r0tor's AP Tuning Thread

#1

r0tor's AP Tuning Thread

**Disclaimer: I do not claim that this is the “correct” or “best” way of tuning a NA RX-8… only something I have found that works. Try this at you own risk.**

OK, I have attempted to put together a thread detailing how I went about tuning my NA RX-8. I have tried several methods like tweaking a Cobb map and tweaking the MAF but have not gotten the results as easily as I had hoped. This method seemed to produce great results in little time. For normally aspirated applications, getting WOT fueling can be done by an AP user with the AccessPORT Race software relatively safely if the user moves cautiously and in small increments.

Step 1) Set your Goals!!!

Nothing is worse then getting into a project and then getting sidetracked in details and drifting helplessly into the abyss that can be tuning at times. I set my goals like this:

1) Examine the Cobb Stage I map and other references to see what is really necessary to change

2) Get rid of fuel trims and try to get AFR’s to match table targets

3) Get a response to a base table of my own making. Use the %error of real AFR’s to target ones to create the next map.

4) Using some interpolation, progress from map to map with a goal of reaching 12.5-12.7 afr across the board.

5) Tweak coolant temps, rpm rev limiters, OMP settings

OK, I have attempted to put together a thread detailing how I went about tuning my NA RX-8. I have tried several methods like tweaking a Cobb map and tweaking the MAF but have not gotten the results as easily as I had hoped. This method seemed to produce great results in little time. For normally aspirated applications, getting WOT fueling can be done by an AP user with the AccessPORT Race software relatively safely if the user moves cautiously and in small increments.

Step 1) Set your Goals!!!

Nothing is worse then getting into a project and then getting sidetracked in details and drifting helplessly into the abyss that can be tuning at times. I set my goals like this:

1) Examine the Cobb Stage I map and other references to see what is really necessary to change

2) Get rid of fuel trims and try to get AFR’s to match table targets

3) Get a response to a base table of my own making. Use the %error of real AFR’s to target ones to create the next map.

4) Using some interpolation, progress from map to map with a goal of reaching 12.5-12.7 afr across the board.

5) Tweak coolant temps, rpm rev limiters, OMP settings

Last edited by r0tor; 05-01-2009 at 11:40 AM.

#2

Step 2) Examine the information that’s out there

My starting point was pretty simple. I installed the Cobb AccessPORT Race software and began inspecting all the available maps to see what exactly Cobb themselves changed to produce their OTS stage 1 map. An easy trick to doing this is copying the maps from the stock map and stage 1 map and pasting it into excel – and then subtracting the stock from the stage 1 to see where changes are made. I will save everyone the trouble of doing this and report that they changed very little which was encouraging.

Cobb merely made changes to the Open Loop Fuel tables labeled “Air/Fuel Gear xxx” tables and the “Trailing Ignition Main” table.

Looking over the various tables there are a variety of things that can effect your fueling. There are the obvious Air/Fuel target tables, there is the MAF scaling, and the injector size scaling. Then there less obvious things like VE curves, Load limits, and other tables in there with cryptic names. I propose for an end user to concentrate on the obvious tables and ignore the rest. The more variables you start changing, the more data you need to really determine what those changes did….

Last Note, ignition timing I am not going to go into detail here. There are a variety of different philosophies and frankly without having a controlled environment that a dyno provides – I can not truly decide which is the right way. Mazda’s stock ignition timing seems pretty fair. Racing Beats suggests that in their own PCM programming that they kept the stock OEM ignition timing. This is the path a chose. Cobb made changes to the trailing ignition timing and did something that is well documented in other NA rotary applications and that’s decreasing the ignition split between leading and trailing. In this case, Cobb closes down the split from 5 degrees from the OEM 15 degrees. They say it makes more power and might be a good thing to try ONCE YOU GET YOUR FUEL TABLES DONE. Decreasing the ignition split will increase the chances of detonation!

Goal #1 complete

My starting point was pretty simple. I installed the Cobb AccessPORT Race software and began inspecting all the available maps to see what exactly Cobb themselves changed to produce their OTS stage 1 map. An easy trick to doing this is copying the maps from the stock map and stage 1 map and pasting it into excel – and then subtracting the stock from the stage 1 to see where changes are made. I will save everyone the trouble of doing this and report that they changed very little which was encouraging.

Cobb merely made changes to the Open Loop Fuel tables labeled “Air/Fuel Gear xxx” tables and the “Trailing Ignition Main” table.

Looking over the various tables there are a variety of things that can effect your fueling. There are the obvious Air/Fuel target tables, there is the MAF scaling, and the injector size scaling. Then there less obvious things like VE curves, Load limits, and other tables in there with cryptic names. I propose for an end user to concentrate on the obvious tables and ignore the rest. The more variables you start changing, the more data you need to really determine what those changes did….

Last Note, ignition timing I am not going to go into detail here. There are a variety of different philosophies and frankly without having a controlled environment that a dyno provides – I can not truly decide which is the right way. Mazda’s stock ignition timing seems pretty fair. Racing Beats suggests that in their own PCM programming that they kept the stock OEM ignition timing. This is the path a chose. Cobb made changes to the trailing ignition timing and did something that is well documented in other NA rotary applications and that’s decreasing the ignition split between leading and trailing. In this case, Cobb closes down the split from 5 degrees from the OEM 15 degrees. They say it makes more power and might be a good thing to try ONCE YOU GET YOUR FUEL TABLES DONE. Decreasing the ignition split will increase the chances of detonation!

