New OILs for 2016 My findings and discussion

#1

New OILs for 2016 My findings and discussion

Hey all,

Ok so i am a noob and proud of it. Recently I have spent hours searching the forum and google searching oil types and specs for my RX8 which has turned up some interesting results which i would like to share with you all and create a discussion for.

Engine oil is a big question asked many times on here which is good because it has gave me allot of pointers to go looking for further information regarding the subject.

Because the Rotary engine naturally burns oil in the cylinders it is no surprise that today's engine oil additives will coke up the apex seals but here is what i have found.

API codes, ACEA codes and ILSEC codes.

Reading through these standardised labels and specs as well as spending allot of time on the Castrol site has uncovered some interesting facts.

There are some new oils out with code specs C2, C3, C4.

These codes allow for very low ash as to protect the catalytic convertor. This is pretty useful for us as we can find a correct spec for the RX* seen as it suffers from this problem allot.

ACEA Engine Oil Specifications - oilspecifications.org

API standards

API Engine Oil Lubricant Specifications - oilspecifications.org

ILSAC standards

ILSAC Oil Specifications - oilspecifications.org

For the RX8 the minimum API spec is SL,SM so an API spec of SN is better. The key i have found is to find an oil with API spec greater than SL but also has at least a ACEA spec of C3 which has an ash, sulphated %wt of 0.8 or less so it burns clean.

A ACEA C4 burns even cleaner at around 0.4 %wt Ash but the API SL spec does not seem to be met with such low ash levels.

Furthermore Mineral and Semi-Synth oils have all had a massive load of additives added which makes their Ash, Sulphated values very high(~1.5%wt) and above so the Mazda manual recommending mineral oil is now out of date due to the additives.

That said there is some Castrol GTX with ACEA grade C4 but does not seem to meet the API SN spec again so one needs drop to a C3 standard to have the API SN grade again.

Both standards are met for conventional, semi-synth and synthetic EDGE titanium oils.

From what websites recommend they say A5/B5 grades which from the data sheets show a very high ash deposit when burnt so i not sure why they recommend this oil.

An API SN with ACEA C3 would be a minimum spec oil to today's standard for the rotary i would have thought.

In the UK we have the choice of 5W30 and upwards, i have not seen 5W20 on the shelf anywhere and i am convinced that a 5W30 from Castrol looses its lubricity in the rotary engine due to the heat it produces especially at 3000rpm and over.

API SN meets the ILSAC specs according to form so you cant use an oil without the container specifying this spec code. The addition of the C3 code seems the best option as they add less phosphor and sulphates in the oil so it burns cleaner from the way I understand it so it is a good choice to use it.

What do you all think, am I on the right track in selecting the best oil for my RX8 or have i just ventured down a rabbit hole into the dark depths of confused marketing jargon?

I am thinking of using Castrol EDGE Titanium 5W40 API SN with ACEA C3. Good or Bad choice?

And anyone know what we do about the 4 Litres of oil that does not drain from the oil coolers?

Ok so i am a noob and proud of it. Recently I have spent hours searching the forum and google searching oil types and specs for my RX8 which has turned up some interesting results which i would like to share with you all and create a discussion for.

Engine oil is a big question asked many times on here which is good because it has gave me allot of pointers to go looking for further information regarding the subject.

Because the Rotary engine naturally burns oil in the cylinders it is no surprise that today's engine oil additives will coke up the apex seals but here is what i have found.

API codes, ACEA codes and ILSEC codes.

Reading through these standardised labels and specs as well as spending allot of time on the Castrol site has uncovered some interesting facts.

There are some new oils out with code specs C2, C3, C4.

These codes allow for very low ash as to protect the catalytic convertor. This is pretty useful for us as we can find a correct spec for the RX* seen as it suffers from this problem allot.

ACEA Engine Oil Specifications - oilspecifications.org

API standards

API Engine Oil Lubricant Specifications - oilspecifications.org

ILSAC standards

ILSAC Oil Specifications - oilspecifications.org

For the RX8 the minimum API spec is SL,SM so an API spec of SN is better. The key i have found is to find an oil with API spec greater than SL but also has at least a ACEA spec of C3 which has an ash, sulphated %wt of 0.8 or less so it burns clean.

