DIY: RENESIS Compression adjustment & Rating, Excel Application

#26

Yes Blacknightz,

Think that in normal conditions the Back Rotor Compression drops faster than the Front one as a result in a future Compression Test i predict that the Standard Difference in Rotors value would be lower than 111 kPa if the rebuilt was successful

Unsuccessful rebuilt means Compression test Values far below 800 kPa .

Another thought is that the unchanged parts between Front and Back Rotor was not in the same condition and have more wear.

Think that in normal conditions the Back Rotor Compression drops faster than the Front one as a result in a future Compression Test i predict that the Standard Difference in Rotors value would be lower than 111 kPa if the rebuilt was successful

Unsuccessful rebuilt means Compression test Values far below 800 kPa .

Another thought is that the unchanged parts between Front and Back Rotor was not in the same condition and have more wear.

thank u...

problem is.... i paid for a all new parts for both front and back... Justice please come soon...

#28

finally got off my butt and put my Rotary Diagnostics laptop compression tool to use, which is commonly used my many high end builders and racers due to the ability to view and analyze the compression cycle in full detail, as opposed to the dealer and other tools that only provide peak values

**** Rotary-engine Compression Tester System

couple of contributions to the thread

The engine does not need to be warm according to Rotary Diagnostics. What it does need is to have been run recently. This ensures there is an internal oil film on the rotor, side plates, and housing surfaces & seals. If the engine has been sitting for a while the oil film will not be evenly distributed. So there really is no need to be burning your hands etc. Warm it up, cool it down, and then test. Even within a few days is generally considered to be OK, but the same day is likely the best option.

On the RX8 all you need to do in preparation of running the test is to disconnect the ESS sensor wiring connection at the sensor. Pulling the fuel pump fuse is not necessary. Pulling the EGI fuse, the common prep step prior to the RX8/Renesis, will prevent the engine from cranking on the RX8. Disconnecting the ESS sensor means the PCM will not be receiving pulse signals while the engine is cranking so no ignition coil or fuel injection functions will be performed as a result. It can result in a code being thrown, so clearing the PCM memory and any codes after the test is something to consider.

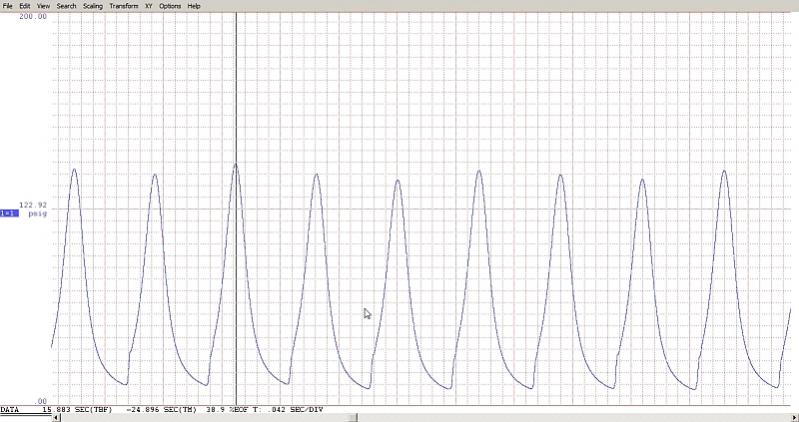

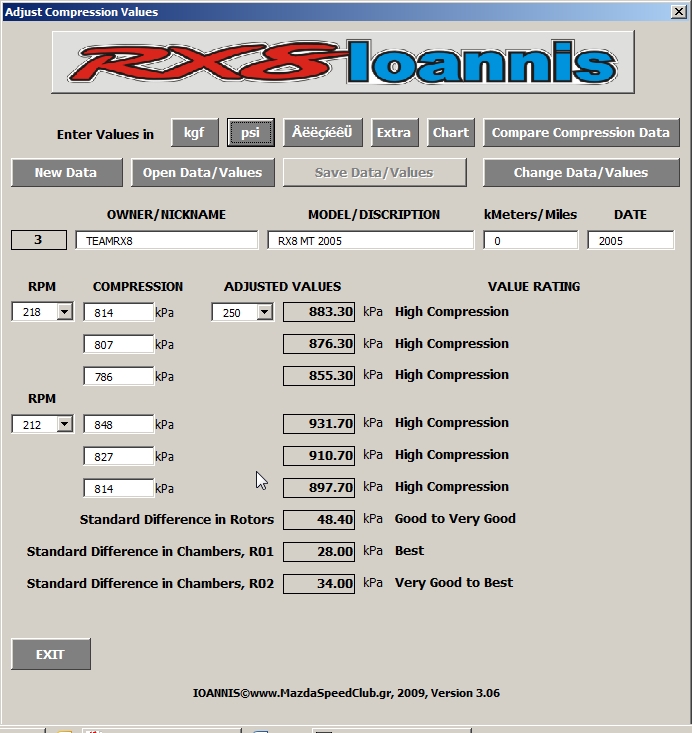

Pleased with my personal results:

