Fuel Delivery Lag

#1

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

Fuel Delivery Lag

Hey guys,

Hoping some people can chime in with some ideas on what I am seeing on my data logs. First a little bit of background:

- Greddy Turbo kit

- HKS SSQV BOV (VTA)

- Rx8 Performance CAI

- GReddy Profec Bspec II EBC

- Stock Fuel Injectors

- Deatschwerks DW200 Fuel Pump

- Pre-mix 6-8 oz of Idemitsu Rotary Premix in each tank

I recently installed my new Rx8 Performance intake and GReddy EBC. After installing these I got a complete re-tune done by that beauty Mr. BRETTSPEED. Everything is running excellent with the new mods apart from one thing; this was noticed during some logging while attempting to home in my EBC settings.

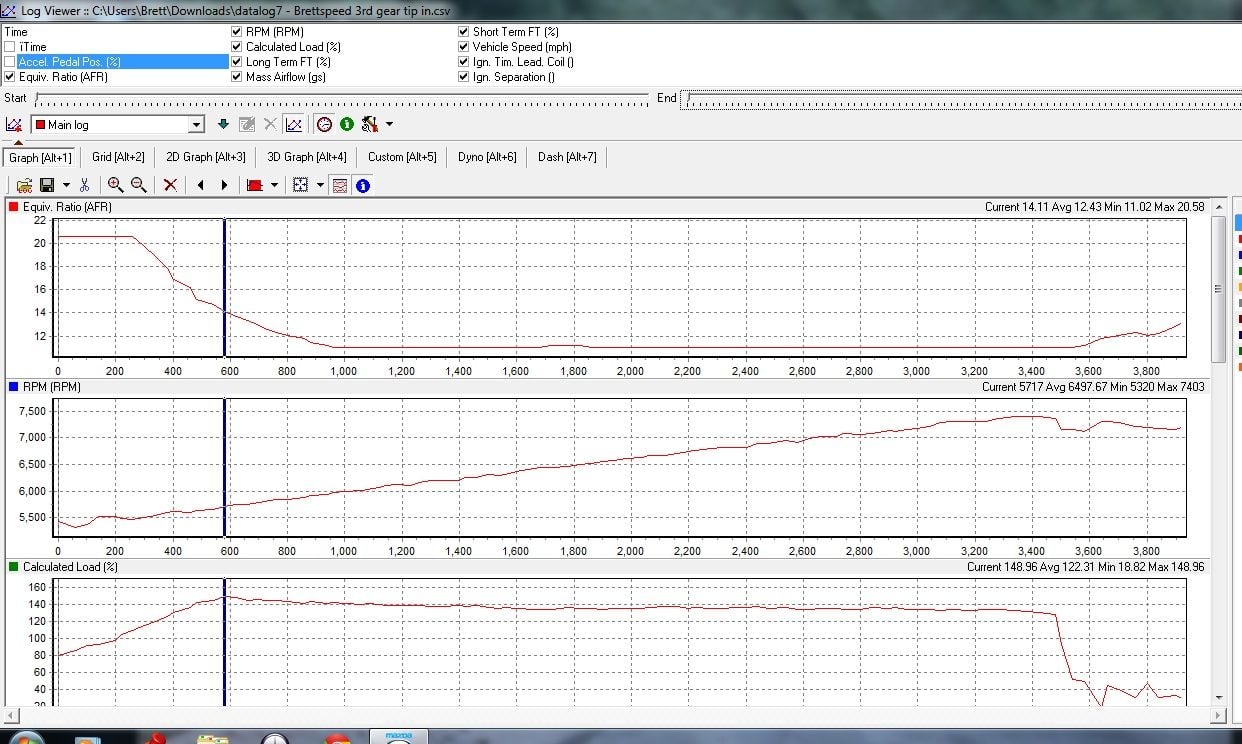

From a coast when I press down my accelerator to WOT and my turbo spools up I am seeing loads and MAF increase as expected, but my AFR's do not start decreasing to a safe rich value until about 1+ seconds after the throttle has been depressed to 99%. In some cases I am seeing loads of over 100% while still seeing AFR's in the 20's!

My first initial thought was that this must be a tuning issue, but chatting with Brett and having him review multiple datalogs using multiple tunes (dug out an old MM tune I had from back in 2011 and did a datalog to find the same issue occurring) I think we have reasonable information to eliminate this as a tuning issue.

My next thought is that maybe my injectors are sticking causing this delay in fuel delivery. To add to this as a note; currently on my fuel pressure gauge at idle I see about 56psi (seems low to me but I've seen this same pressure using 3 different fuel pumps) and when I go WOT I see it drop to a worst case low of about 52psi. Could be related to this but I don't believe it would be because once my AFR's drop they hold right to redline.

Any thoughts out there as to what could be causing this 1 second delay in fuel delivery? I have attached a 3rd gear datalog showing this delay as well. This log was taken with my EBC off and running a max 6psi of boost off the stock Greddy actuator.

