FI Discussion Thread for the Boost Atheists

#152

Well, it's been a few days since I drove the car, but to reiterate what I typed in the other thread: My guage(Autometer) shows@5lbs and gradually increases to @8lbs @8k rpms. I have been told that a guage can be off 1-2lbs based on the weather, which means I could actually have @6-9lbs. I'll be right back w/ my other questions.

At 7000 feet, you will lose several pounds of boost and you will lose one pound for every two inches of mercury the barometer drops.

Because that is the torque peak, so that is the point where the blower should be optimized. That is the point at which the engine will ingest the most air per revolution.

#155

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

I wanted to discuss what would be a properly sized "blower" for our cars, but then I realized even if we could eventually come to some sort of agreement, it wouldn't help those of us who have allready invested in a kit.

#157

Well, there are several problems, some of which I've outlined before.

First, the Lysholm (twin-screw) is only available in a few distinct sizes, so you are forced to select one that is "close enough" in displacement. Typically, especially because of the next point, you go too big rather than too small.

Second, the operational RPM range of a twin-screw is limited. You can only spin it so slow or so fast before you go outside its efficiency band.

These points make it difficult to pick one for the rotary because the "dynamic range" of the motor exceeds that of any potential twin-screw candidate.

So, you select what you want to do and then you shoot for that range.

First, the Lysholm (twin-screw) is only available in a few distinct sizes, so you are forced to select one that is "close enough" in displacement. Typically, especially because of the next point, you go too big rather than too small.

Second, the operational RPM range of a twin-screw is limited. You can only spin it so slow or so fast before you go outside its efficiency band.

These points make it difficult to pick one for the rotary because the "dynamic range" of the motor exceeds that of any potential twin-screw candidate.

So, you select what you want to do and then you shoot for that range.

#158

6200 on an N/A motor. That's one of the interesting points of the "comparison" thread - you can see how various systems have moved the peak up or down the RPM band. Or, in the case of the Pettit, leave it right where it was.

#159

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

Well, there are several problems, some of which I've outlined before.

First, the Lysholm (twin-screw) is only available in a few distinct sizes, so you are forced to select one that is "close enough" in displacement. Typically, especially because of the next point, you go too big rather than too small.

Second, the operational RPM range of a twin-screw is limited. You can only spin it so slow or so fast before you go outside its efficiency band.

These points make it difficult to pick one for the rotary because the "dynamic range" of the motor exceeds that of any potential twin-screw candidate.

So, you select what you want to do and then you shoot for that range.

First, the Lysholm (twin-screw) is only available in a few distinct sizes, so you are forced to select one that is "close enough" in displacement. Typically, especially because of the next point, you go too big rather than too small.

Second, the operational RPM range of a twin-screw is limited. You can only spin it so slow or so fast before you go outside its efficiency band.

These points make it difficult to pick one for the rotary because the "dynamic range" of the motor exceeds that of any potential twin-screw candidate.

So, you select what you want to do and then you shoot for that range.

#161

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

I think that Lysholm recommends 15k as the maximum for the same reason performance shops tune their customer cars conservatively.

I have it on good authority that our blowers can safely turn upwards of 20k+.

I have it on good authority that our blowers can safely turn upwards of 20k+.

#162

Hmm. Lysholm says you can turn that blower safely to 13.5k. 15k is the design maximum. I don't think it makes much sense to spin it past the design maximum.

And, as I said earlier, it very quickly runs out of its peak adiabatic efficiency.

You will actually flow less air at high RPMs as it heats the air up and lowers its density. Mass makes power. PSI sells kits.

And, as I said earlier, it very quickly runs out of its peak adiabatic efficiency.

You will actually flow less air at high RPMs as it heats the air up and lowers its density. Mass makes power. PSI sells kits.

Last edited by MazdaManiac; 12-26-2007 at 10:42 PM.

#164

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

Hmm. Lysholm says you can turn that blower safely to 12k. 15k is the design maximum. I don't think it makes much sense to spin it past the design maximum.

And, as I said earlier, it very quickly runs out of its peak adiabatic efficiency.

You will actually flow less air at high RPMs as it heats the air up and lowers its density. Mass makes power. PSI sells kits.

And, as I said earlier, it very quickly runs out of its peak adiabatic efficiency.

You will actually flow less air at high RPMs as it heats the air up and lowers its density. Mass makes power. PSI sells kits.

