Cobb as a Turbo Tuning Solution and Ideal MAF Placement

#1

Thread Starter

The Stink w.o The Sause

iTrader: (5)

Joined: Jun 2009

Posts: 2,448

Likes: 3

From: North DE

Cobb as a Turbo Tuning Solution and Ideal MAF Placement

This thread is created to question the status quo (COBB = BEST compromise for EMS) of these boards. Even if you are sure the most popular method is the best method to do something, this is a healthy exercise to do from time to time.

For the Tuning: (an oversimplification) MAF placement is key for tuning a MAF-based system. The mass of air flowing into your engine directly correlated with engine load. Engine load is DERIVED from Mass air flow. In turn, the amount of fuel injected AND ignition timing is derived from engine load. If everything is read correctly ... then the entire situation is peachy and you have an optimal tune.

Problems that can occur with stock greddy design, assume Open Loop operation, and proper system operation at the time of tuning:

1) Boost Leak: Your MAF sensor sees more air than is entering your engine. Your ECU thinks engine load is higher than it is in actuality.... spark is retarded and you run rich ... NOT overly DANGEROUS, you will lack power

2) Vacuum Leak: Your MAF sees less air than is entering your engine. ECU thinks load is lower than in actuality ... spark is advanced and you run lean .... BOOOM ... new engine

This thread is to be a discussion on COBB as a tuning tool for turbo applications, and ideal MAF assembly placement in a Turbo application... this is a sensitive topic as it will touch on fact that COBB is a less than ideal poor solution for turbo (in terms of reliability of the entire system). But please bear with me for a minute...

Check out what this guy did and note his MAF placement... https://www.rx8club.com/series-i-major-horsepower-upgrades-93/rear-mount-turbo-project-204248/

I honestly feel that this is the best (and only way) Turbo should be done when tuning with COBB.... note the length of his almost straight pipe before the MAF sensor....

the greddy pull through design is POS in comparison ... it will report wrong temps and is unresponsive to vac leaks that may be present elsewhere in the system...

Some discussion I was having with a few fellow members:

... the stock greddy design works fine as long as you don't get a vacuum leak between ur MAF and turbo.... personally, I don't like betting the life of my engine on a piece of pipe and silicone connector. Vac leak between MAF and compressor = more air going into your engine than your ECU "sees", and if you tuned before the leak surfaced, you can lean out and go boom

The standard rx8 ECU (and COBB) is MAF based ... although this makes tuning a shitton easier, this is FAR from ideal for an FI application.... either way, I am seriously considering modifying the Greddy design and moving the MAF sensor to a better place... BUT its a catch 22, as the MAF needs to see turbulent free air, as your two options are:

1) Keep it in the stock greddy location. It reports the wrong temps, and you run at a risk because of vac/boost leaks, etc. BUT airflow is accurate.

2)Put it after turbo, intercooler, and BOV. It reports correct temps and there is VERY little risk of vac/boost leaks contributing to incorrect readings. BUT you better have a piece of LONG, straight pipe before your MAF as turbulence greatly affects the accuracy of readings

*Disclaimer* I have a COBB, it is awesome for everything, as long as you are N/A and/or supercharged (to an extent), however, I feel that it is a poor solution for turbo. Can it get the job done? Yes. Can it do so reliably ie, if you introduce variables that can be foreseen into the system (like vac leaks)? NO! BTW, you will get vac leaks eventually, its not a question of IF, but a question of WHEN ... most of the time, however, it will happen post turbo and you will *gasp* run rich as a result. Rarely, it can happen before turbo and cause havoc.

The popular AEM CAI mod for the Greddy kit actually increases the probability of the bad type of this leak occurring ... as you add more pipe and more connections between the MAF and turbo...

I can easily see how a minor collision at the track with a piece of debris (or into a snowbank) can introduce a vacuum leak and the driver may think everything is A-Okay when in fact it is not.

Conclusion: COBB, as a tuning solution for TURBO can never be as reliable as other MAP based systems. PERIOD. Although it can come close if you are cautious and generally aware of your car's components' health.

