Documented Engine tear down by Hungarian Mazda dealer

#27

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

Translation

OK, here is the text in a hopefully more readable format than the Google translation. Mind you, I probably mistranslated a few things

RX-8 13B-MSP RENESIS 100,000 km.

Date: 2011-05-05

Mazda RX-8 rotary engine disassembly

Let's jump right in the middle: we've got a Mazda RX-8 with 100,000 km on the odo. According to the maintenance log, the oil change interval was unfortunately pretty long, only at every 20K km (12.5K miles). Let's tear down the engine to see how the rotary engine parts coped with the challenges.

Rarely obvious

Before anyone would think that our dealership would simply remove and disassemble an RX-8 engine just for the sake of gathering experience, I have to tell that there were problems with the motor of this car earlier. The engine always started fine when cold but could not be started again until it was left to cool down. According to the owner, he kept using the car even after the cat collapsed, which was shortly before the mentioned warm start problems appeared. Considering the possible consequences of all this, and eliminating other potential problem sources such as spark plugs and ignition coils, the engine failure remained the only plausible explanation. This was confirmed by the somewhat decreased power output as well.

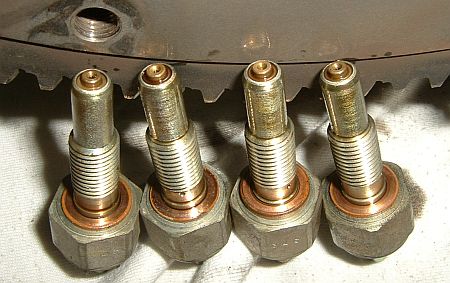

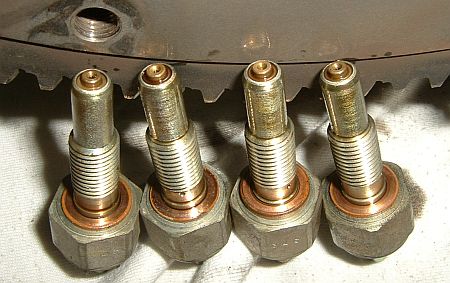

Prior to cracking the engine open, it is worth to take a look at the oil pump system's nozzles that provide the oil to cool the seals (apex, corner, side):

The nozzles are perfectly clean after 100,000 km, using 5W-30 Mazda Dexelia oil that was changed every 20,000 km. Of course it would be surprising if they were contaminated, because they are located at the engine's "intake phase" on the trochoid housings, so the vacuum-driven departing air-oil mixture prevents deposits, irrespective of the oil quality.

These aren't dirty either

Before the breakdown of the engine, it is worth examining the 231-horsepower RENESIS 13B-MSP's auxiliary port valves (APV) as well. Despite the 100,000 km mileage, they remained relatively clean, still very far from having issues caused by accumulated carbon. The picture was taken unfortunately only after cleaning one of the control cylinders, so the reader will have to take my word for it.

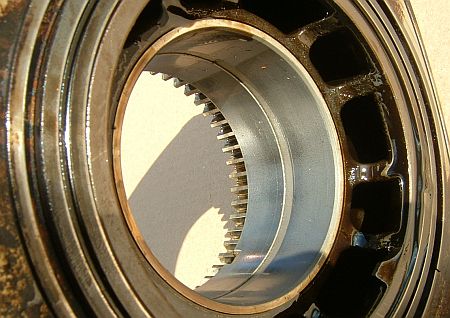

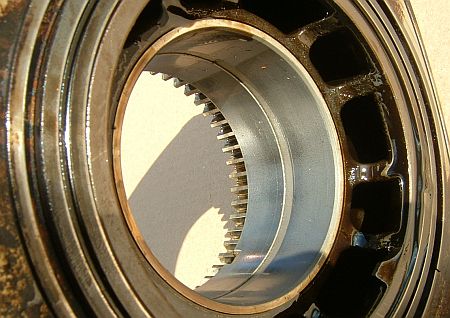

Eccentric shaft front bearing

Turning to the engine, we'll start with the front iron, covering the first trochoid. To be exact, with the stationary gear and eccentric shaft bearing's housing.

.jpg)

Inside we can see the eccentric shaft's front bearing. These kinds of bearings work based on the principle that the injected pressurized oil builds a layer preventing metal-to-metal contact between the shaft and the bearing housing. Oil is supplied by the metering oil pump. The higher the revolutions of the shaft, the more oil is needed, since the increasing load on the faster spinning shaft causes more oil to be displaced from the bearing housing. We can estimate the amount of the oil based on the oil pressure. More pressure = more oil.

