NRS Ceramic Apex Seals (1-Piece, OEM Height)

#51

If you think about it purely from an engineering standpoint and disregard the material used- 1 piece seals taller seals should be stronger than the stock seals . Whether that translates to anything meaningfull in reality I have no idea but I know it is very common for seals to break at the splitt on the stock seal ....

#52

Team: gotta say, i dont really pay attention anymore... keeping up with your complex level of truth, sarcasm, and general cloak and dagger approach to posting just isnt worth anything you provide outside of whats directly specific to racing, which i have no interest to discuss

zen: its a good question, dunno what they use. but for the sake of argument, i'd say they are leaps and bounds beyond most here in terms of any other "issue" that could be considered a weaker link...

and they should be all things considered

Brettus, i would agree in theory. but perhaps in practice its a case of trading a wet noodle for a toothpick which we are asking to hold up your house? stronger sure, but to any effect? the consensus seems to be that poor tuning/detonation gives equal outcome with or without ceramics

zen: its a good question, dunno what they use. but for the sake of argument, i'd say they are leaps and bounds beyond most here in terms of any other "issue" that could be considered a weaker link...

and they should be all things considered

Brettus, i would agree in theory. but perhaps in practice its a case of trading a wet noodle for a toothpick which we are asking to hold up your house? stronger sure, but to any effect? the consensus seems to be that poor tuning/detonation gives equal outcome with or without ceramics

#53

Brettus, i would agree in theory. but perhaps in practice its a case of trading a wet noodle for a toothpick which we are asking to hold up your house? stronger sure, but to any effect? the consensus seems to be that poor tuning/detonation gives equal outcome with or without ceramics

#54

i didnt suggest it, someone whose torn down motors did, and that wasnt the first time i've seen it suggested by someone whose seen the results

Last edited by paulmasoner; 08-01-2010 at 03:53 PM.

#56

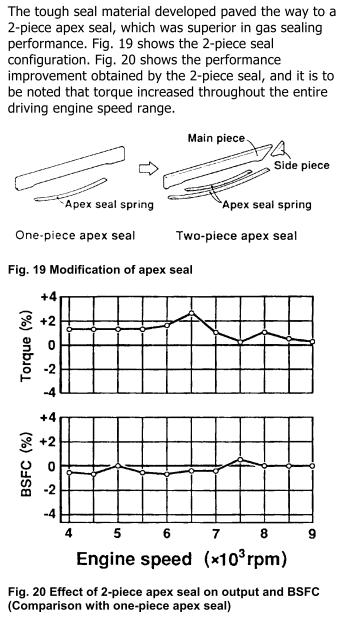

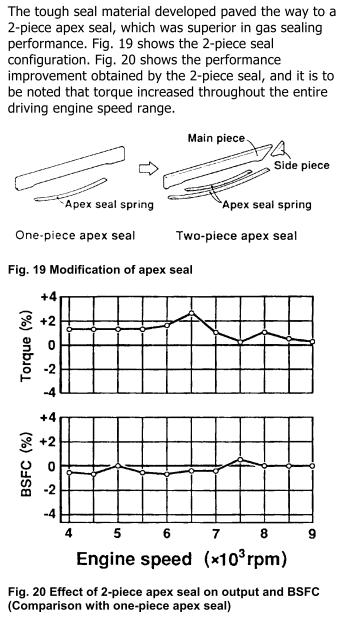

To anyone who may be curious: Mazda used 2 piece ceramic apex seals on their 4 rotor n/a Lemans engine. http://protonet.org/doc/Mazda_R26B_A4.pdf The seals were made of ceramic fibers.

Switching to a 2 piece design resulted in improved torque and fuel economy over their old carbon 1 piece design.

I have to go find the SAE paper on that old 2 rotor race engine from the 80s. One of the main reasons they had been using carbon apex seals (and later ceramic) was that they could withstand the high heat better and they are more easily lubricated. This is probably connected to their reputation for causing less wear on the housings.

I bet those OEM ceramics are nasty.

