Track Day Brakes - Operating Temperature Range

#26

SouthFL, I think one of the contensious points here in this discussion is the widely held belief that (for track style pads) there (must be) is a elevated temperature where pad-to-rotor friction coeficient becomes optimal. Typically this can only be achieved under track conditions.

What I see here is discussion about a point that may no longer be valid for new style pads. That is, specifically, that now technology improvements have eliminated the temp related disadvantage in high friction race pads.

Cobalt Friction Carbon-Ceramic pads have (apparently) been able to extend the 'normal operating range' down out of race condition temperature back into everyday ambient temperature while keeping the high friction characteristics. If so, then that discussion point is a non starter really (and happily - I not just trying to simply diss anyone's favorite pads)

Although I don't have any fancy charts and graphs to quantify this, it is helpful to read the brief synopsis of their technology that they post and get a bit more detail of my conversations with them and their suppliers:

What I was told by their engineers (that goes directly to the point) is that ALL their pads are race quality, not simply modified street pads. The key point to take away is that their prime measurement is of friction level and friction characteristic, not particularly heat range. They don't use any binders, so they are not subject to melting or glazing limitations such as other pads experience. They use only high-pressure to form their pads from the raw materials.

*******

For example, in the case of the RX-8, I was told that RX-8 race teams testing their pads came back with the following emperical choices:

1. Drivers found the most usefull characteristic was high friction front pads and much lower friction rear pads so as not to upset the car under heavy braking.

2. Having all their pads to choose from, the favorites were the XR2 in front. This had the characteristic of an immediate high friction bite followed by an immediate reduction in friction, thereby allowing the front tire to 'squat down' and expand its footprint without locking up, then the friction level goes up again as continued braking is done. Maximum footprint, maiximum friction without needlessly engaging ABS.

3. Having all their pads to choose from, the favorites were the XR5 in the rear. This is a special pad not shown on their web site but one that was developed especially for rear drive cars that tend to shift weight forward under heavy braking, and potentially upsetting the car's brake balalnce and handling.

To that end, the XR5 friction characteristics start with a moderate initial bite followed by a slowly rising friction curve. This helps keeps weight transfer down, and stabilizes the car while braking.

******

I became interested in these pads just because of this kind of engineering, something unlike the other pads available and think it is something worthy of further investigation. It literally allows "tuning" brake pads to the application, to the specific car even. And I didn't want to be changing pads at the track just so I could have superior braking. So the low temp character was important for that selfish reason alone.

But back to this discussion here, perhaps the discussion is at loggerheads as some are working with one frame of reference (heat vs friction) and I am working with another (friction vs time) as the main quality determination and of of what works best.

I hope that some of this verbose explaination makes some sense to others and gives others some insight they might put to use themselves. I have these new XR5/XR2 pads now, so I can give some 1st person feedback soon.

What I see here is discussion about a point that may no longer be valid for new style pads. That is, specifically, that now technology improvements have eliminated the temp related disadvantage in high friction race pads.

Cobalt Friction Carbon-Ceramic pads have (apparently) been able to extend the 'normal operating range' down out of race condition temperature back into everyday ambient temperature while keeping the high friction characteristics. If so, then that discussion point is a non starter really (and happily - I not just trying to simply diss anyone's favorite pads)

Although I don't have any fancy charts and graphs to quantify this, it is helpful to read the brief synopsis of their technology that they post and get a bit more detail of my conversations with them and their suppliers:

Originally Posted by Cobalt Friction

Thermo-Velocity Design Profile

Cobaltís Thermo-Velocity Design Profile(tm) is a core technology applied to the XTR and XR-Series friction composites. This scientific design process results in advanced composites with extremely broad design process results in advanced composites with extremely broad operating temperature ranges, high frictional and thermal stability, and exceptional wear rates. Furthermore, proper brake compound selection can new be made on the basis of desire torque levels alone, without the limitations of narrow operating temperature ranges and widely varying torque profiles.

Cobaltís Thermo-Velocity Design Profile(tm) is a core technology applied to the XTR and XR-Series friction composites. This scientific design process results in advanced composites with extremely broad design process results in advanced composites with extremely broad operating temperature ranges, high frictional and thermal stability, and exceptional wear rates. Furthermore, proper brake compound selection can new be made on the basis of desire torque levels alone, without the limitations of narrow operating temperature ranges and widely varying torque profiles.

