OD's engine build

#26

OD, is there enough room in the side housings to extend the intake ports enough to create a Miller-cycle effect where the intake ports are still open into the compression "stroke"? I genuinely don't know if the coolant jackets would be in the way or not; but if it it is, then it seems like you would get a variable compression effect (10 at idle and then dropping lower as the extended ports opened).

#27

#28

Thread Starter

Registered

iTrader: (3)

Joined: Apr 2004

Posts: 10,828

Likes: 38

From: macon, georgia

absolutely old friend.

another thing would be the new weight of the rotor and the custom balancing that would require.

Using the rx7 rotors allows you to use the counterweights that Mazda already has.

I really dont want to play with ports like that

I tried keeping the apvs open once and that did not work out good-not exactly what you are talking about, but once the boost is gone (decell etc) whats happens is not good

OD

another thing would be the new weight of the rotor and the custom balancing that would require.

Using the rx7 rotors allows you to use the counterweights that Mazda already has.

I really dont want to play with ports like that

I tried keeping the apvs open once and that did not work out good-not exactly what you are talking about, but once the boost is gone (decell etc) whats happens is not good

OD

Last edited by olddragger; 03-26-2011 at 06:18 PM.

#30

if reliability is your game then block off the side exhaust ports and install the earlier housings with peripheral exhaust ports, will require a header manifold to be built though, with standard intake(no BP)/exhaust porting and regular intake operation you will be way ahead of most FI applications here in every regard ...

if you really want to stick with the Reni exhaust then I would highly suggest converting to and using E85 fuel exclusively

if you really want to stick with the Reni exhaust then I would highly suggest converting to and using E85 fuel exclusively

#31

You'd have to use 1st generation RX-7 GSL-SE housings or some 70's 13B housings to accomplish such a thing. Can you still get these new? I thought I heard 12A housings have dried up. Makes me wonder about the old school 13B's.

#32

Ok. Lets get this started.

Because of a recent unexpected happening, I have done a 180 degree turn from selling out to keeping the car and building an FI RX8 engine.

The reason for this thread is because I will be going down the road less travelled and some folks may be interested in what all was done and the results.

Yall know I love the road circuit, and I use my car for frequent DD. Not all the time, but multiple times a week. This car is built to be enjoyed--right? So my demands on the car is a frequent street driving with 3-4 track events a year.

A little history. I have blown a few engines, some as a result of my own learning curve ( yep I was stupid) and some from just plain bad luck. My engine's have been pretty fragile it seems. Least little thing and BLAM!

I have a street tune per Cam at Pettit racing and when comparing it to the ones I can see --it is right where it should be?

My cooling system is great, my fuel supply is the 09 fuel pump assembly and I have never had a problem with pressure or a/f's.

All but one engine have blown on the Road Track, all on the back straight at Road Atlanta--its the highest consistant load area the car experiences with accelleration from 55 to 140 in 3-4-5-6 gears ( you would think fuel pump--right? Buts its not). That has been looked at and fuel delivery is OK.

My self imposed redline has been 7.5-8K

I do run a snow water meth set up.

Sparkplugs always look great.

We cant figue out what is happening. Its not rotor specific It could be front, it could be the rear.

Doesnt seem to be the amount of boost related--blown with 7psi and blown with 10.

No misfires seen.

Running high test pump gas with approx 4% ethanol content per test at gas pump.

l No warning of problems--just a little stumble and then the skip of death--takes 1-2 secs.

Last engine I popped a vacuum line and that caused a stumble, studder and then it blew.

Ok-- with all this in mind It seems my engines could use a little cushion?.

So I have decided to follow the footsteps of Rote 8 and have Pettit (Cam) fit the rx7 turbo low compression rotors into my engine. That will lower the compression ratio to 9:1 versus our 10:1.

My Pettit blower has enough Oompphh to it to flow the amout of air I need to continue approx 300rwhp even with the lower compression rotors.

By using these rotors I see these benefits:?

