Kickers V6 swap thread

#701

in my experience the IC pipe routing is important too, if you have straight pipe runs, they can be pretty small, but if you have some bends, or a lot of bends, bigger is better.

its easy to test, you put a boost gauge on both sides of IC/said pipe and see the pressure drop.

i'd measure the turbo outlet and then pick the next size up as a start...

its easy to test, you put a boost gauge on both sides of IC/said pipe and see the pressure drop.

i'd measure the turbo outlet and then pick the next size up as a start...

#702

Meh, there are decent cheap air water intercoolers availible. I'd use the existing oil cooler locations and go air water. Why reduce your radiator/AC performance when you have so much to work with.

Also, yes you have to go a slightly larger size when dealing with bends.

Also, yes you have to go a slightly larger size when dealing with bends.

#703

I'm trying to make the build as simple and OEM-like as possible which means low-cost, low- maintenance, and high reliability. Air-air costs less ($300~400) and I don't have to worry about pump/electrical failures. Air-air is also idiot-proof and my goal is only 10psi. More then manageable with air-air.

#704

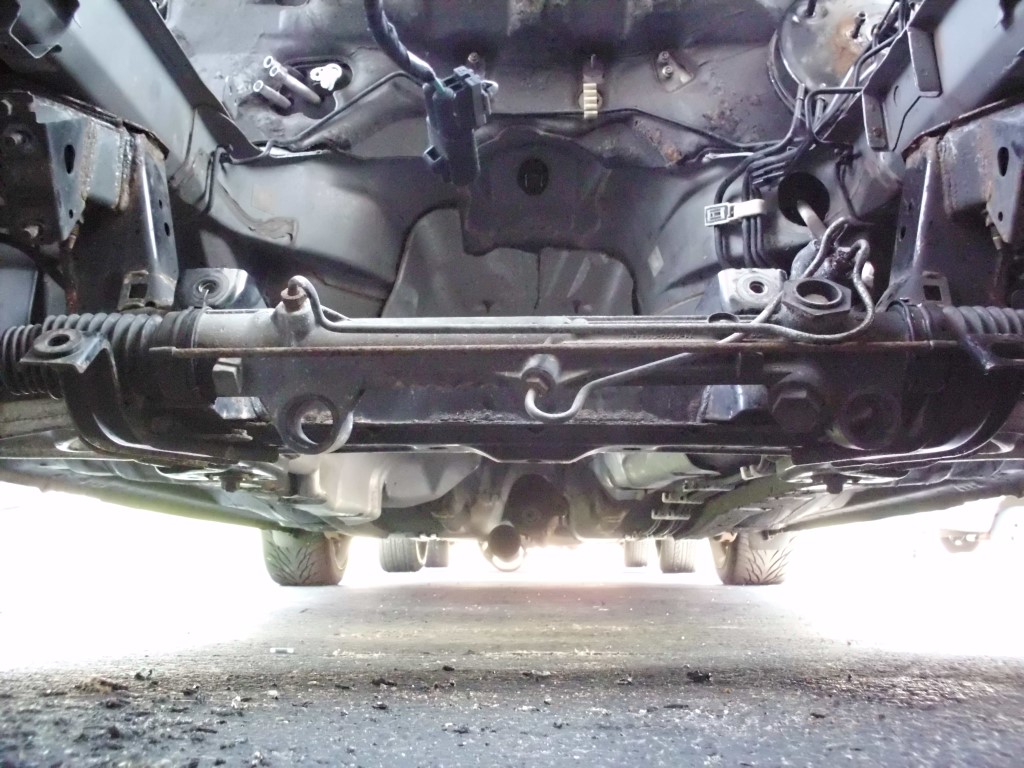

So while I'm waiting for the guy who sold me my engine to find a crank, I decided to fiddle with the steering. The Suzuki Sidekick steering rack fits but the hydraulic lines on the rack itself would have to be moved. I began searching fleebay for images of steering racks and it looks like the rack from a Mustang Cobra would fit nicely. It's easy to mount, the lines are in a good location, and the direction is correct. I don't know it's ratio or throw. A trip to the yard might be in order. They have a nice selection of pulled racks to inspect.