Unfortunately, the pickle is that we need to get our cars inspected. As far as I know COBB is the only thing that allows you to run custom maps and pass inspection.... ie it is OBD2 compliant ... I am not aware of any stand-alones that are

Solutions:

1) get MAP based tuning solution, so you do not have to worry about this

OR

2) Run a dual ECU system (COBB and a stand alone MAP based ECU) for inspection purposes... Is this even possible? Obviously they are not controlling the engine simultaneously ... you have the ability to switch from one to another. I believe MM mentioned something along the lines that the stock ECU simple needs to see sensor inputs to function? Let COBB control APV and other such valves...

OR

3) Sell rx8, buy FD

What are your opinions?

Also, is there any way to split the IAT sensor from the MAF assembly? You can guess why you would want to do this ... keep it as a pull through and but the IAT sensor into the manifold... I am too tired to explain further

For the Tuning: (an oversimplification) MAF placement is key for tuning a MAF-based system. The mass of air flowing into your engine directly correlated with engine load. Engine load is DERIVED from Mass air flow. In turn, the amount of fuel injected AND ignition timing is derived from engine load. If everything is read correctly ... then the entire situation is peachy and you have an optimal tune.

Problems that can occur with stock greddy design, assume Open Loop operation, and proper system operation at the time of tuning:

1) Boost Leak: Your MAF sensor sees more air than is entering your engine. Your ECU thinks engine load is higher than it is in actuality.... spark is retarded and you run rich ... NOT overly DANGEROUS, you will lack power

2) Vacuum Leak: Your MAF sees less air than is entering your engine. ECU thinks load is lower than in actuality ... spark is advanced and you run lean .... BOOOM ... new engine

This thread is to be a discussion on COBB as a tuning tool for turbo applications, and ideal MAF assembly placement in a Turbo application... this is a sensitive topic as it will touch on fact that COBB is a less than ideal poor solution for turbo (in terms of reliability of the entire system). But please bear with me for a minute...

Check out what this guy did and note his MAF placement... https://www.rx8club.com/series-i-major-horsepower-upgrades-93/rear-mount-turbo-project-204248/

I honestly feel that this is the best (and only way) Turbo should be done when tuning with COBB.... note the length of his almost straight pipe before the MAF sensor....

the greddy pull through design is POS in comparison ... it will report wrong temps and is unresponsive to vac leaks that may be present elsewhere in the system...

Some discussion I was having with a few fellow members:

... the stock greddy design works fine as long as you don't get a vacuum leak between ur MAF and turbo.... personally, I don't like betting the life of my engine on a piece of pipe and silicone connector. Vac leak between MAF and compressor = more air going into your engine than your ECU "sees", and if you tuned before the leak surfaced, you can lean out and go boom

The standard rx8 ECU (and COBB) is MAF based ... although this makes tuning a shitton easier, this is FAR from ideal for an FI application.... either way, I am seriously considering modifying the Greddy design and moving the MAF sensor to a better place... BUT its a catch 22, as the MAF needs to see turbulent free air, as your two options are:

1) Keep it in the stock greddy location. It reports the wrong temps, and you run at a risk because of vac/boost leaks, etc. BUT airflow is accurate.

2)Put it after turbo, intercooler, and BOV. It reports correct temps and there is VERY little risk of vac/boost leaks contributing to incorrect readings. BUT you better have a piece of LONG, straight pipe before your MAF as turbulence greatly affects the accuracy of readings

*Disclaimer* I have a COBB, it is awesome for everything, as long as you are N/A and/or supercharged (to an extent), however, I feel that it is a poor solution for turbo. Can it get the job done? Yes. Can it do so reliably ie, if you introduce variables that can be foreseen into the system (like vac leaks)? NO! BTW, you will get vac leaks eventually, its not a question of IF, but a question of WHEN ... most of the time, however, it will happen post turbo and you will *gasp* run rich as a result. Rarely, it can happen before turbo and cause havoc.

The popular AEM CAI mod for the Greddy kit actually increases the probability of the bad type of this leak occurring ... as you add more pipe and more connections between the MAF and turbo...

I can easily see how a minor collision at the track with a piece of debris (or into a snowbank) can introduce a vacuum leak and the driver may think everything is A-Okay when in fact it is not.

Conclusion: COBB, as a tuning solution for TURBO can never be as reliable as other MAP based systems. PERIOD. Although it can come close if you are cautious and generally aware of your car's components' health.

