9krpmrx8's Boost Build Thread

#1

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

UPDATED 12/26/14

First off I want to thank all of my SARX crew but especially Hoss-05, for the countless hours of hard work and help during this build. Without these friends, this would not have been possible.

Okay, so my build is essentially done with the exception of finishing tuning and some odds and ends. It has been a long haul and I have learned a lot, so learn from my stubbornness. If you are lazy and half-*** it then don't cry when **** goes wrong. If you try and cheap out please understand there are huge drawbacks ( I know from first hand experience). There are a million ways to skin a cat, so there is no "right" way really to turbocharge an RX-8 but try and come up with a plan that covers everything and stick to it.

I went ahead and did an engine install at the same time since I had a bad coolant seal in my mazda reman with only 30k on it. I went with a ported 2008 engine from www.pineappleracing.com. It also had heavy duty coolant seals and stage 2 oil mods. Rob @ Pineapple is the man.

Read all of the threads in the major horsepower section regarding the Greddy turbo kit (Greddy fixes, getting the most out of the Greddy kit, Greddy FAQ, etc) and read some Greddy build threads (Brettus, MM, Gregs, Kane, etc.). There are many opinions about almost every aspect of this kit so take the time to read and understand all the issues relating to turbo charging an RX-8 using the Greddy kit. Then decide what the car will be used for, how long you plan on keeping it, how dedicated you are to it, and what power output is acceptable to you. It gets expensive. Then if you are serious, take a look at your car and determine if it is ready to be turbocharged. Is your engine healthy (consuming oil at a normal rate, good compression, etc.) and in proper running order? Do you have all the appropriate supporting mods (that may or may not be needed) like an upgraded fuel pump, fuel injectors, ignition, cooling, engine mounts, exhaust, etc.? Stuff can add up quick so having a head start on these things before pulling the trigger on a turbo kit can be very helpful.

The Turbo:

The Greddy T618Z is a journal bearing, oil cooled only Mitsubishi hybrid unit and will not allow you to make a ton of power out of the box on an RX-8. You can either have it rebuilt as is for around $350.00 and enjoy 260WHP or so if tuned right, or if you want more power, you can upgrade it.

The upgrades available typically add a water cooled center section (should double the life if the Turbo) and a larger compressor wheel and turbine wheel. I highly recommend Bryan at BNR (http://bnrsupercars.com/) since he has done a ton of the Greddy T618Z upgrades for the RX-8 and his service is reported to be top notch. His 60-1 option with his custom wastegate actuator just makes sense in every way. If I could go back I would do that.

My turbo was first rebuilt by AMR but they did not fully understand the RX-8 and the space constraints that the turbo would be installed in. So while they did a great job of rebuilding and upgrading the turbo I had problems fitting it in a position where the oil feed. oil drain, and coolant lines for the turbo were positioned correctly. I tried to work around this and failed. Then I sent my turbo and manifold (so they could fit it on a Renesis to make sure fitment was right) to Turdblown who said they would rebuild my already upgraded turbo, add a billet compressor wheel, and fab up hard lines for the coolant lines on the turbo so that they would clear the manifold, etc. I got my turbo and manifold back (from Comp Turbo in Cali, not Turblown) two months later (much longer than originally quoted) rebuilt and it had the billet compressor wheel installed, but with no hard lines fabricated. So I then had to find and hire a machinist, remove some freeze plugs in the turbo (thanks Houstonrx8er and Shadycrew31 for finding a solution) and have the machinist thread some ports to get the coolant line fittings situated correctly. So basically I was screwed, I paid Turdblown $900.00 to send my turbo to Comp so they could slap on a Billet compressor wheel.