1- decreased charge temps ( verified by Rote) without w/m useage

2- less static compression at TDC

3- have the taller RX7 apex seals

4- heavier rotor and lower rpm ( but still the same as my self imposed one 7.5K-8K)

5- wider tolerance for pump gas

6- no noticeable difference in off boost driving.

I also hope just for more insurance to get my dwell adjusted so I can use a better ignition coil---I just dont trust the oems even though I have never had a known problem with them--- i change them about once a year.

Off course other things will be done to the engine in addition-- like balancing, cleaning up the ports, and Cams little secrets

All comments and ideas are welcome on this thread.

Other than Rote8--i dont know of anyone else running the lower compression rotors?

I hope to send the engine to Cam by next month.

I have a feeling that this is going in the right direction for the type of driving I do?

I'M BACKKK!

OD

Because of a recent unexpected happening, I have done a 180 degree turn from selling out to keeping the car and building an FI RX8 engine.

The reason for this thread is because I will be going down the road less travelled and some folks may be interested in what all was done and the results.

Yall know I love the road circuit, and I use my car for frequent DD. Not all the time, but multiple times a week. This car is built to be enjoyed--right? So my demands on the car is a frequent street driving with 3-4 track events a year.

A little history. I have blown a few engines, some as a result of my own learning curve ( yep I was stupid) and some from just plain bad luck. My engine's have been pretty fragile it seems. Least little thing and BLAM!

I have a street tune per Cam at Pettit racing and when comparing it to the ones I can see --it is right where it should be?

My cooling system is great, my fuel supply is the 09 fuel pump assembly and I have never had a problem with pressure or a/f's.

All but one engine have blown on the Road Track, all on the back straight at Road Atlanta--its the highest consistant load area the car experiences with accelleration from 55 to 140 in 3-4-5-6 gears ( you would think fuel pump--right? Buts its not). That has been looked at and fuel delivery is OK.

My self imposed redline has been 7.5-8K

I do run a snow water meth set up.

Sparkplugs always look great.

We cant figue out what is happening. Its not rotor specific It could be front, it could be the rear.

Doesnt seem to be the amount of boost related--blown with 7psi and blown with 10.

No misfires seen.

Running high test pump gas with approx 4% ethanol content per test at gas pump.

l No warning of problems--just a little stumble and then the skip of death--takes 1-2 secs.

Last engine I popped a vacuum line and that caused a stumble, studder and then it blew.

Ok-- with all this in mind It seems my engines could use a little cushion?.

So I have decided to follow the footsteps of Rote 8 and have Pettit (Cam) fit the rx7 turbo low compression rotors into my engine. That will lower the compression ratio to 9:1 versus our 10:1.

My Pettit blower has enough Oompphh to it to flow the amout of air I need to continue approx 300rwhp even with the lower compression rotors.

By using these rotors I see these benefits:?

1- decreased charge temps ( verified by Rote) without w/m useage

2- less static compression at TDC

3- have the taller RX7 apex seals

4- heavier rotor and lower rpm ( but still the same as my self imposed one 7.5K-8K)

5- wider tolerance for pump gas

6- no noticeable difference in off boost driving.

I also hope just for more insurance to get my dwell adjusted so I can use a better ignition coil---I just dont trust the oems even though I have never had a known problem with them--- i change them about once a year.

Off course other things will be done to the engine in addition-- like balancing, cleaning up the ports, and Cams little secrets

All comments and ideas are welcome on this thread.

Other than Rote8--i dont know of anyone else running the lower compression rotors?

I hope to send the engine to Cam by next month.

I have a feeling that this is going in the right direction for the type of driving I do?

I'M BACKKK!

OD

I feel the low compression rotors resist detonation, and if a detonation does occur, it should be less destructive.

#33

The beginning of this thread made me think OD was building it himself  .

.

I disagree with Zoom44 about the guy from Trinidad, he's not a little sketchy but in fact quite sketchy .

.

Renesis rotors weigh about the same as 13B REW rotors when you add the extra metal seal (I always forget it's name).