Goal #1 complete

Last edited by r0tor; 04-11-2009 at 03:23 PM.

#3

Step 3) Getting rid of those pesky Fuel Trims

Finally the tuning is starting! WOOT!!

I believe zeroing out the fuel trims should be the first step in your tuning practices. It has two advantages: 1) you can more easily see what your changes are doing and 2) with no fuel trims you now longer have to drive the car to settle out trims and then make tuning changes.

OK, to start the process I chose to upload the OEM stock map into my car. You must drive the car around for a day or two with at least 3 cold/warm cycles to establish the Long Term Fuel Trims. Once we establish the fuel trims, its time to do some datalogging of your idle and a steady state cruise in Open Loop fuel control at 4,200 rpms in 4th gear logging at minimum your RPMs, Engine Load, AFR (equiv ratio), LTFT, and STFT. For ease, make these in two log files.

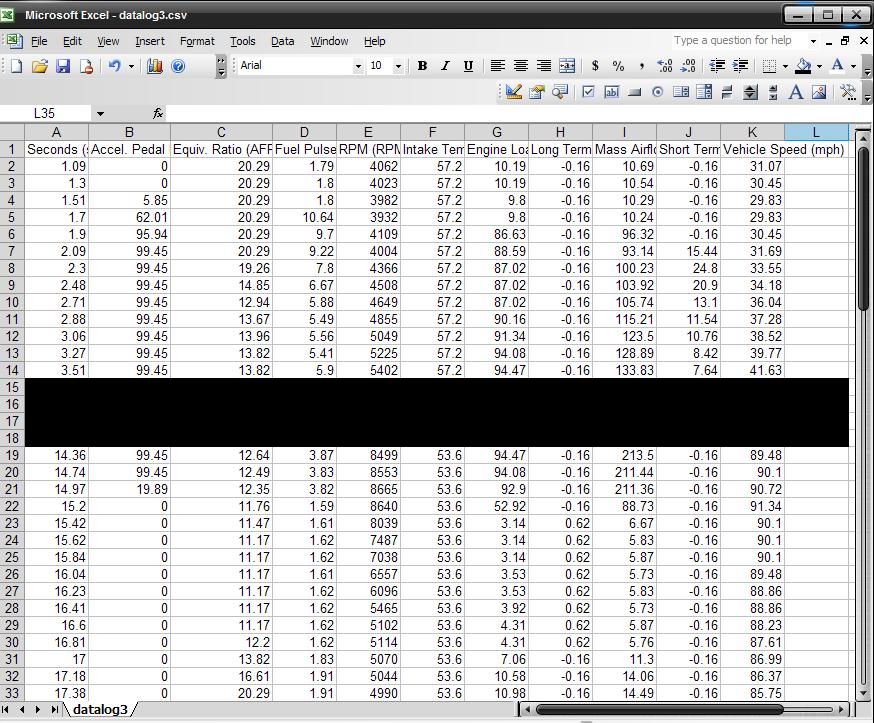

Ok examining your results. Retrieve you logs from your AP and open them in Excel or a like spreadsheet program. For the idle map, find the average of your LTFT, STFT, and MAF. Your STFT should be near zero if you went through enough drive cycles to settle out your LTFT. For your 4200 rpm log, do the same as well as finding the average Load and RPMS.

Samples Below:

As you can see for my idle map, my car had a +3.7 LTFT and a -1 STFT. Adding the fuel trims together, on average my car needs to adjust +2.7 percent to achieve the desired closed loop fuel trim.

For the 4200 rpm map my combined fuel trims were essentially 1%. Next lets look at the desired AFR vs the actual. Look at the average RPMs and Engine Load (4,100 and 32%). In the AccessTuner Race open up the 4th gear fuel table and find the targeted AFR which is ~14.13 in my case. Next take an average of the actual AFR (14.67 for me) and find the % error of the two – which turned out to be 3.8% error. Subtract out my fuel trims and my engine at that condition has an error of 2.8%.

Looking at my results, in each case my error was ~3%. So my move will be 3% to either the MAF or the primary fuel injector. With this knowledge, I decided to scale the “Bank 1 Injector Size” by .97. This will increase the primary injector firing by 3%.

A quick word on MAF tuning vs Fuel Injector tuning.

There is much controversy regarding which way to settle out the fuel trims. You can choose either the MAF or the injectors really. However, keep in mind the MAF is critical in the calculation that determines engine load (which drives almost all engine control functions). My current line of thinking is this: if your maf is showing 5-6 g/s at idle, has a pretty constant reading at idle, and at WOT if it peaks out around the 210-220 for a naturally aspirated car I say it is correctly tuned and does not need to be touched. If you are not getting these results, use your fuel trims and those numbers to adjust the maf scaling.

Finally the tuning is starting! WOOT!!

I believe zeroing out the fuel trims should be the first step in your tuning practices. It has two advantages: 1) you can more easily see what your changes are doing and 2) with no fuel trims you now longer have to drive the car to settle out trims and then make tuning changes.

OK, to start the process I chose to upload the OEM stock map into my car. You must drive the car around for a day or two with at least 3 cold/warm cycles to establish the Long Term Fuel Trims. Once we establish the fuel trims, its time to do some datalogging of your idle and a steady state cruise in Open Loop fuel control at 4,200 rpms in 4th gear logging at minimum your RPMs, Engine Load, AFR (equiv ratio), LTFT, and STFT. For ease, make these in two log files.