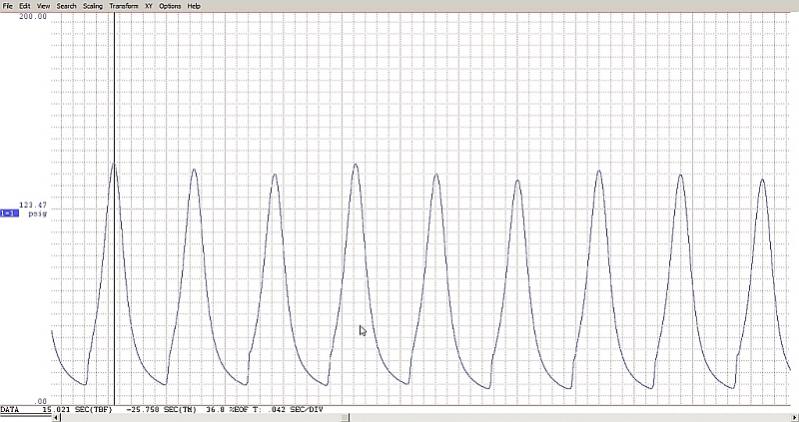

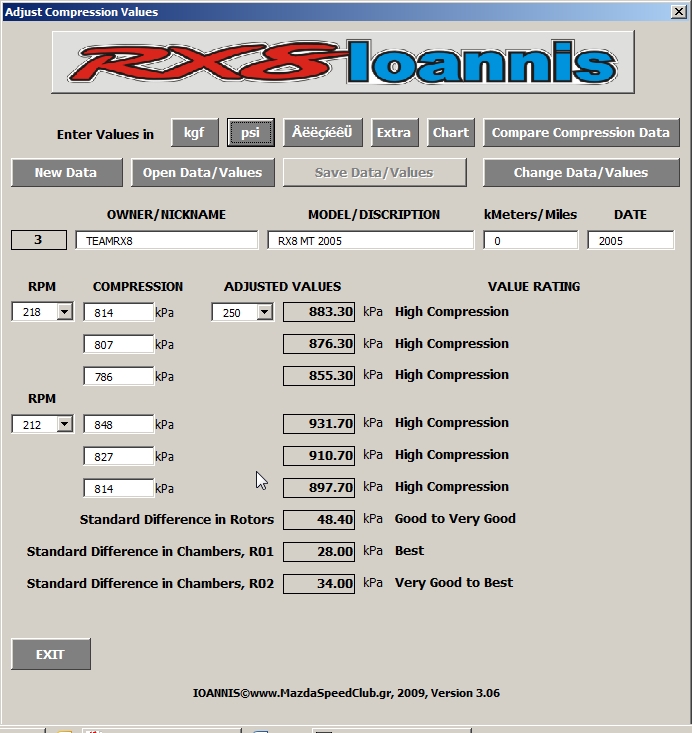

ACTUAL ROTOR 1 (FRONT)

ACTUAL ROTOR 2 (REAR)