I'm excited to see how this may turn out and for the record; Cameron at Pettit has much more forced induction experience than Rick does.

Good luck OD!

Paul

.

. I disagree with Zoom44 about the guy from Trinidad, he's not a little sketchy but in fact quite sketchy

.

.Renesis rotors weigh about the same as 13B REW rotors when you add the extra metal seal (I always forget it's name).

I'm excited to see how this may turn out and for the record; Cameron at Pettit has much more forced induction experience than Rick does.

Good luck OD!

Paul

#34

Thread Starter

Registered

iTrader: (3)

Joined: Apr 2004

Posts: 10,828

Likes: 38

From: macon, georgia

thanks Paul-- Guess we all have oppitunities in learning?

Team-certainly agree that the PP engines seem to handle FI much better. But I dont have a cue as to how to go about it. I dont know of a builder that does either?

I have heard of a few 13B transplants?

I am afraid I am stuck with the renesis. The report on using the lower compression rotors currently is very good.

I am planning and hoping that I can stay out of the higher rpms as much as possible as that SEEMS to be when the side ports start showing their weakness?

Tempted to convert block off the apv?

I think I figued out what caused my engine to blow when that vacuum line popped off--see the pettit thread for the details.

But 1st things 1st. Get it built, then decide and then nail down the tune.

Team-certainly agree that the PP engines seem to handle FI much better. But I dont have a cue as to how to go about it. I dont know of a builder that does either?

I have heard of a few 13B transplants?

I am afraid I am stuck with the renesis. The report on using the lower compression rotors currently is very good.

I am planning and hoping that I can stay out of the higher rpms as much as possible as that SEEMS to be when the side ports start showing their weakness?

Tempted to convert block off the apv?

I think I figued out what caused my engine to blow when that vacuum line popped off--see the pettit thread for the details.

But 1st things 1st. Get it built, then decide and then nail down the tune.

#35

Feedback with lower compression rotors is good, but VERY limited. What you lack there is depth and volume of case studies.

Also keep in mind that you're supercharged, lowering the redline and changing pulley to have your desired powerband is not the best option, picking up the right turbo for your goal would be easier in comparison.

Since you're set on the supercharger why don't you focus on overall reliability (tolerances, rotor balance etc), cooling and a serious double check of every line (come to think you're unlucky with lines in general... fuel lines, vacuum lines etc ). Add a reliable tune with adequate fuelling and you should be set for a long time.

). Add a reliable tune with adequate fuelling and you should be set for a long time.

Sure moving the compression down a bit etc would really help but that's walking into the unknown (for most). Is it really worth the added risk?

Also keep in mind that you're supercharged, lowering the redline and changing pulley to have your desired powerband is not the best option, picking up the right turbo for your goal would be easier in comparison.

Since you're set on the supercharger why don't you focus on overall reliability (tolerances, rotor balance etc), cooling and a serious double check of every line (come to think you're unlucky with lines in general... fuel lines, vacuum lines etc

). Add a reliable tune with adequate fuelling and you should be set for a long time.

). Add a reliable tune with adequate fuelling and you should be set for a long time.Sure moving the compression down a bit etc would really help but that's walking into the unknown (for most). Is it really worth the added risk?

#36

Thread Starter

Registered

iTrader: (3)

Joined: Apr 2004

Posts: 10,828

Likes: 38

From: macon, georgia

Good points. I only know of one person actually running the the rx7 rotors. To wait on a number of people running these and then compiling the results would be counterproductive for me at this time. Certainly agree with the concept though.

The person running these is Rote8 and he also has the Pettit FI package. I dont know of any turbo guys with the lower compression rotors?

I do take some comfort in the fact that Mazda themselves installed the lower compression rotors on the their turbo cars?

Our compresser can handled the needed increase in flow without difficulty--so why switch? I like the concept of constant boost without waste gates and controllers. Just my preference.

It is well proven in general that a lower compression engine tolerates variables better than one with higher compression. That therory should also also apply to our engine?