The RX-8 electric rack is 33.5lbs. The Sidekick hydraulic rack is 19.5lbs. A 14lb savings. The lines, fluid, and pump don't weigh very much. I'd say the hydraulic lines vs. electrical wiring and controller are a wash. The pump and fluid are only a few pounds. I may have saved ~10lbs doing the hydraulic conversion. I can't *weight* so how the car's balance turns out.

The RX-8 electric rack is 33.5lbs. The Sidekick hydraulic rack is 19.5lbs. A 14lb savings. The lines, fluid, and pump don't weigh very much. I'd say the hydraulic lines vs. electrical wiring and controller are a wash. The pump and fluid are only a few pounds. I may have saved ~10lbs doing the hydraulic conversion. I can't *weight* so how the car's balance turns out.

Last edited by kickerfox; 05-08-2013 at 02:21 PM.

#706

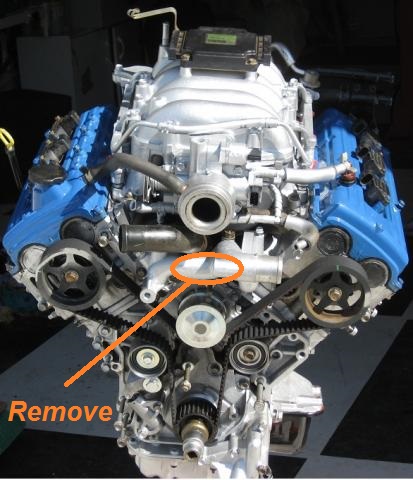

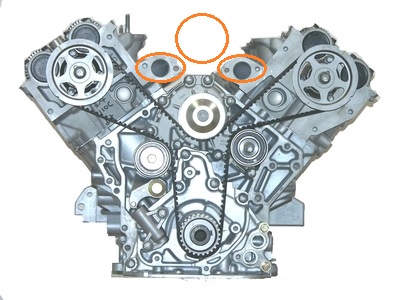

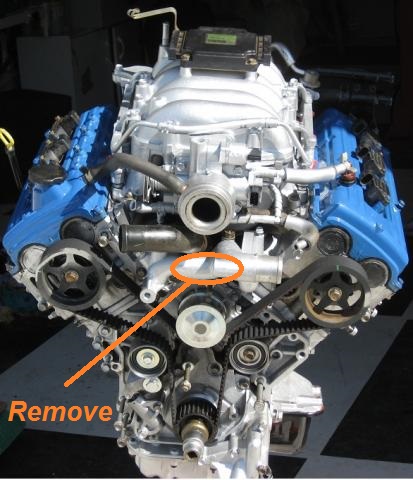

When I make the flange that bolts there it will have AN8 or AN10 oil lines and I'll throw in some AN4~6 fittings on the side for oil feed to the turbos.

When I make the flange that bolts there it will have AN8 or AN10 oil lines and I'll throw in some AN4~6 fittings on the side for oil feed to the turbos.------------------------------------------------------------------------------------------------------------------

