Scale Furai - Scale 20B Nitro Engine

#26

nice update!!!

in response to this question, i couldn't even imagine. the small single piston OS engines get up to 50k, and now this one's a rotary. Assuming an average car goes up to 6k and a normal rotary goes up to 9k, and assuming the single piston OS engine is average, this baby will get up to 75k rpm  whoa!

whoa!

whoa!

whoa!

#28

guess not

guess not

#29

#31

EDIT: sorry for "ruining" the thread. good luck, however!

#33

You should contact some of the large RC manufacturers and ask for some free parts! lol A cool little project like this can attract attention from different people and what not. Get that car in a RC mag

#35

#36

I agree with this suggestion, to some extent. I think your work is exceptional and could get lots of attention from the general public.

#37

^ all depends on what you want to do. So far I have bought two used complete engines (OS 30 Wankel) for $170 each. They are around $350-400 new and you need 2 of them for a "13b" so far im up to ~$350 on the engine.

I have access to a water jet and milling machines for the center/side plates, if you don't its around $40 an hour to have it sent away. I have not looked into materials for the plates/shaft yet, but I do not expect that to be more than $100.

I'm not going this route but here is another option for joining engines...

I have access to a water jet and milling machines for the center/side plates, if you don't its around $40 an hour to have it sent away. I have not looked into materials for the plates/shaft yet, but I do not expect that to be more than $100.

I'm not going this route but here is another option for joining engines...

I am working on a similar project and I hadn't seen this thread....funny! Good luck on your project!

Best regards,

Chris

#38

#40

I had already posted this as a joke some time ago, but here it is again: Mini wankel

