The newest 100% bolt on Greddy Hybrid turbocharger!

#701

Banned

iTrader: (3)

Honestly, I really didn't mean for this to come across as insulting - that is my point.

I have a simple question (the follow-up, well, I won't make any promises) and I'd like a simple answer.

I don't need to be lectured on all this fabrication minutiae - though I'd love to have that discussion in a different context as there is always something new to learn.

I really am trying to voice this question i the most neutral way I can think of, but it seems that I just keep getting deflected and I have to tell you that it does look shady when you do that.

I have a simple question (the follow-up, well, I won't make any promises) and I'd like a simple answer.

I don't need to be lectured on all this fabrication minutiae - though I'd love to have that discussion in a different context as there is always something new to learn.

I really am trying to voice this question i the most neutral way I can think of, but it seems that I just keep getting deflected and I have to tell you that it does look shady when you do that.

#702

Banned

iTrader: (3)

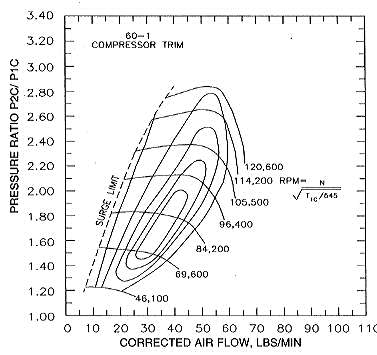

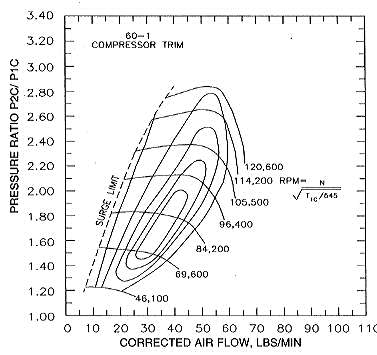

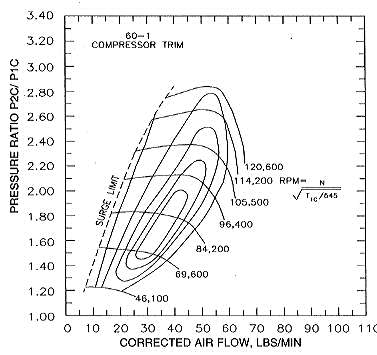

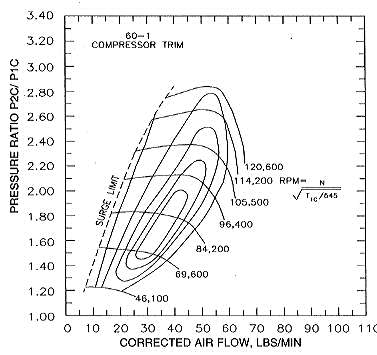

And just for clarification, here is the compressor flow map (provided by Kane, verified by Bryan) for the "60-1":

As you can see, it is a "50 pound compressor" only if you run it out to almost 18 PSI and well off its peak efficiency range.

Which is fine. Not optimal, but people do it all the time.

Just not on a Renesis - for the very reasons that Bryan pointed out.

So, again, I want to understand the thought process behind this recommendation so I know what to do to help customers of mine that have purchased this "upgrade" and are not seeing the flow that they expect.

As you can see, it is a "50 pound compressor" only if you run it out to almost 18 PSI and well off its peak efficiency range.

Which is fine. Not optimal, but people do it all the time.

Just not on a Renesis - for the very reasons that Bryan pointed out.

So, again, I want to understand the thought process behind this recommendation so I know what to do to help customers of mine that have purchased this "upgrade" and are not seeing the flow that they expect.

#703

And just for clarification, here is the compressor flow map (provided by Kane, verified by Bryan) for the "60-1":

As you can see, it is a "50 pound compressor" only if you run it out to almost 18 PSI and well off its peak efficiency range.

Which is fine. Not optimal, but people do it all the time.

Just not on a Renesis - for the very reasons that Bryan pointed out.

So, again, I want to understand the thought process behind this recommendation so I know what to do to help customers of mine that have purchased this "upgrade" and are not seeing the flow that they expect.

As you can see, it is a "50 pound compressor" only if you run it out to almost 18 PSI and well off its peak efficiency range.

Which is fine. Not optimal, but people do it all the time.

Just not on a Renesis - for the very reasons that Bryan pointed out.