In the end I have what I think to be a great turbo but at a cost of around $1700.00 between what I paid AMR and Turblown, plus what I spent on fittings, hoses, scavenge pumps, and a machinist which puts me close to $2100.00 or so. I could have just sent the turbo to BNR in the first place and had a properly rebuilt, upgraded, and clocked turbo and saved $1,000.00. FML. You can have any reputable turbo builder do the work but just make sure they know exactly how it will sit on the manifold in relation to the Renesis engine so that the oil drain and coolant lines fit properly. And make sure the turbo gets balanced (not all turbo shops have the expensive tools to do this). Update: After I got the turbo back from Comp/Turdblown it lasted about 10,000 miles before it failed. I had it rebuilt locally by majestic Turbo in Waco, Texas and they could not have been better.

Larger billet aluminum wheel from Comp:

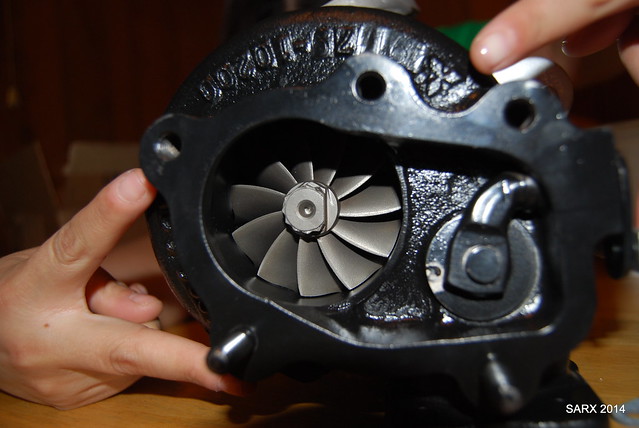

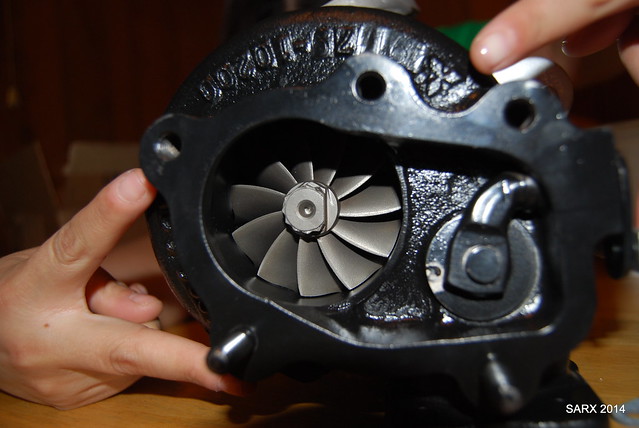

Larger 11 blade Turbine from AMR:

Proper coolant fittings on the correct side of the turbo (not pointing towards the engine and hitting the manifold) from SARX:

Boost Control:

A Electronic Boost controller is ideal according to most reputable tuners. Most here use the Greddy Profec II electronic boost controller. I am running the HKS EVC-S and love it.

I also fabricated and designed a new wastegate actuator setup using parts from ATP and then sent everything to ATP and they refined the designed and after a few trips back and forth this was the final result and works perfectly. Contact me if interested.

Turbo oil pressure regulator setup that I designed and put together. It has built in flow control and pressure regulation and returns to the sump via the lower part of the oil filler neck. It is integrated into our oil filter relocation kit that uses high quality push lock AN fittings and push lock braided hose.

Blow off valve/Diverter Valve:

I am running the Synapse DV, I love it.

Manifold and Downpipe:

You can use the Greddy manifold and DP or pay to have a custom DP and manifold made but whether or not that is worth depends on a few things and is still debatable. So unless you are going all out with a custom kit then just get the Greddy units ceramic coated and call it a day. I also recommend getting all new hardware (class 10.9 metric or better) unless you are dealing with a new Greddy kit with new hardware. IMO, some port matching of the gasket to the manifold where the turbo bolts to the manifold is needed to get it port matched correctly but that is optional. Banging the area of the frame around the DP is recommended by me to free up some room in that area. Proper heat shielding (iconel, lavamat, etc.) is also recommended to protect the frame from the turbo.