*******

For example, in the case of the RX-8, I was told that RX-8 race teams testing their pads came back with the following emperical choices:

1. Drivers found the most usefull characteristic was high friction front pads and much lower friction rear pads so as not to upset the car under heavy braking.

2. Having all their pads to choose from, the favorites were the XR2 in front. This had the characteristic of an immediate high friction bite followed by an immediate reduction in friction, thereby allowing the front tire to 'squat down' and expand its footprint without locking up, then the friction level goes up again as continued braking is done. Maximum footprint, maiximum friction without needlessly engaging ABS.

3. Having all their pads to choose from, the favorites were the XR5 in the rear. This is a special pad not shown on their web site but one that was developed especially for rear drive cars that tend to shift weight forward under heavy braking, and potentially upsetting the car's brake balalnce and handling.

To that end, the XR5 friction characteristics start with a moderate initial bite followed by a slowly rising friction curve. This helps keeps weight transfer down, and stabilizes the car while braking.

******

I became interested in these pads just because of this kind of engineering, something unlike the other pads available and think it is something worthy of further investigation. It literally allows "tuning" brake pads to the application, to the specific car even. And I didn't want to be changing pads at the track just so I could have superior braking. So the low temp character was important for that selfish reason alone.

But back to this discussion here, perhaps the discussion is at loggerheads as some are working with one frame of reference (heat vs friction) and I am working with another (friction vs time) as the main quality determination and of of what works best.

I hope that some of this verbose explaination makes some sense to others and gives others some insight they might put to use themselves. I have these new XR5/XR2 pads now, so I can give some 1st person feedback soon.

#27

^

What's interesting to observe is the range of the Cobalt Friction pads, which you've confirmed, offer flexibility not previously seen. This was my original intent on posting operating ranges- to find a pad with a broader range than the one which I was using, looking for a pad with somewhat higher range than the HP Plus offered (800 deg.), because I was experiencing fade with the HP Plus. The Porterfield R4S offered a 900 deg. range, and as expected, has offered more sustainability at the track, as there is definately less fade than with the HP Plus. Only bad trade-off has been its low friction bite throughout its operating range.

What's interesting to observe is the range of the Cobalt Friction pads, which you've confirmed, offer flexibility not previously seen. This was my original intent on posting operating ranges- to find a pad with a broader range than the one which I was using, looking for a pad with somewhat higher range than the HP Plus offered (800 deg.), because I was experiencing fade with the HP Plus. The Porterfield R4S offered a 900 deg. range, and as expected, has offered more sustainability at the track, as there is definately less fade than with the HP Plus. Only bad trade-off has been its low friction bite throughout its operating range.

Last edited by SouthFL; 07-29-2008 at 10:26 AM.

#28

^ and as in your analogy, for example, Honda V-Tec technology, and those that have followed, all the way to the latest continuously variable cams, have eliminated for all intents and purposes those discussions about what is the 'best' cam.

And as the quest for perfection goes on.... we are all the winners!

And as the quest for perfection goes on.... we are all the winners!

#30

IMO the problem isn't always the pad you use. Other factors like the tires you use, amount of air pressure in the tires, air in your brake lines, suspension setup or even alignment can feel like an over worked pad.

I have been very competitive @ Time Trial Events with the Hawk HPS pads, OEM Rotors and ATE Blue fluid and have not experienced any fade with track temps varying between 90 to 130 degrees.

I have been very competitive @ Time Trial Events with the Hawk HPS pads, OEM Rotors and ATE Blue fluid and have not experienced any fade with track temps varying between 90 to 130 degrees.

#31

IMO the problem isn't always the pad you use. Other factors like the tires you use, amount of air pressure in the tires, air in your brake lines, suspension setup or even alignment can feel like an over worked pad.

I have been very competitive @ Time Trial Events with the Hawk HPS pads, OEM Rotors and ATE Blue fluid and have not experienced any fade with track temps varying between 90 to 130 degrees.

I have been very competitive @ Time Trial Events with the Hawk HPS pads, OEM Rotors and ATE Blue fluid and have not experienced any fade with track temps varying between 90 to 130 degrees.

I regularly drive a track that is very hard on the brakes...and the HPS don't hold up to hard braking at over 120mph without a lot of cool down time. If you get that you might be OK...but 2-3 hard corners and they get real slimmy feeling

#32

The temp range of the HPS 100-800 deg. (same as the HP Plus), but the Plus can sustain up to 900 deg.