Hoping some people can chime in with some ideas on what I am seeing on my data logs. First a little bit of background:

- Greddy Turbo kit

- HKS SSQV BOV (VTA)

- Rx8 Performance CAI

- GReddy Profec Bspec II EBC

- Stock Fuel Injectors

- Deatschwerks DW200 Fuel Pump

- Pre-mix 6-8 oz of Idemitsu Rotary Premix in each tank

I recently installed my new Rx8 Performance intake and GReddy EBC. After installing these I got a complete re-tune done by that beauty Mr. BRETTSPEED. Everything is running excellent with the new mods apart from one thing; this was noticed during some logging while attempting to home in my EBC settings.

From a coast when I press down my accelerator to WOT and my turbo spools up I am seeing loads and MAF increase as expected, but my AFR's do not start decreasing to a safe rich value until about 1+ seconds after the throttle has been depressed to 99%. In some cases I am seeing loads of over 100% while still seeing AFR's in the 20's!

My first initial thought was that this must be a tuning issue, but chatting with Brett and having him review multiple datalogs using multiple tunes (dug out an old MM tune I had from back in 2011 and did a datalog to find the same issue occurring) I think we have reasonable information to eliminate this as a tuning issue.

My next thought is that maybe my injectors are sticking causing this delay in fuel delivery. To add to this as a note; currently on my fuel pressure gauge at idle I see about 56psi (seems low to me but I've seen this same pressure using 3 different fuel pumps) and when I go WOT I see it drop to a worst case low of about 52psi. Could be related to this but I don't believe it would be because once my AFR's drop they hold right to redline.

Any thoughts out there as to what could be causing this 1 second delay in fuel delivery? I have attached a 3rd gear datalog showing this delay as well. This log was taken with my EBC off and running a max 6psi of boost off the stock Greddy actuator.

Last edited by RotaryMachineRx; 06-25-2015 at 07:55 PM.

#3

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

Not sure on fuel temps, no gauge, but it is a stock fuel system (other than pump) on a stock greddy kit in a cool climate, typical weather on nice days are anywhere between 75f - 90f with an average of 82f. My typical steady state coolant temp sits around 181f to 195f, I REALLY have to try hard to break 200f coolant temps unless I bag it hard then stop and let all that heat soak in on an above average hot day.... I'd say the car has never in it's life seen coolant temps of above 205f.

Don't have an oil temp gauge, again for same reasons above.

Edit: Fuel filter and fuel pump assembly have all been replaced in the last year with brand new ones.... fuel pressure did not change from original assembly/filter

Don't have an oil temp gauge, again for same reasons above.

Edit: Fuel filter and fuel pump assembly have all been replaced in the last year with brand new ones.... fuel pressure did not change from original assembly/filter

Last edited by RotaryMachineRx; 06-25-2015 at 07:50 PM.

#5

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

One more tidbit I will also add to original post.... I premix every tank with 6-8 oz of Idemitsu Rotary Premix. I used to dump it into the tank before filling but now I always try to fill about half then add premix before topping tank off.

#6

I wonder if it could be connected to the fuel pulsation damper on the fuel rail ................

If when the accelerator was pressed and the second stage of the fuel pump kicks in there was a surge in pressure that was causing a faulty damper to suddenly bottom out .......maybe

If when the accelerator was pressed and the second stage of the fuel pump kicks in there was a surge in pressure that was causing a faulty damper to suddenly bottom out .......maybe

Last edited by Brettus; 06-25-2015 at 10:19 PM.

#7

Do you have a second wideband? does it drop as soon as you hit the throttle? I've been doing some recent testing with throttle fuel maps, and I could see instant drop on my LC1 wideband, but the accessport has about a 0.6 second delay. You log looks a lot like that.

Last edited by logalinipoo; 06-26-2015 at 02:48 AM.

#8

The pulsation damper is for fuel injectors opening/closing. There is no "surge in pressure" because the relief is at the pump, plus he states that it drops some. If anything it may need a higher flowing fuel pump. 56 psig @ idle is normal for an OE fuel pump.

The Cobb AP is not the best logging tool due to it's limited processing power. There is quite a bit of variance. Run a log with only a few data streams vs many and you will see how far apart and varied the data is as it gets up high in the rpm range. Even the same line of data on a log is not entirely accurate within itself. It's grabbing data in the time between the prior log line to the next one. So all the data on that line is not exactly grabbed together in an instant. It's a scattering of data points within a window of time. You need to minimize the data streams being collected to get the most accuracy, but even then it can only do so much.

The Cobb AP is not the best logging tool due to it's limited processing power. There is quite a bit of variance. Run a log with only a few data streams vs many and you will see how far apart and varied the data is as it gets up high in the rpm range. Even the same line of data on a log is not entirely accurate within itself. It's grabbing data in the time between the prior log line to the next one. So all the data on that line is not exactly grabbed together in an instant. It's a scattering of data points within a window of time. You need to minimize the data streams being collected to get the most accuracy, but even then it can only do so much.