Piping and couplers:

The Greddy couplers and clamps are marginal at best so high quality silicone couplers and clamps are recommended. I personally prefer worm gear clamps over T bolt clamps but wiggens clamps would be best if you are a baller. The Greddy piping fits pretty good and no upgrades in pipe size are needed if you are using the Greddy turbo, manifold, etc. But some gasket matching/porting is needed at the turbo inlet and outlet to get things smoothed out and matched up properly. You will need to have a fitting welded on the intake pipe to the turbo for the blow off recirculation (necessary on a MAF equipped car) and you will need a flange welded on the C6 (throttle body pipe) for the blow off valve you choose. The Greddy MAF housing and filter place the filter in the engine bay which is not ideal so it is common to fab your own intake using a Mazdaspeed or AEM intake MAF housing like I did. I also have a 3.5” pipe routed outside of the engine bay and I am using a WIX paper filter from a Turbocharged GM Ecotec. IMO, the intake piping should be wrapped in DEI cool tape or some type of heat barrier too. In addition I also think a catch can is needed and I went with a simple one from Jegs.

Intake pipe with filter (powedercoated black):

Tray, coolant reservoir, stand alone coolant reservoir for turbo cooling circuit and SOHN reservoir:

Recirc fitting on turbo inlet pipe:

Before gasket matching and porting:

After gasket matching and porting:

Compared to a BNR 60-1

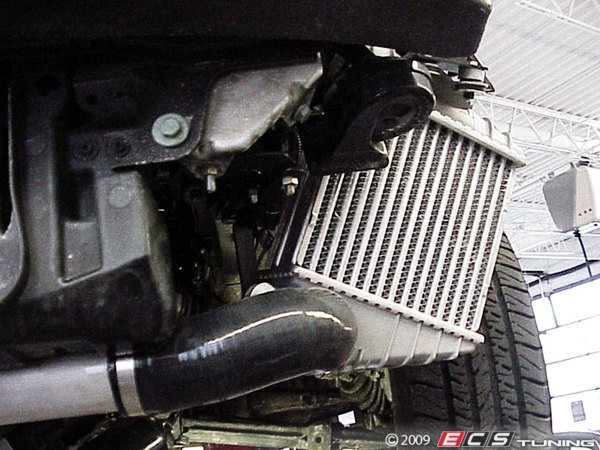

Intercooler:

The Greddy intercooler has a good end tank design and is properly sized. I don’t think any upgrades are needed.

ECU/Engine management:

I am using the Cobb AP and my car was wonderfully tuned by Steve Kan at PRT Performance.

Ignition/Fuel/Spark:

I am using the BHR fuel pump and Ignition. I am running stock RE9BT in the trailing and leading locations.

Hoses and fittings:

I am using high temp silicone heater hose (can't remember brand) for the turbo coolant lines with female JIC Parker Push Lock fittings and male JIC fitting at the Turbo. I am using a braided SS -4an line for the oil feed line with a 0.65 ATP restrictor (I have increased oil pressure in my engine) and the drain line is an ATP high temp silicone oil drain hose connected to the Greddy oil drain pipe and then I have a push lock female JIC fitting on the other end of the hose and male JIC fitting welded to the oil pan. Make sure you get the fitting welded in the correct place as the hose needs a nice path down to the pan to drain properly.

For vacuum hose you can use good Gates or Good Year vacuum hose (not fuel hose, not heater hose, etc.) or if you feel like spending you can get good double walled silicone vacuum hose like what is used in the Hose Candy kits, not the shitty single wall flimsy stuff from NAPA. Makes sure you zip tie all vacuum hoses. You will also need a hose (usually 1”) for blow off valve recirculation.

Oil Drain:

Engine Mounts:

I had my stock mounts filled with 80A urethane. It turned out great.

