this into a product, but with "electrification" all the rage these days, I have my doubts,

Thread

Thread Starter

Forum

Replies

Last Post