As it can be seen in the previous two pictures, this bearing is unfortunately in a seriously worn condition. We rarely encounter such abnormal wear in internal combustion engines, even after much higher mileage. In case of the 13B-MSP RENESIS rotary engine, this is unfortunately quite common. This type of wear is not really justified by any operational condition, only perhaps by abuse after a cold start, or persistently low engine oil level, inadequate cooling ... But not even these circumstances explain it, because we experienced similar wear in several engines, and not every owner will make the same mistakes. Besides, engine design should protect against such errors. Unfortunately, the wear appears to be primarily due to design defects. This is even more puzzling, as a plain bearing's oil supply is not rotary-specific, unlike seal lubrication. Instead, proper scaling of the lubrication system and parts would have been necessary – but more about that later still, when we talk about the rear eccentric shaft bearing.

RX-8 13B-MSP RENESIS 100,000 km.

Date: 2011-05-05

Mazda RX-8 rotary engine disassembly

Let's jump right in the middle: we've got a Mazda RX-8 with 100,000 km on the odo. According to the maintenance log, the oil change interval was unfortunately pretty long, only at every 20K km (12.5K miles). Let's tear down the engine to see how the rotary engine parts coped with the challenges.

Rarely obvious

Before anyone would think that our dealership would simply remove and disassemble an RX-8 engine just for the sake of gathering experience, I have to tell that there were problems with the motor of this car earlier. The engine always started fine when cold but could not be started again until it was left to cool down. According to the owner, he kept using the car even after the cat collapsed, which was shortly before the mentioned warm start problems appeared. Considering the possible consequences of all this, and eliminating other potential problem sources such as spark plugs and ignition coils, the engine failure remained the only plausible explanation. This was confirmed by the somewhat decreased power output as well.

Prior to cracking the engine open, it is worth to take a look at the oil pump system's nozzles that provide the oil to cool the seals (apex, corner, side):

The nozzles are perfectly clean after 100,000 km, using 5W-30 Mazda Dexelia oil that was changed every 20,000 km. Of course it would be surprising if they were contaminated, because they are located at the engine's "intake phase" on the trochoid housings, so the vacuum-driven departing air-oil mixture prevents deposits, irrespective of the oil quality.

These aren't dirty either

Before the breakdown of the engine, it is worth examining the 231-horsepower RENESIS 13B-MSP's auxiliary port valves (APV) as well. Despite the 100,000 km mileage, they remained relatively clean, still very far from having issues caused by accumulated carbon. The picture was taken unfortunately only after cleaning one of the control cylinders, so the reader will have to take my word for it.

Eccentric shaft front bearing

Turning to the engine, we'll start with the front iron, covering the first trochoid. To be exact, with the stationary gear and eccentric shaft bearing's housing.

.jpg)

Inside we can see the eccentric shaft's front bearing. These kinds of bearings work based on the principle that the injected pressurized oil builds a layer preventing metal-to-metal contact between the shaft and the bearing housing. Oil is supplied by the metering oil pump. The higher the revolutions of the shaft, the more oil is needed, since the increasing load on the faster spinning shaft causes more oil to be displaced from the bearing housing. We can estimate the amount of the oil based on the oil pressure. More pressure = more oil.

As it can be seen in the previous two pictures, this bearing is unfortunately in a seriously worn condition. We rarely encounter such abnormal wear in internal combustion engines, even after much higher mileage. In case of the 13B-MSP RENESIS rotary engine, this is unfortunately quite common. This type of wear is not really justified by any operational condition, only perhaps by abuse after a cold start, or persistently low engine oil level, inadequate cooling ... But not even these circumstances explain it, because we experienced similar wear in several engines, and not every owner will make the same mistakes. Besides, engine design should protect against such errors. Unfortunately, the wear appears to be primarily due to design defects. This is even more puzzling, as a plain bearing's oil supply is not rotary-specific, unlike seal lubrication. Instead, proper scaling of the lubrication system and parts would have been necessary – but more about that later still, when we talk about the rear eccentric shaft bearing.

Last edited by Tamas; 10-12-2011 at 02:24 PM.

