16X Technical observations

#1

16X Technical observations

I hope this truly warranted it's own thread as I thought it did. The moderators can decide.

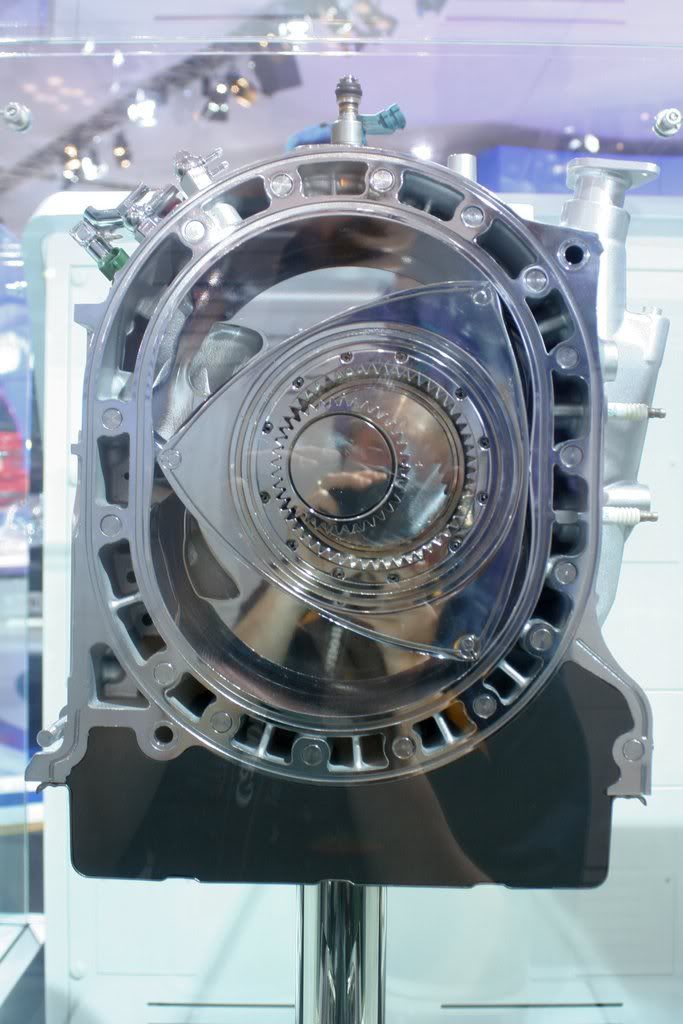

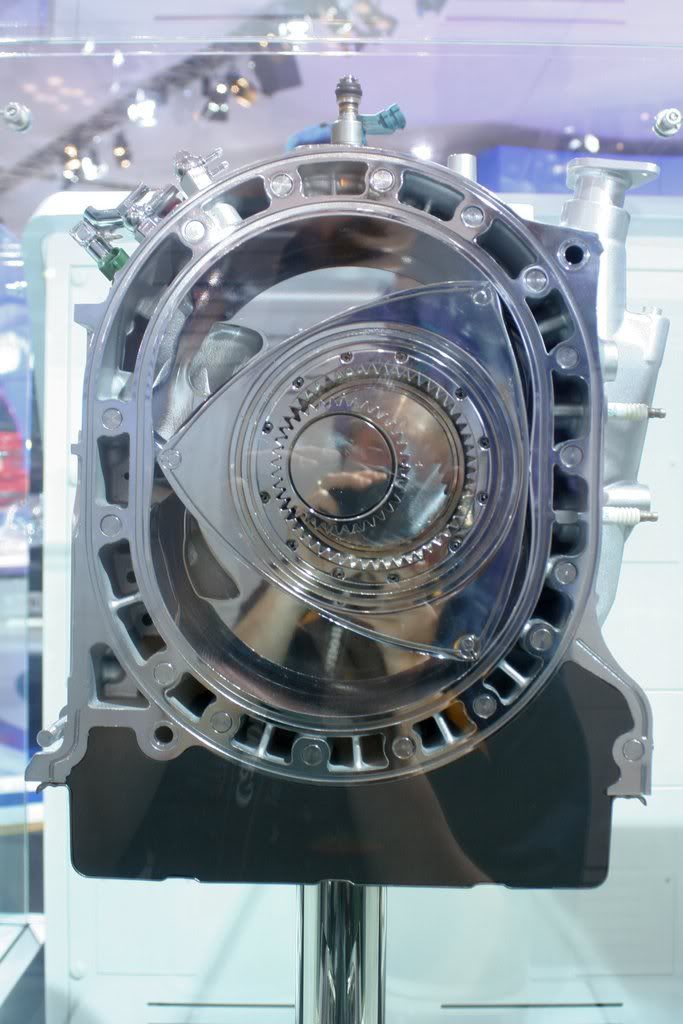

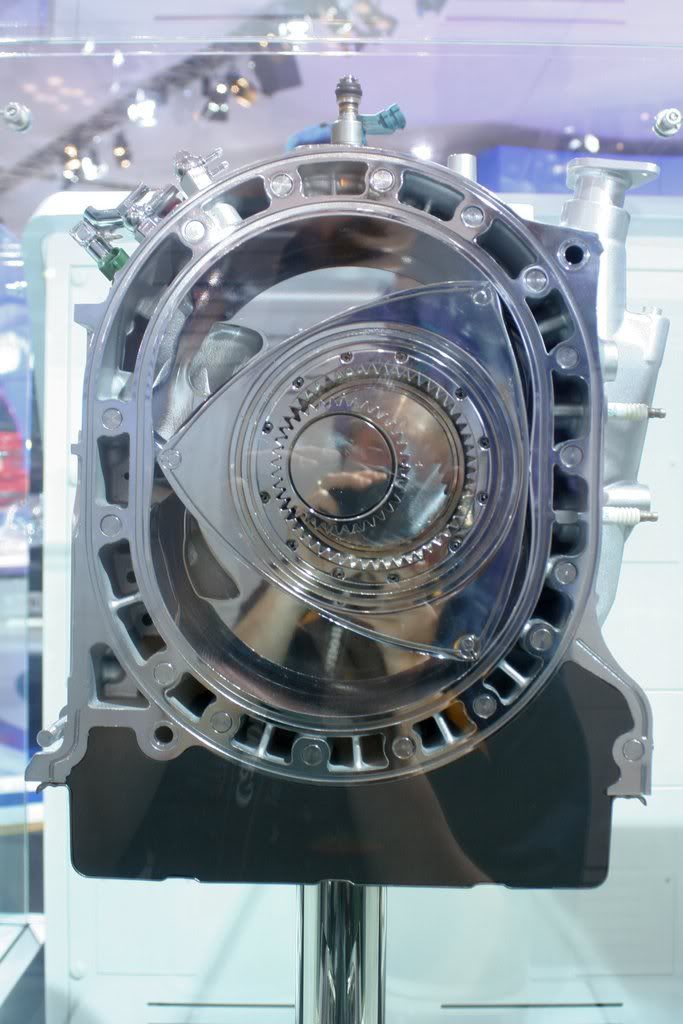

Apart from the rotor housings being reduced in width (Front to back) perhaps to that of a 12A and the added stroke (Eccentricity) with the larger rotors, aluminum side housings, re-sized water passages (Perhaps), direct injection etc, etc, I noticed some very interesting things of note: The motor being displayed is a 4 port induction type for example.

More importantly,a major change I observed on the Aussie forum (That led to this thread) is what appears to be a relocated dowel. This dowel relocation is much more major than some may realize as it would facillitate an extra spark plug.

I could be wrong in my observation but I think the new housings may be cast with that potentially in mind.

I hope I'm right. Fred, feel free to chime in, and I hope others will make technical notes as we recieve more pics and info.

Paul.

Apart from the rotor housings being reduced in width (Front to back) perhaps to that of a 12A and the added stroke (Eccentricity) with the larger rotors, aluminum side housings, re-sized water passages (Perhaps), direct injection etc, etc, I noticed some very interesting things of note: The motor being displayed is a 4 port induction type for example.

More importantly,a major change I observed on the Aussie forum (That led to this thread) is what appears to be a relocated dowel. This dowel relocation is much more major than some may realize as it would facillitate an extra spark plug.

I could be wrong in my observation but I think the new housings may be cast with that potentially in mind.