Variables are inevidable unfortunatly especially with the pump gas that is out there now.

I hear you about the rest of the build and that goes without saying. The tolerances, balancing and other mods will all be done. I am also THINKING about doing an exhaust port coating but I am not sure yet.

The tuning I hope will be handled by Steve Kan. Depends if he will be in Atlanta/Ga area or not when I need it. Cam has a basic tune to get the car running--it is different than the one I now have.

The person running these is Rote8 and he also has the Pettit FI package. I dont know of any turbo guys with the lower compression rotors?

I do take some comfort in the fact that Mazda themselves installed the lower compression rotors on the their turbo cars?

Our compresser can handled the needed increase in flow without difficulty--so why switch? I like the concept of constant boost without waste gates and controllers. Just my preference.

It is well proven in general that a lower compression engine tolerates variables better than one with higher compression. That therory should also also apply to our engine?

Variables are inevidable unfortunatly especially with the pump gas that is out there now.

I hear you about the rest of the build and that goes without saying. The tolerances, balancing and other mods will all be done. I am also THINKING about doing an exhaust port coating but I am not sure yet.

The tuning I hope will be handled by Steve Kan. Depends if he will be in Atlanta/Ga area or not when I need it. Cam has a basic tune to get the car running--it is different than the one I now have.

#37

OD, have you thought about possibly using fittings on the vacuum lines to assure they do not pop off? Were your vacuum lines zip tied?

Last edited by 9krpmrx8; 03-29-2011 at 11:23 AM.

#38

Great Denny!

I understand your points, plus admit that you're as curious as a ferret so you can't resist doing some experiments

If your blower is still in its efficiency range for your goals then forgive that part of my message, i wrote without having the charts at hand!

I understand your points, plus admit that you're as curious as a ferret so you can't resist doing some experiments

If your blower is still in its efficiency range for your goals then forgive that part of my message, i wrote without having the charts at hand!

#39

Thread Starter

Registered

iTrader: (3)

Joined: Apr 2004

Posts: 10,828

Likes: 38

From: macon, georgia

I am going to weild them on.

Seriously though-- i had zip ties on and it popped off at the one way valve--engine side. I now have a more sturdy one way valve to use than the oem one (green/white). It has a little ridge on it for the line to grab.

I had this line hooked to the lim nipple and the exhaust heat may have affected it--dont know for sure.

I do know from here on out EVERY line of ANY type will be double zipped! I also zip tie the fuel lines.

I have never had a vacuum line pop off except when I first installed the kit couple years ago. That time is wasnt a problem-- wasnt at high rpm or high boost.

Ferret?! That fits and you are right I love analysis and contemplation. I always ask "Why"

I love analysis and contemplation. I always ask "Why"

I drive people crazy at the hospital.

I do wish I had more equipment to address things properly.

Seriously though-- i had zip ties on and it popped off at the one way valve--engine side. I now have a more sturdy one way valve to use than the oem one (green/white). It has a little ridge on it for the line to grab.

I had this line hooked to the lim nipple and the exhaust heat may have affected it--dont know for sure.

I do know from here on out EVERY line of ANY type will be double zipped! I also zip tie the fuel lines.

I have never had a vacuum line pop off except when I first installed the kit couple years ago. That time is wasnt a problem-- wasnt at high rpm or high boost.

Ferret?! That fits and you are right

I love analysis and contemplation. I always ask "Why"

I love analysis and contemplation. I always ask "Why"I drive people crazy at the hospital.

I do wish I had more equipment to address things properly.

Last edited by olddragger; 03-29-2011 at 11:38 AM.

#42

just a question.. probably get flamed for this ( suit is on ) what would happen if one were to build Identical rotors as the renensis but with aluminum? besides the obvious weight reduction, would that change compression, or strength? throw it off balance ect...

#43

It would just be lighter. Compression is based on the combustion pocket. Super light weight isn't very useful for non race cars. The RPMs would fall uncontrollably fast. You could make it lower compression though, but then it wouldn't be "identical".

