20B must go on

#26

The turbo uses oil for lubrication and coolant for.... cooling.

So you gotta run both.

As for the injectors - normally the injector sits INSIDE the fuel rail and has 1 or two o-ring connections. Then the brakets for the rail bolt to the manifold; and the injectors would still have a bit of wiggle room without leaking fuel. I would didtch those metal tops and run it like a normal fuel rail.

So you gotta run both.

As for the injectors - normally the injector sits INSIDE the fuel rail and has 1 or two o-ring connections. Then the brakets for the rail bolt to the manifold; and the injectors would still have a bit of wiggle room without leaking fuel. I would didtch those metal tops and run it like a normal fuel rail.

#30

Mod/Organizer of DGRRX

Joined: Jul 2003

Posts: 907

Likes: 0

From: Birmingham, AL ... before Cincinnati, OH

Stick,

If you got the cash, i would also highly recommend Mazmart/Rick Engman to build you a proper 20B. If I had the cash, I would get him to build it for me. He's by far most experienced and have built 4 rotor engines for Jim Downing and such. You will not find as qualified 3-4 rotor builders like him in this country.

Regarding some of your questions... All I can say is that since you are starting over, you might start looking at other people's 20B builds. I would NOT use that LIM and also UIM added injectors. I have no clue why Mazsport did that but if he hasn't explained to you then I would just go back to stock 20B LIM and UIM... Also, you might start thinking what kind of power you are shooting for and what purpose you are wanting to do this 20B swap... That would better tell those who know what you should do... Personally, my 20B swap, I'm only shooting for about 600-800RWHP. I'm getting it built, balanced, by my builder who I've personally known for past 5 years.

Another great 3 rotor builder is in Florida. His name is Carlos Lopez. He also built many 3 rotor engines for race cars and such. He also balances rotors and built turbo and NA 3 rotors.

Good luck and if you have any other questions, give me a shout. Also, Gordon Monsen who I've mentioned before have 20B NA FD and he's located in PA somewhere.

If you got the cash, i would also highly recommend Mazmart/Rick Engman to build you a proper 20B. If I had the cash, I would get him to build it for me. He's by far most experienced and have built 4 rotor engines for Jim Downing and such. You will not find as qualified 3-4 rotor builders like him in this country.

Regarding some of your questions... All I can say is that since you are starting over, you might start looking at other people's 20B builds. I would NOT use that LIM and also UIM added injectors. I have no clue why Mazsport did that but if he hasn't explained to you then I would just go back to stock 20B LIM and UIM... Also, you might start thinking what kind of power you are shooting for and what purpose you are wanting to do this 20B swap... That would better tell those who know what you should do... Personally, my 20B swap, I'm only shooting for about 600-800RWHP. I'm getting it built, balanced, by my builder who I've personally known for past 5 years.

Another great 3 rotor builder is in Florida. His name is Carlos Lopez. He also built many 3 rotor engines for race cars and such. He also balances rotors and built turbo and NA 3 rotors.

Good luck and if you have any other questions, give me a shout. Also, Gordon Monsen who I've mentioned before have 20B NA FD and he's located in PA somewhere.

#31

Mod/Organizer of DGRRX

Joined: Jul 2003

Posts: 907

Likes: 0

From: Birmingham, AL ... before Cincinnati, OH

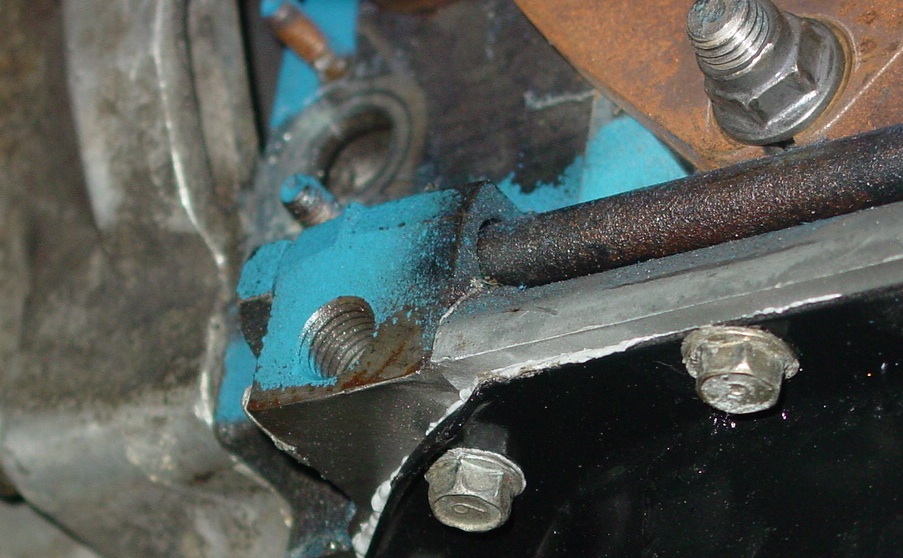

about the first photo.