Unfortunately, the pickle is that we need to get our cars inspected. As far as I know COBB is the only thing that allows you to run custom maps and pass inspection.... ie it is OBD2 compliant ... I am not aware of any stand-alones that are

Solutions:

1) get MAP based tuning solution, so you do not have to worry about this

OR

2) Run a dual ECU system (COBB and a stand alone MAP based ECU) for inspection purposes... Is this even possible? Obviously they are not controlling the engine simultaneously ... you have the ability to switch from one to another. I believe MM mentioned something along the lines that the stock ECU simple needs to see sensor inputs to function? Let COBB control APV and other such valves...

OR

3) Sell rx8, buy FD

What are your opinions?

Also, is there any way to split the IAT sensor from the MAF assembly? You can guess why you would want to do this ... keep it as a pull through and but the IAT sensor into the manifold... I am too tired to explain further

Last edited by stinksause; 02-13-2011 at 02:40 PM.

#3

I used to have a reasonably bad vacuum leak that I was unaware of for some time . It was there when I started the tuning and did make tuning more difficult but I did manage to get it tuned with PT (same as Cobb in function) .

Fixing the leak made it go rich (as you would expect) .

I don't think the risk of a vac leak appearing as time goes by is that great so I'm happy that I'm not taking a big risk of a one causing an engine failure . Running a safe rich tune and monitoring AFR via a guage is also good insurance .

Fixing the leak made it go rich (as you would expect) .

I don't think the risk of a vac leak appearing as time goes by is that great so I'm happy that I'm not taking a big risk of a one causing an engine failure . Running a safe rich tune and monitoring AFR via a guage is also good insurance .

#6

Or is it just for monitoring?

How did you do this? I can I find it in your build thread?

#7

/\ This is the IAT the ECU sees - yes .

https://www.rx8club.com/series-i-do-yourself-forum-73/diy-iat-sensor-turbo-164751/

https://www.rx8club.com/series-i-do-yourself-forum-73/diy-iat-sensor-turbo-164751/

Last edited by Brettus; 02-13-2011 at 05:59 PM.