Ok examining your results. Retrieve you logs from your AP and open them in Excel or a like spreadsheet program. For the idle map, find the average of your LTFT, STFT, and MAF. Your STFT should be near zero if you went through enough drive cycles to settle out your LTFT. For your 4200 rpm log, do the same as well as finding the average Load and RPMS.

Samples Below:

As you can see for my idle map, my car had a +3.7 LTFT and a -1 STFT. Adding the fuel trims together, on average my car needs to adjust +2.7 percent to achieve the desired closed loop fuel trim.

For the 4200 rpm map my combined fuel trims were essentially 1%. Next lets look at the desired AFR vs the actual. Look at the average RPMs and Engine Load (4,100 and 32%). In the AccessTuner Race open up the 4th gear fuel table and find the targeted AFR which is ~14.13 in my case. Next take an average of the actual AFR (14.67 for me) and find the % error of the two – which turned out to be 3.8% error. Subtract out my fuel trims and my engine at that condition has an error of 2.8%.

Looking at my results, in each case my error was ~3%. So my move will be 3% to either the MAF or the primary fuel injector. With this knowledge, I decided to scale the “Bank 1 Injector Size” by .97. This will increase the primary injector firing by 3%.

A quick word on MAF tuning vs Fuel Injector tuning.

There is much controversy regarding which way to settle out the fuel trims. You can choose either the MAF or the injectors really. However, keep in mind the MAF is critical in the calculation that determines engine load (which drives almost all engine control functions). My current line of thinking is this: if your maf is showing 5-6 g/s at idle, has a pretty constant reading at idle, and at WOT if it peaks out around the 210-220 for a naturally aspirated car I say it is correctly tuned and does not need to be touched. If you are not getting these results, use your fuel trims and those numbers to adjust the maf scaling.

Last edited by r0tor; 04-11-2009 at 03:26 PM.

#4

Step 4) Check you results

In the AccessTuner Race program, I took the stock map and multiplied the “Bank 1 Injector Size” (pick the cell and hit M for multiply then .97) and then saved the map with a new name. I uploaded the new map into the AP and flashed my car. I proceeded to drive around for a few drive cycles and repeated step 3. In my case, my car was now idling with 0-1% fuel trims and also hitting the 4200 rpm afr target with a percent. If this was not the case, use the injector sizing to zero in on the idle and then tweak the maf curve so your hitting the 4200 rpm afr target.

Goal #2 complete!!

In the AccessTuner Race program, I took the stock map and multiplied the “Bank 1 Injector Size” (pick the cell and hit M for multiply then .97) and then saved the map with a new name. I uploaded the new map into the AP and flashed my car. I proceeded to drive around for a few drive cycles and repeated step 3. In my case, my car was now idling with 0-1% fuel trims and also hitting the 4200 rpm afr target with a percent. If this was not the case, use the injector sizing to zero in on the idle and then tweak the maf curve so your hitting the 4200 rpm afr target.

Goal #2 complete!!

Last edited by r0tor; 04-11-2009 at 03:27 PM.

#5

Step 5) Starting the WOT tuning.

