The 450whp Renesis engine - why it will never happen - theory

#126

I don't agree that porting gains nothing.. i would argue, flow can be doubled when the choke points (corners on the inside of the port) are eliminated. Thos choke points half the effective flow area of the exhaust port.

Additionally, supercharger eliminates the back pressure thus allowing much higher flow through the port.

I still owe you the math we mention in the 400whp pmp gas topic .... No its not negligible. And the power draw of a good SC is very simmilar to the power draw of a turbo due to back pressure.

A modern centrifugal SC on a ProMod will make the same power as turbo at the same boost (with some margin on "same")

Additionally, supercharger eliminates the back pressure thus allowing much higher flow through the port.

I still owe you the math we mention in the 400whp pmp gas topic .... No its not negligible. And the power draw of a good SC is very simmilar to the power draw of a turbo due to back pressure.

A modern centrifugal SC on a ProMod will make the same power as turbo at the same boost (with some margin on "same")

#127

@MincVinyl i dont think its the port opening area, i think its the flow capacity of the exhaust runners due to the very sharp corners creating choke point (at high flow velocity the can more than halv the effective flow area)

Another thing we have a problem with is the ignition.. an inductive ignition is great for low rpm where the arc duration is beneficial to be longer to make sure all is ignited, but on high rpm, this is not good. A discharge takes 1.5-2mS.. a full cycle takes 6.6mS at redline (9k rpm)... This means the spark plug is burning for 120deg...

A CDI ignition discharges in 0.2-0.3mS which is much more precise / concentrated and thus better ignition is achieved.

On 4T engines this comes in to effect at MUCH larger cylinder pressures since the speed is much slower and combustion is easier on the piston engine and the air fuel mixture is more turbulent thus the flame front spreads faster .

Another thing we have a problem with is the ignition.. an inductive ignition is great for low rpm where the arc duration is beneficial to be longer to make sure all is ignited, but on high rpm, this is not good. A discharge takes 1.5-2mS.. a full cycle takes 6.6mS at redline (9k rpm)... This means the spark plug is burning for 120deg...

A CDI ignition discharges in 0.2-0.3mS which is much more precise / concentrated and thus better ignition is achieved.

On 4T engines this comes in to effect at MUCH larger cylinder pressures since the speed is much slower and combustion is easier on the piston engine and the air fuel mixture is more turbulent thus the flame front spreads faster .

#128

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

I don't agree that porting gains nothing.. i would argue, flow can be doubled when the choke points (corners on the inside of the port) are eliminated. Thos choke points half the effective flow area of the exhaust port.

Additionally, supercharger eliminates the back pressure thus allowing much higher flow through the port.

I still owe you the math we mention in the 400whp pmp gas topic .... No its not negligible. And the power draw of a good SC is very simmilar to the power draw of a turbo due to back pressure.

A modern centrifugal SC on a ProMod will make the same power as turbo at the same boost (with some margin on "same")

Additionally, supercharger eliminates the back pressure thus allowing much higher flow through the port.

I still owe you the math we mention in the 400whp pmp gas topic .... No its not negligible. And the power draw of a good SC is very simmilar to the power draw of a turbo due to back pressure.

A modern centrifugal SC on a ProMod will make the same power as turbo at the same boost (with some margin on "same")

The day you make 400whp at 14psi with an Eshaft driven SC is the day I'll believe you!

#129

@Brettus That is question of money for me, and not technical possibility. Also not everything is accessible

Also as you know your self, its not the Psi, its the g/s

As I can than easily bring Greddy kit in as a reference claiming a turbo cant make 400 whp at 14psi.

Double the WHP is not double the engine power as drivetrain losses are not a fixed % (loss through driven gear pairs is, parasitic losses are not), the more power the less is lost on parasitic loads..