#9

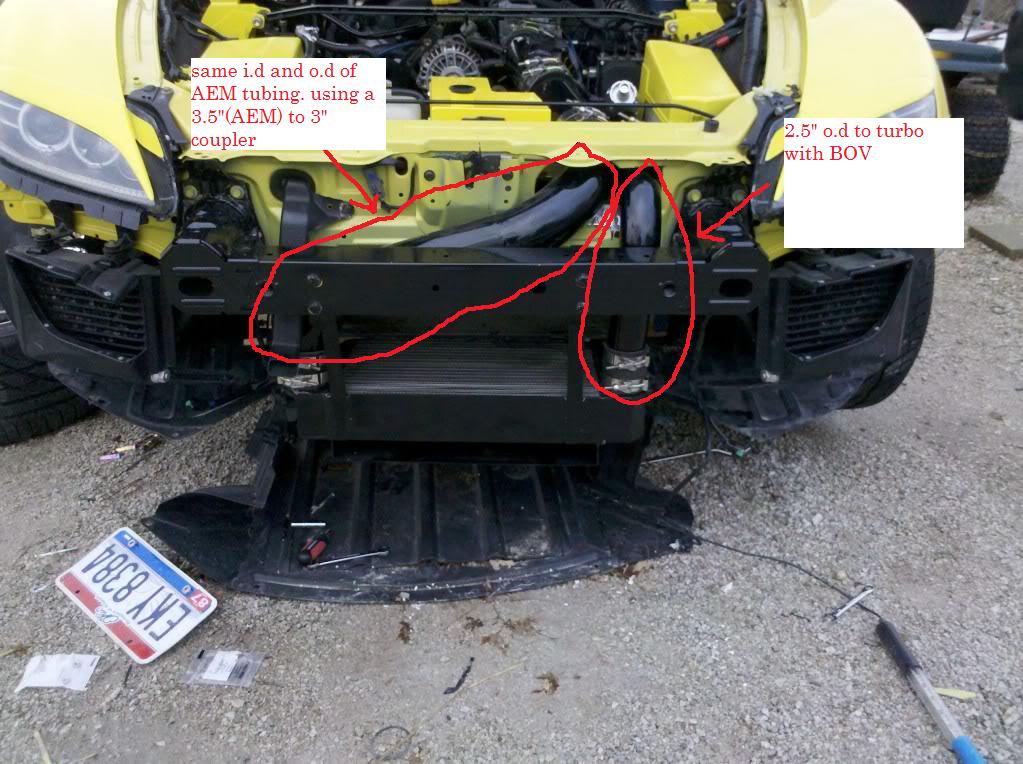

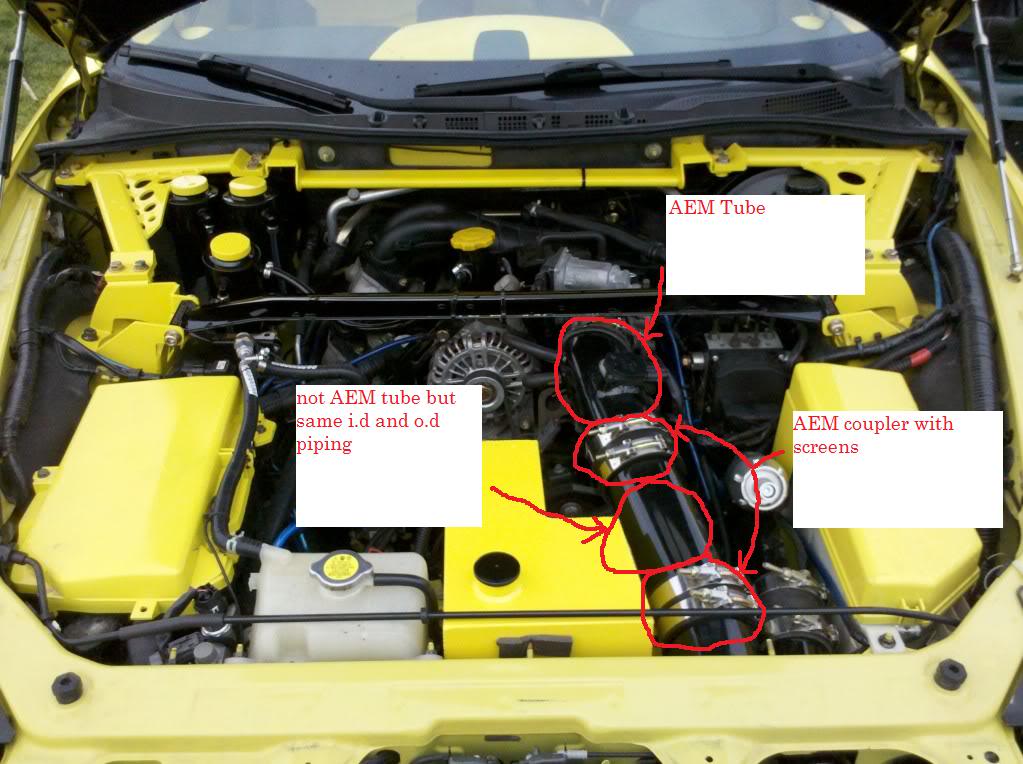

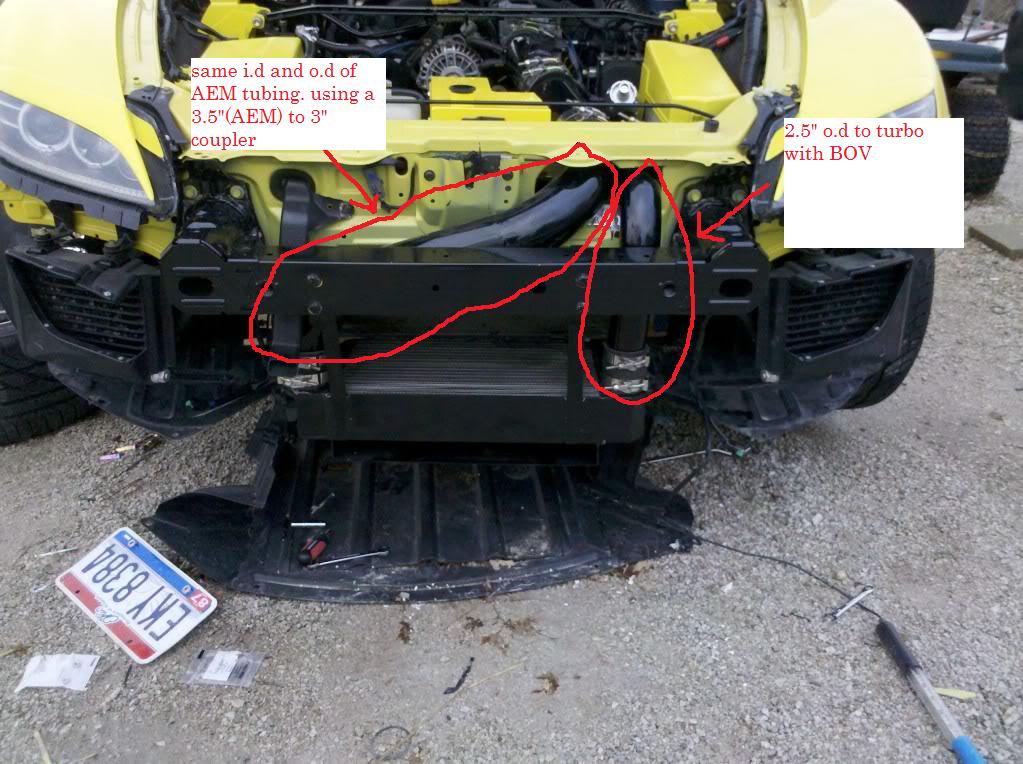

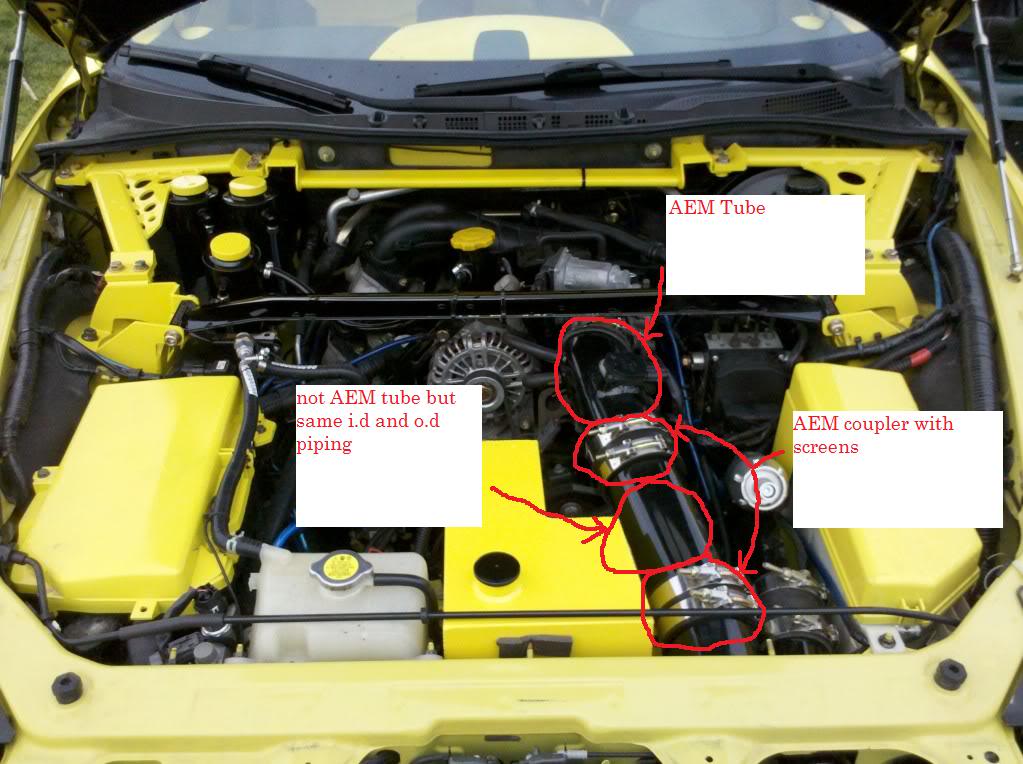

well since WCS informed me my thread came up here is my final set up details so no one has to look for it. the last install the piping in the engine bay is straighter than in the picture.

Last edited by bumblebeerx8; 02-13-2011 at 07:22 PM.

#11

So the reason that the COBB is a poor tuning solution is because it cannot handle mechanical issues as well?

Last I checked, engine management choice was more about function, cost and complexity and not whether or not it fixes mechanical mistakes.

Last I checked, engine management choice was more about function, cost and complexity and not whether or not it fixes mechanical mistakes.