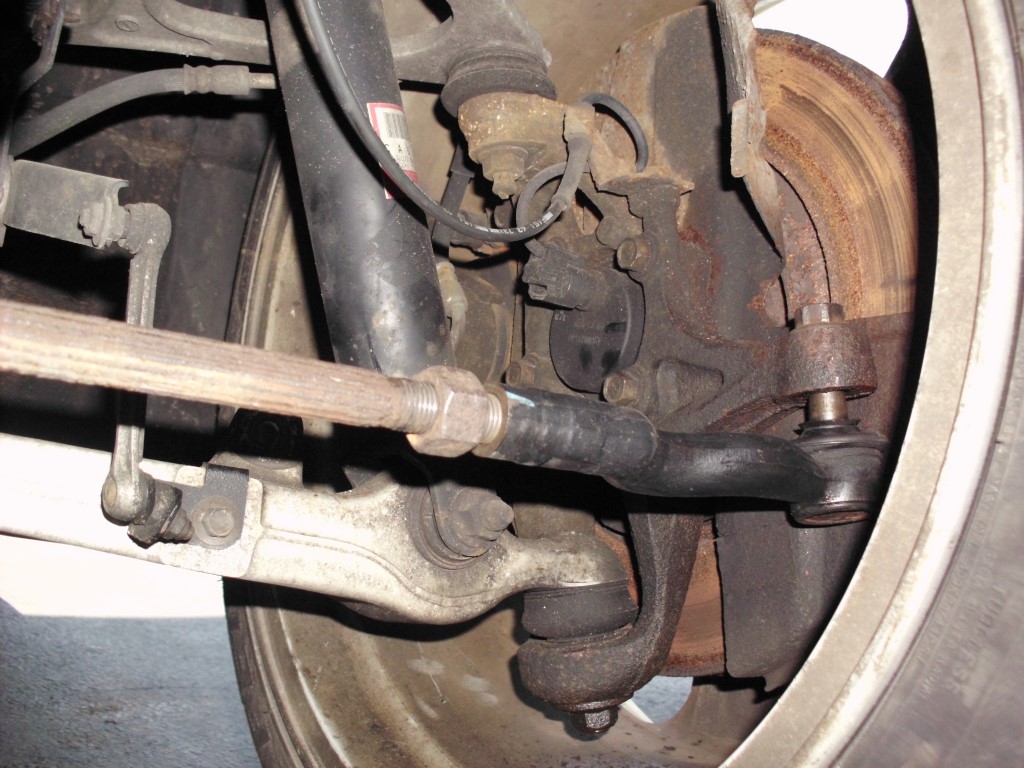

Here's the Mustang rack in place but not mounted. I'll need to add some mounts to the sub-frame and remove the original electric rack's mounts. The RX-8 tie-rod ends are the same thread as the Mustang but the tie-rods themselves each needed to be shortened by 1".

The rack was $60 and came with the lines. The high-pressure line is nice and long and will easily reach the Isuzu pump. I just need the hose shop to swap the pump-end fitting.

A little hard to see in the second pic but the rack mounts with 2 bolts with rubber grommets that I didn't receive. I'm sure the Mustang performance part places have polys for it.

Last edited by kickerfox; 05-08-2013 at 02:21 PM.

#708

Mazda, Isuzu, Honda, Nissan, Suzuki, Ford, Pontiac, and Chevy parts so far.

I was showing the thrust bearings to a friend of mine when it dawned on me why they failed. Whoever rebuilt this engine put them in backwards. The bearing has an oil channel that normally rides against the crank but it was installed with the grove facing the main bearing. Not only would the oil not have direct access to the bearing surface, it would pressurize behind the bearing forcing it into the crank. Damn amateurs.

I was showing the thrust bearings to a friend of mine when it dawned on me why they failed. Whoever rebuilt this engine put them in backwards. The bearing has an oil channel that normally rides against the crank but it was installed with the grove facing the main bearing. Not only would the oil not have direct access to the bearing surface, it would pressurize behind the bearing forcing it into the crank. Damn amateurs.

Last edited by kickerfox; 05-09-2013 at 05:09 PM.

#710

Also, I'm not sure how involved the electric steering was with the 8's ECU. I believe the system had speed proportionate steering. If so, I probably wouldn't have been able to control it.

The only issue I'm going to have is a SLIGHT toe change as the suspension travels up and down since there's a change in the steering geometry. The only difference I'll feel is a 50,000 mile tire lasting 49,000.

#711

Well it looks like I'm screwed until I find another '99 Isuzu Amigo v6 manual at the yards. The yard junked the one I was getting my parts from and the other half of the wiring harness I bought was still in it along with many other parts I still needed.

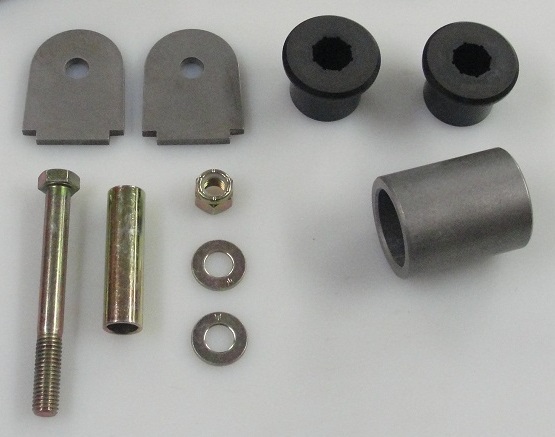

In the mean time I ordered new Mustang inner tie rods and I found aftermarket poly bushings for the steering rack. I also ordered up some 4130 tubing for the mounts. I cut off the original steering mounts and as soon as my parts show up I can finalize the steering.