You are comparing the latest gen of turbocharger to what ever knowledge is there about superchargers. Latest gen being 15y old (on roots, even more on screw type, I dont like centrifugal way of power delivery, which is only good for drag) and the latest gens havent been used in aftermarket. Only cars that run them and have projects with them are the one they came factory with them.

For the rest, there are less projects all out than there is hybrid renesis builds.

Give some lower boost level like 8-10 psi where we can compare as I cant build a 14psi engine for at least 2 years.. over here I cant have almost any engine mods and its impossible to make them legal so a "track" only car that cant be registered is a very expensive experiment just to prove my point..

I do plan to build a high psi capable engine but that is far.. atm im stuck on f'in lowering springs for 1 year that my car is not street legal...

Petit one had 270hp on 8psi with severally undersized AWIC capacity, and that SC is 30y old design

Also as you know your self, its not the Psi, its the g/s

As I can than easily bring Greddy kit in as a reference claiming a turbo cant make 400 whp at 14psi.

Double the WHP is not double the engine power as drivetrain losses are not a fixed % (loss through driven gear pairs is, parasitic losses are not), the more power the less is lost on parasitic loads..

You are comparing the latest gen of turbocharger to what ever knowledge is there about superchargers. Latest gen being 15y old (on roots, even more on screw type, I dont like centrifugal way of power delivery, which is only good for drag) and the latest gens havent been used in aftermarket. Only cars that run them and have projects with them are the one they came factory with them.

For the rest, there are less projects all out than there is hybrid renesis builds.

Give some lower boost level like 8-10 psi where we can compare as I cant build a 14psi engine for at least 2 years.. over here I cant have almost any engine mods and its impossible to make them legal so a "track" only car that cant be registered is a very expensive experiment just to prove my point..

I do plan to build a high psi capable engine but that is far.. atm im stuck on f'in lowering springs for 1 year that my car is not street legal...

Petit one had 270hp on 8psi with severally undersized AWIC capacity, and that SC is 30y old design

Last edited by MilosB; 11-02-2024 at 02:22 PM.

#130

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

Give some lower boost level like 8-10 psi where we can compare as I cant build a 14psi engine for at least 2 years.. over here I cant have almost any engine mods and its impossible to make them legal so a "track" only car that cant be registered is a very expensive experiment just to prove my point..

Kinda feels like you want to argue with me about everything lately - mostly about things you don't have any actual experience with. Time for you to front up and put your theories into practice...IMHO!

#131

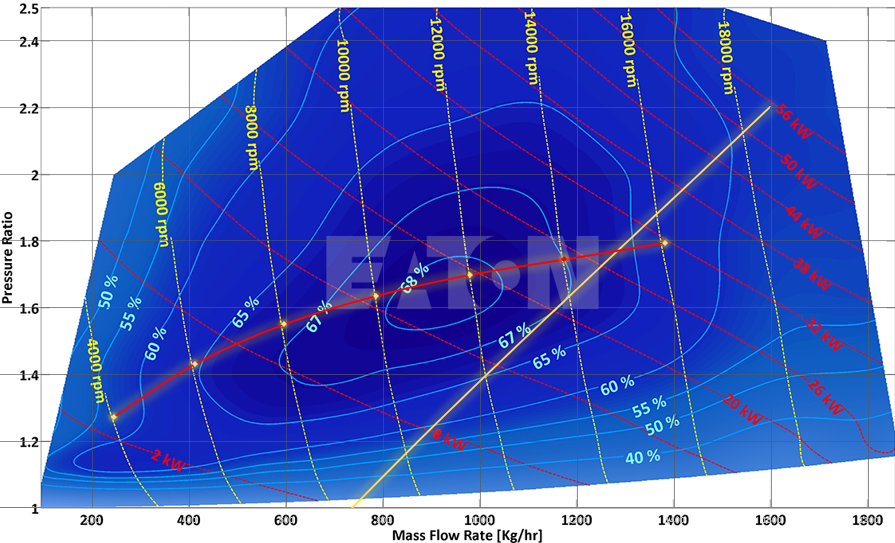

(diagonal yellow line is 8500 engine rpm depending on drive ratio)

Also have built many piston turbo race engines (petrol and diesel alike).. My understanding of turbos is very sound and so is the working principle of an engine, how power is generated and how much backpressure influences the power and efficiency of an engine. Internal temperatures of combustion chamber through the cycle ect...