Personally, I would think that Sebring would turn the HPS into toothpaste. The HP Plus can barely sustain lapping there from my experience with it.

High Performance Street (HPS) – An excellent street pad featuring low dust, high friction, rotor friendly, and silent running. Stops 10% shorter than OE pads. Optimal operational temperature range is 100-800 degrees F.

High Performance Street Plus (Plus) – For more aggressive drivers, this dual purpose pad is a compromise design suitable for street use and some open track use. This pad has a higher coefficient of friction than the HPS pad. The optimum operational temperature range is 100-800 degrees F and, for short periods of time, up to 900 degrees F. Expect more dust and some noise in exchange for better braking.

High Performance Street Plus (Plus) – For more aggressive drivers, this dual purpose pad is a compromise design suitable for street use and some open track use. This pad has a higher coefficient of friction than the HPS pad. The optimum operational temperature range is 100-800 degrees F and, for short periods of time, up to 900 degrees F. Expect more dust and some noise in exchange for better braking.

#33

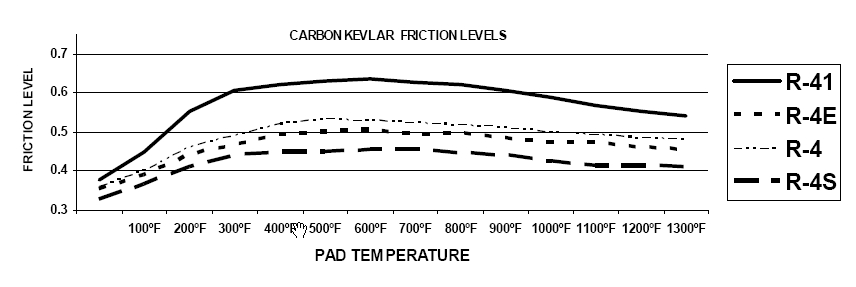

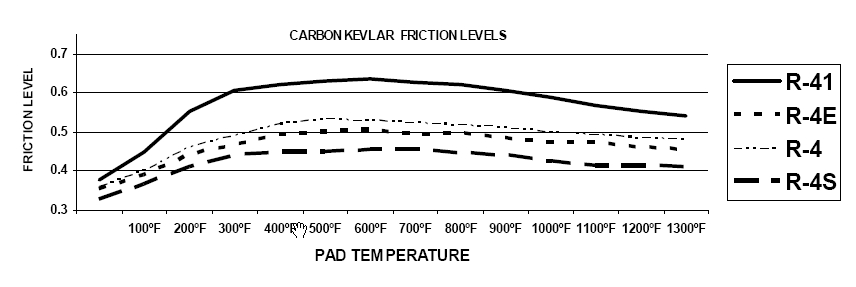

those numbers don't mean sh-t because they're just general heat ranges, you need a mu vs temp graph to fully understand what's what. Many high heat pads will grip decent at low temp, but are very hard on the rotor surface until a certain temp is reached. Heat ranges don't tell you much because it really boils down to what the actual friction coefficient is. These are much more useful than some general temperature range quote:

a couple others to consider for street/track duty

EBC Yellow

Porterfield R4-1

Raybestos makes some decent track-only pads too.

.

a couple others to consider for street/track duty

EBC Yellow

Porterfield R4-1

Raybestos makes some decent track-only pads too.

.

#35

I have a set EBC yellowstuff pads coming for the front of my Honda Ridgeline truck. These are not the same as their yellowstuff track pads, but are instead a derivative made especially for trucks/SUVs doing towing duty. I'd be interested in hearing what you think about about the EBC yellow track pads. EBCs biggest problem seems to be distribution. They have a catalog full of pads that nobody seems to carry and take 3 weeks or more to oder in. Some of the pads they list part numbers for are not available period, like the rear pads for my truck.

I'd be interested in knowing if the yellow track pad actually has tapered leading and trailing edges as shown in their marketing pics. You would typically only do this for a basic street pad, not a performance pad. The Porterfield R4-1s are 100% full thickness across the entire surface as are most other track-oriented pads.

I'd be interested in knowing if the yellow track pad actually has tapered leading and trailing edges as shown in their marketing pics. You would typically only do this for a basic street pad, not a performance pad. The Porterfield R4-1s are 100% full thickness across the entire surface as are most other track-oriented pads.