NORMALIZED ENGINE RESULTS

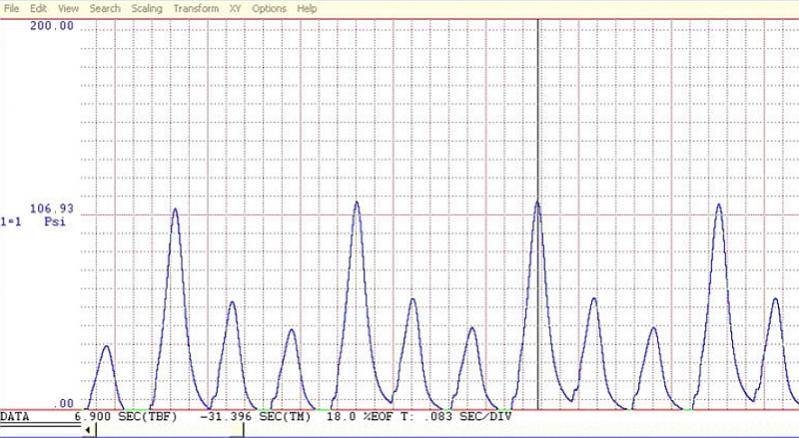

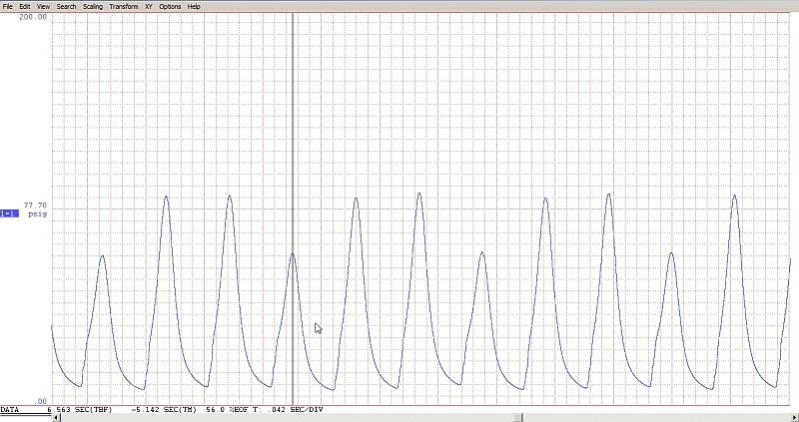

Been trying to troubleshoot an issue for another local member. Engine started making the SSV tapping sound and also a "rapping/sort-of-knocking" sound in the 4000-7000 rpm range while accelerating WOT. Over the last few years I've had several people contacting me about a similar issue, but this is the first one I got my hands on. Engine cranks quickly, idles fine, and drives every day use fine otherwise. Did not think it was the engine because of this. Checked many things; SSV operation/solenoid, coils, plugs, pulled UIM, etc. Did finally figure out that the the "rapping" sound is coming from the engine intake system (AEM CAI) and exiting out the intake filter. Finally decided to run the compression test and result from Rotor 2 (Rear) tells the tale; reading 30 psig low actual on one rotor face. Rotor 1 (front) and the other two faces on Rotor 2 were fine otherwise. My assessment is that is likely a side seal on that face and the sound is compressed air/combustion gasses getting past the seal and back into the intake. It is also what is causing intake pulsing at idle, which in turn is the cause for the SSV valve tapping sound:

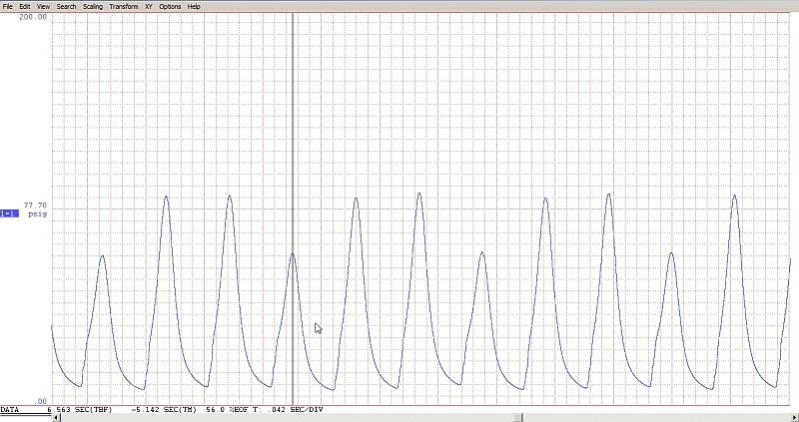

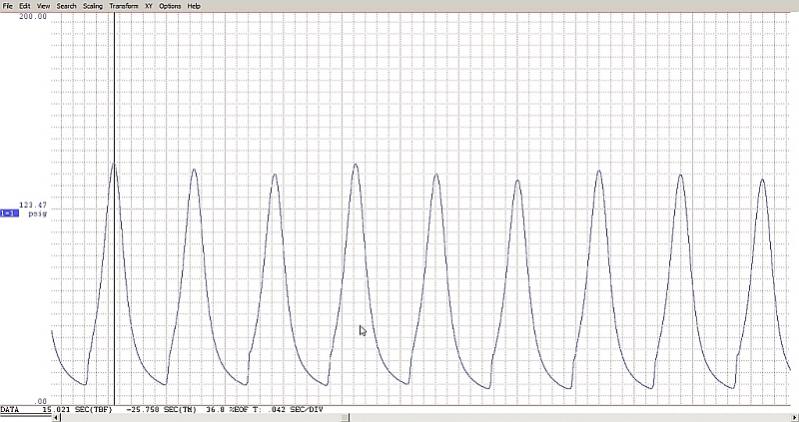

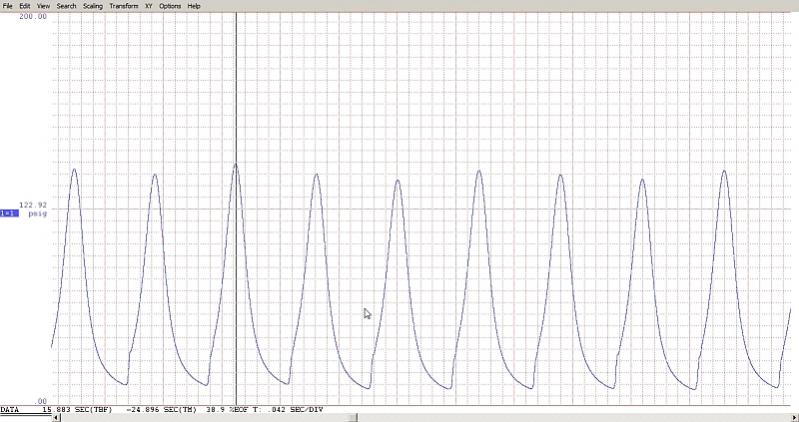

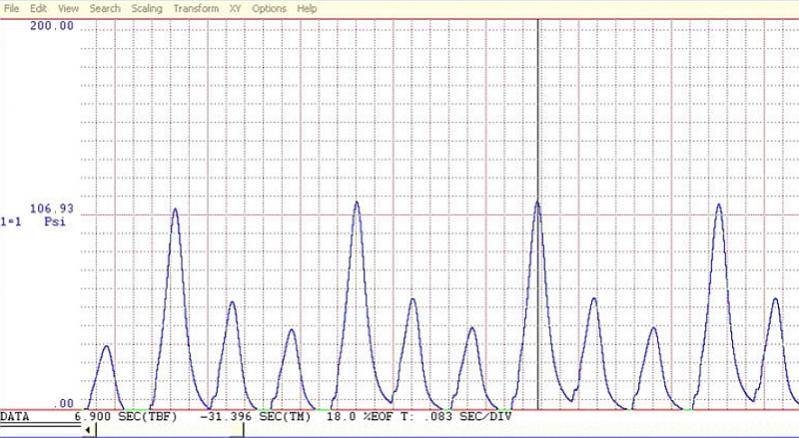

A bad corner seal is generally known to cause starting and idle issues. I don't have an example graph of this condition for demonstration purposes, but since the engine starts & idles fine I ruled the corner seals out. A failed or bad apex seal generally results in two simultaneous bad rotor pulse readings because air & combustion gasses moves across the bad apex seal between the two adjacent rotor faces. Here is a typical example of a bad apex seal:

.

**** Rotary-engine Compression Tester System

couple of contributions to the thread

The engine does not need to be warm according to Rotary Diagnostics. What it does need is to have been run recently. This ensures there is an internal oil film on the rotor, side plates, and housing surfaces & seals. If the engine has been sitting for a while the oil film will not be evenly distributed. So there really is no need to be burning your hands etc. Warm it up, cool it down, and then test. Even within a few days is generally considered to be OK, but the same day is likely the best option.

On the RX8 all you need to do in preparation of running the test is to disconnect the ESS sensor wiring connection at the sensor. Pulling the fuel pump fuse is not necessary. Pulling the EGI fuse, the common prep step prior to the RX8/Renesis, will prevent the engine from cranking on the RX8. Disconnecting the ESS sensor means the PCM will not be receiving pulse signals while the engine is cranking so no ignition coil or fuel injection functions will be performed as a result. It can result in a code being thrown, so clearing the PCM memory and any codes after the test is something to consider.

Pleased with my personal results:

ACTUAL ROTOR 1 (FRONT)

ACTUAL ROTOR 2 (REAR)

NORMALIZED ENGINE RESULTS

Been trying to troubleshoot an issue for another local member. Engine started making the SSV tapping sound and also a "rapping/sort-of-knocking" sound in the 4000-7000 rpm range while accelerating WOT. Over the last few years I've had several people contacting me about a similar issue, but this is the first one I got my hands on. Engine cranks quickly, idles fine, and drives every day use fine otherwise. Did not think it was the engine because of this. Checked many things; SSV operation/solenoid, coils, plugs, pulled UIM, etc. Did finally figure out that the the "rapping" sound is coming from the engine intake system (AEM CAI) and exiting out the intake filter. Finally decided to run the compression test and result from Rotor 2 (Rear) tells the tale; reading 30 psig low actual on one rotor face. Rotor 1 (front) and the other two faces on Rotor 2 were fine otherwise. My assessment is that is likely a side seal on that face and the sound is compressed air/combustion gasses getting past the seal and back into the intake. It is also what is causing intake pulsing at idle, which in turn is the cause for the SSV valve tapping sound:

A bad corner seal is generally known to cause starting and idle issues. I don't have an example graph of this condition for demonstration purposes, but since the engine starts & idles fine I ruled the corner seals out. A failed or bad apex seal generally results in two simultaneous bad rotor pulse readings because air & combustion gasses moves across the bad apex seal between the two adjacent rotor faces. Here is a typical example of a bad apex seal:

.

Last edited by TeamRX8; 10-15-2012 at 11:31 PM.

#34

Thread

Thread Starter

Forum

Replies

Last Post

Touge

Canada Forum

0

09-01-2015 10:47 PM