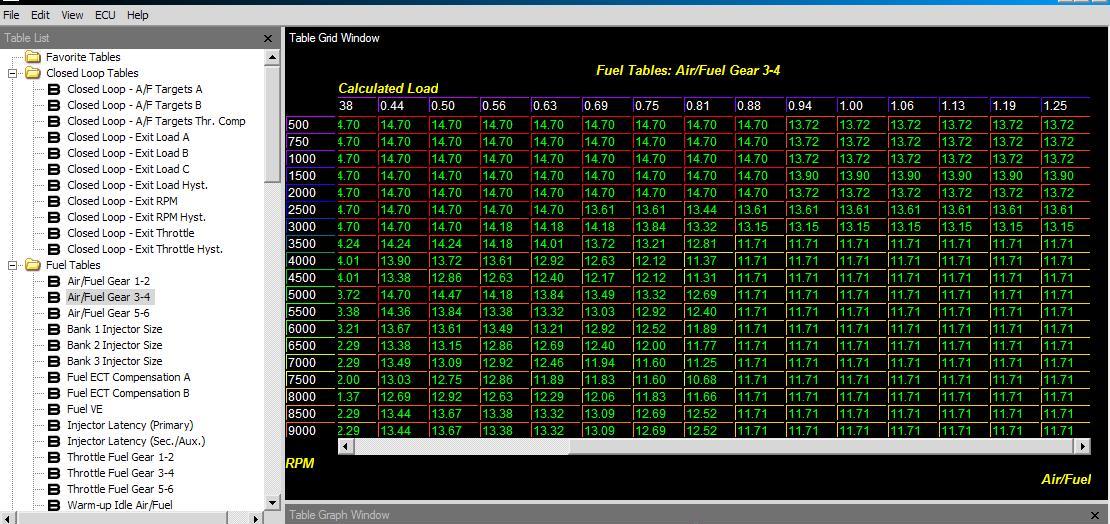

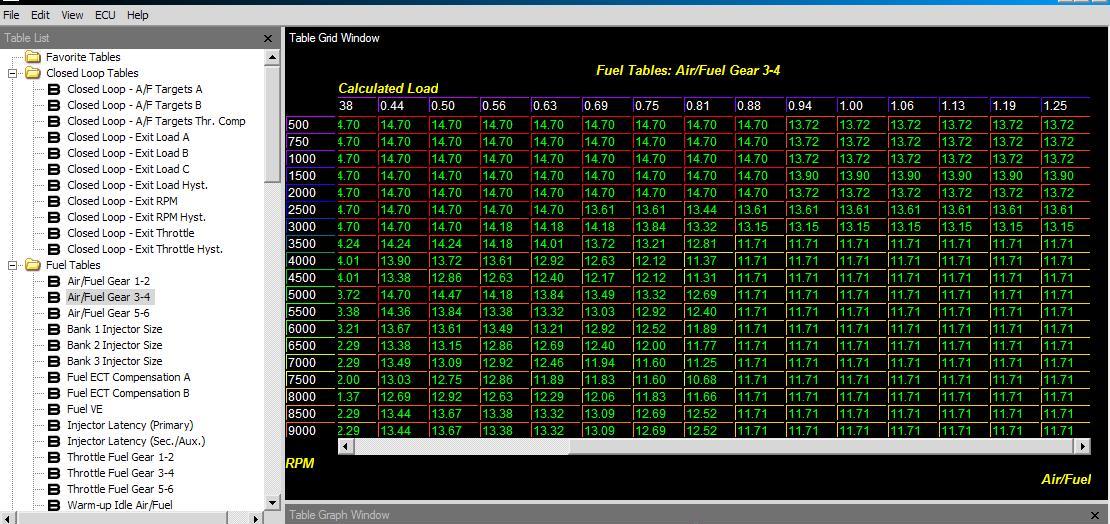

Now that we have the fuel trims being a non issue, its time to go after those WOT afr’s. To do this, I proposed to myself well I need a baseline to start. Looking at the OEM fuel curves in the Gears 1-2 and 3-4 maps, I noticed that once you get about 85% Load and above 4,000 rpms the cells remain constant for each rpm row.

Call it a stroke of insanity, stupidity, or evil genius I made this whole region have a target of 11.7 for lack of a better place or strategy to start from. In retrospect, doing this over again I probably would have been a little more cautios and aimed more for a lower 11 in the region or at least in the tricky 6000-7000 rpms region.

Starter Map seen below:

Do something similar to this sample and save the map with a new name. Make use of the Map Notes field while saving to keep track of what your all changing. Upload the map into your AP, flash your car and now your ready for some WOT datalogging.

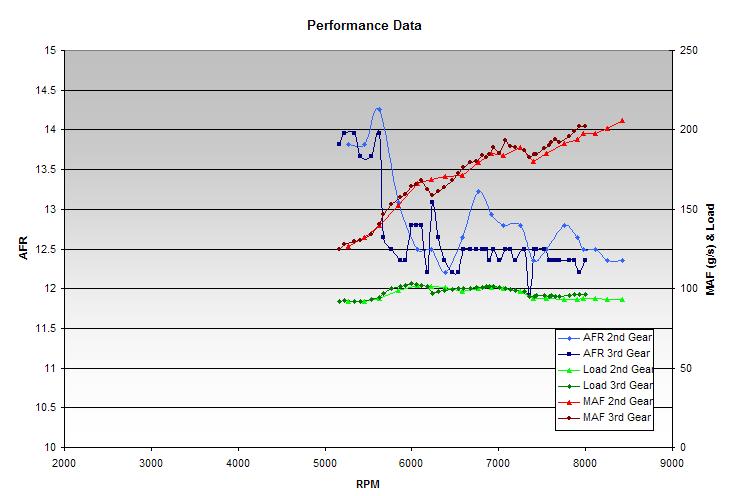

Log at a minimum your RPMs, Engine Load, AFR, LTFT, STFT, MAF, and Vehicle speed. Do this safely from 3000 rpms to 9000 rpms in 2nd and 3rd gear in the same logfile. To examine the data, I suggest using a spreadsheet I created that automatically sorts through the data and graphs it for you – download the AP datalogging spreadsheet here http://www.enter.net/~justin/RX8.htm