#12

#13

Thread Starter

The Stink w.o The Sause

iTrader: (5)

Joined: Jun 2009

Posts: 2,448

Likes: 3

From: North DE

team, that's true but I didn't have the understanding when I participated in them that I do now

Flashwing, Cobb is great, as long as you are NA. Once FI, the shortcoming of the stock ECU start to catch up to you. It can get the job done, but it is not ideal... ie you can get a better set-up if you are willing to fork the cash ... Cost is not a hypothetical consideration.... This goes back to the philosophy of Pay a bit more and do it right rather than not and have to fix stuff later on ... but maybe I am being a perfectionist

mechanical failures are still considered system failures

Everyone else, thanks a lot for your input

Flashwing, Cobb is great, as long as you are NA. Once FI, the shortcoming of the stock ECU start to catch up to you. It can get the job done, but it is not ideal... ie you can get a better set-up if you are willing to fork the cash ... Cost is not a hypothetical consideration.... This goes back to the philosophy of Pay a bit more and do it right rather than not and have to fix stuff later on ... but maybe I am being a perfectionist

COBB is a less than ideal poor solution for turbo (in terms of reliability of the entire system)

Everyone else, thanks a lot for your input

Last edited by stinksause; 02-14-2011 at 01:00 PM.

#16

I wont argue the fact that a blow through system would be more reliable but if you are monitoring your AFR's there shouldn't be a huge problem with blown engines because of this. Also I'd say 90% of the time your couplers/piping post turbo will fail before pre-turbo sections. Also with the stock Greddy set-up there are only two couplers pre-turbo while there are 4 or 5 post turbo (depending on if you use a 90deg coupler after IC or use the stock GReddy IC elbow).

#17

The AccessPORT is definitely a bad solution for mechanical mistakes, bad design, poor implementation and equipment issues.

So, if one is too lazy/inept to build, maintain and troubleshoot a proper mechanical system, the AccessPORT, being the single best, most in-depth engine management solution for any RX-8 performance application, is probably not the best choice.

I'd suggest the Int-X. It runs the engine equally poorly when the setup is sound as when it is compromised.

Having tuned only several hundreds of these things, my option probably isn't worth much.

So, if one is too lazy/inept to build, maintain and troubleshoot a proper mechanical system, the AccessPORT, being the single best, most in-depth engine management solution for any RX-8 performance application, is probably not the best choice.

I'd suggest the Int-X. It runs the engine equally poorly when the setup is sound as when it is compromised.

Having tuned only several hundreds of these things, my option probably isn't worth much.

#18

Thread Starter

The Stink w.o The Sause

iTrader: (5)

Joined: Jun 2009

Posts: 2,448

Likes: 3

From: North DE

thanks for the input.... all good points

As I am not that well educated on EMS systems, I am afraid of suggesting something foolish... and then getting flamed ...

That being said...

Int-x wouldn't be my top choice either ... the IDEAL choice would probably be a combination of two things... COBB for OMP and APV, VDI etc and a standalone for fuel injection and spark

That would retain COBB for using airflow (and, by extension load) to only be responsible for OMP ... at the track with heavy premix, this should not be a huge issue if there is some sort of mech failure....

I would also use a blow through system (ideally)

MM, what other EMS systems have you used prior to your rx8 days

I also believe you said at some point that the rx8 ECU needs to only see sensor inputs to operate?

There is a local rotary shop that installed a 13B-REW and had it run on the rx8 ECU + Int-X.

They had a nightmare hacking and wiring up extra components to get it to stop throwing CEL's

I feel that if COBB was thrown into that mix, the job would have been a lot easier

your thoughts?

As I am not that well educated on EMS systems, I am afraid of suggesting something foolish... and then getting flamed ...

That being said...

Int-x wouldn't be my top choice either ... the IDEAL choice would probably be a combination of two things... COBB for OMP and APV, VDI etc and a standalone for fuel injection and spark

That would retain COBB for using airflow (and, by extension load) to only be responsible for OMP ... at the track with heavy premix, this should not be a huge issue if there is some sort of mech failure....

I would also use a blow through system (ideally)

MM, what other EMS systems have you used prior to your rx8 days

I also believe you said at some point that the rx8 ECU needs to only see sensor inputs to operate?