Judging by my friends '04 RX-8, mine will turn the wheels about 5~10deg more then stock and the Mustang ratio is 2-5/8 turn lock-to-lock vs. stock at 3 turns.

In the mean time I ordered new Mustang inner tie rods and I found aftermarket poly bushings for the steering rack. I also ordered up some 4130 tubing for the mounts. I cut off the original steering mounts and as soon as my parts show up I can finalize the steering.

Judging by my friends '04 RX-8, mine will turn the wheels about 5~10deg more then stock and the Mustang ratio is 2-5/8 turn lock-to-lock vs. stock at 3 turns.

Last edited by kickerfox; 05-12-2013 at 11:38 AM.

#712

Just some more pics.

The sub-frame is drilled and the steering rack is temporarily bolted in until my 4130 tubing gets here. The AC just clears the rack's input shaft. The drivers side engine mount will be in the way of the intermediate shaft but I planed on making engine mounts with universal polys anyways. If I could have got away with the Isuzu ones, I may have tried. The last two pics are universal engine mount examples.

The sub-frame is drilled and the steering rack is temporarily bolted in until my 4130 tubing gets here. The AC just clears the rack's input shaft. The drivers side engine mount will be in the way of the intermediate shaft but I planed on making engine mounts with universal polys anyways. If I could have got away with the Isuzu ones, I may have tried. The last two pics are universal engine mount examples.

Last edited by kickerfox; 05-12-2013 at 09:14 PM.

#714

Last night I got the Amigo gas pedal in place by making a simple bracket that bolts where the 8's pedal goes. It's functional where it is but I'd like to change the plastic pedal to something I can use to mount the RX-8's matching pedal cover.

#716

I've been poking around the VX (Isuzu Vehicross) communities and besides HPHeaven there's another company called Dynamotive that's been building the Isuzu v6 for some time.

To quote Mark's (from Dynamotive) discussion with a VX owner...

"I have not seen a s.o.h.c 6vd1 however, I have a lot of experience with the dohc version (would be the same bottom end) I have one here at the moment running 1680hp, the stock rods fail at around 600hp and the stock pistons fail at around 450hp. I can't comment on the flow of the heads, because I haven't seen s.o.h.c. but for the twin cam we run larger valves and custom porting, 80mm throttle body and big cams. Even on the mild engine with a gt3582r turbo (700hp capacity) we see around 520 rwhp"

As you know my goal was ~380hp with daily-driver reliability. The more "real world" info I find the more confidence I have in the engine meeting that goal, and then some, apparently.

EDIT - So I've personally been in communication with Dynamotive today. Everything is hear-say until I hear it from the horses mouth. Thankfully, this is what they told me...

"Hi Jeff, we do have a lot of experience with these engines, with a safe tune up you will have no problems with your engine at 450 flywheel horsepower (400 at the wheels) If you have the engine apart to replace the crankshaft I would pull the pistons out and “open” the rings gaps on the first and second rings to .005” per Inch or .018”-.020” top ring gap. The stock crankshaft is strong enough for about 700-800 hp (we have run them over 1200hp for short bursts). While you have it apart you might also look at the main bearing oil feed, the oil is fed through the Alum cradle that bolts to the main caps, the rear main gets the least amount of oil, we modify the feed to come in the centre and feed out from there, we also modify the oil pump for more pressure and “port and polish” the oil pump for better flow. All these things are easy while you have the engine apart. We have run stock engines to 600hp for short bursts. To make 450hp you need at least a GT3582R running 10 psi boost through an air to air intercooler, the valve springs will hold up to 10psi boost at 6500rpm it should make 450hp at 6200rpm. I recommend shimming the oil pump 5mm or 3/16” never had an oil pump failure, never seen rod bearing failure, yes drill all main oil feeds, the good thing with turbo engines is you don’t need to rev them hard, like I said earlier we have run many of these stock at 450hp and 10psi boost, creep the boost or rpm up and that’s when things get scary. I hope this helps"

I'm almost finished with the steering. At least I got to turn the wheels with the steering wheel today. I made a simple aluminum adaptor to couple a Suzuki Sidekick's steering u-joint to the mustang rack. The Suzuki shaft will then be welded to the 8's shaft to make a one piece steering shaft, similar to the original, that is still easily removable. I retained the telescopic collision joint that prevents the steering wheel from being smashed into your face in a front end collision. Pics tomorrow.