The following users liked this post:

IamFodi (09-28-2017)

#28

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

The front rotor housing

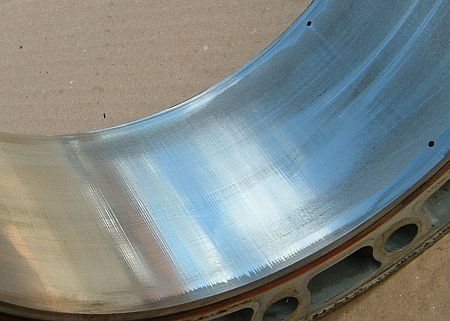

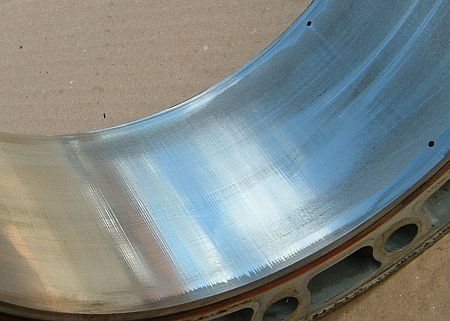

Continuing with our Wankel engine, we arrive to the front rotor housing. Obviously, the condition of an engine cannot be assessed by just eyeballing it, it has to be measured. Nevertheless, as the following pictures show, the front rotor's sliding surfaces or the trochoid are in a surprisingly good shape despite of the 100,000 km mileage and subpar maintenance.

Let's do a bit of math! 50 km/h average speed for 100,000 km means 2,000 hours of operation. If we calculate with an average eccentric shaft RPM of 3,000, this means 360 million revolutions of the eccentric shaft. The rotors completed exactly three times less revolutions, or 120 million, since we have 1/3 rotor revolutions for each full turn of the eccentric shaft. Considering the length of the trochoid sliding surface, this means that the apex seals traveled about 100,000 km. Although the average speed data is only theoretical, it's interesting that the apex seals completed practically the same distance like the car itself.

In case of the piston engine of a 2.5 liter Mazda6, the piston rings travel about 72,000 km when calculating with similar averages. This is about 30% less, let alone the load and lubrication differences (a disadvantage for the Wankel). On top of that, the 2.5 liter is a relatively long stroke engine, so in case of a shorter stroke engine, the piston ring travel is even less.

In our RENESIS, the front trochoid and it's surface shows a rather significant wear at the edges, which can be attributed to increased heat exposure on the sides, due to the side exhaust ports. This is so despite the fact that most of the cooling engine oil arrives here as well, through the tiny holes visible on the above photo.

The picture shows the front rotor housing cover's exhaust port. Following the peripheric exhaust ports on previous Mazda Wankels, the shape of the side ports introduced on the Renesis was chosen to clean the side and corner seals of carbon deposits. Their effectiveness is visible from the deposits at the narrow end of the port. This means that either there were less carbon deposits in this motor, or they were blown out due to regular high load operation. The small amount of deposits may also be evidence that they originate from the fuel instead of burning of the rather small amount of the engine oil (compared to the overall volume). Apart from a detailed technical explanation, if the deposits originated from the oil, then there should be more of them considering the neglected maintenance of this engine.

The front rotor housing's other exhaust port is also quite clean:

Continuing with our Wankel engine, we arrive to the front rotor housing. Obviously, the condition of an engine cannot be assessed by just eyeballing it, it has to be measured. Nevertheless, as the following pictures show, the front rotor's sliding surfaces or the trochoid are in a surprisingly good shape despite of the 100,000 km mileage and subpar maintenance.

Let's do a bit of math! 50 km/h average speed for 100,000 km means 2,000 hours of operation. If we calculate with an average eccentric shaft RPM of 3,000, this means 360 million revolutions of the eccentric shaft. The rotors completed exactly three times less revolutions, or 120 million, since we have 1/3 rotor revolutions for each full turn of the eccentric shaft. Considering the length of the trochoid sliding surface, this means that the apex seals traveled about 100,000 km. Although the average speed data is only theoretical, it's interesting that the apex seals completed practically the same distance like the car itself.

In case of the piston engine of a 2.5 liter Mazda6, the piston rings travel about 72,000 km when calculating with similar averages. This is about 30% less, let alone the load and lubrication differences (a disadvantage for the Wankel). On top of that, the 2.5 liter is a relatively long stroke engine, so in case of a shorter stroke engine, the piston ring travel is even less.

In our RENESIS, the front trochoid and it's surface shows a rather significant wear at the edges, which can be attributed to increased heat exposure on the sides, due to the side exhaust ports. This is so despite the fact that most of the cooling engine oil arrives here as well, through the tiny holes visible on the above photo.