I hope I'm right. Fred, feel free to chime in, and I hope others will make technical notes as we recieve more pics and info.

Paul.

#2

Here's the Aussie thread link with the excellent pics.

https://www.rx8club.com/australia-new-zealand-forum-37/renesis-16x-tokyo-motor-show-information-photos-129821/

Paul.

https://www.rx8club.com/australia-new-zealand-forum-37/renesis-16x-tokyo-motor-show-information-photos-129821/

Paul.

#3

Sorry Paul, I realize why you insist on the motor being a 4-port after I opened this thread.

Looking from the exterior of the motor, it sure is misleading. It looks like a 6port from the side until you crack it open.

Why do Mazda put those holes there tho? I am speculating that it is STILL a 6port design, 6 intake runners running into the engine, BUT those two ports on the side plates share the same intake port.

________

Novana Residence Condominium

Looking from the exterior of the motor, it sure is misleading. It looks like a 6port from the side until you crack it open.

Why do Mazda put those holes there tho? I am speculating that it is STILL a 6port design, 6 intake runners running into the engine, BUT those two ports on the side plates share the same intake port.

________

Novana Residence Condominium

Last edited by Renesis_8; 09-11-2011 at 01:46 PM.

#4

Assuming it has the same dimensions as the 13B. As stated before, they narrowed the coolage passage to make room for the displacement increase. Now, wouldn't cooling be an issue with decreased coolant passage area, then they'll need to up the coolant flow to keep up with the demand.

How is the water temp for 13B-MSP driven hard? Or they'll use more oil to cool the engine (3 holes per rotor), and maybe perhaps a really big oil cooler. Actually I like this idea, 2/3 cooling from coolant and the other 1/3 from oil. It is just like the racing rotaries.

________

VOLCANO VAPORIZER SALE

How is the water temp for 13B-MSP driven hard? Or they'll use more oil to cool the engine (3 holes per rotor), and maybe perhaps a really big oil cooler. Actually I like this idea, 2/3 cooling from coolant and the other 1/3 from oil. It is just like the racing rotaries.

________

VOLCANO VAPORIZER SALE

Last edited by Renesis_8; 09-11-2011 at 01:46 PM.

#5

well, the center port is the same size as now, which sucks, but given the effort, I have to assume the tried a larger center housing and it just didnt add any material power.

Paul, I see your point about the spark plug, but why aren't we seeing it already with the prototype? figured that would be shown if it was the direct they are going.

Paul, I see your point about the spark plug, but why aren't we seeing it already with the prototype? figured that would be shown if it was the direct they are going.

#6

The 3rd spark plug could go right where the circle is above the dowel.

I think its for racing applications. If thats the case, they will make a peripheral port 16X or derivatives.

Or just in case they need the extra plug to meet future emissions.

________

Washington Medical Marijuana

I think its for racing applications. If thats the case, they will make a peripheral port 16X or derivatives.

Or just in case they need the extra plug to meet future emissions.

________

Washington Medical Marijuana

Last edited by Renesis_8; 09-11-2011 at 01:46 PM.

#7

Even if the area is the same as 13B-MSP, it could still flow the same at 7500rpm vs 9000rpm in a 13B.

The exhaust ports are definitely different! It almost looks like a ported exhaust port!

________

Art On The Hill Condo

Last edited by Renesis_8; 09-11-2011 at 01:46 PM.

#9

Assuming it has the same dimensions as the 13B. As stated before, they narrowed the coolage passage to make room for the displacement increase. Now, wouldn't cooling be an issue with decreased coolant passage area, then they'll need to up the coolant flow to keep up with the demand.

How is the water temp for 13B-MSP driven hard? Or they'll use more oil to cool the engine (3 holes per rotor), and maybe perhaps a really big oil cooler. Actually I like this idea, 2/3 cooling from coolant and the other 1/3 from oil. It is just like the racing rotaries.

How is the water temp for 13B-MSP driven hard? Or they'll use more oil to cool the engine (3 holes per rotor), and maybe perhaps a really big oil cooler. Actually I like this idea, 2/3 cooling from coolant and the other 1/3 from oil. It is just like the racing rotaries.

