2005 RX8 - Turbo LSx 6spd Build

#1

2005 RX8 - LS1/T56 Build

UPDATED CHANGE OF PLANS POST #2

Hey Everyone,

Ive been somewhat reluctant to start a build thread on this, as I dont really feel like arguing with anyone over the plausibility of the swap.

Anyways, some history on the car, I have started with a 2005 Mazda RX8 6spd with 102,000km that I picked up in toronto off a younger guy who had a mishap that damaged the front end of the car. Other then the damage to the front end, the car is in beautiful shape, hasnt seen any winter duty, and has been well kept. And for the price of $2800CAD, knowing I was intending on altering alot of what was damaged anyways, I decided I couldnt pass it up.

The goal for the car is 600+ RWHP, with comfortable streetability, tons of torque, and something that is a little different then the rest.

Now, the plan for the build is to use a aluminum block LS1, 3.905 bore with forged pistons & rods for 347" setup, however I think I will put a 4.8L truck motor in initially while I iron out tuning, and also because im curious to see how much boost I can jam into it

I am going to use a 2011-2013 Corvette ZR1 Harness & E67 PCM both for excellent boost control, and more information available in the HS & LS CANbus lines.

The biggest hurdle everyone is coming against is the electronics. To tackle this we are developing a module that will stand as a gateway in the network to convert and input data and basically act as a interpreter between the modules. We are still developing this, so I will update more information as I progress.

The turbo setup is a Turbonetics TC78, I am using a TiAl 38mm wastegate, and TiAl 50mm BOV. I intend on either upping the wastegate size eventually for low boost control, or adding a 2nd wastegate.

I am still collecting all the parts for it, I will be doing a 14" Brembo front brake kit based off the Cadillac CTS-V brakes.

Heres a pictures of the project.

When I first picked Roxanne up

In the shop with my RX7 track car project:

Turbo & goodies:

Stripped the front end off to assess what damage was done from the accident, and then moved it over to my dad's shop to do the turbo hot side fabrication & mounting (Its also gettin pretty friggen cold in my other shop with not heat!)

Removed the motor out the bottom of the car, as I am used to pulling motors from 4th gen F-bodies that require this and I find it quite easy.

The heart & rotary soul have been ripped out

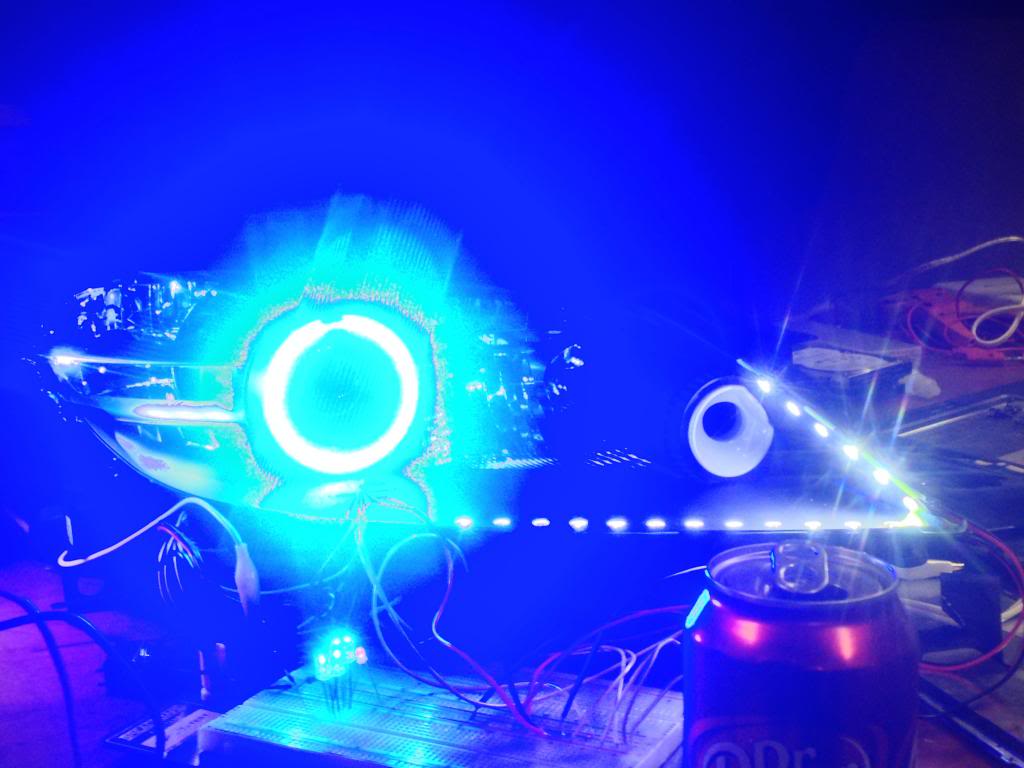

These are a work in progress, but decided to make my own custom LED headlights for the car. This is a shot of some of it mocked up, and then a test when hooked up to my electronics equipment. Had to take the picture in HDR as the LED ring is super bright. LED halo ring will be controlled independently as blue is illegal in Ontario to have on the front of the car, will just have the blue halo on for show when headlights off. It has 9 LED's across the bottom, 6 up the side, then 3 under each of the bar's off the side of the projector trim hoop. I ordered some carbon fiber to see if I can produce the projector trim piece out of carbon as that would look pretty trick I think.