So, again, I want to understand the thought process behind this recommendation so I know what to do to help customers of mine that have purchased this "upgrade" and are not seeing the flow that they expect.

Last edited by Frosty288; 05-17-2010 at 09:01 AM.

#704

Turbocharger Guru

Thread Starter

Honestly, I really didn't mean for this to come across as insulting - that is my point.

I have a simple question (the follow-up, well, I won't make any promises) and I'd like a simple answer.

I don't need to be lectured on all this fabrication minutiae - though I'd love to have that discussion in a different context as there is always something new to learn.

I really am trying to voice this question i the most neutral way I can think of, but it seems that I just keep getting deflected and I have to tell you that it does look shady when you do that.

I have a simple question (the follow-up, well, I won't make any promises) and I'd like a simple answer.

I don't need to be lectured on all this fabrication minutiae - though I'd love to have that discussion in a different context as there is always something new to learn.

I really am trying to voice this question i the most neutral way I can think of, but it seems that I just keep getting deflected and I have to tell you that it does look shady when you do that.

Brousing the web, I found this site. States PR/efficiency%/Lb flow or CFM.

http://www.ztechz.net/id6.html

If you do a 2.0 PR and the 60 lb/min on the map, you are off the island in efficiency. IMO is the best pump gas rotary turbo. That and the 62-1 are ideal. It is my opinion, and I know others have their opinions. I also made 440.2 RWHP and 360 RWTQ with the 62-1 in a small turbine housing. That was at 20 psi with a mild tune. I dragged down many of bikes with that turbo from an interstate roll... You go to some of the major tuners: Chris Anderson, Jason Bauhman, Steve Kan ect and they will say the 60-1/62-1 perform great for pump gas.

Bryan@BNR

Last edited by Bryan@BNR; 05-18-2010 at 01:15 AM.

#705

Turbocharger Guru

Thread Starter

I had this same issue with the Toyota supra twins. They generated backpressure and just blew the wastegate valve open and the boost would drop or not get any higher. Once I put a 17 psi base actuator on it, the turbos will go all the way to 28 psi no problem. I tried several different actuators until we found the right one.

#706

Banned

iTrader: (3)

You are so close to actually understanding how this works it is frustrating.

You are showing the two related sides of the problem, but you are not seeing their connection.

You need to get past the idea of "volume" or "CFM".

Yes it absolutely does - when you stop thinking in terms of "volume" and start looking at mass!

This is almost perfect:

until you say this:

The turbo does NOT generate pressure. The motor does in its resistance to mass airflow.

The turbo doesn't "turn harder" - it only has one "hardness" and that is the mass flow per rev of the compressor wheel.

If the resistance to flow on one motor is greater than another, the resultant pressure will be higher for the same mass flow.

If the resultant pressure is outside of what the turbo can produce efficiently, power stops increasing even if pressure goes up because mass flow is not increasing (because of the increase in charge temperature caused by the inefficiency of the compressor).

Yes. Those are compressor maps.

They show MASS flow on the bottom and PRESSURE RATIO on the left.

The concentric circles indicate how efficient the turbo is at producing a given MASS flow at a given PRESSURE RATIO.

The semi-horizontal lines indicate the SHAFT SPEED required to generate that flow.

OK. Stop right there.

A turbo doesn't "do" a certain amount of flow at a set pressure.

You spin a turbo to a specific speed and it will accelerate the VOLUME of air as defined by the VOLUME of the compressor wheel. The motor then acts as a RESTRICTION to the movement of that air.

The greater the restriction, the higher the BOOST and the lower the MASS FLOW.

Theoretically, an unrestricted system will flow infinitely at infinite shaft speed with zero boost. (If it weren't for that pesky gas law.)

In other words, an ideal engine would show ZERO "boost".

Of course it doesn't work that way - even the volute of the turbo is, in itself, a restriction. It converts velocity to pressure by restricting flow.

OK. A "CFM" calculation will indicate the VOLUME of the air displaced by the motor, not the MASS.

400 RWHP on a motor is an ABSOLUTE air mass, requiring no other calculation other than the BSFC of the motor.

One horsepower = 0.1346 pounds of air on a rotary motor.

Always.

All day long. No need for "CFM" or any other approximation.

[In fact, your CFM number will be all over the place because of all the temperature changes (which are already accounted for in mass) that will occur in the process of moving the air from the filter to the tailpipe.]