There is a local rotary shop that installed a 13B-REW and had it run on the rx8 ECU + Int-X.

They had a nightmare hacking and wiring up extra components to get it to stop throwing CEL's

I feel that if COBB was thrown into that mix, the job would have been a lot easier

your thoughts?

Last edited by stinksause; 02-14-2011 at 07:36 PM.

#20

Tuff love coming up. Give me the benefit of the doubt till you read this post.

I think we're past that point. If you don't have extensive experience with other EMS systems or even the accessPORT itself then this discussion isn't going to be much more than an exercise in how much someone does not know about tuning rather than examining alternatives.

A fantastic summary. If the ONLY basis for not using the accessPORT is because it doesn't have built in safeguards for mistakes then you are expecting a technical application that does not exist.

You have to understand that a computer, not a person, runs the RX8. The basics are that a computer takes in a set of data points and based on programmed values it makes decisions about how to run the car. The car doesn't have any way of telling the difference between a vacuum leak or a dead fuel pump. Some stand-alone systems have safeguards designed into them to protect the car from total destruction. However, a stand-alone management system is designed with the expectation that the user is doing something to a car that it was not designed for.

The accessPORT utilizes the stock PCM which was not designed with the expectation that the user would reprogram the car. No safe guards were necessary because that was the responsibility of the engineers. The car is tuned to account for safety.

That being said, there is a serious price point difference between a stand-alone and the accessPORT. That being said, the stock PCM is very capable in terms of resolution.

My experience is not nearly as extensive as MazdaManiac's, but I can say that the process of tuning for FI is very similar if not exactly as NA. The behaviors of the car and the relationship between the tuning process and the product produced by the PCM is exactly the same.

The ONLY difference is FI tuning must be done with much more care and attention to detail because mistakes carry serious consequences. Misfires while NA are bad but not usually bad enough to nuke a motor. Turbo/supercharged motors will most certainly be nuked.

So the result is that you cannot say the accessPORT is great for NA but not great for a turbo or supercharger setup. They are one of the same. The numbers are different, the process is the same.

I'm not saying you shouldn't express your opinion Stink and I'm not saying your ignorant. I'm simply trying to make the case that your expectations are not realistic for the tuning process.

The car must be in proper mechanical working condition otherwise the tuning process will not work. One cannot work properly without the other.

All that being said, one of the aspects both myself and the BHR team as a whole look for are better ways to get things done. If there is a better tuning product out there I'm interested in hearing the reasoning.

The items to consider when looking at a tuning solution:

- Price

- Ease of use (this means installation, using software etc)

- Capability (resolution, features, robustness etc)

When considering all of those options, the AP continues to be the dominant solution. There are products that do 1 or 2 items better than the AP but not all 3. I hardly consider the AP a compromise because 99% of RX8 owners will never even utilize the full capability of the AP. Adding extra features would be a waste.

I'm very interested to hear alternatives and reasons for doing so. However, without experience with other tuning solutions this thread isn't going anywhere.

As I am not that well educated on EMS systems, I am afraid of suggesting something foolish... and then getting flamed ...

So, if one is too lazy/inept to build, maintain and troubleshoot a proper mechanical system, the AccessPORT, being the single best, most in-depth engine management solution for any RX-8 performance application, is probably not the best choice.

You have to understand that a computer, not a person, runs the RX8. The basics are that a computer takes in a set of data points and based on programmed values it makes decisions about how to run the car. The car doesn't have any way of telling the difference between a vacuum leak or a dead fuel pump. Some stand-alone systems have safeguards designed into them to protect the car from total destruction. However, a stand-alone management system is designed with the expectation that the user is doing something to a car that it was not designed for.

The accessPORT utilizes the stock PCM which was not designed with the expectation that the user would reprogram the car. No safe guards were necessary because that was the responsibility of the engineers. The car is tuned to account for safety.

That being said, there is a serious price point difference between a stand-alone and the accessPORT. That being said, the stock PCM is very capable in terms of resolution.

My experience is not nearly as extensive as MazdaManiac's, but I can say that the process of tuning for FI is very similar if not exactly as NA. The behaviors of the car and the relationship between the tuning process and the product produced by the PCM is exactly the same.

The ONLY difference is FI tuning must be done with much more care and attention to detail because mistakes carry serious consequences. Misfires while NA are bad but not usually bad enough to nuke a motor. Turbo/supercharged motors will most certainly be nuked.