#165

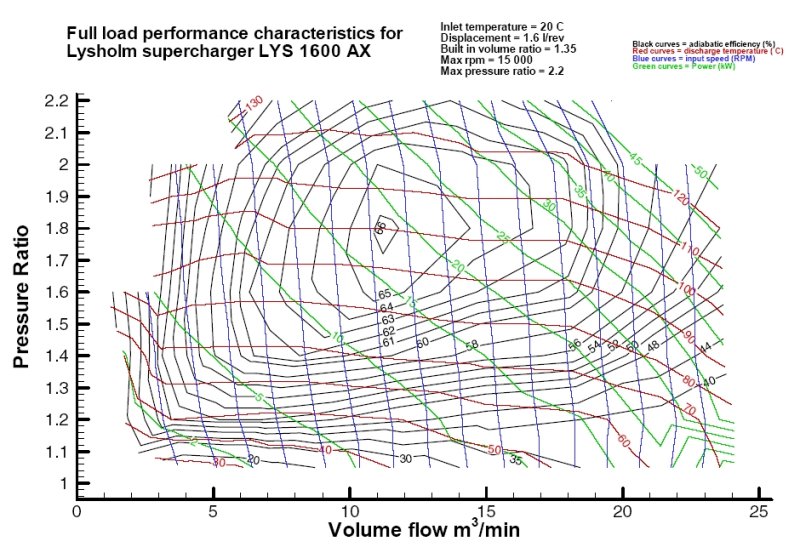

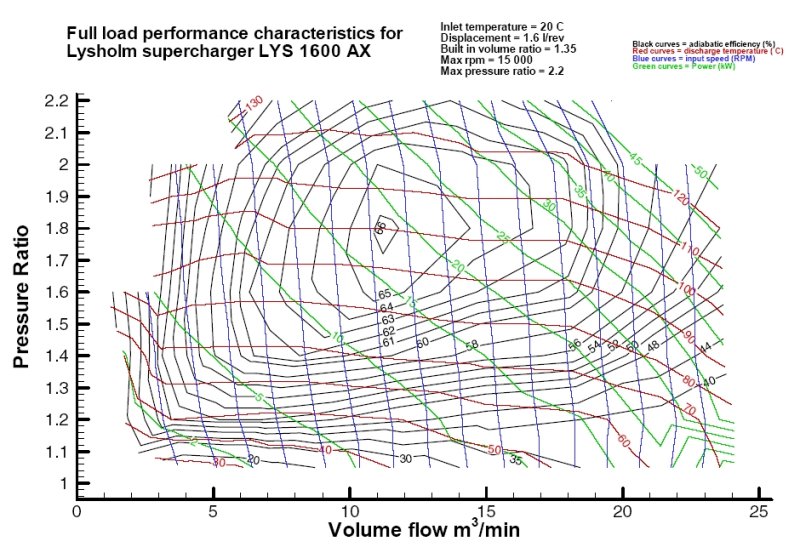

Here is the flow map for the Pettit blower:

As you can see, even if you did spin it out to 15k (where it will begin to fail), you'll be dumping more than 45 HP into it just to keep it spinning and the adiabatic efficiency (which was only 66% at peak, more than 10% less than a turbo) will have dropped to 54% - around the efficiency of a Roots-type.

And that's just to maintain 8 PSI!

I mean mass - the actual way we determine the power generated by FI.

You might be familiar with CFM. If you multiply 0.0765 times CFM, you will get pounds - but only a room temperature at sea level.

As soon as you start to heat the air, you might still be flowing X CFM, but the mass will drop and mass is how we make power.

Cooling the blower isn't the problem. Its inertia. The insides of the blower have a fixed mass and the faster you spin it, the higher the harmonic partials go until you reach a resonant frequency and *boom*. Something fails catastrophically.

As you can see, even if you did spin it out to 15k (where it will begin to fail), you'll be dumping more than 45 HP into it just to keep it spinning and the adiabatic efficiency (which was only 66% at peak, more than 10% less than a turbo) will have dropped to 54% - around the efficiency of a Roots-type.

And that's just to maintain 8 PSI!

You might be familiar with CFM. If you multiply 0.0765 times CFM, you will get pounds - but only a room temperature at sea level.

As soon as you start to heat the air, you might still be flowing X CFM, but the mass will drop and mass is how we make power.

Cooling the blower isn't the problem. Its inertia. The insides of the blower have a fixed mass and the faster you spin it, the higher the harmonic partials go until you reach a resonant frequency and *boom*. Something fails catastrophically.

Last edited by MazdaManiac; 12-26-2007 at 11:11 PM.

#166

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

MM, would you mind telling us what rpm you would recommend spinning the blower at(for the street) based on the above chart?

I think I know how to read it, but it would help if you could explain in reference to the chart.

I think I know how to read it, but it would help if you could explain in reference to the chart.