The picture shows the front rotor housing cover's exhaust port. Following the peripheric exhaust ports on previous Mazda Wankels, the shape of the side ports introduced on the Renesis was chosen to clean the side and corner seals of carbon deposits. Their effectiveness is visible from the deposits at the narrow end of the port. This means that either there were less carbon deposits in this motor, or they were blown out due to regular high load operation. The small amount of deposits may also be evidence that they originate from the fuel instead of burning of the rather small amount of the engine oil (compared to the overall volume). Apart from a detailed technical explanation, if the deposits originated from the oil, then there should be more of them considering the neglected maintenance of this engine.

The front rotor housing's other exhaust port is also quite clean:

Last edited by Tamas; 10-15-2011 at 12:53 AM.

The following users liked this post:

IamFodi (09-28-2017)

#29

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

One could say that at 900 degrees Celsius the engine oil has little chance, but it seems neither oil combustion deposits, nor carbon from gasoline combustion can accumulate, even though the latter is present in much greater quantities. The picture above clearly shows that the side sliding surface is quite normal, ďporousĒ (better oil adhesion).

Front rotor

In Wankel engines, so in the Mazda RENESIS 13B-MSP as well, the rotor's trajectory is determined not by the trochoid's oval track but the eccentric shaft and the already introduced stationary gear. The rotor doesn't physically touch the trochoid surface, only the seals get in contact with it and the side covers.

Thus, in principle the rotor should not wear, if itís plain bearing, stationary gear and the eccentric shaft bearing keep it on the correct path. But before we get excited hearing this, the rotor CAN wear, even if the bearings are intact. The rotor seals, especially the apex seals are constantly moving in their grooves. Combustion deposits between the seal and its grooves, the result of seal movements, and the worn seals can increase the width of seal grooves exceeding the tolerances.

Despite of all this and the 100,000 km mileage, this rotor is in reusable condition.

The rotor plane bearing (picture above) is considered in good condition, compared to the previously discussed eccentric shaft bearings. The side oil seals and cut-off seals also remained in good condition, without substantive changes, and can be easily moved in their nests.

The caked-on carbon on the rotors shouldn't fool anyone! There are no problematic deposits at the significant locations, plus the view is made worse by the motor oil dripping onto the carbon during engine disassembly. Although the positioning gear is already removed, on the above photo it is clearly visible how important is the precise guidance and balancing of the rotor that weighs almost 4 kg. This can be significantly affected by a worn eccentric shaft bearing.

Front rotor

In Wankel engines, so in the Mazda RENESIS 13B-MSP as well, the rotor's trajectory is determined not by the trochoid's oval track but the eccentric shaft and the already introduced stationary gear. The rotor doesn't physically touch the trochoid surface, only the seals get in contact with it and the side covers.

Thus, in principle the rotor should not wear, if itís plain bearing, stationary gear and the eccentric shaft bearing keep it on the correct path. But before we get excited hearing this, the rotor CAN wear, even if the bearings are intact. The rotor seals, especially the apex seals are constantly moving in their grooves. Combustion deposits between the seal and its grooves, the result of seal movements, and the worn seals can increase the width of seal grooves exceeding the tolerances.

Despite of all this and the 100,000 km mileage, this rotor is in reusable condition.

The rotor plane bearing (picture above) is considered in good condition, compared to the previously discussed eccentric shaft bearings. The side oil seals and cut-off seals also remained in good condition, without substantive changes, and can be easily moved in their nests.

The caked-on carbon on the rotors shouldn't fool anyone! There are no problematic deposits at the significant locations, plus the view is made worse by the motor oil dripping onto the carbon during engine disassembly. Although the positioning gear is already removed, on the above photo it is clearly visible how important is the precise guidance and balancing of the rotor that weighs almost 4 kg. This can be significantly affected by a worn eccentric shaft bearing.

The following users liked this post:

IamFodi (09-28-2017)

#30

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

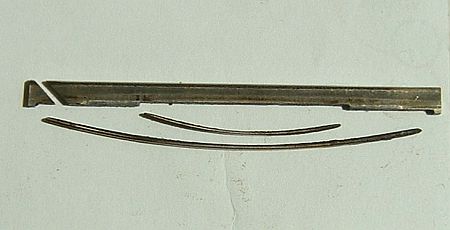

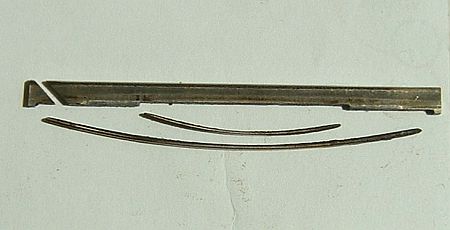

Apex, corner and side seals (rotor 1)

We arrived to the front rotor's apex seals, corner seals and side seals. I will share the measured wear data with the reader.