High boost pressure has 2 consequences:

- work needed to be done to exhaust at emap =2bar instead of emap = 1.2bar... for NA

- "egr" .. 2x the mass of air will remain in the chamber meaning less available for next charge resulting in higher boost for same MAF assuming equal intercooling capacity (assuming emap=2)

power (kW) = Work * times/s

at 8ooorpm = 133 revs /s = 35kW for turbo, 21kW...NA .. Thus at least 14kW is lost for driving the turbine. in practice it is more as that low Drive/compression ratio is perfect by all means and usually results in much later boosting turbo than you have,.. lets not forget @ciprianrx8 who had 3. something ratios (emap >3 bar) which meant it took 32kW of power to drive the turbocharger

2.) for a CR of 10:1 in best case with emap = 1.2 12% of the engine volume mass will be occupied with "EGR" gasses. for emap=2bar, 20% volume mass of the engine will be EGR.. resulting that for same boost of 1bar (to keep it simple calcs) you can squeeze in 94% of engine volume mass on SC and 90% of volume mass on a turbo with emap=2 meaning that you efectivelly have 4% more mass of air to burn on the SC...

I hope you can understand this math and logic and/or correct me where I am wrong. these are just simple thermodynamics and work related formulae.. My idea is not to fight, but to show other options and perhaps correct where I think others are wrong.

#132

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

Why do you think that? For target boost for 12psi ish max (it depends on the VE of the engine, mass flow is the input of the SC unlike turbochargers) at 8.5k rpm The power draw of the SC at 4000 rpm for example is only 8kW and makes 8PSi of boost (assuming 95% VE) the SC is suppling 375g/s of air.at 8500 rpm and draw 26kW at that boost level. this is roughly what I am building for, though, it will be limited to 10 psi initially with throttle.

(diagonal yellow line is 8500 engine rpm depending on drive ratio)

where am I arguing with you ?

Also have built many piston turbo race engines (petrol and diesel alike).. My understanding of turbos is very sound and so is the working principle of an engine, how power is generated and how much backpressure influences the power and efficiency of an engine. Internal temperatures of combustion chamber through the cycle ect...

High boost pressure has 2 consequences:

power (kW) = Work * times/s

at 8ooorpm = 133 revs /s = 35kW for turbo, 21kW...NA .. Thus at least 14kW is lost for driving the turbine. in practice it is more as that low Drive/compression ratio is perfect by all means and usually results in much later boosting turbo than you have,.. lets not forget @ciprianrx8 who had 3. something ratios (emap >3 bar) which meant it took 32kW of power to drive the turbocharger

2.) for a CR of 10:1 in best case with emap = 1.2 12% of the engine volume mass will be occupied with "EGR" gasses. for emap=2bar, 20% volume mass of the engine will be EGR.. resulting that for same boost of 1bar (to keep it simple calcs) you can squeeze in 94% of engine volume mass on SC and 90% of volume mass on a turbo with emap=2 meaning that you efectivelly have 4% more mass of air to burn on the SC...

I hope you can understand this math and logic and/or correct me where I am wrong. these are just simple thermodynamics and work related formulae.. My idea is not to fight, but to show other options and perhaps correct where I think others are wrong.

(diagonal yellow line is 8500 engine rpm depending on drive ratio)

where am I arguing with you ?

Also have built many piston turbo race engines (petrol and diesel alike).. My understanding of turbos is very sound and so is the working principle of an engine, how power is generated and how much backpressure influences the power and efficiency of an engine. Internal temperatures of combustion chamber through the cycle ect...