Cooling:

I am running a Mizu dual core aluminum radiator with a dual FAL fan setup and a Derale secondary cooler with built in fan mounted in the stock passenger side oil cooler location for engine coolant. For oil I am running -10AN custom Parker Push Lock hose, Push Lock JIC fittings, 180F oil thermostat (Mocal or earl's is nice), OEM drivers side oil cooler with the thermostat removed, and a custom secondary 19 row oil cooler mounted in front of the radiator and AC condenser.

Mizu Dual Pass:

I am running the FAL 420 puller (2500CFM). The 480 will work and is 3000CFM and reversible and comes with the controller and will fit as well even though the fan motors are taller.

Derale Secondary w/puller fan:

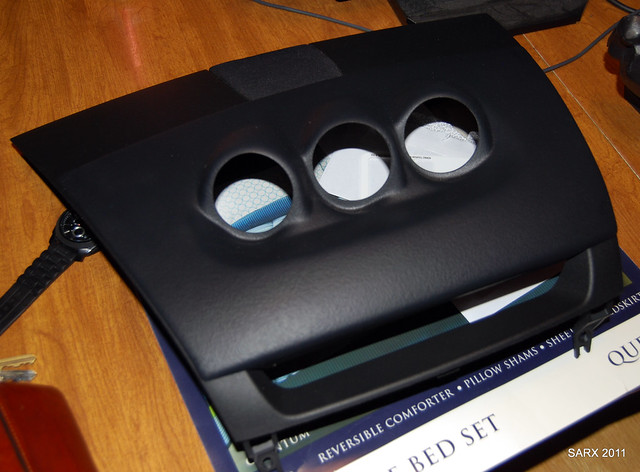

Gauges:

I have the dual vent gauge pod by blockhead8, Lotek triple gauge pod, and the Good Box. I have Prosport premium 52mm oil pressure, fuel pressure, oil temp, and the 52mm PLX multigauge which will run AFR, secondary boost, EGT, and IAT. The last gauge spot in the Lotek will likely go to voltage. The good box is for OBD-II data and boost as well. Then of course I also have the Cobb AP.

Dual pod:

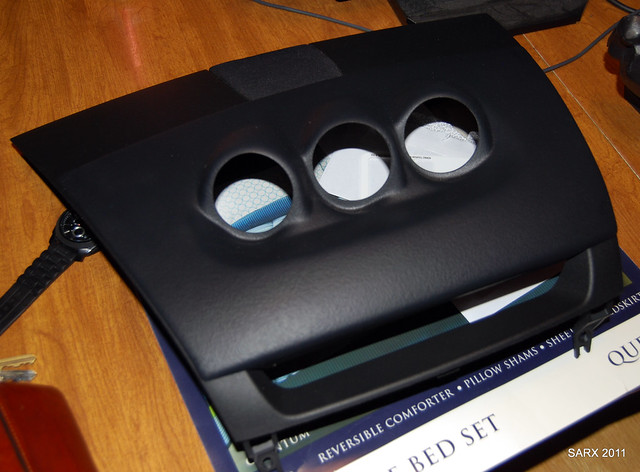

Lotek:

Goodbox

PLX 52mm Multi:

Stage 8 locking nut system for turbo to manifold

First off I want to thank all of my SARX crew but especially Hoss-05, for the countless hours of hard work and help during this build. Without these friends, this would not have been possible.

Okay, so my build is essentially done with the exception of finishing tuning and some odds and ends. It has been a long haul and I have learned a lot, so learn from my stubbornness. If you are lazy and half-*** it then don't cry when **** goes wrong. If you try and cheap out please understand there are huge drawbacks ( I know from first hand experience). There are a million ways to skin a cat, so there is no "right" way really to turbocharge an RX-8 but try and come up with a plan that covers everything and stick to it.

I went ahead and did an engine install at the same time since I had a bad coolant seal in my mazda reman with only 30k on it. I went with a ported 2008 engine from www.pineappleracing.com. It also had heavy duty coolant seals and stage 2 oil mods. Rob @ Pineapple is the man.