A rotor has three apex seals, located at the tips of the rotor. Sliding over the trochoid surface of the housing, they provide chamber tightness together with the six corner seals and side seals.

Mazda officially allows 1 mm wear of the apex seals which, according to our estimate, occurs at about 240,000 km mileage. This is certainly not random data, since we measured about 0.5 mm wear in 100,000 km at our front rotor. As their mass and thickness decreases, seal wear also diminishes to a certain extent. Wear from their constant up-down movement can also be measured on their lateral surface, although this doesn't reach critical level either.

The above pictured side seals of the front rotor practically retained their factory dimensions after 100,000 km. In order to prevent deposits in the grooves that can cause the seals to get stuck, the seals have a wedge shape which appears to have worked perfectly. All six side seals can move freely in their grooves.

Rear rotor housing

The rear rotor is bounded on one side by the intermediate housing. The front rotorís rear surface is sliding on the opposite side of it. Contrary to the front and rear cover, the eccentric shaft has no bearing here.

.jpg)

Compared to the front rotor covers that are in relatively good condition, the rear rotorís sliding surfaces are quite worn as it can be seen on the photo, especially at the exhaust port area. At the same time, there are relatively little deposits in the right corner of the exhaust port. We could already see the same at the front rotor as well. This cornerís purpose is to prevent forming of deposits.

Similar to the intermediate housing surface, the condition of the rear trochoid is also worse than the front. The surface is highly uneven in some places showing wear and scrapes. Yet the most worrisome is the transverse crack at the leading spark plug hole.

We arrived to the front rotor's apex seals, corner seals and side seals. I will share the measured wear data with the reader.

A rotor has three apex seals, located at the tips of the rotor. Sliding over the trochoid surface of the housing, they provide chamber tightness together with the six corner seals and side seals.

Mazda officially allows 1 mm wear of the apex seals which, according to our estimate, occurs at about 240,000 km mileage. This is certainly not random data, since we measured about 0.5 mm wear in 100,000 km at our front rotor. As their mass and thickness decreases, seal wear also diminishes to a certain extent. Wear from their constant up-down movement can also be measured on their lateral surface, although this doesn't reach critical level either.

The above pictured side seals of the front rotor practically retained their factory dimensions after 100,000 km. In order to prevent deposits in the grooves that can cause the seals to get stuck, the seals have a wedge shape which appears to have worked perfectly. All six side seals can move freely in their grooves.

Rear rotor housing

The rear rotor is bounded on one side by the intermediate housing. The front rotorís rear surface is sliding on the opposite side of it. Contrary to the front and rear cover, the eccentric shaft has no bearing here.

.jpg)

Compared to the front rotor covers that are in relatively good condition, the rear rotorís sliding surfaces are quite worn as it can be seen on the photo, especially at the exhaust port area. At the same time, there are relatively little deposits in the right corner of the exhaust port. We could already see the same at the front rotor as well. This cornerís purpose is to prevent forming of deposits.

Similar to the intermediate housing surface, the condition of the rear trochoid is also worse than the front. The surface is highly uneven in some places showing wear and scrapes. Yet the most worrisome is the transverse crack at the leading spark plug hole.

The following users liked this post:

IamFodi (09-28-2017)

#31

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

The second chamberís rear cover surface doesnít bring a lot of news. It is not as good as in the front, but exhaust port deposits are not significantly present here either. Based on the wear shown, we can conclude that the rear rotor chamber was subject to definitely higher thermal load than the front, but itís also strongly susceptible that occasionally, these parts were suffering from too quick thermal changes. This may indicate not sufficiently careful warm-ups. Probably thatís the reason for the trochoid ďgiving inĒ at the point where it is the thinnest.

Rear rotor

The rear rotor Ė similarly to the front Ė remained in reusable condition after 100,000 km. The seal grooves are within tolerances, and the already discussed seal movements didnít cause problematic wear so far. No seal was stuck due to deposits.

.jpg)

The rotor bearings - that have a much larger diameter than the eccentric shaft bearings Ė remained in relatively good condition, although we still wouldnít rebuild a motor with this mileage utilizing used bearings like these. There are no signs of wear on the rotor gears either. Apparently the engine oil managed to keep up with the increased heat load in these areas.