High boost pressure has 2 consequences:

- work needed to be done to exhaust at emap =2bar instead of emap = 1.2bar... for NA

- "egr" .. 2x the mass of air will remain in the chamber meaning less available for next charge resulting in higher boost for same MAF assuming equal intercooling capacity (assuming emap=2)

power (kW) = Work * times/s

at 8ooorpm = 133 revs /s = 35kW for turbo, 21kW...NA .. Thus at least 14kW is lost for driving the turbine. in practice it is more as that low Drive/compression ratio is perfect by all means and usually results in much later boosting turbo than you have,.. lets not forget @ciprianrx8 who had 3. something ratios (emap >3 bar) which meant it took 32kW of power to drive the turbocharger

2.) for a CR of 10:1 in best case with emap = 1.2 12% of the engine volume mass will be occupied with "EGR" gasses. for emap=2bar, 20% volume mass of the engine will be EGR.. resulting that for same boost of 1bar (to keep it simple calcs) you can squeeze in 94% of engine volume mass on SC and 90% of volume mass on a turbo with emap=2 meaning that you efectivelly have 4% more mass of air to burn on the SC...

I hope you can understand this math and logic and/or correct me where I am wrong. these are just simple thermodynamics and work related formulae.. My idea is not to fight, but to show other options and perhaps correct where I think others are wrong.

So while the turbo is 10psi@4000 with backpressure at around 7psi a SC is likely at what ...... 6ish psi? Don't need to do any maths on that .... the SC will pale by comparison. Not even remotely close.

And my apologies for assuming you don't have experience. I should have qualified that by saying; with a Renesis.

Re the maths: maths is good where you have accurate data that supports reality. I'm pretty sure you don't have that in this case. What actually happens WRT the internal pressures vs EMAP may not even be close to matching what your maths is showing.

Again ...put in the work, get it running, then come back and tell me I'm wrong once you have actually tested it.

The following users liked this post:

tnt116 (11-02-2024)

#133

Again, for SC you target mass flow and not boost.

Boost is just a consequence as how restrictive the intake is and I have to chose a drive ratio. I rather have to choke the throttle than order a new custom pulley for 1/2mm diference..

.. if I change VE from 0.9 to 0.95 to 1 the boost changes. Its in a principle a constant displacement pump. Same as an engine oil pump. Flow is constant (provided intake air is constant density) and pressure is the result...

For a 10psi cap I can spin the SC harder like plotted and close the throttle and it will reduce power consumption by the SC and than I can have boost sooner. As it is plotted, just not going up to 12psi same way that you regulate your turbo with a boost controller.

The efficiency of the SC wont go down to much with lower intake density unlike a centrifugal compressor/supercharger.

The drive pressure/work will be that no matter what engine it js.. it is simple conservative of energy. It doesnt take same work to exhaust to different external pressures.

You can give me few points along the rpm emap (NA and Turbo/boost) and than its simple math and we can compare it against compressor which is very well known data as EATON is an OEM supplier.

Boost is just a consequence as how restrictive the intake is and I have to chose a drive ratio. I rather have to choke the throttle than order a new custom pulley for 1/2mm diference..

.. if I change VE from 0.9 to 0.95 to 1 the boost changes. Its in a principle a constant displacement pump. Same as an engine oil pump. Flow is constant (provided intake air is constant density) and pressure is the result...

For a 10psi cap I can spin the SC harder like plotted and close the throttle and it will reduce power consumption by the SC and than I can have boost sooner. As it is plotted, just not going up to 12psi same way that you regulate your turbo with a boost controller.

The efficiency of the SC wont go down to much with lower intake density unlike a centrifugal compressor/supercharger.

The drive pressure/work will be that no matter what engine it js.. it is simple conservative of energy. It doesnt take same work to exhaust to different external pressures.