Switching to a 2 piece design resulted in improved torque and fuel economy over their old carbon 1 piece design.

I have to go find the SAE paper on that old 2 rotor race engine from the 80s. One of the main reasons they had been using carbon apex seals (and later ceramic) was that they could withstand the high heat better and they are more easily lubricated. This is probably connected to their reputation for causing less wear on the housings.

I bet those OEM ceramics are nasty.

#57

Now that I sit down and digest this information, I'm forced to confront the fact that I've known that seals are a weak point, but I've always been confused as to why. Metallurgy has progressed so far since the original rotary engines; that being said, I can't understand why we're still fighting seal design. Or, maybe we've actually reached a pretty good design and are just arguing over wich of the good designs is marginally better.

Ceramics can certainly withstand extreme concentrated heat better than any steel, as well as move that heat away from concentrated areas better. We've all seen pictures of a red hot ceramic cube being picked up at its corners with bare fingers. The drawback of ceramics is a lower elastic modulus and a lower high dynamic load (shock) tolerance. All that being said, is it reasonable to think that ceramic seals would hold up better in a high stress application such as high boost/high rpm FI. I still don't understand why they are associated with lower compression/idle problems. It seems a tradeoff that shouldn't have to be made.

Ceramics can certainly withstand extreme concentrated heat better than any steel, as well as move that heat away from concentrated areas better. We've all seen pictures of a red hot ceramic cube being picked up at its corners with bare fingers. The drawback of ceramics is a lower elastic modulus and a lower high dynamic load (shock) tolerance. All that being said, is it reasonable to think that ceramic seals would hold up better in a high stress application such as high boost/high rpm FI. I still don't understand why they are associated with lower compression/idle problems. It seems a tradeoff that shouldn't have to be made.

#58

It's because they are 1 piece . I would hazzard a guess that they don't make them in a 2 piece design because they would be even more inclined to break at the splitt than the OEM seals ....

#59

Team: gotta say, i dont really pay attention anymore... keeping up with your complex level of truth, sarcasm, and general cloak and dagger approach to posting just isnt worth anything you provide outside of whats directly specific to racing, which i have no interest to discuss

Happy ranting to you ....

#61

Well as I posted above, Mazda did use two piece ceramic seals in their R26B race engine.

#64

and? you got 2 rotors, and boost. and make 300-350 maybe?

well they had 4 rotors, no boost, and made 700...

that has to do what with seals being 1 or 2 piece?

airflow per displacement is the same, you just need boost to reach what they did NA, the tuning has to be as precise either way... whats the difference

well they had 4 rotors, no boost, and made 700...

that has to do what with seals being 1 or 2 piece?

airflow per displacement is the same, you just need boost to reach what they did NA, the tuning has to be as precise either way... whats the difference

#65

I do not have any mystical ninja knowledge or experience here, so perhaps I simply can't compete with you and the online persona you've developed for yourself here.

The ONLY people with any REAL usefull knowledge and experience, are the Mazmart's and the like. And from what I can see, most of theirs comes from motorsports applications.

All I've tried to do is express an opinion of my own, explain and debate why I have this opinion. And hope that there is some sort of usefull learning that comes out of it in the end. I may be right, I may be wrong, there may be NO right/wrong answer. All I know is that everything I have found or been presented with does not change my opinion. Perhaps finding more posts like Mazmart's could shed more light and possibly change that, I dont know.

But I can tell you that by choosing to acknowledge me(for whatever reason), and doing nothing in that act but being a douche and shooting from the sidelines, offering no opinion/thought/reasoning/etc to the discussion... has just one more person ready write you off as that egotistical ***** who races around parking lots

#66

and? you got 2 rotors, and boost. and make 300-350 maybe?

well they had 4 rotors, no boost, and made 700...

that has to do what with seals being 1 or 2 piece?

airflow per displacement is the same, you just need boost to reach what they did NA, the tuning has to be as precise either way... whats the difference

well they had 4 rotors, no boost, and made 700...

that has to do what with seals being 1 or 2 piece?

airflow per displacement is the same, you just need boost to reach what they did NA, the tuning has to be as precise either way... whats the difference

Have you not noticed the difference between an NA power curve and that of an FI engine ?