#37

After reading up about the Yellow stuff pads I considered them. I even meet a fast 05 Mustang owner at Tremblant that had the Cobalt XR2-XR3 combo previously on his car but for this event he had the Yellow Stuff. He said he was quite happy about their performance. They weren't as good as Cobalt in braking power and they seemed to wear a bit quicker. It seemed he would re buy them. He has done another event with them I'll ask him if he still feels the same about them.

BTW here his vid.

http://www.youtube.com/watch?v=WBPCPUjbcP8

In the end I went with the Cobalt XR2 XR5 combo. I had enough of experimenting. If they are good enough for Grand Am RX8's they have to be good for me.

IMO if you are threshold braking with r-comps(pulling over a 1g in braking) you absolutely need dedicated track pads.

BTW here his vid.

http://www.youtube.com/watch?v=WBPCPUjbcP8

In the end I went with the Cobalt XR2 XR5 combo. I had enough of experimenting. If they are good enough for Grand Am RX8's they have to be good for me.

IMO if you are threshold braking with r-comps(pulling over a 1g in braking) you absolutely need dedicated track pads.

#38

Originally Posted by ThecdnRx8

http://www.youtube.com/watch?v=WBPCPUjbcP8

In the end I went with the Cobalt XR2 XR5 combo. I had enough of experimenting. If they are good enough for Grand Am RX8's they have to be good for me.

IMO if you are threshold braking with r-comps(pulling over a 1g in braking) you absolutely need dedicated track pads.

How did you find the GT Sport to X2/X5 Upgrade? Did it help your braking and entering? What was your best lap time, braking Gs w/the new pads?

Last edited by Spin9k; 08-21-2008 at 10:18 AM.

#39

but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

The solution was 2 things:

1) http://www.northerntool.com/webapp/w...2878_200342878

You'd not think twisting lugs would drain so much of your energy, but when you think about it and consider... 5 lugs x 4 wheels x 2 take off then back on = 40 lugs per change.... Whew!!

2) Use your low profile floor jack at the front side jack point - It'll take both wheels on a side easily off the ground with just a few pumps.

Changing pads at the final go-home tire swap would only add perhaps 4-5 min per wheel - one bolt off, one bolt back on at 25 ft/lbs.

#40

If you think about it, given the function of brake pads and the physics involved in the task given, you probably will have an easier time finding Bigfoot...

You may come up with a compromise that you can live with, but it will be a compromise

#41

I was feeling the same exhaustion as you SouthFL - I guess I'm a bit lazy too  but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

The solution was 2 things:

1) http://www.northerntool.com/webapp/w...2878_200342878

You'd not think twisting lugs would drain so much of your energy, but when you think about it and consider... 5 lugs x 4 wheels x 2 take off then back on = 40 lugs per change.... Whew!!

2) Use your low profile floor jack at the front side jack point - It'll take both wheels on a side easily off the ground with just a few pumps.

Changing pads at the final go-home tire swap would only add perhaps 4-5 min per wheel - one bolt off, one bolt back on at 25 ft/lbs.

but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

but I found the solution. Now I've been changing tires like a pro ... and with minimal effort to the point I think one track day I changed between my r-comp and rain tires maybe 3 times! Although I'm not down to the 7 seconds switch of an F1 team, I'm in the 7-10min range with hardly a sweat

The solution was 2 things:

1) http://www.northerntool.com/webapp/w...2878_200342878

You'd not think twisting lugs would drain so much of your energy, but when you think about it and consider... 5 lugs x 4 wheels x 2 take off then back on = 40 lugs per change.... Whew!!

2) Use your low profile floor jack at the front side jack point - It'll take both wheels on a side easily off the ground with just a few pumps.

Changing pads at the final go-home tire swap would only add perhaps 4-5 min per wheel - one bolt off, one bolt back on at 25 ft/lbs.

The front pad swap is very easy. Rear pads are a bitch to swap out if the street pad is thicker than the track pad. Perhaps the impact wrench could be used to twist the piston back in? That would make things easier. Pushing/turning rear pistons back in by hand would be a real pain in the *** to do at the track. It's tough enough to do at home with no hurry.

The ideal would be to leave in the rear pad for track/street duty and have a dedicated track pad up front for track days so that only the front needs to be swapped out. The Porterfield R4 (front) / R4S (rear) combo is a possibility.

