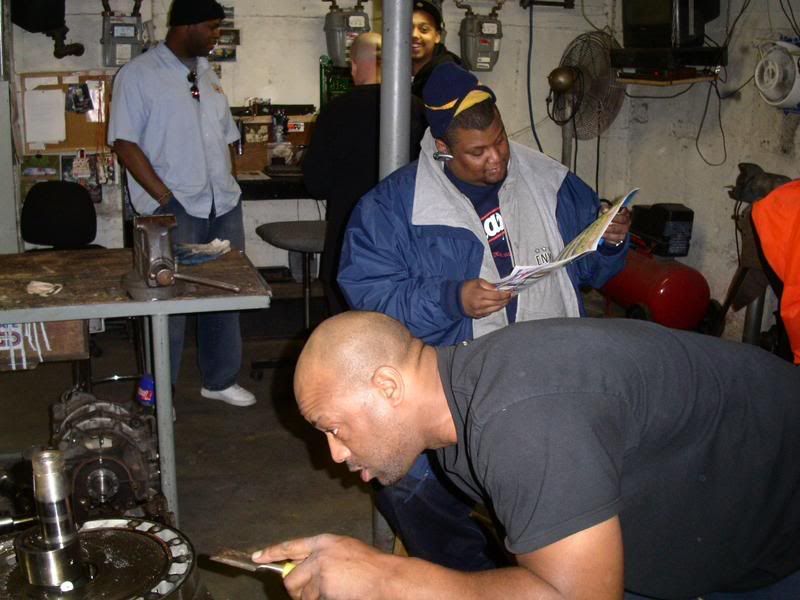

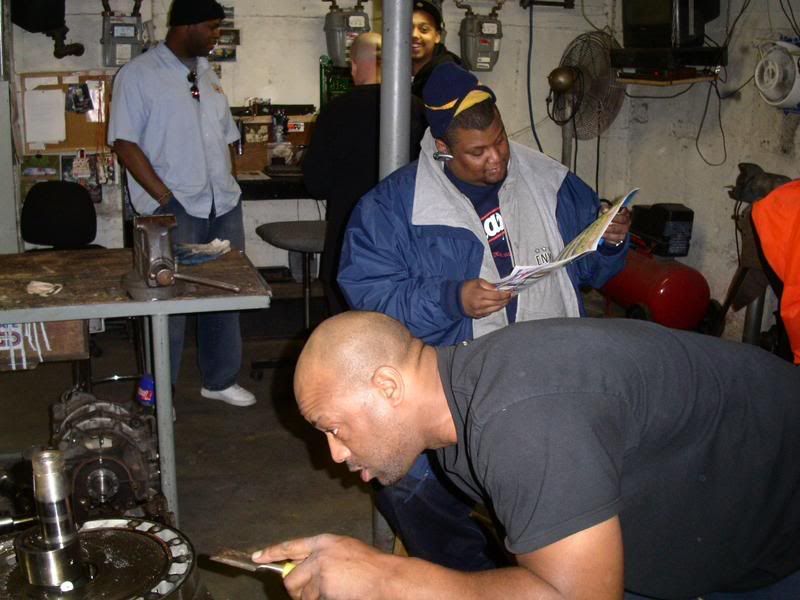

First Rotary Engine Tear Down (56k Beware)

#1

Well today i got my cherry popped 3 times. We tore down 1 12A engine, and two 13B engines.

12A was in my boys first gen, was leaking oil

13B was in my old 88SE car which for some odd reason wound up back into myhands after 5 years (Small world). I think it had a coolant leak

13B in my 89 GTU that i sold, the engine was seized due to a thrustwasher disintergration.

First we started with the 12a, i was helping here and there with the parts etc. I took pics of the tear down step by step for a future write up.

The 13B from my old 88, i didnt take any pictures of it, was actually getting more hands on.

The second and more messed up 13B from the 89 GTU was done 100% by me, took me a lil bit longer than the other guys, but i did okay. Till i hite one major issue, the thrust washer where the front cover is located was DISINTERGRATED. So i decided to finish it off another day.

Here are some pics enjoy

PREPARATION

12A Tear Down

CUSTOM MADE ENGINE STAND

In Peices

Jason NYC

12A was in my boys first gen, was leaking oil

13B was in my old 88SE car which for some odd reason wound up back into myhands after 5 years (Small world). I think it had a coolant leak

13B in my 89 GTU that i sold, the engine was seized due to a thrustwasher disintergration.

First we started with the 12a, i was helping here and there with the parts etc. I took pics of the tear down step by step for a future write up.

The 13B from my old 88, i didnt take any pictures of it, was actually getting more hands on.

The second and more messed up 13B from the 89 GTU was done 100% by me, took me a lil bit longer than the other guys, but i did okay. Till i hite one major issue, the thrust washer where the front cover is located was DISINTERGRATED. So i decided to finish it off another day.

Here are some pics enjoy

PREPARATION

12A Tear Down

CUSTOM MADE ENGINE STAND

In Peices

Jason NYC

#6

it was fun. Next were going to clean off everything properly and see whats good and whats not. The 12a looks fine, and the two 13Bs we think we can make 1 really good one. Then were either gonna slap that on our toyota starlet, vw golf or into the rx4. STill dunno yet lol

More pics here http://s155.photobucket.com/albums/s...ROTARYROCKET6/

Jason NYC

More pics here http://s155.photobucket.com/albums/s...ROTARYROCKET6/

Jason NYC

#9

well the 12a is def gonna be rebuilt, were putting that baby in a car. IT was just missing two orings on between the irons and housing so the oil was spewing thru there. it was running fine before that. Little cleaning and we will see whats up.