Also at what rpm did they achieve 700 hp ? You realise that makes a difference right ?

Think combustion chamber pressure .......

#67

Are you STILL stuck on the whp number Paul ? really man , you gotta think harder LOL

Have you not noticed the difference between an NA power curve and that of an FI engine ?

Also at what rpm did they achieve 700 hp ? You realise that makes a difference right ?

Think combustion chamber pressure .......

Have you not noticed the difference between an NA power curve and that of an FI engine ?

Also at what rpm did they achieve 700 hp ? You realise that makes a difference right ?

Think combustion chamber pressure .......

why dont you try thinking harder brett... it makes no difference whatsoever how the air gets in the motor. if you put a given mass of air inside a given volume for compression and combustion, the end result is the same, regardless of how it gets there.

#68

You need to think about how an NA engine makes it's peak power vs an FI engine .

NA - high rpm ,high hp, low torque , low combustion chamber pressure, low possibility of catastrophic detonation .

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation .

Airflow could be the same in both scenarios, but It's a totally different set of conditions for the apex seal to survive .

NA - high rpm ,high hp, low torque , low combustion chamber pressure, low possibility of catastrophic detonation .

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation .

Airflow could be the same in both scenarios, but It's a totally different set of conditions for the apex seal to survive .

#69

let me see if i can be clearer here as its obvious there is a disconncet....

your comment about the 2 piece seals in the R26B engine being applied to an NA engine are totally irrelevant. whether the air gets into the motor via natural aspiration, boost, or magically transported in there all star trek like... a given mass of air and a given mass of fuel contains a finite amount of energy that can be released via combustion.

wow, your kidding right man? NA and FI have NOTHING to do with combustion chamber pressure directly. how much air you put in the combustion chamber is the ONLY thing that affects that pressure. hell you DEFINE pressure here by how much air you have in the combustion chamber... its obvious you still never got the whole boost vs flow thing you have gone on about for so long.

you keep talking about boost like it matters... FI doesnt MAKE more pressure in the combustion chamber. FI or boost simply creates a larger pressure differential between the intake tract and the newly opening combustion chamber. the pressure differential dictates how much air gets in before the ports close.

in your case you HAVE to create that larger pressure delta to get that much air in the motor. lets call it X quantity of air stuffed in Y space(combustion chamber.

the R26B in question happened to be designed in a way that didnt require FI to get 2X quantity of air into 2Y space.

the end result is that you have a roughly equal amount of air, and thus potential energy release and pressure in any of those 6 rotors(either 2 of yours or any of the 4 from the R26B)

you can banter about the differences in power curves from an NA or FI engine all you want, it doesnt change the physics

your comment about the 2 piece seals in the R26B engine being applied to an NA engine are totally irrelevant. whether the air gets into the motor via natural aspiration, boost, or magically transported in there all star trek like... a given mass of air and a given mass of fuel contains a finite amount of energy that can be released via combustion.

You need to think about how an NA engine makes it's peak power vs an FI engine .

NA - high rpm ,high hp, low torque , low combustion chamber pressure, low possibility of catastrophic detonation .

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation .

Airflow could be the same in both scenarios, but It's a totally different set of conditions for the apex seal to survive .

NA - high rpm ,high hp, low torque , low combustion chamber pressure, low possibility of catastrophic detonation .

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation .

Airflow could be the same in both scenarios, but It's a totally different set of conditions for the apex seal to survive .

you keep talking about boost like it matters... FI doesnt MAKE more pressure in the combustion chamber. FI or boost simply creates a larger pressure differential between the intake tract and the newly opening combustion chamber. the pressure differential dictates how much air gets in before the ports close.

in your case you HAVE to create that larger pressure delta to get that much air in the motor. lets call it X quantity of air stuffed in Y space(combustion chamber.

the R26B in question happened to be designed in a way that didnt require FI to get 2X quantity of air into 2Y space.

the end result is that you have a roughly equal amount of air, and thus potential energy release and pressure in any of those 6 rotors(either 2 of yours or any of the 4 from the R26B)

you can banter about the differences in power curves from an NA or FI engine all you want, it doesnt change the physics

#70

NA - high rpm ,high hp, low torque , low combustion chamber pressure, low possibility of catastrophic detonation .