Read all of the threads in the major horsepower section regarding the Greddy turbo kit (Greddy fixes, getting the most out of the Greddy kit, Greddy FAQ, etc) and read some Greddy build threads (Brettus, MM, Gregs, Kane, etc.). There are many opinions about almost every aspect of this kit so take the time to read and understand all the issues relating to turbo charging an RX-8 using the Greddy kit. Then decide what the car will be used for, how long you plan on keeping it, how dedicated you are to it, and what power output is acceptable to you. It gets expensive. Then if you are serious, take a look at your car and determine if it is ready to be turbocharged. Is your engine healthy (consuming oil at a normal rate, good compression, etc.) and in proper running order? Do you have all the appropriate supporting mods (that may or may not be needed) like an upgraded fuel pump, fuel injectors, ignition, cooling, engine mounts, exhaust, etc.? Stuff can add up quick so having a head start on these things before pulling the trigger on a turbo kit can be very helpful.

The Turbo:

The Greddy T618Z is a journal bearing, oil cooled only Mitsubishi hybrid unit and will not allow you to make a ton of power out of the box on an RX-8. You can either have it rebuilt as is for around $350.00 and enjoy 260WHP or so if tuned right, or if you want more power, you can upgrade it.

The upgrades available typically add a water cooled center section (should double the life if the Turbo) and a larger compressor wheel and turbine wheel. I highly recommend Bryan at BNR (http://bnrsupercars.com/) since he has done a ton of the Greddy T618Z upgrades for the RX-8 and his service is reported to be top notch. His 60-1 option with his custom wastegate actuator just makes sense in every way. If I could go back I would do that.

My turbo was first rebuilt by AMR but they did not fully understand the RX-8 and the space constraints that the turbo would be installed in. So while they did a great job of rebuilding and upgrading the turbo I had problems fitting it in a position where the oil feed. oil drain, and coolant lines for the turbo were positioned correctly. I tried to work around this and failed. Then I sent my turbo and manifold (so they could fit it on a Renesis to make sure fitment was right) to Turdblown who said they would rebuild my already upgraded turbo, add a billet compressor wheel, and fab up hard lines for the coolant lines on the turbo so that they would clear the manifold, etc. I got my turbo and manifold back (from Comp Turbo in Cali, not Turblown) two months later (much longer than originally quoted) rebuilt and it had the billet compressor wheel installed, but with no hard lines fabricated. So I then had to find and hire a machinist, remove some freeze plugs in the turbo (thanks Houstonrx8er and Shadycrew31 for finding a solution) and have the machinist thread some ports to get the coolant line fittings situated correctly. So basically I was screwed, I paid Turdblown $900.00 to send my turbo to Comp so they could slap on a Billet compressor wheel.

In the end I have what I think to be a great turbo but at a cost of around $1700.00 between what I paid AMR and Turblown, plus what I spent on fittings, hoses, scavenge pumps, and a machinist which puts me close to $2100.00 or so. I could have just sent the turbo to BNR in the first place and had a properly rebuilt, upgraded, and clocked turbo and saved $1,000.00. FML. You can have any reputable turbo builder do the work but just make sure they know exactly how it will sit on the manifold in relation to the Renesis engine so that the oil drain and coolant lines fit properly. And make sure the turbo gets balanced (not all turbo shops have the expensive tools to do this). Update: After I got the turbo back from Comp/Turdblown it lasted about 10,000 miles before it failed. I had it rebuilt locally by majestic Turbo in Waco, Texas and they could not have been better.

Larger billet aluminum wheel from Comp:

Larger 11 blade Turbine from AMR:

Proper coolant fittings on the correct side of the turbo (not pointing towards the engine and hitting the manifold) from SARX:

Boost Control:

A Electronic Boost controller is ideal according to most reputable tuners. Most here use the Greddy Profec II electronic boost controller. I am running the HKS EVC-S and love it.