You can give me few points along the rpm emap (NA and Turbo/boost) and than its simple math and we can compare it against compressor which is very well known data as EATON is an OEM supplier.

Last edited by MilosB; 11-03-2024 at 02:26 AM.

#134

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

The best way would be to have a clutch on the SC that allows variable speed- does such a thing exist?

Last edited by Brettus; 11-03-2024 at 03:10 PM.

#135

On a roots/screw type SC the throttle is pre SC , thus jt will lower the intake density thus at same rpm it will produce less mass flow.

#139

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

So .... taking that into consideration ... what boost would we need the turbo to be at, as a fair comparison?

I could set it for around 20psi at 4000rpm tapering down to 10psi at the redline if I wanted to prove a point - but that seems a bit silly.

I could set it for around 20psi at 4000rpm tapering down to 10psi at the redline if I wanted to prove a point - but that seems a bit silly.

#140

But you can set a boost as that is the input for a turbo, you can do whatever you want with it with just few pushes of a button. I have to machine a different drive pulley to get a different settings so only thing I can make is to "cap" the max by some boost control (same as you do, as you dont rely on the spring in WG to control the boost level but you have a 4 port boost controller. That brings the boost in much sooner than a pure mechanical one would be. Dont understand the argument here.

I can only set volume flow. Inset it "high" with medium VE of 0.95 (just checked it)'.. if VE=1 than its 10.5psi at 8700 rpm or to be more precise ... These should be the targets with VE=1 and a 1.85 drive ratio (which it should be if I measured the water pump drive pulley correctly)

g/s-psi@rpm (rpm is odd numbers as it is against supercharger speeds)

70-3.5@2161

117-5.6@3242

168-7.2@4324

220-8.4@5405

274-9.2@6486

328-9.8@7568

386-10.5@8649

VE effects total mass flow as the chart compensates for temperature of the charge air and efficiency based on P.R.

I can only set volume flow. Inset it "high" with medium VE of 0.95 (just checked it)'.. if VE=1 than its 10.5psi at 8700 rpm or to be more precise ... These should be the targets with VE=1 and a 1.85 drive ratio (which it should be if I measured the water pump drive pulley correctly)

g/s-psi@rpm (rpm is odd numbers as it is against supercharger speeds)

70-3.5@2161

117-5.6@3242

168-7.2@4324

220-8.4@5405

274-9.2@6486

328-9.8@7568

386-10.5@8649

VE effects total mass flow as the chart compensates for temperature of the charge air and efficiency based on P.R.

Last edited by MilosB; 11-03-2024 at 05:20 PM.

#141

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,609

Likes: 1,536

From: Y-cat-o NZ

Well - the argument as I understood it was about whether a turbo has free energy available to it, implying that it would make more power than a crank driven SC at any given rpm/boost level.

We got sidetracked on torque at low rpm and you mentioned how you would gimp it at high rpm to get the torque up at low rpm so I suggested I could manipulate a turbo as well - without gimping the top end.

So if we get back to the original argument ........ then we would have to compare them both at the same boost level before you start closing the throttle (ie before gimping the efficiency).

Sound about right?

We got sidetracked on torque at low rpm and you mentioned how you would gimp it at high rpm to get the torque up at low rpm so I suggested I could manipulate a turbo as well - without gimping the top end.

So if we get back to the original argument ........ then we would have to compare them both at the same boost level before you start closing the throttle (ie before gimping the efficiency).

Sound about right?

#142

The gimping is only to protect the engine. Not as a comparison of anything. That Is why I gave all the data. And we will be able to compare them once I actually measure the boost in the engine  as VE as you can see impacts it significantly. Not MAF that much .

as VE as you can see impacts it significantly. Not MAF that much .

as VE as you can see impacts it significantly. Not MAF that much .

as VE as you can see impacts it significantly. Not MAF that much .

The following users liked this post:

MilosB (11-03-2024)

Thread

Thread Starter

Forum

Replies

Last Post