Apex, corner and side seals, rear rotor

The probable higher heat load is clearly visible on the rear apex seals, compared to the front. All three rear apex seals are 0.1 mm shorter than the front counterparts.

Side seal wear is virtually non-measurable, and their distance from the corner seals is also within tolerances. Seal springs are in good condition as well.

The following users liked this post:

IamFodi (09-28-2017)

#32

Registered Lunatic

iTrader: (1)

Joined: Aug 2003

Posts: 3,581

Likes: 38

From: SF Bay Area, California

Eccentric shaft rear bearing

At the beginning of this article we saw how much wear the eccentric shaft’s front plain bearing surface sustained. Unfortunately the same can be said about the rear bearing that’s attached to the rear cover, together with the stationary gear. It seems the eccentric shaft of the Renesis sometimes extracts more oil from its bearings than the supplied volume. By “sometimes” we mean temperature or revolution spikes or even careless warm-up. On top of that, such bearing wear would require even more oil being supplied.

The higher the temperature of the bearing, and the higher the RPM, the higher oil pressure would be required to provide sufficient quantities of motor oil circulating through the bearing. Many people believe that higher viscosity oil is the solution, but the thicker oil flows slower at the same pressure, so that less oil is less able to cool the bearing. Consequently, the increased bearing temperature thins out the oil, which is supplied too slowly. Thus the usage of xxw-40 or xxw-50 motor oil doesn’t really offer sufficient help.

In fact we may say that Mazda engineers have created their highest RPM rotary motor ever, with the lowest ever maximum oil pressure (5.1 bar max.), and this is just the basic anomaly. In addition, this is just part of the problem. Our phase-I and phase-II solution provides the first steps to eliminate this complex issue.

(This is basically their service offering that increases oil pressure by a modification, as far as I understand)

The eccentric shaft (or rotary main shaft)

The eccentric shaft is practically equivalent to the crankshaft of the piston engine. It converts the planetary motion of the rotors into rotary motion that drives the transmission. The eccentric shaft provides the oil supply to the plane bearings of the rotors. The rotors are also cooled by the oil distributed by the eccentric shaft’s oil squirter.

(red text = rotor bearing oil supply nozzle

Purple text = oil squirter)

The more oil flows through the eccentric shaft, the better it will cool the rotors. Shaft wear is not common, since the bearing’s metal is softer. Balancing the shaft has more importance, but this shaft was found to be good.

New heart

The car received an all-new factory (Japan only) engine, because according to the owner's expectations, it must be able to serve at least another problem-free 100 000 km. It has all the chances too, as oil changes will happen at every 10,000 km at the most, with fully synthetic 0W-30 oil. Shorter oil change intervals and the higher stability of the fully synthetic oil are a great step forward. The lower cold side index motor oil will also assist in faster eccentric shaft lubrication at startup, which will reduce the load on the eccentric shaft bearings. This is further helped by our mazda-auto phase-II modification that was also applied to the new motor.

Application of the mazda-aurto phase-I modification will increase the supplied oil quantity which improves the RENESIS’ load bearing capability. In addition, the careful break-in procedure will now help to prolong the life of the engine. Max. RPM during the first 750 km was up to 3000-3500 then until 1000 km in some cases up to 4000.

As a private opinion, I want to note that quite a number of Mazda RX-8s in Hungary began their life as demo or test vehicles, and unfortunately, due to lack of sufficient information and warning, these cars had no chance for the aforementioned gentle break-in. There are some exceptions of course.

Old and new

Warm start problems of the old engine were probably caused by the rear trochoid housing’s wear and damage. The crack likely appeared due to rapid temperature changes that were caused by ignition issues, careless break-in or both. Replacing the trochoid housing and the cost of all seals plus labor of a high quality remanufacturing process is likely getting close to the price of a brand new factory engine.

Moreover, in this case we’d only end up with a remanufactured motor (reusing some less worn - but still worn - parts). So I guess it needs no further explanation that life expectancy of such a remanufactured motor cannot be expected to compare to a new engine.

WARNING! Contrary to other rumors, Mazda uses only completely new engines straight from the factory in Japan. These are not remanufactured engines, which can also be proven by their serial number. Remanufactured engines are only used in North America, but these cannot be imported.

At the beginning of this article we saw how much wear the eccentric shaft’s front plain bearing surface sustained. Unfortunately the same can be said about the rear bearing that’s attached to the rear cover, together with the stationary gear. It seems the eccentric shaft of the Renesis sometimes extracts more oil from its bearings than the supplied volume. By “sometimes” we mean temperature or revolution spikes or even careless warm-up. On top of that, such bearing wear would require even more oil being supplied.