400 WHP is probably 450 or so at the motor. 450 * 0.1346 = 60 pounds/min.

(454 g/sec for the rest of us.)

Mass airflow removes all of those "complications" in figuring out turbo application because it accounts for the interrelationship of volume and temperature.

Now, knowing how much mass the motor needs, you can go about picking a turbo that can flow that mass efficiently.

Where your experience pays off is in realizing that different motors will flow better or worse that others, increasing the pressure ratio required to yield the desired mass flow.

Because the Renesis becomes a greater flow restriction after 35 pounds of air or so than the REW, the effective Pr to create the same amount of power as the REW will go up.

So, it will take a "bigger" turbo (so to speak) to make the same power on the MSP as the REW.

But that has nothing to do with CFM because the motors have identical displacement.

This is why we must speak in terms of air mass, not volume.

Which brings us to precisely why your argument is so frustrating. You are, essentially, already talking about air mass when you acknowledge that it takes different turbos to make the same power at the same volume, but you don't just make the connection.

We've already gone through this.

The wastegate is a lever. Like a see-saw.

If you want the advantage, you can either move the fulcrum or get yourself a fat kid.

The easiest way to move the fulcrum in this case is to add a few feet of extra board to your side.

You do this by increasing the ratio of the diameter of the WG flap to the actuator's diaphragm.

This allows you to have the same cracking pressure but exert more force on the flap.

If you make the actuator diaphragm twice the size it is now, you exert 10 times as much clamping force on the WG flap without increasing the cracking pressure.

The equivalent of the fat kid is to raise the spring pressure, which will also raise the cracking pressure.

Not ideal if you want to run the same net flow as before.

Oh - And its the "tertiary" ports (the APV), not the secondary ports where the boost falls off.

This is a pretty complex relationship and not just because the port area of the motor increases by 50% or so at that RPM.

You are showing the two related sides of the problem, but you are not seeing their connection.

You need to get past the idea of "volume" or "CFM".

Pressure ratio doesnt depict speed of the compressor.

This is almost perfect:

Speed of the compressor and its volume do go together and are fixed. The size of the engine is going to change your pressure ratios and flow rates. When you have more cubic inches, it takes more volume to fill the combustion chambers, therefore it takes more RPM for the compressor to generate the equivelent volume.

The turbo does NOT generate pressure. The motor does in its resistance to mass airflow.

The turbo doesn't "turn harder" - it only has one "hardness" and that is the mass flow per rev of the compressor wheel.

If the resistance to flow on one motor is greater than another, the resultant pressure will be higher for the same mass flow.

If the resultant pressure is outside of what the turbo can produce efficiently, power stops increasing even if pressure goes up because mass flow is not increasing (because of the increase in charge temperature caused by the inefficiency of the compressor).

Brousing the web, I found this site. States PR/efficiency%/Lb flow or CFM.

http://www.ztechz.net/id6.html

http://www.ztechz.net/id6.html

They show MASS flow on the bottom and PRESSURE RATIO on the left.

The concentric circles indicate how efficient the turbo is at producing a given MASS flow at a given PRESSURE RATIO.

The semi-horizontal lines indicate the SHAFT SPEED required to generate that flow.

A turbo doesn't "do" a certain amount of flow at a set pressure.

You spin a turbo to a specific speed and it will accelerate the VOLUME of air as defined by the VOLUME of the compressor wheel. The motor then acts as a RESTRICTION to the movement of that air.

The greater the restriction, the higher the BOOST and the lower the MASS FLOW.

Theoretically, an unrestricted system will flow infinitely at infinite shaft speed with zero boost. (If it weren't for that pesky gas law.)

In other words, an ideal engine would show ZERO "boost".

Of course it doesn't work that way - even the volute of the turbo is, in itself, a restriction. It converts velocity to pressure by restricting flow.

400 RWHP on a motor is an ABSOLUTE air mass, requiring no other calculation other than the BSFC of the motor.

One horsepower = 0.1346 pounds of air on a rotary motor.

Always.

All day long. No need for "CFM" or any other approximation.

[In fact, your CFM number will be all over the place because of all the temperature changes (which are already accounted for in mass) that will occur in the process of moving the air from the filter to the tailpipe.]

400 WHP is probably 450 or so at the motor. 450 * 0.1346 = 60 pounds/min.

(454 g/sec for the rest of us.)