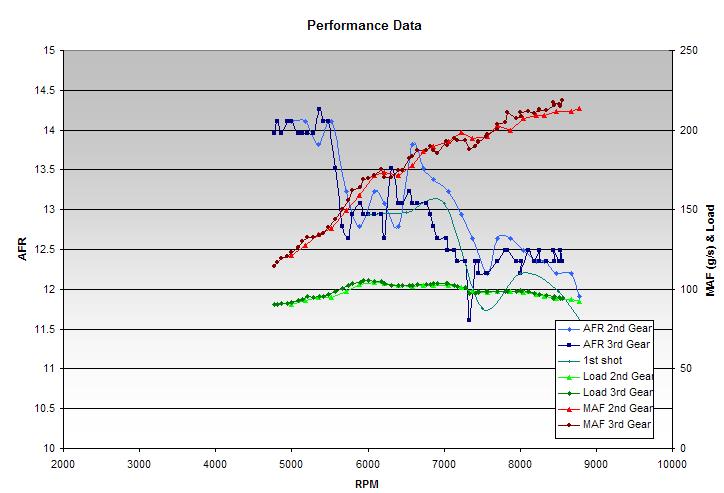

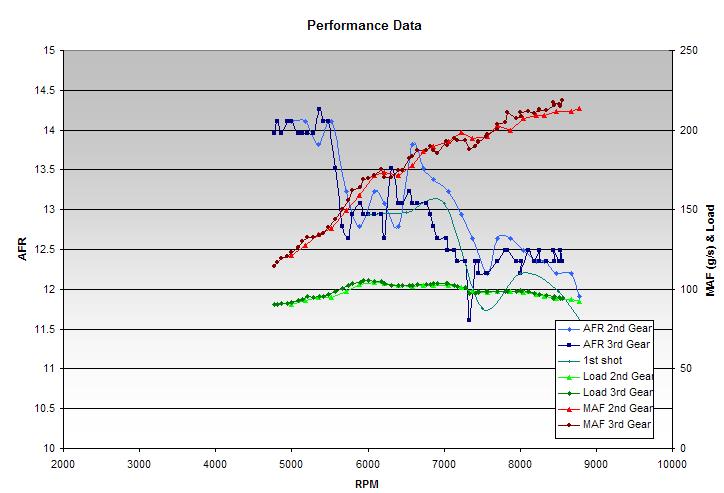

Below is the graph of my actual outcome. As you can see, I was leaner then my target in most cases and also leaner then my end target in some cases… which is why I’d suggest starting with my lower AFR targets then I did!! Also ignore below 5500 rpms as the ecu is just first starting to get out of closed loop fuel control.

Graph:

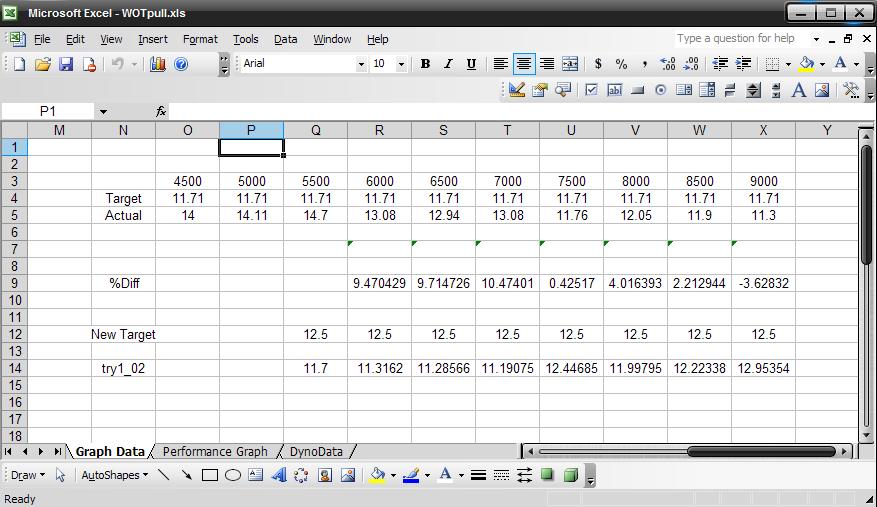

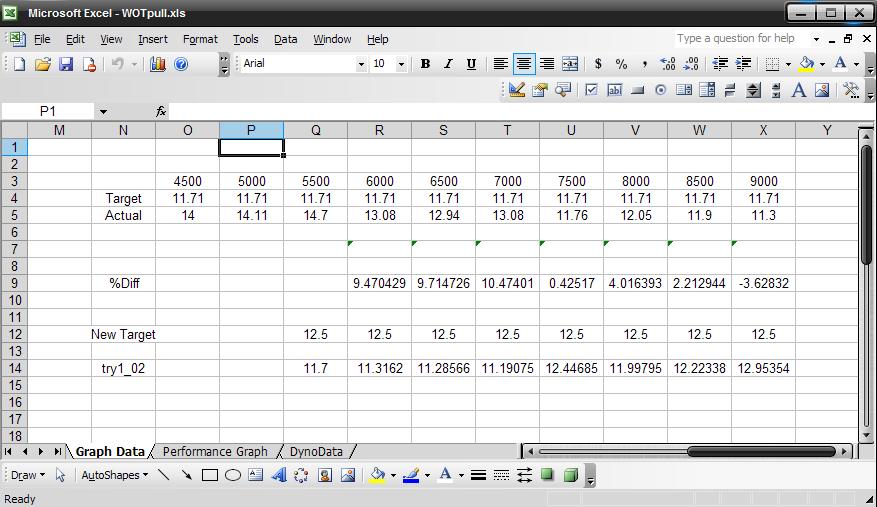

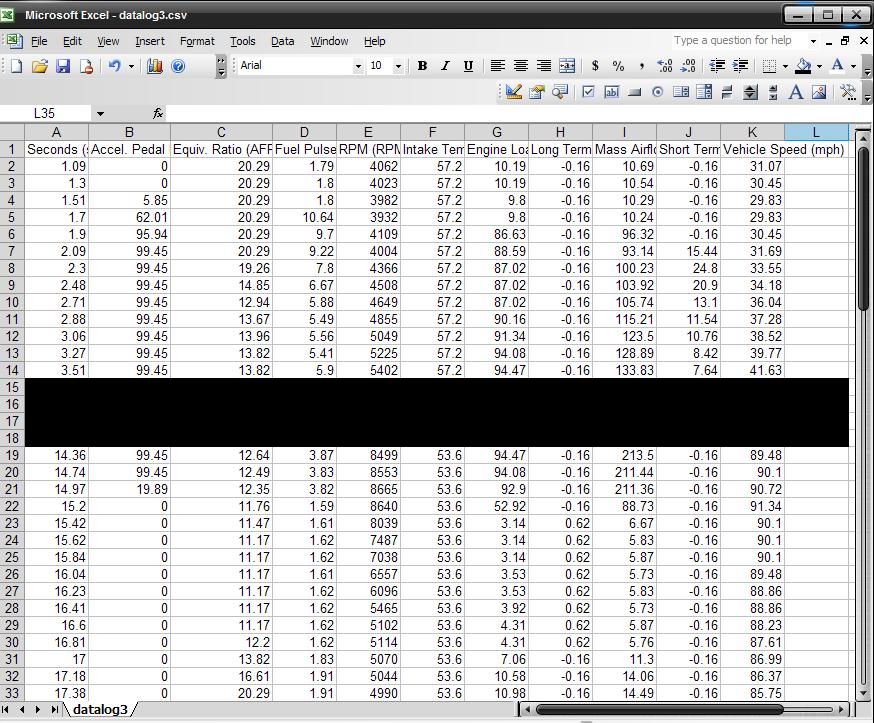

Now I wanted to try use the % error method to determine a logic starting place for my next round of maps. Being brave, I also wanted to try and target 12.5 for the next map (again, in retrospect I could have been more cautious…). So I computer the error in each gear and then adjusted my 12.5 target. So in other words, if I had a 10% overshoot I’d aim for 10% less then 12.5.

Excel math below:

Now that we have the fuel trims being a non issue, its time to go after those WOT afr’s. To do this, I proposed to myself well I need a baseline to start. Looking at the OEM fuel curves in the Gears 1-2 and 3-4 maps, I noticed that once you get about 85% Load and above 4,000 rpms the cells remain constant for each rpm row.

Call it a stroke of insanity, stupidity, or evil genius I made this whole region have a target of 11.7 for lack of a better place or strategy to start from. In retrospect, doing this over again I probably would have been a little more cautios and aimed more for a lower 11 in the region or at least in the tricky 6000-7000 rpms region.

Starter Map seen below:

Do something similar to this sample and save the map with a new name. Make use of the Map Notes field while saving to keep track of what your all changing. Upload the map into your AP, flash your car and now your ready for some WOT datalogging.

Log at a minimum your RPMs, Engine Load, AFR, LTFT, STFT, MAF, and Vehicle speed. Do this safely from 3000 rpms to 9000 rpms in 2nd and 3rd gear in the same logfile. To examine the data, I suggest using a spreadsheet I created that automatically sorts through the data and graphs it for you – download the AP datalogging spreadsheet here http://www.enter.net/~justin/RX8.htm

Below is the graph of my actual outcome. As you can see, I was leaner then my target in most cases and also leaner then my end target in some cases… which is why I’d suggest starting with my lower AFR targets then I did!! Also ignore below 5500 rpms as the ecu is just first starting to get out of closed loop fuel control.

Graph:

Now I wanted to try use the % error method to determine a logic starting place for my next round of maps. Being brave, I also wanted to try and target 12.5 for the next map (again, in retrospect I could have been more cautious…). So I computer the error in each gear and then adjusted my 12.5 target. So in other words, if I had a 10% overshoot I’d aim for 10% less then 12.5.

Excel math below:

Last edited by r0tor; 04-12-2009 at 08:34 PM.

#6

Step 6) Rinse Wash and Repeat

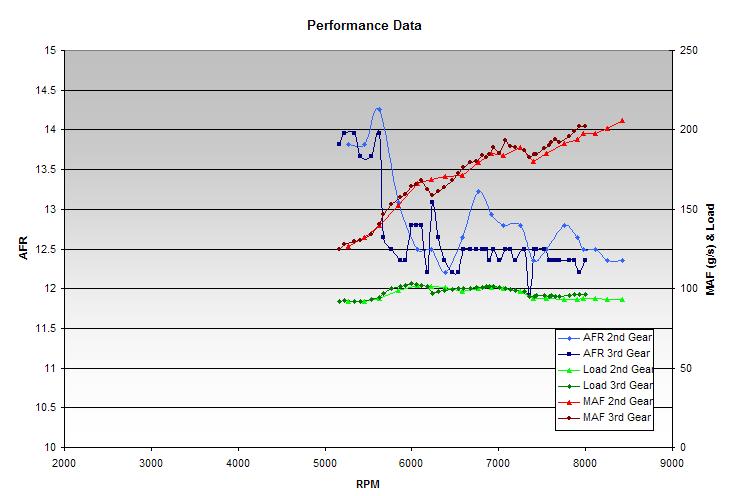

So after saving the next generation of maps, its off to datalog and do some more tweaking as we did previously.

Results:

As you can see its getting better! I figured from this point I could “rinse, wash, and repeat” as necessary. Unfortunately, was wrong and here I can help everyone with my mistake.

So after saving the next generation of maps, its off to datalog and do some more tweaking as we did previously.

Results:

As you can see its getting better! I figured from this point I could “rinse, wash, and repeat” as necessary. Unfortunately, was wrong and here I can help everyone with my mistake.

Last edited by r0tor; 04-11-2009 at 03:32 PM.

#7

Step 7) Tuning is an art and not a science

Up to this point I was treating tuning as a science. I was using purely math. That was my partial undoing for 2 map iterations. While the science gets you close, it’s the touch of an artist that will dial your map completely in. To understand this, look at the raw datalogged numbers.

The RX-8 from factory has the ability to cut all fuel while the engine is under engine braking. Therefore when your off the gas in gear, you see the AFR go to 20 or above. Look at the raw numbers. On the WOT pull I started off the gas and then went immediately WOT. You can see for 2 data sets after going WOT the AFR is still indicating 20 or above from the engine braking. At the end of the run I got off the gas abruptly and went into engine braking. The AFR output did not adjust to show this for many many data sets later. There is a lag to the AFR and its completely variable!