I made a simple aluminum adaptor to couple a Suzuki Sidekick's steering u-joint to the mustang rack. The Suzuki shaft will then be welded to the 8's shaft to make a one piece steering shaft, similar to the original, that is still easily removable. I retained the telescopic collision joint that prevents the steering wheel from being smashed into your face in a front end collision. Pics tomorrow.

To quote Mark's (from Dynamotive) discussion with a VX owner...

"I have not seen a s.o.h.c 6vd1 however, I have a lot of experience with the dohc version (would be the same bottom end) I have one here at the moment running 1680hp, the stock rods fail at around 600hp and the stock pistons fail at around 450hp. I can't comment on the flow of the heads, because I haven't seen s.o.h.c. but for the twin cam we run larger valves and custom porting, 80mm throttle body and big cams. Even on the mild engine with a gt3582r turbo (700hp capacity) we see around 520 rwhp"

As you know my goal was ~380hp with daily-driver reliability. The more "real world" info I find the more confidence I have in the engine meeting that goal, and then some, apparently.

EDIT - So I've personally been in communication with Dynamotive today. Everything is hear-say until I hear it from the horses mouth. Thankfully, this is what they told me...

"Hi Jeff, we do have a lot of experience with these engines, with a safe tune up you will have no problems with your engine at 450 flywheel horsepower (400 at the wheels) If you have the engine apart to replace the crankshaft I would pull the pistons out and “open” the rings gaps on the first and second rings to .005” per Inch or .018”-.020” top ring gap. The stock crankshaft is strong enough for about 700-800 hp (we have run them over 1200hp for short bursts). While you have it apart you might also look at the main bearing oil feed, the oil is fed through the Alum cradle that bolts to the main caps, the rear main gets the least amount of oil, we modify the feed to come in the centre and feed out from there, we also modify the oil pump for more pressure and “port and polish” the oil pump for better flow. All these things are easy while you have the engine apart. We have run stock engines to 600hp for short bursts. To make 450hp you need at least a GT3582R running 10 psi boost through an air to air intercooler, the valve springs will hold up to 10psi boost at 6500rpm it should make 450hp at 6200rpm. I recommend shimming the oil pump 5mm or 3/16” never had an oil pump failure, never seen rod bearing failure, yes drill all main oil feeds, the good thing with turbo engines is you don’t need to rev them hard, like I said earlier we have run many of these stock at 450hp and 10psi boost, creep the boost or rpm up and that’s when things get scary. I hope this helps"

I'm almost finished with the steering. At least I got to turn the wheels with the steering wheel today.

I made a simple aluminum adaptor to couple a Suzuki Sidekick's steering u-joint to the mustang rack. The Suzuki shaft will then be welded to the 8's shaft to make a one piece steering shaft, similar to the original, that is still easily removable. I retained the telescopic collision joint that prevents the steering wheel from being smashed into your face in a front end collision. Pics tomorrow.

I made a simple aluminum adaptor to couple a Suzuki Sidekick's steering u-joint to the mustang rack. The Suzuki shaft will then be welded to the 8's shaft to make a one piece steering shaft, similar to the original, that is still easily removable. I retained the telescopic collision joint that prevents the steering wheel from being smashed into your face in a front end collision. Pics tomorrow.

Last edited by kickerfox; 05-15-2013 at 02:42 AM.

#717

The steering shaft is now made up of the RX8 shaft coming out of the firewall welded to a Suzuki Sidekick u-joint that was easy to adapt to the Mustang rack. The steering wheel is dead center with equal turns lock-to-lock and turns smooth as silk. It feels better then the RX-8 rack. It feels more like my Miata which was 2.8 turns. Mustang rack is 2.6 turns. What it amounts to is if your hand is at 10 and you palm a right turn, you wind up at about 2 at lock. That feels right to me. Same goes starting at 2 palming left you wind up at 10. I can't wait to drive it and see how it feels coming out of a corner.