Mass airflow removes all of those "complications" in figuring out turbo application because it accounts for the interrelationship of volume and temperature.

Now, knowing how much mass the motor needs, you can go about picking a turbo that can flow that mass efficiently.

Where your experience pays off is in realizing that different motors will flow better or worse that others, increasing the pressure ratio required to yield the desired mass flow.

Because the Renesis becomes a greater flow restriction after 35 pounds of air or so than the REW, the effective Pr to create the same amount of power as the REW will go up.

So, it will take a "bigger" turbo (so to speak) to make the same power on the MSP as the REW.

But that has nothing to do with CFM because the motors have identical displacement.

This is why we must speak in terms of air mass, not volume.

Which brings us to precisely why your argument is so frustrating. You are, essentially, already talking about air mass when you acknowledge that it takes different turbos to make the same power at the same volume, but you don't just make the connection.

I honestly think we need a way stiffer actuator to counter the backpressure made when the secondary ports open. That is typically where the boost falls down. I will have to find the right wastegate actuator for this application and make installation hardware to adapt it. That actuator is so weak.

The wastegate is a lever. Like a see-saw.

If you want the advantage, you can either move the fulcrum or get yourself a fat kid.

The easiest way to move the fulcrum in this case is to add a few feet of extra board to your side.

You do this by increasing the ratio of the diameter of the WG flap to the actuator's diaphragm.

This allows you to have the same cracking pressure but exert more force on the flap.

If you make the actuator diaphragm twice the size it is now, you exert 10 times as much clamping force on the WG flap without increasing the cracking pressure.

The equivalent of the fat kid is to raise the spring pressure, which will also raise the cracking pressure.

Not ideal if you want to run the same net flow as before.

Oh - And its the "tertiary" ports (the APV), not the secondary ports where the boost falls off.

This is a pretty complex relationship and not just because the port area of the motor increases by 50% or so at that RPM.

Last edited by MazdaManiac; 05-17-2010 at 01:12 PM.

#710

Boosted Kiwi

iTrader: (2)

You need an actuator twice the diameter of the existing one but with the SAME cracking pressure . To do that the SPRING must be large enough to overcome the force from the diaphram . This means the spring is exerting 10 (your figure) times the force on the wg arm and you have control of that force via the diaphragm and a boost controller .

or................................................ ......... you could just do my trick and crank WG closed LOL

#711

Banned

iTrader: (3)

That is great if you intend to run a whole bunch more boost than the wastegate is designed to provide (it is a 7 PSI actuator, after all), but it won't work if you just want the normal 7 PSI all the way across the power band.

You can either stop the bleeding or you can just crank down on the tourniquet until you don't feel the injury any longer.

#712

Boosted Kiwi

iTrader: (2)

Except you are raising the cracking pressure of the actuator, raising the boost and limiting the opening angle of the wastegate.

That is great if you intend to run a whole bunch more boost than the wastegate is designed to provide (it is a 7 PSI actuator, after all), but it won't work if you just want the normal 7 PSI all the way across the power band.

.

That is great if you intend to run a whole bunch more boost than the wastegate is designed to provide (it is a 7 PSI actuator, after all), but it won't work if you just want the normal 7 PSI all the way across the power band.

.

But i do concede -your way is better .

#719

Banned

iTrader: (3)

I try not to get into arguments I haven't already won.

In other words, I don't ask questions for which I don't already have the answer.

As far as the last word goes, the forum is full of examples where the last word, being correct, came from someone other than myself.

#720

Yeah boost creep/fluctuation sucks..

The SAAB I had didn't have the best sized wastegate and when set for 21psi would sometimes fluctuate to 23-26.

=blown motor. I think that actuator spring was for about 10psi? Way outside of it's operating range.

Spring tension should be the lowest pressure you run, and shouldn't be too far off from target pressure...imo.

The SAAB I had didn't have the best sized wastegate and when set for 21psi would sometimes fluctuate to 23-26.

=blown motor. I think that actuator spring was for about 10psi? Way outside of it's operating range.

Spring tension should be the lowest pressure you run, and shouldn't be too far off from target pressure...imo.

#723

Banned

iTrader: (3)

A properly set-up boost controller will deliver perfect, smooth turbo output under all conditions.

Mechanical-only still has to deal with the limitations of spring rate and the need for separate "cracking" and "full-open" pressures.

Why do you think ALL OEM turbo cars come with PCM-controlled boost control these days?