#44

BearBlasterExtraordinair!

iTrader: (3)

Joined: Nov 2010

Posts: 731

Likes: 3

From: Haughton, Louisiana

Balance, yes. Compression, no, if you kept it the exact same as stock. Strength? Possibly. Are the stock ones iron? Not sure what they are made of. I don't know how well aluminum would hold up in a MSP rotary.

#45

http://atkinsrotary.com/store/catalo...g-p-16855.html

Once built you will essentially have a street port 13B with a fancy intake manifold that plugs right into the RX-8 chassis/PCM. Build a custom header to mate with the cat/midpipe and you are done, then tune it.

.

Last edited by TeamRX8; 03-29-2011 at 11:11 PM.

#47

What? There is lots of metal on the face of the older 13B rotors to scallop them, I've done it and have had it done for a couple customers engines.

The stock Renny rotors are iron, yes.

A company in Florida makes aluminum rotors for older 13B engines that are 10:1 comp ratio, but can be machined with a deeper dish for less compression.

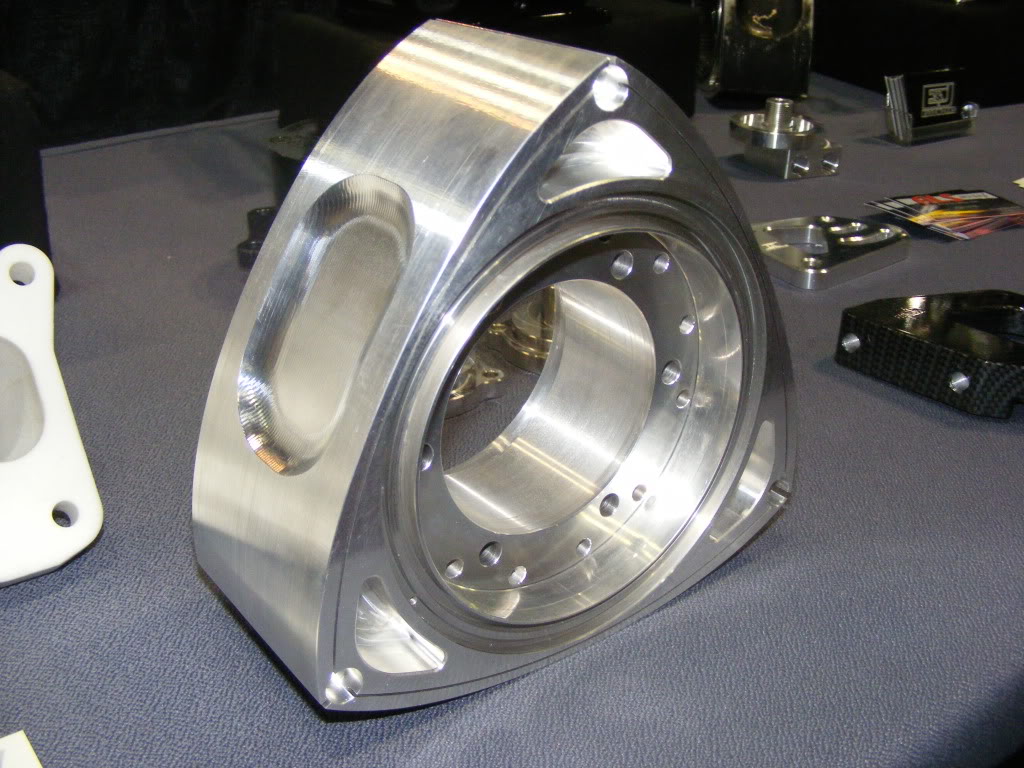

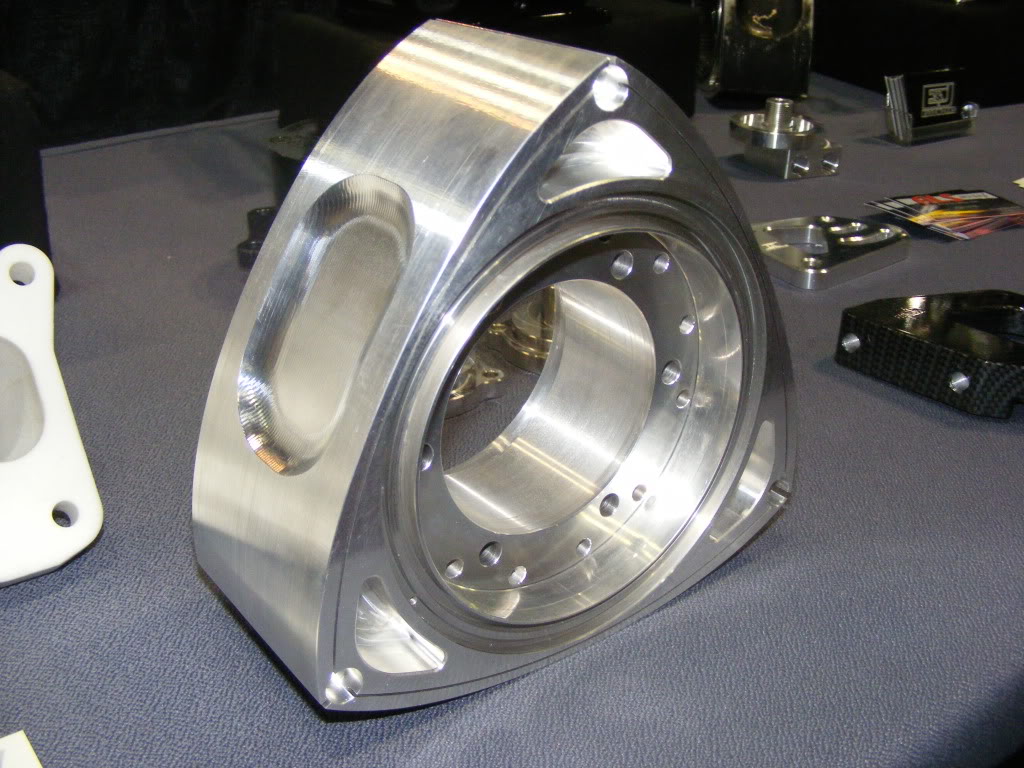

Test rotor, already run sucessfully in an engine with no problems

To be quite honest, I had no idea the older 13B rotors would work with the Renny irons. I always thought the side seal location on the old rotors would drop the seals into the intake/exhaust ports.

If I woulda known that, I would have built a low comp Renny engine years ago haha.

The stock Renny rotors are iron, yes.