#1 will have fabricated adapter connected to remote filter housing

#2 is engine oil fill hole. about #2, some people install vacuum ports here, what's the reason behind it? is this where i would install the oil catch can?

#3 are these water lines for the heater? seems to be running with brake lines, so i was curious.

and where is the power steering pump located in the rx8?

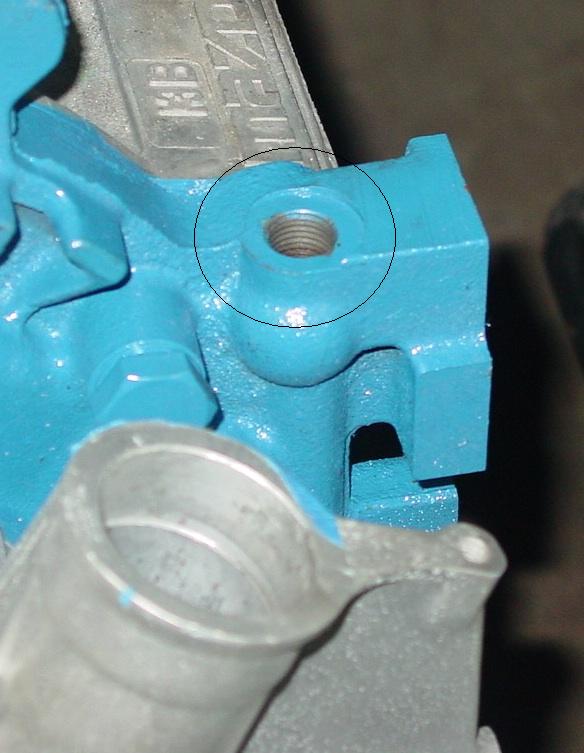

as for the second picture,

what do you guys recommend I use to hook up these injector ports? they have no threads or anything.

thanks!

#1 will have fabricated adapter connected to remote filter housing

#2 is engine oil fill hole. about #2, some people install vacuum ports here, what's the reason behind it? is this where i would install the oil catch can?

#3 are these water lines for the heater? seems to be running with brake lines, so i was curious.

and where is the power steering pump located in the rx8?

as for the second picture,

what do you guys recommend I use to hook up these injector ports? they have no threads or anything.

thanks!

#2 - Its not a vac. port.. you could add your oil cat can.

#3 - Those are your fuel line. You might also have to set up a return line for your fuel system.

2nd pic - I would go back to stock 20B set up and get a custom fuel rails for the 20B. I don't like how Mazsport made this and not sure how they were planning to run it.

#32

Mod/Organizer of DGRRX

Joined: Jul 2003

Posts: 907

Likes: 0

From: Birmingham, AL ... before Cincinnati, OH

NO!!! even though turbo is water cooled... main cooling comes from the oil. YOU would have to run OIL to the turbos!! which means, you should use the inlet and return oil lines to the turbo.

#33

Mod/Organizer of DGRRX

Joined: Jul 2003

Posts: 907

Likes: 0

From: Birmingham, AL ... before Cincinnati, OH

I would high suggest you use both primary and secondary injectors.

Also, WOW, that LIM looks like a chop shop job!!! I would NOT use that LIM...

#34

Ok Stick im game. First things first. Dont worrie about the little things like what injectors your gona use. You gotta mount your engine and tranny then build off of that. I didnt see any pics of any mounts, just a hole to put the beast in. I have an easy way for you to mount the motor and tranny and do it lower then you planned or anyone planned. Itl make it easy to get it in and out and give you lots more room for goodies. Do it like we did in this beast

http://www.youtube.com/watch?v=E2ung98buGc

Its a solid piece of aluminum plate 3/8 thick. You drill it out so all the bolt holes line up on the motor, sounds like more work but trust me, itl take you an afternoon to fit the motor to it and it doubles as a tranny brace. Plus your gona have the center of gravity under the axels. Ill look under an 8 at the shop and find you some good bolting points for the unibody. Dont worrie about rebuilding your engine yet, just try to make everything fit first. That way if you get somthing in it you dont freak out since its gona come appart anyway. Next thing is your driveshaft, but mount your motor first. If you want I can ask cam if he wants to sell the one we made for the GT car, if not or if he wants to much money I can make a templet for ya.

http://www.youtube.com/watch?v=E2ung98buGc

Its a solid piece of aluminum plate 3/8 thick. You drill it out so all the bolt holes line up on the motor, sounds like more work but trust me, itl take you an afternoon to fit the motor to it and it doubles as a tranny brace. Plus your gona have the center of gravity under the axels. Ill look under an 8 at the shop and find you some good bolting points for the unibody. Dont worrie about rebuilding your engine yet, just try to make everything fit first. That way if you get somthing in it you dont freak out since its gona come appart anyway. Next thing is your driveshaft, but mount your motor first. If you want I can ask cam if he wants to sell the one we made for the GT car, if not or if he wants to much money I can make a templet for ya.