With this in hand I looked back at some numbers I had been chasing. That section of a bit higher then wanted AFR around 6000 rpms actually needed to be adjusted at 5000-5500 rpms. That annoying large lump at 2nd gear at 7,000 rpms actually correlates to the spike in 3rd at 6500 rpms and is actually the APV valve opening at 6250 rpms and needs to be adjusted at 6000-6500 rpms. This is wear tuning leaves science (well simple science and math anyway) and takes on an art.

With that said, my 5th map I adjusted my target to 12.7 and it actually became my final for now!

Goal 4 pretty much complete!!

Up to this point I was treating tuning as a science. I was using purely math. That was my partial undoing for 2 map iterations. While the science gets you close, it’s the touch of an artist that will dial your map completely in. To understand this, look at the raw datalogged numbers.

The RX-8 from factory has the ability to cut all fuel while the engine is under engine braking. Therefore when your off the gas in gear, you see the AFR go to 20 or above. Look at the raw numbers. On the WOT pull I started off the gas and then went immediately WOT. You can see for 2 data sets after going WOT the AFR is still indicating 20 or above from the engine braking. At the end of the run I got off the gas abruptly and went into engine braking. The AFR output did not adjust to show this for many many data sets later. There is a lag to the AFR and its completely variable!

With this in hand I looked back at some numbers I had been chasing. That section of a bit higher then wanted AFR around 6000 rpms actually needed to be adjusted at 5000-5500 rpms. That annoying large lump at 2nd gear at 7,000 rpms actually correlates to the spike in 3rd at 6500 rpms and is actually the APV valve opening at 6250 rpms and needs to be adjusted at 6000-6500 rpms. This is wear tuning leaves science (well simple science and math anyway) and takes on an art.

With that said, my 5th map I adjusted my target to 12.7 and it actually became my final for now!

Goal 4 pretty much complete!!

Last edited by r0tor; 04-11-2009 at 03:36 PM.

#8

OK Lastly I will go over my changes for rev limiters, fan activation, and coolant temps...

For the rev limiters:

I set the "Rev Limit" to 9300

I set the "Warm-up Rev limit ECT Threshold" to 125 def F for valet parking protection

Fan Acitvation:

Fan 1-A to 189 def F

Fan 1-B to 189 deg F (i believe this is the ignition off fan temp)

Fan 2 to 194 deg F

... this is pretty much Racing BEats numbers...

OMP map

I adjusted the map in bands of adding 3 steps to the upper left areas, 4 steps to the middle areas, and up to 5 steps or 60 total steps in the bottom right corner. This provides a large increase of oil in light cruising which is wear my car is normally.... I admit this probably should be reviewed a bit

For the rev limiters:

I set the "Rev Limit" to 9300

I set the "Warm-up Rev limit ECT Threshold" to 125 def F for valet parking protection

Fan Acitvation:

Fan 1-A to 189 def F

Fan 1-B to 189 deg F (i believe this is the ignition off fan temp)

Fan 2 to 194 deg F

... this is pretty much Racing BEats numbers...

OMP map

I adjusted the map in bands of adding 3 steps to the upper left areas, 4 steps to the middle areas, and up to 5 steps or 60 total steps in the bottom right corner. This provides a large increase of oil in light cruising which is wear my car is normally.... I admit this probably should be reviewed a bit

Last edited by r0tor; 04-11-2009 at 03:44 PM.

#9

...ok thats it for now... some grammar checking and stuff to follow at a later date

One last word... this does not really compare with what someone like MM will provide for you in a map of his level. He goes the extra step further to tweak things to increase fuel mileage, increase driveability, changes the throttle mapping... ect ect ect

One last word... this does not really compare with what someone like MM will provide for you in a map of his level. He goes the extra step further to tweak things to increase fuel mileage, increase driveability, changes the throttle mapping... ect ect ect

Last edited by r0tor; 04-11-2009 at 03:57 PM.

#10

Good work Rotor . You put a lot of effort into presenting this for the forum

Something I would like to add - i'm sure you realised this but i did not see you mention it anywhere .

Every time you reflash the pcm you reset the fuel trims to zero . This is why sorting out your fuel trims is so important early on . You may think you have a good tune only to find it goes out the window a few days later if you don't do that step.

Something I would like to add - i'm sure you realised this but i did not see you mention it anywhere .

Every time you reflash the pcm you reset the fuel trims to zero . This is why sorting out your fuel trims is so important early on . You may think you have a good tune only to find it goes out the window a few days later if you don't do that step.

#13

I have been waiting to see somebody do this.

I was thinking that when the time comes to pull my engine, I will pull the injectors and get them flow tested. Did you think about doing that also? I Can't decide on Race Tuner or Pro Tuner.

#14

Good work Rotor . You put a lot of effort into presenting this for the forum

Something I would like to add - i'm sure you realised this but i did not see you mention it anywhere .

Every time you reflash the pcm you reset the fuel trims to zero . This is why sorting out your fuel trims is so important early on . You may think you have a good tune only to find it goes out the window a few days later if you don't do that step.

Something I would like to add - i'm sure you realised this but i did not see you mention it anywhere .

Every time you reflash the pcm you reset the fuel trims to zero . This is why sorting out your fuel trims is so important early on . You may think you have a good tune only to find it goes out the window a few days later if you don't do that step.

#15

If (well more like when...) I yank my engine I'd probably do the same.

As to the products, I don't think you can go wrong with either. The AP is really handy though now that the AP handheld can datalog.

#16

Good stuff - just to add, make note of the mods you have going into this process.... anything that monkeys with the intake means you need to spend extra time on the MAF scale before you do anything else.