I can also talk to Cobalt Friction to see if the GT-Sport in back could be paired with another one of their compounds up front.

These cars really need a staggered setup to keep the rear end in place under hard braking.

Last edited by SouthFL; 08-21-2008 at 12:44 PM.

#42

Actually that's what I do, leave the rear pads in. The rears don't squeel. I used the GT Sport previously in the rear and now have the X5 in the rear, no squeeling there. Actually turning the brake cyl in the rear back in is a snap with the brake tool ($10 any parts store) and a socket wrench w/extension. It's maybe a 60 second job. Without the tool it could be a bitch I would agree, also just make sure you're turning it the correct direction (clockwise). It's very simple...really!

#43

Actually that's what I do, leave the rear pads in. The rears don't squeel. I used the GT Sport previously in the rear and now have the X5 in the rear, no squeeling there. Actually turning the brake cyl in the rear back in is a snap with the brake tool ($10 any parts store) and a socket wrench w/extension. It's maybe a 60 second job. Without the tool it could be a bitch I would agree, also just make sure you're turning it the correct direction (clockwise). It's very simple...really!

With the X5 in back, what do you use up front for street driving?

Last edited by SouthFL; 08-21-2008 at 12:58 PM.

#44

I'll find out this weekend at Calabogie. Hoping to shave a few more seconds now that my RA-1's are slicks. Hey Spin9k I'm still waiting for your MT data. BTW The Mustang was the same one at Calabogie and his Mustang is indeed well very set up and also very well driven.

SouthFL if you are already swapping out wheels, pads are only what an extra 15min. This will be my first weekend doing it so I'll let you know how it works out.

BTW I got this tool for the rear caliper and it works like a charm. I highly recommend it If you plan I switching rear pads out often.

http://www.bosstoolsupply.com/index....D&ProdID=11917

If you are interested I have a set of Cobalt GTS pads with 4 track days and plenty of material on them.

SouthFL if you are already swapping out wheels, pads are only what an extra 15min. This will be my first weekend doing it so I'll let you know how it works out.

BTW I got this tool for the rear caliper and it works like a charm. I highly recommend it If you plan I switching rear pads out often.

http://www.bosstoolsupply.com/index....D&ProdID=11917

If you are interested I have a set of Cobalt GTS pads with 4 track days and plenty of material on them.

#46

I put my GT Sports back in front. I'm addicited to the inital bite and friction they give and would feel virtually brake-less if I had to go back to that 'ordinary' brake feel

The occassional 5 --> 0 mph noise from them is nothing compared to the superior feel and grip (I use the shims and anti-squeel goo on all my front pads).

The occassional 5 --> 0 mph noise from them is nothing compared to the superior feel and grip (I use the shims and anti-squeel goo on all my front pads).

#48

got my SUV/Truck yellowstuff pads in, they have a very small taper on each end, not like the huge taper shown on their webpage

should get them on Sunday or Monday along with a new pair of Centric rotors, just in time for the 1600 mile tow to KC

should get them on Sunday or Monday along with a new pair of Centric rotors, just in time for the 1600 mile tow to KC

#49

I use the XR2/5 cobalts. Less dust than Hawk blue I used before and the wear is amazingly even. I do change out to stock pads however, even given the great brake feel for street use the 2/5 brakes squeel some when cold and not heavily braked, but work surprisingly well even cold.

The proof is in the braking and I have had no fade or trouble with modulation with the cobalt brakes and the material is easy to clean and non corrosive. They are better than the Hawk blues for my driving and are real easy on the discs.

The proof is in the braking and I have had no fade or trouble with modulation with the cobalt brakes and the material is easy to clean and non corrosive. They are better than the Hawk blues for my driving and are real easy on the discs.

#50

Something interesting - This is a summary sheet I got from Cobalt when requesting more detail on the XR5 compound since there was nothing on the Cobalt web site about them. It gives some verbage to all pads in the series. I think it helps to understand their "friction tuning" philosphy.

Although I've never thought the RX-8 exhibited "rapid and high levels of weight transfer" under braking (XR2/XR5 combo), if that's what works then I'm happy - I'm sure the Grand Am teams have it figured out.

Although I've never thought the RX-8 exhibited "rapid and high levels of weight transfer" under braking (XR2/XR5 combo), if that's what works then I'm happy - I'm sure the Grand Am teams have it figured out.