A ACEA C4 burns even cleaner at around 0.4 %wt Ash but the API SL spec does not seem to be met with such low ash levels.

Furthermore Mineral and Semi-Synth oils have all had a massive load of additives added which makes their Ash, Sulphated values very high(~1.5%wt) and above so the Mazda manual recommending mineral oil is now out of date due to the additives.

That said there is some Castrol GTX with ACEA grade C4 but does not seem to meet the API SN spec again so one needs drop to a C3 standard to have the API SN grade again.

Both standards are met for conventional, semi-synth and synthetic EDGE titanium oils.

From what websites recommend they say A5/B5 grades which from the data sheets show a very high ash deposit when burnt so i not sure why they recommend this oil.

An API SN with ACEA C3 would be a minimum spec oil to today's standard for the rotary i would have thought.

In the UK we have the choice of 5W30 and upwards, i have not seen 5W20 on the shelf anywhere and i am convinced that a 5W30 from Castrol looses its lubricity in the rotary engine due to the heat it produces especially at 3000rpm and over.

API SN meets the ILSAC specs according to form so you cant use an oil without the container specifying this spec code. The addition of the C3 code seems the best option as they add less phosphor and sulphates in the oil so it burns cleaner from the way I understand it so it is a good choice to use it.

What do you all think, am I on the right track in selecting the best oil for my RX8 or have i just ventured down a rabbit hole into the dark depths of confused marketing jargon?

I am thinking of using Castrol EDGE Titanium 5W40 API SN with ACEA C3. Good or Bad choice?

And anyone know what we do about the 4 Litres of oil that does not drain from the oil coolers?

#3

This may finally be a rabbit hole worth traveling. Lower ash can only be a good thing.

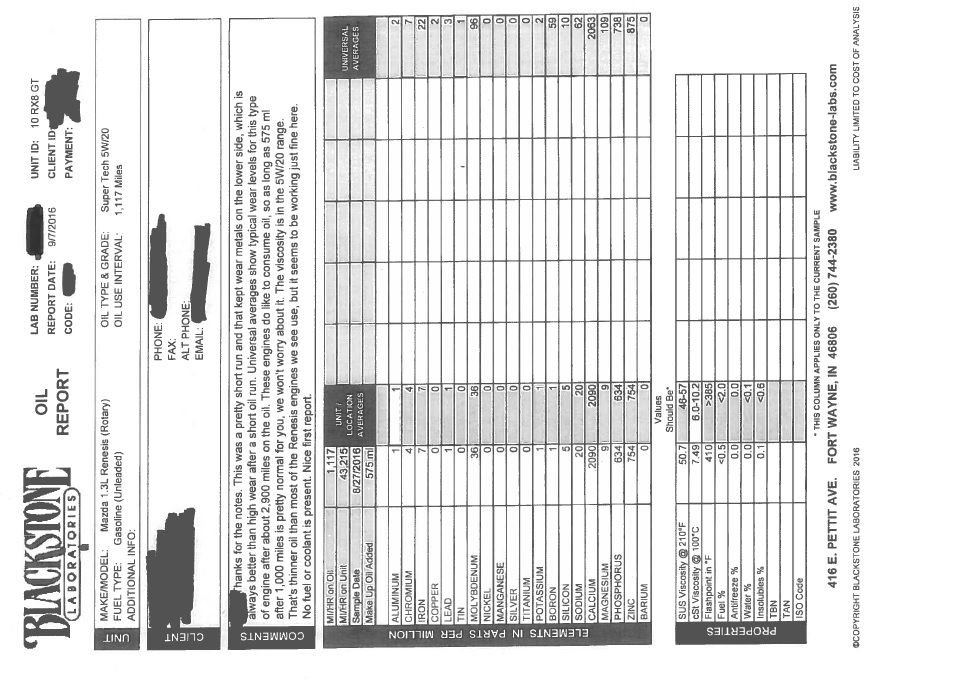

That oil certainly won't hurt anything, as long as you change it regularly (every 3K miles seems to be best according to used oil analysis).

The oil that remains in the lines and coolers will eventually be diluted down to nothing as you continue to change the oil. I wouldn't worry about it.