The higher the temperature of the bearing, and the higher the RPM, the higher oil pressure would be required to provide sufficient quantities of motor oil circulating through the bearing. Many people believe that higher viscosity oil is the solution, but the thicker oil flows slower at the same pressure, so that less oil is less able to cool the bearing. Consequently, the increased bearing temperature thins out the oil, which is supplied too slowly. Thus the usage of xxw-40 or xxw-50 motor oil doesn’t really offer sufficient help.

In fact we may say that Mazda engineers have created their highest RPM rotary motor ever, with the lowest ever maximum oil pressure (5.1 bar max.), and this is just the basic anomaly. In addition, this is just part of the problem. Our phase-I and phase-II solution provides the first steps to eliminate this complex issue.

(This is basically their service offering that increases oil pressure by a modification, as far as I understand)

The eccentric shaft (or rotary main shaft)

The eccentric shaft is practically equivalent to the crankshaft of the piston engine. It converts the planetary motion of the rotors into rotary motion that drives the transmission. The eccentric shaft provides the oil supply to the plane bearings of the rotors. The rotors are also cooled by the oil distributed by the eccentric shaft’s oil squirter.

(red text = rotor bearing oil supply nozzle

Purple text = oil squirter)

The more oil flows through the eccentric shaft, the better it will cool the rotors. Shaft wear is not common, since the bearing’s metal is softer. Balancing the shaft has more importance, but this shaft was found to be good.

New heart

The car received an all-new factory (Japan only) engine, because according to the owner's expectations, it must be able to serve at least another problem-free 100 000 km. It has all the chances too, as oil changes will happen at every 10,000 km at the most, with fully synthetic 0W-30 oil. Shorter oil change intervals and the higher stability of the fully synthetic oil are a great step forward. The lower cold side index motor oil will also assist in faster eccentric shaft lubrication at startup, which will reduce the load on the eccentric shaft bearings. This is further helped by our mazda-auto phase-II modification that was also applied to the new motor.

Application of the mazda-aurto phase-I modification will increase the supplied oil quantity which improves the RENESIS’ load bearing capability. In addition, the careful break-in procedure will now help to prolong the life of the engine. Max. RPM during the first 750 km was up to 3000-3500 then until 1000 km in some cases up to 4000.

As a private opinion, I want to note that quite a number of Mazda RX-8s in Hungary began their life as demo or test vehicles, and unfortunately, due to lack of sufficient information and warning, these cars had no chance for the aforementioned gentle break-in. There are some exceptions of course.

Old and new

Warm start problems of the old engine were probably caused by the rear trochoid housing’s wear and damage. The crack likely appeared due to rapid temperature changes that were caused by ignition issues, careless break-in or both. Replacing the trochoid housing and the cost of all seals plus labor of a high quality remanufacturing process is likely getting close to the price of a brand new factory engine.

Moreover, in this case we’d only end up with a remanufactured motor (reusing some less worn - but still worn - parts). So I guess it needs no further explanation that life expectancy of such a remanufactured motor cannot be expected to compare to a new engine.

WARNING! Contrary to other rumors, Mazda uses only completely new engines straight from the factory in Japan. These are not remanufactured engines, which can also be proven by their serial number. Remanufactured engines are only used in North America, but these cannot be imported.

Last edited by Tamas; 10-11-2011 at 07:20 PM.

The following users liked this post:

IamFodi (09-28-2017)

#36

Thx for the translation ! ahh, much better than some "robotic google translate"

this part

you can say it's a design defect, or not.

it's still based on a 20-30 freaking years old design, it's the same freaking bearing for all the years + this is the highest power NA engine + it's calling for 5w30 oil ... well at least 5w30 is better than 20? you see marks like that much SOONER on 5w20 engines than 5w30 ... oh yeah 20w50 ALL THE WAY BABY umm yeah

umm yeah

ohhh and did they mention SYNTHETIC OIL IN ROTARY? OH NO YOU DIDn'T ANGRY MOBS OF YAY U DON'T KNOW **** MAZDA KNOWS BETTER WILL GO AFTER U NOW !