I was worried about the Isuzu pump playing nice with the Mustang rack because (I thought) the Isuzu had a worm box not a rack and pinion. When I started looking up pressures specs I saw a photo of the 2000 Passport steering and it was a rack and pinion. I didn't realize that. My pump should be a lot closer to what I need because rack and pinion steering generally run at a higher pressure then a worm box. I can always adjust the pump pressure by shimming the bypass spring in the pump.

I was worried about the Isuzu pump playing nice with the Mustang rack because (I thought) the Isuzu had a worm box not a rack and pinion. When I started looking up pressures specs I saw a photo of the 2000 Passport steering and it was a rack and pinion. I didn't realize that. My pump should be a lot closer to what I need because rack and pinion steering generally run at a higher pressure then a worm box. I can always adjust the pump pressure by shimming the bypass spring in the pump.

Last edited by kickerfox; 05-16-2013 at 02:48 AM.

#718

I decided on a Ford v8 throttle body. There are quite a few sizes available including some pretty large aftermarket ones. I'm not sure what this particular one is from but it's only 65mm. I had to pull 4 of them before I found the one with the minimum airflow adjustment on it. That will come in handy I'm sure. I'll be using the Isuzu IAC valve but it will be mounted somewhere else (back of the plenum) and this TB doesn't have a provision for one anyways. That works to my advantage. There are also progressive versions of this TB on another Ford. I may try it some day. A progressive throttle may help my lead-foot gas mileage.

We don't need no stinkin' mill! Here's my DIY throttle body flange that will be welded to the custom plenum. Unfortunately the head flanges won't be so easy. I'll have to have those flanges laser cut. I decided on studs to prevent thread wear. I don't want to have to make it again.

We don't need no stinkin' mill! Here's my DIY throttle body flange that will be welded to the custom plenum. Unfortunately the head flanges won't be so easy. I'll have to have those flanges laser cut. I decided on studs to prevent thread wear. I don't want to have to make it again.

Last edited by kickerfox; 05-17-2013 at 12:14 AM.

#720

Not much going on atm. I'm back in the parts gathering stages waiting for flanges to come back from the machine shop. They mount to the water outlets at front of the heads. I'm not sure if I want to splurge on AN plumbing yet but the flanges I'm making will accept an -16AN. An aluminum aftermarket Miata radiator will fit nicely and allows me to run both hoses all the way to the radiator instead of a making an adaptor to use a single radiator hose.

I did get a chance to push the car down the road and turn it hard. No binding.

I did get a chance to push the car down the road and turn it hard. No binding.

#721

#722

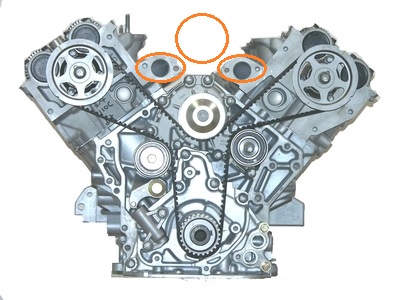

Here's the outlet flanges but unfortunately the shop missed that the holes are not inline but offset 2mm. They will need to be redone.

They mount to the heads so the stock outlet tube can be discarded to make room for the throttle body.

They mount to the heads so the stock outlet tube can be discarded to make room for the throttle body.

Last edited by kickerfox; 05-22-2013 at 03:17 PM.

#723

I'm not sure where I got my original information from (months ago) about the RX8 cluster but it was my understanding that the cluster took the speed sensor input directly because the odometer reading was stored in the cluster. This was incorrect. The speedometer *is* on the canbus. The speed sensor is wired to the ECU.

This leaves me three options:

1. Replace the entire cluster with another vehicle's cluster (tacky)

2. Use all aftermarket gauges. (expensive but slightly less tacky)

3. Piggy back the RX8 ECU onto the Isuzu ECU and wire the Isuzu ECU to the OBD2 port and CEL. (cheap but could get complicated and may not be 100% functional)

I'd really like to keep all the factory gauges functional. Everything but the speedometer would be easy to wire into another system.

If I piggy the RX8 ECU it's going to bitch about a lot of sensors being missing. Many of them are feedback systems like the oil pump and aux port valve. Throwing codes doesn't matter but if it goes into limp-mode and that mode effects the DSC, ABS, or the throttle, then I'll have issues. It's a little too late to experiment with the stock ECU but I'd imagine, in limp mode, the ABS would still work for safety reasons. If I wanted to retain DSC I'd have to use the electronic throttle and I have a feeling limp mode limits how far it opens.