That oil certainly won't hurt anything, as long as you change it regularly (every 3K miles seems to be best according to used oil analysis).

The oil that remains in the lines and coolers will eventually be diluted down to nothing as you continue to change the oil. I wouldn't worry about it.

#4

Thanks guys.

I been continuing my research on this and it is interesting to see the differences between manufacturers and the viscosity ratings used.

If we look at the Castrol edge 0W30 A3/B3 @ 100'c it has a viscosity of 9.7 cSt when the Castrol 0w30 with spec C3 has a viscosity @ 100'c of 12.3 cSt.

Furthermore the 5w40 Castrol edge has a viscosity of 13 @ 100'c. That is 0.7 off from the 0w30 edge C3 oil.

If you put in your reg to the Halfords site it recommends the magnatec 0w30 A3/B4(which has a high ash, sulphated rating due to higher zinc sulphate additive) and Patronas 5w30.

The Patronas XS 5000 5w30 which meets API-SN spec and ACEA-C3 and has a viscosity of 11.6 cSt @ 100'c but also advertises cooltech which is some synthetic heat conductive additive in the oil to keep it cooler(especially for oil cooled cars)

All these oils seem to meet the specs of HTHS High Temp High Sheer which is Dynamic viscosity breakdown @ 150'c

The differences between the Castrol 0w30 and 5w40 C3's are so close it is depending on climate temperature and or race tuning. There is really nothing in it and due to the 5w40 having a higher viscosity index by +3 it is a no brainier in that it seems more sensible to use the 5w40 in the UK summer climate.

0w pour point is around -50'c which i don't think we have ever had in the UK ever. That said the 0w30 would reach operating temperature faster than the 5w40.

As would the Patronas which would get up to temp faster to clean, lubricate and flow in the hydrodynamic bearings at the cost of less load pressure handling.

Am i right in thinking that if you drive hard you are better off with that higher viscosity to handle the hard heavy load of a heavy foot?

I been continuing my research on this and it is interesting to see the differences between manufacturers and the viscosity ratings used.

If we look at the Castrol edge 0W30 A3/B3 @ 100'c it has a viscosity of 9.7 cSt when the Castrol 0w30 with spec C3 has a viscosity @ 100'c of 12.3 cSt.

Furthermore the 5w40 Castrol edge has a viscosity of 13 @ 100'c. That is 0.7 off from the 0w30 edge C3 oil.

If you put in your reg to the Halfords site it recommends the magnatec 0w30 A3/B4(which has a high ash, sulphated rating due to higher zinc sulphate additive) and Patronas 5w30.

The Patronas XS 5000 5w30 which meets API-SN spec and ACEA-C3 and has a viscosity of 11.6 cSt @ 100'c but also advertises cooltech which is some synthetic heat conductive additive in the oil to keep it cooler(especially for oil cooled cars)

All these oils seem to meet the specs of HTHS High Temp High Sheer which is Dynamic viscosity breakdown @ 150'c

The differences between the Castrol 0w30 and 5w40 C3's are so close it is depending on climate temperature and or race tuning. There is really nothing in it and due to the 5w40 having a higher viscosity index by +3 it is a no brainier in that it seems more sensible to use the 5w40 in the UK summer climate.

0w pour point is around -50'c which i don't think we have ever had in the UK ever. That said the 0w30 would reach operating temperature faster than the 5w40.

As would the Patronas which would get up to temp faster to clean, lubricate and flow in the hydrodynamic bearings at the cost of less load pressure handling.

Am i right in thinking that if you drive hard you are better off with that higher viscosity to handle the hard heavy load of a heavy foot?

#5

Im general, sure, you want higher viscosity for high load conditions, but only insofar as high viscosity translates to film shear strength. You could have a viscous oil with poor film strength.

My 2c on any oil discussion is as long as crankcase oil is injected and burnt, you're fighting a compromise between bearing protection and ash/deposit content. You're sort of illustrating that in this discussion.

Bearings need additives like zinc and detergents to remove previous oil varnishes, injection needs the exact opposite. The only way to break the compromise is a Sohn adapter, so if you're serious about the right oil for the job, that's step 0, IMO. Then you can run high zinc, high viscosity synthetic in the crankcase and dedicated, thinner, ashless oil for injection.