I also fabricated and designed a new wastegate actuator setup using parts from ATP and then sent everything to ATP and they refined the designed and after a few trips back and forth this was the final result and works perfectly. Contact me if interested.

Turbo oil pressure regulator setup that I designed and put together. It has built in flow control and pressure regulation and returns to the sump via the lower part of the oil filler neck. It is integrated into our oil filter relocation kit that uses high quality push lock AN fittings and push lock braided hose.

Blow off valve/Diverter Valve:

I am running the Synapse DV, I love it.

Manifold and Downpipe:

You can use the Greddy manifold and DP or pay to have a custom DP and manifold made but whether or not that is worth depends on a few things and is still debatable. So unless you are going all out with a custom kit then just get the Greddy units ceramic coated and call it a day. I also recommend getting all new hardware (class 10.9 metric or better) unless you are dealing with a new Greddy kit with new hardware. IMO, some port matching of the gasket to the manifold where the turbo bolts to the manifold is needed to get it port matched correctly but that is optional. Banging the area of the frame around the DP is recommended by me to free up some room in that area. Proper heat shielding (iconel, lavamat, etc.) is also recommended to protect the frame from the turbo.

Piping and couplers:

The Greddy couplers and clamps are marginal at best so high quality silicone couplers and clamps are recommended. I personally prefer worm gear clamps over T bolt clamps but wiggens clamps would be best if you are a baller. The Greddy piping fits pretty good and no upgrades in pipe size are needed if you are using the Greddy turbo, manifold, etc. But some gasket matching/porting is needed at the turbo inlet and outlet to get things smoothed out and matched up properly. You will need to have a fitting welded on the intake pipe to the turbo for the blow off recirculation (necessary on a MAF equipped car) and you will need a flange welded on the C6 (throttle body pipe) for the blow off valve you choose. The Greddy MAF housing and filter place the filter in the engine bay which is not ideal so it is common to fab your own intake using a Mazdaspeed or AEM intake MAF housing like I did. I also have a 3.5” pipe routed outside of the engine bay and I am using a WIX paper filter from a Turbocharged GM Ecotec. IMO, the intake piping should be wrapped in DEI cool tape or some type of heat barrier too. In addition I also think a catch can is needed and I went with a simple one from Jegs.

Intake pipe with filter (powedercoated black):

Tray, coolant reservoir, stand alone coolant reservoir for turbo cooling circuit and SOHN reservoir:

Recirc fitting on turbo inlet pipe:

Before gasket matching and porting:

After gasket matching and porting:

Compared to a BNR 60-1

Intercooler:

The Greddy intercooler has a good end tank design and is properly sized. I don’t think any upgrades are needed.

ECU/Engine management:

I am using the Cobb AP and my car was wonderfully tuned by Steve Kan at PRT Performance.

Ignition/Fuel/Spark:

I am using the BHR fuel pump and Ignition. I am running stock RE9BT in the trailing and leading locations.

Hoses and fittings:

I am using high temp silicone heater hose (can't remember brand) for the turbo coolant lines with female JIC Parker Push Lock fittings and male JIC fitting at the Turbo. I am using a braided SS -4an line for the oil feed line with a 0.65 ATP restrictor (I have increased oil pressure in my engine) and the drain line is an ATP high temp silicone oil drain hose connected to the Greddy oil drain pipe and then I have a push lock female JIC fitting on the other end of the hose and male JIC fitting welded to the oil pan. Make sure you get the fitting welded in the correct place as the hose needs a nice path down to the pan to drain properly.

For vacuum hose you can use good Gates or Good Year vacuum hose (not fuel hose, not heater hose, etc.) or if you feel like spending you can get good double walled silicone vacuum hose like what is used in the Hose Candy kits, not the shitty single wall flimsy stuff from NAPA. Makes sure you zip tie all vacuum hoses. You will also need a hose (usually 1”) for blow off valve recirculation.

Oil Drain:

Engine Mounts:

I had my stock mounts filled with 80A urethane. It turned out great.