#9

The Cobb AP is not the best logging tool due to it's limited processing power. There is quite a bit of variance. Run a log with only a few data streams vs many and you will see how far apart and varied the data is as it gets up high in the rpm range. Even the same line of data on a log is not entirely accurate within itself. It's grabbing data in the time between the prior log line to the next one. So all the data on that line is not exactly grabbed together in an instant. It's a scattering of data points within a window of time. You need to minimize the data streams being collected to get the most accuracy, but even then it can only do so much.

#10

I'm not implying that there isn't an issue, just that you can't count on the AP logs to be entirely accurate compared to higher quality devices as mentioned in one of the other replies.

Why would a faulty pulsation damper be empty under high pressure/low injector flow conditions before going WOT? Once it fills it can't empty without pulling a vacuum. It would be a one time deal of the seal leaking and the cavity filling. I suppose there would some air trapped inside.

Why would a faulty pulsation damper be empty under high pressure/low injector flow conditions before going WOT? Once it fills it can't empty without pulling a vacuum. It would be a one time deal of the seal leaking and the cavity filling. I suppose there would some air trapped inside.

#11

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

Basically whether it is from 0-99% throttle or from a cruise at like 30-99% throttle, when I hammer on the pedal there is a delay which is causing a lean spot in the log.

In the car I feel it bog/loss of power, hear the exhaust rapidly backfire 2-4 times (not shotgun blasts but more of a popping noise) then it picks back up and is strong to redline..... initially from feel I thought it was actually a rich spot causing un-burnt fuel to ignite in my hot turbo/exhuast... similar to how I can make it backfire on command with the VTA BOV

Last edited by RotaryMachineRx; 06-26-2015 at 11:41 AM.

#12

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

I am seeing 56psi on a DW200 though... and is it not any concern for it to drop down to 52psi? Admittedly 52psi is very worse case senario and in most situations it only drops to about 54psi but I thought 60psi for an aftermarket higher flowing pump should be the norm with minimal pressure drop?

Other things that have passed through my mind; could it be an electrical problem? Possibility that my pop off valve is not keeping 100% closed on the initial surge of fuel when going WOT instantaneously like that?

#13

On my Walbro, it never drops below 58PSI under full load and stays at 60-61PSI 99% of the time. Have you tested the fuel pump resistor? Mine just died suddenly but I'm not sure if it can act up intermittently.

#15

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

I have not.... the reason I bring up an electical issue is that I had a loose cable causing a short last summer and I believe it was the power supply to the fuse box on the driver side front of the car. It caused me to have to replace the battery and alternator and was actually melting some plastic and causing some burn spots where it was mounted to that fuse box... maybe fuel pump relay or fuel pump speed control relay?

Last edited by RotaryMachineRx; 06-26-2015 at 12:40 PM.

#17

I wouldn't be concerned about the 56psi but 9k is right in that you shouldn't be seeing any pressure drop at all . Especially at low rpm .

Did you weld the popoff valve closed when you fitted the DW200 ?

Did you weld the popoff valve closed when you fitted the DW200 ?

#18

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

^ You you bet, heated up a flat head screwdriver then folded the outside edge of the plastic over onto the top of the pop off valve to keep it shut.... I don't have a retaining ring tool to check it out again and I'm certain I did it correctly but I just wanted to know if the symptoms could possibly point to that as a factor...

#20

Why would a faulty pulsation damper be empty under high pressure/low injector flow conditions before going WOT? Once it fills it can't empty without pulling a vacuum. It would be a one time deal of the seal leaking and the cavity filling. I suppose there would some air trapped inside.

#21

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

Injectors are original, have never been removed and same goes for coolant temp sensor. Car has 70,000 kms (44000mi). I plan on trying to run a fuel system cleaner additive to my next tank but I am currently away from the car for work for a while.

#22

Yeah, it could be a partial clogging on an injector. But it could also be the ECT sensor related as well. The ECT only cost twenty bucks and is an important sensor so I would at least test if not just replace it.

#23

Thread Starter

SPOOLN8

iTrader: (1)

Joined: Nov 2008

Posts: 2,258

Likes: 226

From: Edmonton, Alberta, Canada

My concern is that I don't want to go through all the work of pulling the UIM off then getting at those injectors when the root cause for this delay is something else IE. a 4psi fuel pressure drop when I floor it....

Scott you have a link for more info on the coolant sensor? (where it is, how to get at it?) Also why would the coolant temp sensor be linked to fuel pressure? See my post #3 again; my coolant temp readings on my AP are completely normal...

Scott you have a link for more info on the coolant sensor? (where it is, how to get at it?) Also why would the coolant temp sensor be linked to fuel pressure? See my post #3 again; my coolant temp readings on my AP are completely normal...

Last edited by RotaryMachineRx; 06-26-2015 at 05:17 PM.

#25

A 4 psi drop wouldn't cause the issue , but is certainly an indicator to another issue which may well be the cause.

Do you have a multimeter to check output voltage from the fuel pump resistor ? Maybe it isn't dropping into the second stage ....

Do you have a multimeter to check output voltage from the fuel pump resistor ? Maybe it isn't dropping into the second stage ....