My 2c on any oil discussion is as long as crankcase oil is injected and burnt, you're fighting a compromise between bearing protection and ash/deposit content. You're sort of illustrating that in this discussion.

Bearings need additives like zinc and detergents to remove previous oil varnishes, injection needs the exact opposite. The only way to break the compromise is a Sohn adapter, so if you're serious about the right oil for the job, that's step 0, IMO. Then you can run high zinc, high viscosity synthetic in the crankcase and dedicated, thinner, ashless oil for injection.

#6

Im general, sure, you want higher viscosity for high load conditions, but only insofar as high viscosity translates to film shear strength. You could have a viscous oil with poor film strength.

My 2c on any oil discussion is as long as crankcase oil is injected and burnt, you're fighting a compromise between bearing protection and ash/deposit content. You're sort of illustrating that in this discussion.

Bearings need additives like zinc and detergents to remove previous oil varnishes, injection needs the exact opposite. The only way to break the compromise is a Sohn adapter, so if you're serious about the right oil for the job, that's step 0, IMO. Then you can run high zinc, high viscosity synthetic in the crankcase and dedicated, thinner, ashless oil for injection.

My 2c on any oil discussion is as long as crankcase oil is injected and burnt, you're fighting a compromise between bearing protection and ash/deposit content. You're sort of illustrating that in this discussion.

Bearings need additives like zinc and detergents to remove previous oil varnishes, injection needs the exact opposite. The only way to break the compromise is a Sohn adapter, so if you're serious about the right oil for the job, that's step 0, IMO. Then you can run high zinc, high viscosity synthetic in the crankcase and dedicated, thinner, ashless oil for injection.

#8

The oil in question is most likely Idemitsu, but any quality JASO FC or FD 2 cycle oil is likely just as good.

Last edited by Steve Dallas; 10-02-2016 at 07:32 PM.

#9

Great research Fiercer, I came across your post because I was looking for information about whether or not we should use oil additives like BG MOA in the RX-8. Your research and what you have found on the forum seems to rule that out.

#10

I still think RX8s are easier to lube than German hot running cars.

If you can run your rotary as hot as those cars, the water jacket seals will crater at least.

I've run 0w40 Mobil 1 for years, and it's dirt cheap.

I'd recommend nearly any oil modern oil for German cars with 12-14cst@100 C.

My car is 6speed auto so It never gets over 7k rpm, but It just barely sips MO.

The best way to preserve engine is to use a FC or FD gasoline premix oil of approx 8 oz per 12 gallons.

It's easy to just flop some (8oz) out of bottle before filling up gas.

If you can run your rotary as hot as those cars, the water jacket seals will crater at least.

I've run 0w40 Mobil 1 for years, and it's dirt cheap.

I'd recommend nearly any oil modern oil for German cars with 12-14cst@100 C.

My car is 6speed auto so It never gets over 7k rpm, but It just barely sips MO.

The best way to preserve engine is to use a FC or FD gasoline premix oil of approx 8 oz per 12 gallons.

It's easy to just flop some (8oz) out of bottle before filling up gas.

#11

I'll add my .02.

From what I understand is you want to run the thinnest oil possible while maintaining the desired oil pressure at high load/high heat.

most wear comes from cold start ups, run a 5W or 0W on the low end, the high end run an oil that maintains a solid 60+PSI under full load racing or what not.

the ideal oil might be 5W-30, and run one with high zinc content. if you cannot maintain pressure with this weight, run a thicker oil or cool the oil better with ducted oil coolers or whatever is the problem. This also assumes you are running a sohn adapter.

From what I understand is you want to run the thinnest oil possible while maintaining the desired oil pressure at high load/high heat.

most wear comes from cold start ups, run a 5W or 0W on the low end, the high end run an oil that maintains a solid 60+PSI under full load racing or what not.

the ideal oil might be 5W-30, and run one with high zinc content. if you cannot maintain pressure with this weight, run a thicker oil or cool the oil better with ducted oil coolers or whatever is the problem. This also assumes you are running a sohn adapter.

#12

This is a pretty good discussion of tolerances vs. oil pressure vs. viscosity:

Oil Pressure Tech by Kennedy's Dynotune

Oil Pressure Tech by Kennedy's Dynotune

#13

I'll add my .02.