I will keep updating this as I progress. I will have all my exhaust tubing for the hotside in this week and hopefully by next weekend i can have alot of the mounting and turbo exhaust parts done.

**UPDATE NOV 18/13**

We got the support beam out, and did some test fitting tonight.

GTO T56 is the only way to go unless you want your shifter in the dash. Approx 33" from back of motor to shifter hole center, which is exactly perfect to GTO (28" approx for F-body)

The motor fits in nicely, with the exception that the ABS is in the way. That will be taken care of soon. The heads are very tight to the firewall, which is great for weight balance, and it isnt too close to hit.

I have designed my mounts & ordered some parts that will be in thursday so i can get the mounts & rack & pinion setup. I am tempted to go with a F-body hydraulic rack, both for feel, and the fact that I hate the idea of lowering the stock rack for clearance, as its going to F up the steering angles, along with the fact that the car will be lowered, so looking at like 4" effectively lower then stock position. We'll see how it goes, as test fitting has made me realize i may be OK for running one of my forward exhaust pipes around all the accessories for turbo feed.

The electronics are really up in the air. I have a few different routes I can take, and am working out which is the simplest and most effective. Am toying with the idea of implementing my own ABS & Traction control system from a ZR1, however I am working on figuring out the host CANbus computer & how it wakes up the other modules. Anyone with any CANbus hacking & mazda network information, I would love to chat!

ANYWAYS.

Heres a few shots of tonights progress, I am thoroughly enjoying this build.

Support bar removed & sway bar down:

lowering a spare motor we had in the shop to do our first mockup to get ideas for planning turbo kit.

Motor sat in on some wood blocks (rack is in, so front is 1.5" or so higher then it will actually sit)

Most cars I swap this motor in, make it look tiny.

UPDATE: Dec 14/2013

Progress has been slow the last few weeks as my fleet at work has decided to try to murder itself. Cummins ISC & ISX guts everywhere! Also picked up a Duramax for cheap needing some attention, so have had my hands full!

I dropped the rack to get an accurate idea of where the engine is going to sit and so i can do more planning for the turbo hot side parts:

Theres enough space around the motor. The passenger side has alot of room, drivers side not so much. Easier for me as my exhaust will plumb forward, and i have ample space for a 3.5" down pipe to sneak down the side of the motor. However, retaining A/C would be impossible with the turbo setup the way I am doing it.

Head clearance to firewall is good, this is as far back as i can get the motor. I am planing to shift as much backwards as i can, to get back towards 50/50 weight distribution that the car had before I hacked it up LOL. I had to massage the firewall a little bit to clear everything, but I have test fit heads and its OK. (note: pics are prior to massaging the firewall. Merely re routed some lines & cleaned up sheet metal stamping lips)

Last edited by Chezmanbespoke; 02-02-2015 at 10:01 PM. Reason: Change of plans

#5

Updated original post!

#11

#13

Threw another update up.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

#14

Will you be able to reproduce the gateway and sell them once you are done?

Threw another update up.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

#15

Threw another update up.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

I have a big pile of exhaust tubing and flanges to fabricate all my mounts & turbo hot side. Will update as soon as I can get away from blown up turbo diesels!

The electronic CANbus Gateway is progressing beautifully! I have been working closely with my brother who is a Computer Scientist, and a couple friends in Vancouver who are computer hackers & mechatronics engineers.

We are essentially creating our own CANbus network on a mashup of Mazda & GM bus languages that will only allow certain data from each to make it into the network.

The systems are fairly straight forward in their dominant-recessive bit identifier & message system, however with almost 0 information available on what data is in the lines, we have had to do significant reverse engineering of both systems.

The module will allow 100% function of GM & Mazda systems, as the GM system is essentially stand alone, and we only were looking to extract certain data to convert and feed into the mazda system for full interior and factory ABS/TC function. We have so far been able to get a fair bit of extra function into the dash display on the 8, being able to put in our own welcome messages, even using that as a display for other systems like a radar detector, parking sensors etc etc.

#16

There is no way i can see that you would have full function traction control, ABS and Elec P/S without a gateway module. How would you have the Mazda OEM computer half function and not complain? It needs to see some sensor inputs, and rather then add extra sensors and triggers like other swaps have done, just convert existing data. All data needed is available in some form

I refuse to do the crank trigger on the front of the motor for the tach, the tach will get its signal from the gateway module that will convert the GM signal.

I am all ears to other ways to go about this!

#18

Oh and the engine you have mached up is setting too far back. You need to pull it up about an inch. Cause the camaro shifter is to short if the engine sits all the way back but if you swap to the gto shifter it sits 1" back.

And if you would like my engine stands bolt to the subframe of the car with easy to remove and install.

And if you would like my engine stands bolt to the subframe of the car with easy to remove and install.

#19

Oh and the engine you have mached up is setting too far back. You need to pull it up about an inch. Cause the camaro shifter is to short if the engine sits all the way back but if you swap to the gto shifter it sits 1" back.

And if you would like my engine stands bolt to the subframe of the car with easy to remove and install.

And if you would like my engine stands bolt to the subframe of the car with easy to remove and install.

What are the shape of yours? I have to get a bit creative on my passenger side one to make sure I have room for a 3.5" down pipe

Thread

Thread Starter

Forum

Replies

Last Post

Mr.Durden

RX-8's For Sale/Wanted

4

08-12-2015 03:21 PM