#11

couple questions for people that know?

1. why r the injectors located where they r and not closer to the plug, between plugs?

2 what is the rotor material? aluminum would be nice, titanium?

3. It looks like the combustion chamber is split into 2 chambers, r all rotaries like this, is this a new design? if so reasoning behind it?

4. it appears as if the 16x dish on the rotor face is longer, how will this affect combustion?

1. why r the injectors located where they r and not closer to the plug, between plugs?

2 what is the rotor material? aluminum would be nice, titanium?

3. It looks like the combustion chamber is split into 2 chambers, r all rotaries like this, is this a new design? if so reasoning behind it?

4. it appears as if the 16x dish on the rotor face is longer, how will this affect combustion?

Last edited by gr8rx; 10-27-2007 at 09:01 PM.

#12

I disagree about it being a 4 port as I see signs it is a 6 port. Namely the additional outer runners although funny looking. The giveaway is on the computer screen that shows the exploded view. It shows a 6 port.

It is not a bridgeport. You will never see this. It's not even an option.

It is not a bridgeport. You will never see this. It's not even an option.

#13

couple questions for people that know?

1. why r the injectors located where they r and not closer to the plug, between plugs?

2 what is the rotor material? aluminum would be nice, titanium?

3. It looks like the combustion chamber is split into 2 chambers, r all rotaries like this, is this a new design? if so reasoning behind it?

4. it appears as if the 16x dish on the rotor face is longer, how will this affect combustion?

1. why r the injectors located where they r and not closer to the plug, between plugs?

2 what is the rotor material? aluminum would be nice, titanium?

3. It looks like the combustion chamber is split into 2 chambers, r all rotaries like this, is this a new design? if so reasoning behind it?

4. it appears as if the 16x dish on the rotor face is longer, how will this affect combustion?

Regarding the injector and dish, several reasons. Some people might say the new layout allows for enough stratification of charge density to inhibit detonation. Other people would argue with that.

Oh yeah, don't be surprised if the friction coating in production looks a little more gold in color then silver.

#14

those holes above the spark plugs may be for knock sensors. With Direct injection, detonation will be very crucial as its the A/F is being mixed right before ignition. I wonder if they use a direct drive fuel pump like they do on the 2.3L disi?

#15

The "split combustion chamber" is the result of the trochoid geometry, which creates the hump that seperates to two sides.

Last edited by DemonRX-8; 10-29-2007 at 12:44 PM.

#16

I'll throw here my comment.

This is probably the image that leads someone to state it's a 4 port engine.

Actually, the picture doesn't show the port/s on the end plate very well: it could be a single port or two very close ports. However, if those were wo distinct ports, they would be very small, only marginally bigger, when combined, than the primary port.

That would mean that the secondary port would be smaller than the primary port, which to me doesn't make sense.

The question remains about the extra hole in the end plate. I think there's a somple solution: couldn't it be that the holes are both machined/cast regardless of the version (4 vs 6 port), but then the aux. port itself is only opened in six port engines? This would explain everything IMHO. It would make the manufacturing process for both version more similar (reducing cost) and at the same time it would reduce the weight of the 4 port version.

About bridgeporting now:

Just follow the line formed by the housing / middle plate junction. This line is easily visible in the upper and lower parts of the engine. Following this line, it's possible to see that it passes between the primary port and the "bridgeport", a sure proof that the "bridgeport" is actually a reflection. By the way, a similar reflection is visible for the exhaust.

Finally the third spark plug: what about it being reserved for the six port engine, together with the aux port?

Just my 2.8 cents (nearly 2.9)

This is probably the image that leads someone to state it's a 4 port engine.

Actually, the picture doesn't show the port/s on the end plate very well: it could be a single port or two very close ports. However, if those were wo distinct ports, they would be very small, only marginally bigger, when combined, than the primary port.

That would mean that the secondary port would be smaller than the primary port, which to me doesn't make sense.

The question remains about the extra hole in the end plate. I think there's a somple solution: couldn't it be that the holes are both machined/cast regardless of the version (4 vs 6 port), but then the aux. port itself is only opened in six port engines? This would explain everything IMHO. It would make the manufacturing process for both version more similar (reducing cost) and at the same time it would reduce the weight of the 4 port version.