#167

Sorry, I put up the wrong map. The right one is up there now. 15k is the RPM limit.

Mechanically. it will probably do 17k, but thats about it.

But for the same reasons, you don't want to do it.

The blower is at peak efficiency at 8 PSI an 12 m^3/min, which is 423 CFM which is 32 pounds of air at STP.

That is just about the air requirement of the Renesis at 7600 RPM and a PR of 1.8.

Mechanically. it will probably do 17k, but thats about it.

But for the same reasons, you don't want to do it.

The blower is at peak efficiency at 8 PSI an 12 m^3/min, which is 423 CFM which is 32 pounds of air at STP.

That is just about the air requirement of the Renesis at 7600 RPM and a PR of 1.8.

Last edited by MazdaManiac; 12-26-2007 at 11:18 PM.

#170

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

MM, the chart does show the blower losing efficiency above 12k rpm, but is it taking into account the effects of an intercooler, or aftercooler??

Also, are not the rotors dynamically balanced when the supercharger is built??

Also, are not the rotors dynamically balanced when the supercharger is built??

#171

An intercooler won't make the blower more efficient, it just reduces the charge temperature. If the mass isn't there, it just isn't there.

It doesn't "loose efficiency" above 12k, it flat out nose-dives.

Positive displacement blowers are designed to work in their efficiency range and that is about it. If it is properly sized and matched to the motor, it will only be asked to do so.

The blowers are, of course, balanced extremely well. If they were not, they would come apart well below 5k RPM.

The Renesis is very well balanced, but you can't spin it at twice its design limit RPM.

It doesn't "loose efficiency" above 12k, it flat out nose-dives.

Positive displacement blowers are designed to work in their efficiency range and that is about it. If it is properly sized and matched to the motor, it will only be asked to do so.

The blowers are, of course, balanced extremely well. If they were not, they would come apart well below 5k RPM.

The Renesis is very well balanced, but you can't spin it at twice its design limit RPM.

#172

Registered User

Join Date: Jun 2002

Location: Misinformation Director - Evolv Chicago

Posts: 3,086

Likes: 0

Received 0 Likes

on

0 Posts

Here is the flow map for the Pettit blower:

As you can see, even if you did spin it out to 15k (where it will begin to fail), you'll be dumping more than 45 HP into it just to keep it spinning and the adiabatic efficiency (which was only 66% at peak, more than 10% less than a turbo) will have dropped to 54% - around the efficiency of a Roots-type.

And that's just to maintain 8 PSI!

As you can see, even if you did spin it out to 15k (where it will begin to fail), you'll be dumping more than 45 HP into it just to keep it spinning and the adiabatic efficiency (which was only 66% at peak, more than 10% less than a turbo) will have dropped to 54% - around the efficiency of a Roots-type.

And that's just to maintain 8 PSI!

And Gen V Eaton/Magnuson units have the same efficiency as above. And the Gen VI, 4 lobe units, now peak into the mid 70s.

The Lysholm engineers I've spoken with recommended not going anywhere near redline on their models and instead to be smart and upsize...less rpm = less stress on bearings, less NVH issues, etc (I know you know all this having stated you've had SCd cars)...also, to run an oil feed in near all situations. I'm sure most of that advice was just them covering their ***, but some merits to what they were saying I would guess also applies...

edit: the Gen VI units are 4 lobe, not 6...

Last edited by Red Devil; 01-03-2008 at 09:31 AM.

#173

Registered User

Join Date: Jun 2002

Location: Misinformation Director - Evolv Chicago

Posts: 3,086

Likes: 0

Received 0 Likes

on

0 Posts

Then, at some point a while later it was announced, or leaked they were going with a larger unit...

#174

Dongbag extrordinare

Join Date: Nov 2004

Location: Away from the fruits of my labor

Posts: 1,090

Likes: 0

Received 0 Likes

on

0 Posts

Mass??

All of the other lysholm charts show volumetric efficiency. For some reason the 1.6 doesn't.

Doesn't the fact that the blower is still moving @90+ percent of its size in air above the recommended rpms tell us that more power can be made above 15k rpms??

Doesn't the fact that the blower is still moving @90+ percent of its size in air above the recommended rpms tell us that more power can be made above 15k rpms??

#175

Registered User

Join Date: Jun 2002

Location: Misinformation Director - Evolv Chicago

Posts: 3,086

Likes: 0

Received 0 Likes

on

0 Posts

If you're looking for an accurate compressor map to really figure out what you can do, I'd suggest contacting Pettit and asking for the correct map, or even just the size SC so you can go to Autorotor and get the map directly from them. Kenne Bell also distributes Autorotor and you may be able to get the map there.