#41

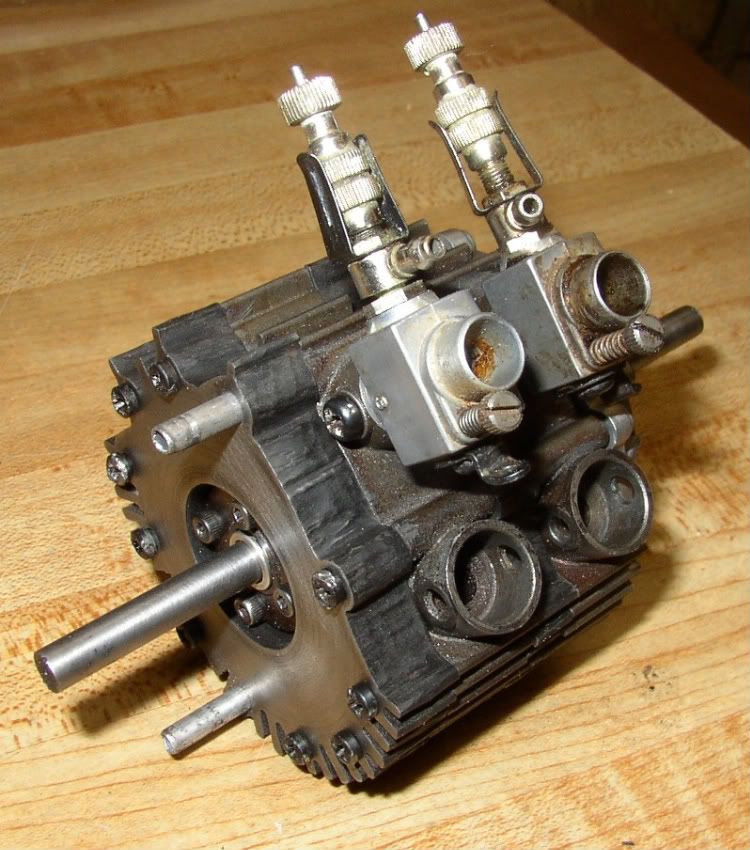

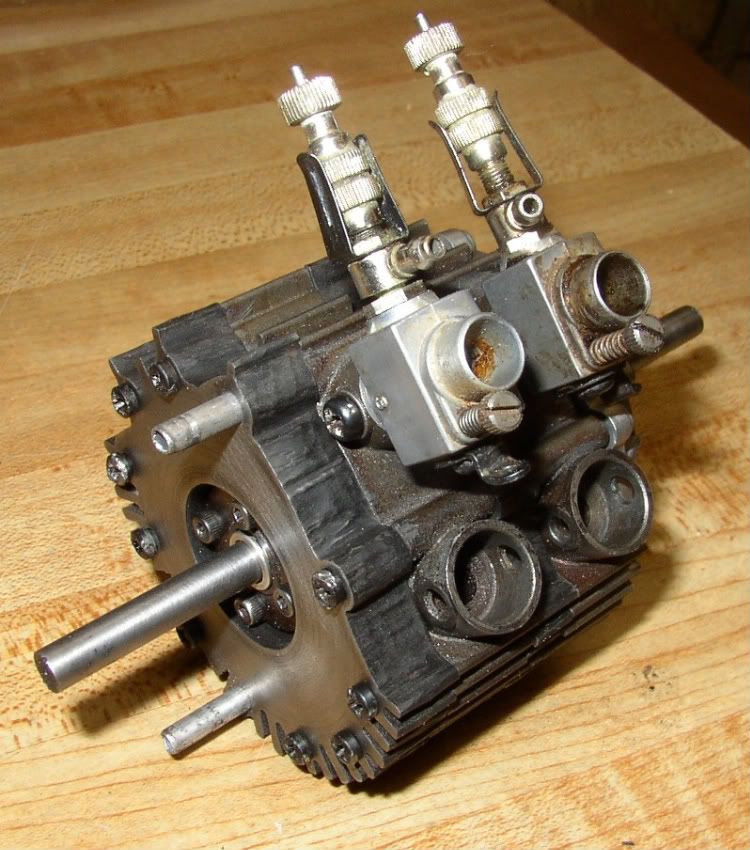

here is my almost complete 13b. So far the only remaining tasks are to buy threaded rod for the long bolts, thread the eccentric shaft, bend the exhaust tubing, and order some new apex seal springs.

The engine does not have the water passages drilled yet because I am waiting to see if they are truly necessary for the model. I will run the engine while monitoring the temperature to decide. I have attached the front OS engine cover (bell housing location) to hopefully gain some cooling from the side mounted fins.

The side housings and eccentric shaft were also heated until they were glowing red and then oil quenched to help harden the surfaces and increase wear resistance. Note to self: do not grab the end of the pliers that were holding red hot metal with you bare hands!

Rear side housing ready to be cut to shape.

Just completed grinding the rear housing profile, the alignment rods need to be cut to length.

The engine completed to this point.

I hope to have a video of it running in the next few weeks. Somehow during the machining I managed to lose one of my fixed gears so I will have to order one of them as well, great waste of $40.

The engine does not have the water passages drilled yet because I am waiting to see if they are truly necessary for the model. I will run the engine while monitoring the temperature to decide. I have attached the front OS engine cover (bell housing location) to hopefully gain some cooling from the side mounted fins.

The side housings and eccentric shaft were also heated until they were glowing red and then oil quenched to help harden the surfaces and increase wear resistance. Note to self: do not grab the end of the pliers that were holding red hot metal with you bare hands!

Rear side housing ready to be cut to shape.

Just completed grinding the rear housing profile, the alignment rods need to be cut to length.

The engine completed to this point.

I hope to have a video of it running in the next few weeks. Somehow during the machining I managed to lose one of my fixed gears so I will have to order one of them as well, great waste of $40.

#42

What type of rpms are you estimating to spin? That tiny of a motor I am assuming the rpms would be north of 15k ? Also on your motor why does the housing have fins or spines on it? Is this for cooling, strength, stress or just by design ?

Such a cool project, keep up the good work.

Such a cool project, keep up the good work.

#43

^thanks, I appreciate it.

A single OS engine is capable of 1.27hp @ 17k rpm's. I cannot give an exact answer on what my red line will be but, since I have increased the size of the engine the rpm's should be below 17k.

The fins on the housing are for cooling since it is made for rc planes it is air cooled from the propeller.

This project is to develop a prototype to test my machining and get experience with small scale rotaries. If this works I have already begun designs on a scale engine based exactly from the 13b (1/4 scale), and will include side and oil seals, water jacket, oil lubricated bearings, etc. This will not be made from any available engines, so all parts would be one off machined parts.

A single OS engine is capable of 1.27hp @ 17k rpm's. I cannot give an exact answer on what my red line will be but, since I have increased the size of the engine the rpm's should be below 17k.

The fins on the housing are for cooling since it is made for rc planes it is air cooled from the propeller.

This project is to develop a prototype to test my machining and get experience with small scale rotaries. If this works I have already begun designs on a scale engine based exactly from the 13b (1/4 scale), and will include side and oil seals, water jacket, oil lubricated bearings, etc. This will not be made from any available engines, so all parts would be one off machined parts.

#45

Glad to see you are still working on this project and making progress! Can't wait to see the video of this little wonder engine running! If you ever get to the point of making a kit, let me know please!