#35

The reason I say itl only take you an afternoon is I just did a 2 rotor version for the guy who bought the car before we shipped it to south america 2 weeks ago and still also have the plate for the 3 rotor, acualy we still have the perif port motor but im sure you wouldnt want to buy it cause Cam wont sell it so he says but everything is for sale if you now what I meen.

#37

Also you can plug that oil fill hole, if your going with the plate and just have a can for oil and go dry sump. Man, your gona have alot of room, might want to think about putting in some goodies like a blower

#38

as for converting you gas pedal to mech i have had to do do this with my swap. i just bought a firewall mount billet pedal from lokar with a 4ft stainless braided and teflon coated cable. remove the old gas pedal assembly, you get to use the top hole of the lokar pedal into one of the old bolt holes with a 10mm bolt. i welded another bolt to the floor right under the existing one and if fits perfect with the factory pedals. as for the cable just pop a 3/8" hole in the firewall and hook it up.. if you need pics just let me know

#41

Ok, talked to Cam, he said he would let the plate go for $300. You said you have the motor and Tranny. I put some thought into how you should set the motor. You bolt the motor and tranny to the plate less drive shaft. Put stuff on like pullys and the things that might get in the way such as the intake, maybe the altinator and crap like that. Set the assembly under the car in the general area but on the floor. Ok, this is were your gona need to go slow and take your time. Lower the car over the top of the engine till you sit it on the ground, keep in mind you need to lift it back up off. Use shims like concrete squares that you would use for a sidwalk at home depot. Adjust your plate and motor as needed, the key is go slow. Once you have the body on the ground and your motor in the exact spot were you want it, figure out were you need to trim the plate. Lift the car back off if you need to trim parts off of the plate that dont allow the car to sit flat on the ground. Ok, once you do that fab up parts that bolt to points like wear your old motor mounts were and the tranny cross brace. Find atleast 6 points to tie the plate into. Build the mounts strong for odvios reasons.

#42

Last edited by Renesis_8; 09-11-2011 at 03:55 PM.

#46

wow thanks guys. I just read everything! Kane/HB, thanks for answering my questions. In retrospect, I admit some were just purely idiotic questions  , but you've all been really nice. Moon, thanks again for your help. I'm interested, but I first need to figure out how much everything else would cost for the dry-sump conversion before I proceed. I imagine I would need a new front iron and few other supporting hardwares or at the least some connection to the oil pick-up.

, but you've all been really nice. Moon, thanks again for your help. I'm interested, but I first need to figure out how much everything else would cost for the dry-sump conversion before I proceed. I imagine I would need a new front iron and few other supporting hardwares or at the least some connection to the oil pick-up.

Good news! My Haltech E11v2 just shipped from California today. If I get it by this weekend, I'll start connecting the wires. M&W units should be coming any day now.

btw, Moon, I should have some answers for you by this weekend.

, but you've all been really nice. Moon, thanks again for your help. I'm interested, but I first need to figure out how much everything else would cost for the dry-sump conversion before I proceed. I imagine I would need a new front iron and few other supporting hardwares or at the least some connection to the oil pick-up.

, but you've all been really nice. Moon, thanks again for your help. I'm interested, but I first need to figure out how much everything else would cost for the dry-sump conversion before I proceed. I imagine I would need a new front iron and few other supporting hardwares or at the least some connection to the oil pick-up.Good news! My Haltech E11v2 just shipped from California today. If I get it by this weekend, I'll start connecting the wires. M&W units should be coming any day now.

btw, Moon, I should have some answers for you by this weekend.

#47

as for converting you gas pedal to mech i have had to do do this with my swap. i just bought a firewall mount billet pedal from lokar with a 4ft stainless braided and teflon coated cable. remove the old gas pedal assembly, you get to use the top hole of the lokar pedal into one of the old bolt holes with a 10mm bolt. i welded another bolt to the floor right under the existing one and if fits perfect with the factory pedals. as for the cable just pop a 3/8" hole in the firewall and hook it up.. if you need pics just let me know

thanks!!

please feel free to post your pics here.

#49

The problem is the engine is so far back that your fuel rail and primaries might not fit without some mods...

Last edited by angeljoelv; 10-22-2008 at 10:39 PM.