I'll be pulling my brains out trying to find a solution for this. IF I keep the RX8 ECU I will likely keep the drive-by-wire system in which case the cruise will work, ABS will likely work, DSC might work (unlikely with the electric rack being removed), and the RX8 ECU will be in control of the v6 idle (I'll put the RX8 reluctor ring on the v6 crank pulley). This may cause the Isuzu ECU to complain about the IAC circuit not responding. I've never heard of a car going into limp mode over 02 sensors so I may not have to tie those into the RX8 ECU.

I was just looking at the '05 Miata cluster and it would work electrically but not cosmetically.

This leaves me three options:

1. Replace the entire cluster with another vehicle's cluster (tacky)

2. Use all aftermarket gauges. (expensive but slightly less tacky)

3. Piggy back the RX8 ECU onto the Isuzu ECU and wire the Isuzu ECU to the OBD2 port and CEL. (cheap but could get complicated and may not be 100% functional)

I'd really like to keep all the factory gauges functional. Everything but the speedometer would be easy to wire into another system.

If I piggy the RX8 ECU it's going to bitch about a lot of sensors being missing. Many of them are feedback systems like the oil pump and aux port valve. Throwing codes doesn't matter but if it goes into limp-mode and that mode effects the DSC, ABS, or the throttle, then I'll have issues. It's a little too late to experiment with the stock ECU but I'd imagine, in limp mode, the ABS would still work for safety reasons. If I wanted to retain DSC I'd have to use the electronic throttle and I have a feeling limp mode limits how far it opens.

I'll be pulling my brains out trying to find a solution for this. IF I keep the RX8 ECU I will likely keep the drive-by-wire system in which case the cruise will work, ABS will likely work, DSC might work (unlikely with the electric rack being removed), and the RX8 ECU will be in control of the v6 idle (I'll put the RX8 reluctor ring on the v6 crank pulley). This may cause the Isuzu ECU to complain about the IAC circuit not responding. I've never heard of a car going into limp mode over 02 sensors so I may not have to tie those into the RX8 ECU.

I was just looking at the '05 Miata cluster and it would work electrically but not cosmetically.

Last edited by kickerfox; 05-23-2013 at 12:51 PM.

#724

I have some untested code for faking out the e-shaft sensor. Should be able to throw together a program that takes the coil trigger wire and makes it into an e-shaft/rpm signal. Beyond that you would need to block all CELs associated with RX8 emissions, don't forget about the evap system. Could be done with an AP.

Probably be easier to spoof the canbus, but that's beyond my current abilities. It would take something similar to goodbox/rxduino.

Also you could remove the instrument cluster and drive the gauges directly, big hassle.

Probably be easier to spoof the canbus, but that's beyond my current abilities. It would take something similar to goodbox/rxduino.

Also you could remove the instrument cluster and drive the gauges directly, big hassle.

#725

I have some untested code for faking out the e-shaft sensor. Should be able to throw together a program that takes the coil trigger wire and makes it into an e-shaft/rpm signal. Beyond that you would need to block all CELs associated with RX8 emissions, don't forget about the evap system. Could be done with an AP.

Probably be easier to spoof the canbus, but that's beyond my current abilities. It would take something similar to goodbox/rxduino.

Also you could remove the instrument cluster and drive the gauges directly, big hassle.

Probably be easier to spoof the canbus, but that's beyond my current abilities. It would take something similar to goodbox/rxduino.

Also you could remove the instrument cluster and drive the gauges directly, big hassle.

How do you keep the simulated ESS pulestrain's frequency in sync with an alternitive engine's RPM? Lets say the ESS signal looks like pppppppppp---p---pppppppppp Do you calculate the time between ignition pulses so that that entire pulsetrain shown fits between ignition pulses?

I'm sorting wiring now but I think I'm going to keep the RX8 ECU in the car and try to get as much of it working as I can. The Isuzu ECU will run the engine and be wired to the CEL and OBDII port so all I need to do is keep the RX8 ECU out of limp mode so the throttle works.

EDIT - My new coolant flanges were finished this morning. The shop was also producing some disc hubs for Brembo. Fun stuff.

Last edited by kickerfox; 05-25-2013 at 04:20 PM.