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation

FI - lower rpm , high hp , high torque , high combustion chamber pressure , high possibility of catastrophic detonation

let me restate this just in case... your little argument is so fundamentally flawed this is the only way i know how to address it.

combustion chamber pressure is the the force that acts upon lever(rotor) to turn the e-shaft, etc etc. Combustion chamber pressure has nothing to do with FI or NA. it has to do with how much air is in there.

let me ask you this... how do you make more combustion chamber pressure?

you have to combust more air/fuel right? you gonna deny that?

a known amount of air/fuel creates a known combustion pressure(thus the force acting on the lever etc etc). you gonna deny that?

now please tell me you realize that regardless of HOW the air gets there, the constraints in regards to tuning/detonation/etc are the same if you are talking about the same amount of stuff going into the same amount of space.

you could have a smurf huffing and puffing at your intake ports and if he manages to get an arbitrary 30 grams of air in there, its exactly the same as if you turbo did it, or if the motor and intake was designed to draw in that much air naturally

#72

really? thats the best you can do to defend yourself? to quote a single line taken out of context?

when you can understand this and have something usefull to say, get back to me..

if you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it NA

and you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it FI

then the combustion chamber pressures are the same. because its that pressure that ultimately creates the power. Its like hitting a nail with a hammer or a rock, if the end result is the same, then the forces applied were the same - regardless of the tool used.

i refer back to power again because of your argument that a 2.6L making 700HP is vastly different in terms of combustion pressure than a 1.3L making 350HP.

when you can understand this and have something usefull to say, get back to me..

if you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it NA

and you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it FI

then the combustion chamber pressures are the same. because its that pressure that ultimately creates the power. Its like hitting a nail with a hammer or a rock, if the end result is the same, then the forces applied were the same - regardless of the tool used.

i refer back to power again because of your argument that a 2.6L making 700HP is vastly different in terms of combustion pressure than a 1.3L making 350HP.

Last edited by paulmasoner; 09-04-2010 at 06:48 PM.

#73

if you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it NA

and you have a 1 liter motor making 300 horsepower, or flowing a given amount of air, or whatever... and doing it FI

then the combustion chamber pressures are the same. .

Mind you , I can't imagine why the FI engine wouldn't make more power at the same rpm because of the higher combustion chamber pressures ......

Last edited by Brettus; 09-04-2010 at 07:06 PM.

#74

well last time i checked the mazda motor in question made its power at 9,000rpms... seems pretty damn similar to ours.

and last i checked we were discussing 2 rotary engines with virtually the same physical dimensions and properties in each rotor as ours does...

this is getting boring brett.... you havent said anything that wasnt entirely vague or irrelevant to the debate here...

and last i checked we were discussing 2 rotary engines with virtually the same physical dimensions and properties in each rotor as ours does...

this is getting boring brett.... you havent said anything that wasnt entirely vague or irrelevant to the debate here...

#75

let me do this barney style and blown out of proportion so maybe you can see it

one of them has an NA induction but its intake is smooth, and designed to flow well at the desired range.

the other wasnt given that fancy nice intake and REQUIRES FI to achieve the same flow thus making the same power.

in both cases the same amount of air goes in and the same amount of power is made. power being made is DIRECTLY proportional to how much force is applied to the rotor acting as a lever on the e-shaft. if the two setups make the same power, then the have the same forces acting upon that lever, those forces are your pressure

take a ballon... if its blown up to a certain size, the pressure inside is the same regardless of how the air got IN the ballon... is ANY of this getting through?

Last edited by paulmasoner; 09-04-2010 at 07:17 PM.