A company in Florida makes aluminum rotors for older 13B engines that are 10:1 comp ratio, but can be machined with a deeper dish for less compression.

Test rotor, already run sucessfully in an engine with no problems

To be quite honest, I had no idea the older 13B rotors would work with the Renny irons. I always thought the side seal location on the old rotors would drop the seals into the intake/exhaust ports.

If I woulda known that, I would have built a low comp Renny engine years ago haha.

#48

Unless you are datalogging you have no idea what your afrs are. Gauges lie. I think your tune blew your engine. Ditch the stock seals as a starter, we stock the best units out there, the goopy units( in both rx8 and rx7 dimensions ).

#49

What? There is lots of metal on the face of the older 13B rotors to scallop them, I've done it and have had it done for a couple customers engines.

To be quite honest, I had no idea the older 13B rotors would work with the Renny irons. I always thought the side seal location on the old rotors would drop the seals into the intake/exhaust ports.

If I woulda known that, I would have built a low comp Renny engine years ago haha.

To be quite honest, I had no idea the older 13B rotors would work with the Renny irons. I always thought the side seal location on the old rotors would drop the seals into the intake/exhaust ports.

If I woulda known that, I would have built a low comp Renny engine years ago haha.

You can fit older rotors but you have to machine them to accomodate the third sealing ring, it's been done before with success