THe 13B we will see if we make 1 good engine or just keep the parts for future repairs or sell them i guess.

Well we got more beer after that we got 6 of the big Heins, i dont drink much took me 2 coronas =)

More pics

http://s155.photobucket.com/albums/s...ROTARYROCKET6/

THe 13B we will see if we make 1 good engine or just keep the parts for future repairs or sell them i guess.

Well we got more beer after that we got 6 of the big Heins, i dont drink much took me 2 coronas =)

More pics

http://s155.photobucket.com/albums/s...ROTARYROCKET6/

#12

At least you started with the appropriate set of yellow and green tools in the cooled storage toolbox.

With the proper tools, even the toughest job can be made more enjoyable.

I'd highly recommend you invest in some other tools for rebuilding engines. My favorites have to be the 'Papa Johns' discs, and the 'Fast Boys Wings' wing assemblies.

Enjoy!

With the proper tools, even the toughest job can be made more enjoyable.

I'd highly recommend you invest in some other tools for rebuilding engines. My favorites have to be the 'Papa Johns' discs, and the 'Fast Boys Wings' wing assemblies.

Enjoy!

#13

I helped a friend rebuild a 12A in an '80 RX-8. Lots of fun.

If you have any questions, let me know.. I may remember some tips. (BTW don't hookup the washer fluid tank to the carb cold-start assist line..... it'll gum up the carb really badly.. guess at how we found that out?) :P

(BTW don't hookup the washer fluid tank to the carb cold-start assist line..... it'll gum up the carb really badly.. guess at how we found that out?) :P

--Mark

If you have any questions, let me know.. I may remember some tips.

(BTW don't hookup the washer fluid tank to the carb cold-start assist line..... it'll gum up the carb really badly.. guess at how we found that out?) :P

(BTW don't hookup the washer fluid tank to the carb cold-start assist line..... it'll gum up the carb really badly.. guess at how we found that out?) :P--Mark

#14

Originally Posted by skillmaker

At least you started with the appropriate set of yellow and green tools in the cooled storage toolbox.

With the proper tools, even the toughest job can be made more enjoyable.

I'd highly recommend you invest in some other tools for rebuilding engines. My favorites have to be the 'Papa Johns' discs, and the 'Fast Boys Wings' wing assemblies.

Enjoy!

With the proper tools, even the toughest job can be made more enjoyable.

I'd highly recommend you invest in some other tools for rebuilding engines. My favorites have to be the 'Papa Johns' discs, and the 'Fast Boys Wings' wing assemblies.

Enjoy!

#19

Originally Posted by rotaryWizard

whats your experience with the renesis?

Anyone want to donate a renesis? I guess not lol, bad jason

I will be doing a full write up sometime this summer, but not right now kinda busy with school, but ater i think ill be good.

Originally Posted by RoXanneBlack8

the hole for the trailing plugs are smaller to reduce blowby when the apex seals pass over them

For those of you who dont know, Leading (Lower), Trailing (top), good way of remembering them =)

Best regards

Jason NYC

NYRA President

www.nyrotary.com

#20

i think 'blowby' means gases that could pass over the apex seal as it crosses the spark opening. if the hole's diameter is larger than the thickness of the seal, then there would be some time where flow over the seal is possible. (though passing over any void would probably let some gas past the seal)

btw, nice work -

I'm a little jealous as I don't have much opportunity to do that kind of thing.

btw, nice work -

I'm a little jealous as I don't have much opportunity to do that kind of thing.

#22

Originally Posted by secret8gent

i think 'blowby' means gases that could pass over the apex seal as it crosses the spark opening. if the hole's diameter is larger than the thickness of the seal, then there would be some time where flow over the seal is possible. (though passing over any void would probably let some gas past the seal)

btw, nice work -

I'm a little jealous as I don't have much opportunity to do that kind of thing.

btw, nice work -

I'm a little jealous as I don't have much opportunity to do that kind of thing.

thanks, that does pose an interesting point.

Yaeh i dont have enuff time either, but what i did was i got my test back and i bombed it, so i was mad upset during class. Then i kept thinking happy thoughts sex, rotary. ANd im like i cant get sex so rotary it is. SO i got up and left, the teacher was like jason where are you going, im going over the test, i said to get my rx7. She didnt understand. Funny thing is the class is a transportation class.

SO i cut school, got my car and the same day did the 3 engines. So i made a lil time. SPring break is coming up so is my NYRA meet on 4/8 in Valley Stream LI, so ima be working on my car the entire spring break. GOing to put portions of my suspension on =)

Thanks to everyone for checking out the pics

#23

Originally Posted by ROTARYROCKET7

This is one thing i never knew about, and never heard anyone mention. The size of the spark plug holes are different.

Wow, that's one of the weirdest burn patterns I've ever seen on a housing

Was that the 12A, or the 13B?

Edit: Doh, didn't notice the aux. ports in on the iron..13B. Still, weird burn mark!

Thread

Thread Starter

Forum

Replies

Last Post

Sifu

RX-8 Parts For Sale/Wanted

3

08-30-2015 11:51 PM