So the result is that you cannot say the accessPORT is great for NA but not great for a turbo or supercharger setup. They are one of the same. The numbers are different, the process is the same.

I'm not saying you shouldn't express your opinion Stink and I'm not saying your ignorant. I'm simply trying to make the case that your expectations are not realistic for the tuning process.

The car must be in proper mechanical working condition otherwise the tuning process will not work. One cannot work properly without the other.

All that being said, one of the aspects both myself and the BHR team as a whole look for are better ways to get things done. If there is a better tuning product out there I'm interested in hearing the reasoning.

The items to consider when looking at a tuning solution:

- Price

- Ease of use (this means installation, using software etc)

- Capability (resolution, features, robustness etc)

When considering all of those options, the AP continues to be the dominant solution. There are products that do 1 or 2 items better than the AP but not all 3. I hardly consider the AP a compromise because 99% of RX8 owners will never even utilize the full capability of the AP. Adding extra features would be a waste.

I'm very interested to hear alternatives and reasons for doing so. However, without experience with other tuning solutions this thread isn't going anywhere.

#21

I find the AccessPORT to be pretty versatile as well, in addition to what Jeff and Todd say. There are alternatives out there and that's a given but they either are meant for the track realm only or they are just "toys".

Many of them are good at what they do in the context that they were designed for, with our stock pcm you get a perfect daily driver and a 99% perfect track car. Boosted or not makes no difference, the tuner does

I think that you should look into the most viable\available alternatives (Int-x, v-con fpro, adaptronic select for the rx8, motec m2r and m880,haltec platinum pro\sport whatever, link g4, bosch and magneti marelli motorsport pcms) and compare them to the stock pcm. Not the accessPORT, the pcm's capabilities.

After that you'll probably see our points

If you can afford a 15.000$ Magneti Marelli pcm then...

Many of them are good at what they do in the context that they were designed for, with our stock pcm you get a perfect daily driver and a 99% perfect track car. Boosted or not makes no difference, the tuner does

I think that you should look into the most viable\available alternatives (Int-x, v-con fpro, adaptronic select for the rx8, motec m2r and m880,haltec platinum pro\sport whatever, link g4, bosch and magneti marelli motorsport pcms) and compare them to the stock pcm. Not the accessPORT, the pcm's capabilities.

After that you'll probably see our points

If you can afford a 15.000$ Magneti Marelli pcm then...

#22

Thread Starter

The Stink w.o The Sause

iTrader: (5)

Joined: Jun 2009

Posts: 2,448

Likes: 3

From: North DE

Flashwing, thanks for breaking that down...

I guess what I am trying to suggest is the possibility of using AP in combination with another system....

Control rpm-sensitive figures (APV, etc), fans, and oil injection with the stock PCM/ accessport, and leave spark, fueling and or watermeth, etc to another, MAP based stand-alone

I guess what I am trying to suggest is the possibility of using AP in combination with another system....

Control rpm-sensitive figures (APV, etc), fans, and oil injection with the stock PCM/ accessport, and leave spark, fueling and or watermeth, etc to another, MAP based stand-alone

Last edited by stinksause; 02-15-2011 at 11:08 AM.

#23

Why would you do that? How is the stock pcm's management of spark and fuelling inadequate? To what extent?

The simple answer is: yes, it can be done. The real one is: it can be done but it is not worth it.

The simple answer is: yes, it can be done. The real one is: it can be done but it is not worth it.

#25

you dont really need my input here as my points are being covered.

that being said

you understand even less than i thought you did. run the PCM with a custom flash AND a Stand Alone?

that being said

That being said...

Int-x wouldn't be my top choice either ... the IDEAL choice would probably be a combination of two things... COBB for OMP and APV, VDI etc and a standalone for fuel injection and spark

That would retain COBB for using airflow (and, by extension load) to only be responsible for OMP ... at the track with heavy premix, this should not be a huge issue if there is some sort of mech failure....

Int-x wouldn't be my top choice either ... the IDEAL choice would probably be a combination of two things... COBB for OMP and APV, VDI etc and a standalone for fuel injection and spark

That would retain COBB for using airflow (and, by extension load) to only be responsible for OMP ... at the track with heavy premix, this should not be a huge issue if there is some sort of mech failure....

?

?