#19

Great thread r0tor. Especially appreciate the part regarding the hard to find info on OMP and fan adjustments. I've been grabbing data for a while in prep to tune but this thread will make it even more approachable.

Very well done.

Very well done.

#20

Oh and I should have some lower load and gas mileage tuning tips maybe in a couple weeks or whenever i get time to get all the data together.

.... of course then again "i don't know what i'm doing" so who knows

#21

you can actually go up to 9 steps or so at idle and low load conditions if you really want. My car tended to show some smoke during startup though so it got backed down to 6.

Oh and I should have some lower load and gas mileage tuning tips maybe in a couple weeks or whenever i get time to get all the data together.

.... of course then again "i don't know what i'm doing" so who knows

Oh and I should have some lower load and gas mileage tuning tips maybe in a couple weeks or whenever i get time to get all the data together.

.... of course then again "i don't know what i'm doing" so who knows

If you haven't looked at the stock vs. Cobb economy tunes I might see if I can repeat what you did with divining Cobb's approach to their performance tunes to their approach toward economy tunes. Be a decent test to see what people who really don't know what they're doing can accomplish with your approach.

#22

I havent' had time to asee where I am on my rx8 project, I've done to many WOT runs on each tank to see where my mileage is. But I've been able to add 20% fuel mileage on other vehicles with timing adjustments and fueling adjustments.

Next order of bizzz, I too see blip of smoke at start-up, I'll try to lower the OMP like you suggested, but what is the strategy from switching from Throttle based to load based?

Also, tuning question, I get a lean spot from about 3k to 5.5 k losing about 1 - 1.5 points afr, my table is even the whole way, but my afr always spikes lean there. They look pretty smooth above 6k. Any suggestions on latency tuning, or otherwise advice? I was thinking a simple scaling adjustment of the secondary for more fuel when it opens, which would make me richer when the aux opens, which I would have to lean abit? Any thoughts?

Next order of bizzz, I too see blip of smoke at start-up, I'll try to lower the OMP like you suggested, but what is the strategy from switching from Throttle based to load based?

Also, tuning question, I get a lean spot from about 3k to 5.5 k losing about 1 - 1.5 points afr, my table is even the whole way, but my afr always spikes lean there. They look pretty smooth above 6k. Any suggestions on latency tuning, or otherwise advice? I was thinking a simple scaling adjustment of the secondary for more fuel when it opens, which would make me richer when the aux opens, which I would have to lean abit? Any thoughts?

#23

The afr will be lean below 5.5k as the stock ecu programming remains in closed loop control basically. I haven't played with this, but there is a series of closed loop exit tables you can change (can't remember the exact names without having it in front of me). I believe if you look at them you'll find that below ~5500rpms that the exit load is around 100% and your car probably is not hitting 100% load because of volumetric efficiency issues.

In theory, you should be able to lower the exit load to maybe 80% in that area of the map and your car should slip into open loop control and your AFR will then be less However, you will sacrifice some gas mileage doing that in a daily driver mode.

My theory on the dual MOP maps is its a failsafe against a MAF failure... i just adjusted both maps in a similar fashion.

In theory, you should be able to lower the exit load to maybe 80% in that area of the map and your car should slip into open loop control and your AFR will then be less However, you will sacrifice some gas mileage doing that in a daily driver mode.

My theory on the dual MOP maps is its a failsafe against a MAF failure... i just adjusted both maps in a similar fashion.

#24

I just backtracked some of my thoughts, I am going to fatten up my throttle based fueling in that area to see if it corrects anything. Also noted on cooler days, my VE is >90 at >3k. Which I would expect to be out of CL by that kind of load situation.

I dont' have the OL/CL tables to look at... anyhelp?

Back to the OMP, my values are less than your map already by 3, EXCEPT where the 60 values are, maybe because of CA emmisions... + I can't find the throttle based OMP table...

Your theory on the dual MOP/OMP... I don't know the strategy for certain, I've asked on different occaisions on the THrottle to Load based switching with no definate answers. My theory is similar to an Alpha setup, low load/rpm handle by tables refering to Throttle/RPM VE, and higher values by the MAF based load values. Also akin to a MAF failure backup, the tables would still operate based on THEORETICAL FLOW. Although, my idle is extremely rich without the MAF ( could be caused by the lack of IAT), and driving was a bit off too on AFRs, but driveable.

I dont' have the OL/CL tables to look at... anyhelp?

Back to the OMP, my values are less than your map already by 3, EXCEPT where the 60 values are, maybe because of CA emmisions... + I can't find the throttle based OMP table...

Your theory on the dual MOP/OMP... I don't know the strategy for certain, I've asked on different occaisions on the THrottle to Load based switching with no definate answers. My theory is similar to an Alpha setup, low load/rpm handle by tables refering to Throttle/RPM VE, and higher values by the MAF based load values. Also akin to a MAF failure backup, the tables would still operate based on THEORETICAL FLOW. Although, my idle is extremely rich without the MAF ( could be caused by the lack of IAT), and driving was a bit off too on AFRs, but driveable.

#25

actually, looking at the closed loop exit tables they don't seem to completely explain why it hangs onto open loop until 5500 rpms either unless there is a scaling issue on this map -shrug-

It might actually be this open set of open loop tables though... I don't think the AP logs open vs closed loop condition so i'm not certain at this point.

It might actually be this open set of open loop tables though... I don't think the AP logs open vs closed loop condition so i'm not certain at this point.

Last edited by r0tor; 04-30-2009 at 07:08 PM.