About bridgeporting now:

Just follow the line formed by the housing / middle plate junction. This line is easily visible in the upper and lower parts of the engine. Following this line, it's possible to see that it passes between the primary port and the "bridgeport", a sure proof that the "bridgeport" is actually a reflection. By the way, a similar reflection is visible for the exhaust.

Finally the third spark plug: what about it being reserved for the six port engine, together with the aux port?

Just my 2.8 cents (nearly 2.9)

#17

If you save that picture and zoom in, you can see it is a 6 port. The dividing wall is very tiny and hard to see.

There is no bridgeport. That is a reflection of the rotor dish. It's apparent shape is odd due to the way the chamber shape reflects it. It's a bit like a fun house mirror.

There is no bridgeport. That is a reflection of the rotor dish. It's apparent shape is odd due to the way the chamber shape reflects it. It's a bit like a fun house mirror.

#18

Yes, I thought it was a 4 port, but, it is a 6..

Being a larger rotor with the larger stroke, I wonder when compared to the 13B what noise and vibration levels (if I can associate that word with a rotary) would be like, as the 16X has larger spinning mass.

More than likely very little, but the thought crossed my mind.

From close ups pics there appears no change in corner and apex seal design.

Having said that,?Are the 16X Apex seals slightly thicker (by say 0.5mm)?

I am still a little concerned at the length of the side seals.

BUT, IT IS A BONZA LOOKING MOTOR IN ALL CHROME!!! Isn't IT!

Being a larger rotor with the larger stroke, I wonder when compared to the 13B what noise and vibration levels (if I can associate that word with a rotary) would be like, as the 16X has larger spinning mass.

More than likely very little, but the thought crossed my mind.

From close ups pics there appears no change in corner and apex seal design.

Having said that,?Are the 16X Apex seals slightly thicker (by say 0.5mm)?

I am still a little concerned at the length of the side seals.

BUT, IT IS A BONZA LOOKING MOTOR IN ALL CHROME!!! Isn't IT!

#19

#21

I am impressed. Its a factory "Bridge port" engine. Although the "Bridged port" must be actuator controlled making it a 6-port bridge port...........lol

Those that know the non 13B-MSP ported engines will know that a bridge ported rotary breathes very well & makes excellent power, at the cost of a lumpy idle & fuel consumption but is mostly used for racing purposes anyway.

Years ago, Mazda actually stated that the 12A engine was the perfect dimesions for combustion & the 13B was a compromise.

Will be interesting to see the housing width (12A=70mm - 13B=80mm) when more technical specs are released.

REgards

Those that know the non 13B-MSP ported engines will know that a bridge ported rotary breathes very well & makes excellent power, at the cost of a lumpy idle & fuel consumption but is mostly used for racing purposes anyway.

Years ago, Mazda actually stated that the 12A engine was the perfect dimesions for combustion & the 13B was a compromise.

Will be interesting to see the housing width (12A=70mm - 13B=80mm) when more technical specs are released.

REgards

#22

I am impressed. Its a factory "Bridge port" engine. Although the "Bridged port" must be actuator controlled making it a 6-port bridge port...........lol

Those that know the non 13B-MSP ported engines will know that a bridge ported rotary breathes very well & makes excellent power, at the cost of a lumpy idle & fuel consumption but is mostly used for racing purposes anyway.

Years ago, Mazda actually stated that the 12A engine was the perfect dimesions for combustion & the 13B was a compromise.

Will be interesting to see the housing width (12A=70mm - 13B=80mm) when more technical specs are released.

REgards

Those that know the non 13B-MSP ported engines will know that a bridge ported rotary breathes very well & makes excellent power, at the cost of a lumpy idle & fuel consumption but is mostly used for racing purposes anyway.

Years ago, Mazda actually stated that the 12A engine was the perfect dimesions for combustion & the 13B was a compromise.

Will be interesting to see the housing width (12A=70mm - 13B=80mm) when more technical specs are released.

REgards

#24

What are the bits just inside(outside of chamber) of the ports? On some pics they are there, even on the exploded assembly? It looks like there might be a valve there, but on some pics there is nothing there. What is that???