this part

We rarely encounter such abnormal wear in internal combustion engines, even after much higher mileage. In case of the 13B-MSP RENESIS rotary engine, this is unfortunately quite common. This type of wear is not really justified by any operational condition, only perhaps by abuse after a cold start, or persistently low engine oil level, inadequate cooling ... But not even these circumstances explain it, because we experienced similar wear in several engines, and not every owner will make the same mistakes. Besides, engine design should protect against such errors. Unfortunately, the wear appears to be primarily due to design defects. This is even more puzzling, as a plain bearing's oil supply is not rotary-specific, unlike seal lubrication. Instead, proper scaling of the lubrication system and parts would have been necessary – but more about that later still, when we talk about the rear eccentric shaft bearing.

it's still based on a 20-30 freaking years old design, it's the same freaking bearing for all the years + this is the highest power NA engine + it's calling for 5w30 oil ... well at least 5w30 is better than 20? you see marks like that much SOONER on 5w20 engines than 5w30 ... oh yeah 20w50 ALL THE WAY BABY

umm yeah

umm yeahohhh and did they mention SYNTHETIC OIL IN ROTARY? OH NO YOU DIDn'T ANGRY MOBS OF YAY U DON'T KNOW **** MAZDA KNOWS BETTER WILL GO AFTER U NOW !

Last edited by nycgps; 10-13-2011 at 01:54 AM.

#37

They comment on the stationary bearings failures as a low pressure problem, but bearings load up with hydrostatic pressure also from turning.

9krpmrx8 didn't have any of this on his teardown, but he did run 0w40 or 5w40 oils.

Many people here know to run at least xw40 oil to preserve those bearings.

I noticed that Subaru warned against using 5w30 in their turbos, and I see better used oil analysis with other oils like 0w30, 0w40, and even 10w30.

9krpmrx8 didn't have any of this on his teardown, but he did run 0w40 or 5w40 oils.

Many people here know to run at least xw40 oil to preserve those bearings.

I noticed that Subaru warned against using 5w30 in their turbos, and I see better used oil analysis with other oils like 0w30, 0w40, and even 10w30.

#38

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

Yeah I am pretty set on either 0W-40 or 5W-40 Mobil1 after seeing how well my bearing looked. there are usually oil change specials on either 5W-40 or 0W-40 mobil1 at all times between the different parts stores so I will get either depending which is on special.

#43

#44

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

I agree, if you are running stock oil pressure is something to consider when you make your choice in oil. For me, I never saw a difference in oil pressure between the dealer fill 5W-20 (mobil clean 2000).0W-30 GC, to Rotella T6 5W-40, Mobil1 5W-40, and Mobil1 0W-40. S2 owners need not worry about oil pressure or the OMP system.

#45

I go in this order..

1.Warm Up (Always has been and always will be with any rotary, at least until coolant temp reaches 40c, after roughly 4-5 min's from stone cold)

2.Oil Pressure (Higher pressure more flow/renewal/cooler oil at Bearings.

3.0W, I don't and will never agree in a rotary, 5W30 Minimum*.

4.Pre-mix

* Provided an OP upgrade has been done.

#46

Yep Agree...

I go in this order..

1.Warm Up (Always has been and always will be with any rotary, at least until coolant temp reaches 40c, after roughly 4-5 min's from stone cold)

2.Oil Pressure (Higher pressure more flow/renewal/cooler oil at Bearings.

3.0W, I don't and will never agree in a rotary, 5W30 Minimum*.

4.Pre-mix

* Provided an OP upgrade has been done.

I go in this order..

1.Warm Up (Always has been and always will be with any rotary, at least until coolant temp reaches 40c, after roughly 4-5 min's from stone cold)

2.Oil Pressure (Higher pressure more flow/renewal/cooler oil at Bearings.

3.0W, I don't and will never agree in a rotary, 5W30 Minimum*.

4.Pre-mix

* Provided an OP upgrade has been done.

#47

Most people never warm up their cars...Mazda's re-manufactured motors scare me.. mine has held up so far 20k miles of boost @10 psi... once this motor goes i cant wait to see how the internals look. My FC had about 130k miles before it went out due to cracked housing putting combustion in the coolant system, and it didnt look nearly as bad as this!

#49

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

Most people never warm up their cars...Mazda's re-manufactured motors scare me.. mine has held up so far 20k miles of boost @10 psi... once this motor goes i cant wait to see how the internals look. My FC had about 130k miles before it went out due to cracked housing putting combustion in the coolant system, and it didnt look nearly as bad as this!

Yeah I was down right religious about warming my car up, oil changes, etc. And according to Rob at pineapple the housings in my reman that failed after 30,000 miles should not have ever been reused but Mazda chose to reuse them so..........

In the end a failed coolant was the culprit on my engine but he said the crack in the housing near the spark plug hole would have become and issue sooner or later.