Cooling:

I am running a Mizu dual core aluminum radiator with a dual FAL fan setup and a Derale secondary cooler with built in fan mounted in the stock passenger side oil cooler location for engine coolant. For oil I am running -10AN custom Parker Push Lock hose, Push Lock JIC fittings, 180F oil thermostat (Mocal or earl's is nice), OEM drivers side oil cooler with the thermostat removed, and a custom secondary 19 row oil cooler mounted in front of the radiator and AC condenser.

Mizu Dual Pass:

I am running the FAL 420 puller (2500CFM). The 480 will work and is 3000CFM and reversible and comes with the controller and will fit as well even though the fan motors are taller.

Derale Secondary w/puller fan:

Gauges:

I have the dual vent gauge pod by blockhead8, Lotek triple gauge pod, and the Good Box. I have Prosport premium 52mm oil pressure, fuel pressure, oil temp, and the 52mm PLX multigauge which will run AFR, secondary boost, EGT, and IAT. The last gauge spot in the Lotek will likely go to voltage. The good box is for OBD-II data and boost as well. Then of course I also have the Cobb AP.

Dual pod:

Lotek:

Goodbox

PLX 52mm Multi:

Stage 8 locking nut system for turbo to manifold

Last edited by 9krpmrx8; 03-27-2015 at 12:03 AM.

#7

Roof mounted with a roof scoop. Stay classy. edit: ^^Is an intercooler really something you want to make low profile? Don't you want the most airflow and surface area you can get?

Last edited by J8635621; 04-04-2011 at 12:11 PM.

#8

that wouldnt be bad, just run the two smaller ones, would definitely have a unique look to it provided they fit properly as well as are able to properly cool, dont know why they wouldnt be able to

#11

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

yeah something with less cooling capacity would be no bueno.

yeah something with less cooling capacity would be no bueno.Thanks I will look at it's specs.

Yeah and i bet they can cool plenty. 8 maniac has an Audi S4 with bigger turbos, etc. and they use the same style corner inter coolers.

#12

Yes. Aboot bloody time

I don't think a low profile intercooler will be bad, provided it does the job.

Good luck with this build 9k! Keeping both of my eyes on it, for near future reference

I don't think a low profile intercooler will be bad, provided it does the job.

Good luck with this build 9k! Keeping both of my eyes on it, for near future reference

#14

Didn't Pettit make something like that? I remember seeing it in the Pettit Supercharger Owners thread a loooong time ago. It may have been a second radiator instead. I think there was some discussion about that not being too effective with 110* temps on a black asphalt road. I'm no expert

Last edited by J8635621; 04-04-2011 at 12:33 PM.

#16

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

Didn't Pettit make something like that? I remember seeing it in the Pettit Supercharger Owners thread a loooong time ago. It may have been a second radiator instead. I think there was some discussion about that not being too effective with 110* temps on a black asphalt road. I'm no expert

#19

#21

1st of all--you are going to have to change your name to 8krpm!

1- That is how I have my secondary radiator mounted now--works well. You oil cooler would do ok like that.

2- You can stack the coolers and still have plenty of air flow. Mount your intercooler up front of the front support beam and your oil cooler behind the support beam. 2nd radiators could be in the oem oil cooler spots. Actually with a little plumbing the oil coolers can be turned into secondary radiators themselves.

3- you could always go with an air water intercooler. Each has its plus's and minus's

Welcome to the craziness.

PM me anytime if I can help.

OD

1- That is how I have my secondary radiator mounted now--works well. You oil cooler would do ok like that.

2- You can stack the coolers and still have plenty of air flow. Mount your intercooler up front of the front support beam and your oil cooler behind the support beam. 2nd radiators could be in the oem oil cooler spots. Actually with a little plumbing the oil coolers can be turned into secondary radiators themselves.

3- you could always go with an air water intercooler. Each has its plus's and minus's

Welcome to the craziness.

PM me anytime if I can help.

OD