From what I understand is you want to run the thinnest oil possible while maintaining the desired oil pressure at high load/high heat.

most wear comes from cold start ups, run a 5W or 0W on the low end, the high end run an oil that maintains a solid 60+PSI under full load racing or what not.

the ideal oil might be 5W-30, and run one with high zinc content. if you cannot maintain pressure with this weight, run a thicker oil or cool the oil better with ducted oil coolers or whatever is the problem. This also assumes you are running a sohn adapter.

From what I understand is you want to run the thinnest oil possible while maintaining the desired oil pressure at high load/high heat.

most wear comes from cold start ups, run a 5W or 0W on the low end, the high end run an oil that maintains a solid 60+PSI under full load racing or what not.

the ideal oil might be 5W-30, and run one with high zinc content. if you cannot maintain pressure with this weight, run a thicker oil or cool the oil better with ducted oil coolers or whatever is the problem. This also assumes you are running a sohn adapter.

Diesel oil CL4/SM has larger levels of ZDDP but will fry your cat faster.

My balance is to change the oil more frequently and use cheaper non-brand name oil that is SN-grade and tested by the PQIA and SAE like AUtoZone oil (always < 3000 miles per OCI and target around 1000-1500 miles). Most non-branded oil is made, blended, and packaged by Warren Oil or Valvoline/Ashland.

#14

I think every oil recommendation should come with a few used oil analyses. We end up reaching for personal stories and certifications because we lack any actual data.

For example, ZDDP is a solution to a problem: it's a dry lubricant that prevents metal on metal bearing contact. It doesn't mean that removing ZDDP leads to shorter bearing life, it only means that the job or preventing metal on metal contact falls to something else. Maybe molybdenum, maybe a stronger oil film, maybe other things. To confirm how well that something does it, look for metals in your oil. No metals, no problem.

For example, ZDDP is a solution to a problem: it's a dry lubricant that prevents metal on metal bearing contact. It doesn't mean that removing ZDDP leads to shorter bearing life, it only means that the job or preventing metal on metal contact falls to something else. Maybe molybdenum, maybe a stronger oil film, maybe other things. To confirm how well that something does it, look for metals in your oil. No metals, no problem.

#15

I'm just starting to learn about this lubrication issue. The big demon is supposed to be ash and other deposits. You might have fewer deposits with 2 stroke oil, but are the deposits really excessive and unacceptable if you just leave everything alone and stock and run Mazda's recommendations? Have deposits from 4 stroke oil really ruined many engines? I'm just trying to get a handle on how much of a concern this really is.

I intend to use my '05 with a dealer installed replacement engine with about 20k miles on it for an autocross and track toy, meaning it will probably see fewer than 5k miles a year, but they will be enthusiastic miles. Would I be ok with a stock system, running some sort of 30w? Would it be ok to toss some 2 stroke premix in the tank without disconnecting the omp, just as a little extra insurance?

I intend to use my '05 with a dealer installed replacement engine with about 20k miles on it for an autocross and track toy, meaning it will probably see fewer than 5k miles a year, but they will be enthusiastic miles. Would I be ok with a stock system, running some sort of 30w? Would it be ok to toss some 2 stroke premix in the tank without disconnecting the omp, just as a little extra insurance?

Last edited by Greasyman; 12-05-2016 at 01:02 PM.

#16

That's what I do: 5W20 (SN rating) oil in the sump and JASO FD-rated synthetic premix in the fuel. I run 0.25 oz/gal all the time and I've seen 1 oz/gal for tracking. I change my oil often ~ 1000 miles because I have the time and a quick drain valve to do it conveniently. 5W30 (SN rated) is fine since it's recommended by Mazda ex-US.

#18

Do they really hold that much? The crankcase holds about 4 liters. If the coolers and lines really hold as much as the engine, shouldn't we drain those with each oil change, otherwise it's like you are running half dirty and half new oil.

Last edited by Greasyman; 12-05-2016 at 03:53 PM.

#19

S2 holds 4.5L with filter change for the sump-only oil. I've heard that another 3 L in the cooler and cooler lines. It took me 5 short 200-500 mi short change intervals to get back to nearly clear oil.