Turbo Oil Pressure Regulator

#76

The stainless steel line I use, it's rated up to 500F..that's inner rated, but outside, it's stainless steel, I don't know..I have my return made of this line, and it's next to manifold and downpipe, till now, it's still good..

Last edited by halimsteven; 02-25-2014 at 06:54 PM.

#77

9k can you post where you got those flow control valves? I've been watching ebay and looking I can not find it anywhere. The closest I can find is a 3/8" 1.5 gpm.

Does anyone think 1.5 GPM might be too much oil flow from the engine?

Does anyone think 1.5 GPM might be too much oil flow from the engine?

#78

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

I had to order those straight from Vonberg, I see them for sale but never in the size I needed. I did buy three though since they are made to order. Mine are 1.0GPM but I think .75GPM might be the sweet spot. We planned the testing, just need to get to actually doing it, too much other **** going on right now.

#79

How much did vonberg charge? If you have a Extra I would be intrested. I like the flow control valve, but I am thinking of putting a T between the control and the turbo. Then putting a 40-50PSI cracking pressure check valve that dumps back into the oil pan.

#81

Yeah, I'm thinking of putting the flow controller where you propose a restrictor. With out a restrictor before the pressure regulator you are just going to lower your system pressure to the regulators set point.

I would leave a gauge on it for a while to see if it's getting Max flow and then bypassing(ie the pressure stays at the set point)

IF the pressure is below the set point then you know the turbo could use a little more oil.

I would leave a gauge on it for a while to see if it's getting Max flow and then bypassing(ie the pressure stays at the set point)

IF the pressure is below the set point then you know the turbo could use a little more oil.

#82

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

Like so? I plan on using a quick disconnect so I can hook up the gauge when I want to use it and remove when not. I would like to do quality quick disconnects all around but they are really expensive.

http://www.flickr.com/photos/9krpmrx8/13075265725/

http://www.flickr.com/photos/9krpmrx8/13075265725/

Last edited by 9krpmrx8; 03-10-2014 at 10:37 PM.

#83

Yeah That's how I see it working.

Have you decided on the QD that you want yet? I have some pretty good contacts for stuff like that.

I also have a digital gauge. So I will run a extra pressure transducer and just plug it in to check it from time to time.

Have you decided on the QD that you want yet? I have some pretty good contacts for stuff like that.

I also have a digital gauge. So I will run a extra pressure transducer and just plug it in to check it from time to time.

#88

Just keep one thing in mind; In general quick connectors will introduce a flow dependent pressure drop and extra fault source. So when experimenting, it might be nice to have, but for a permanent solution I'd not recommend it. High end or not.

#89

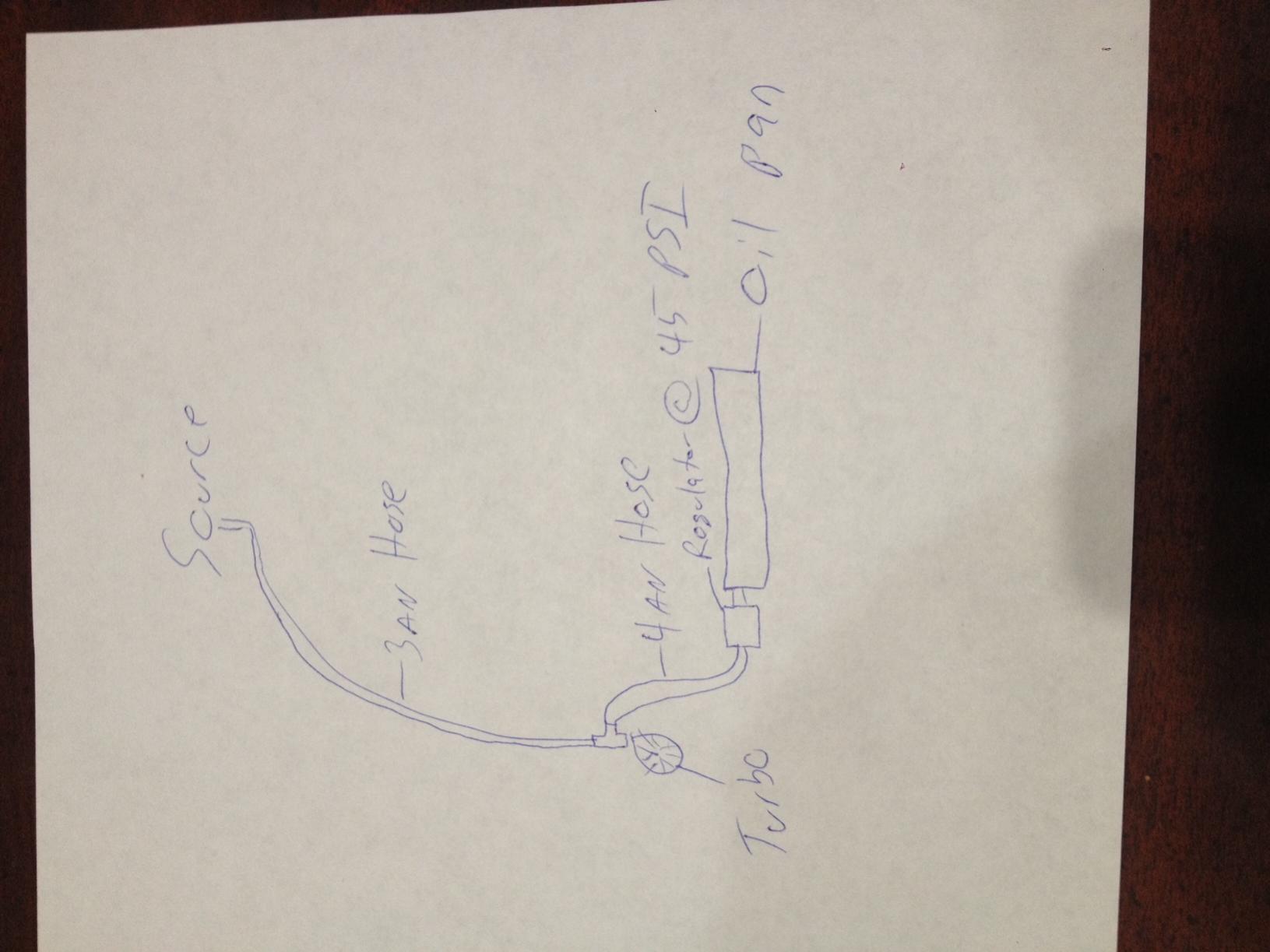

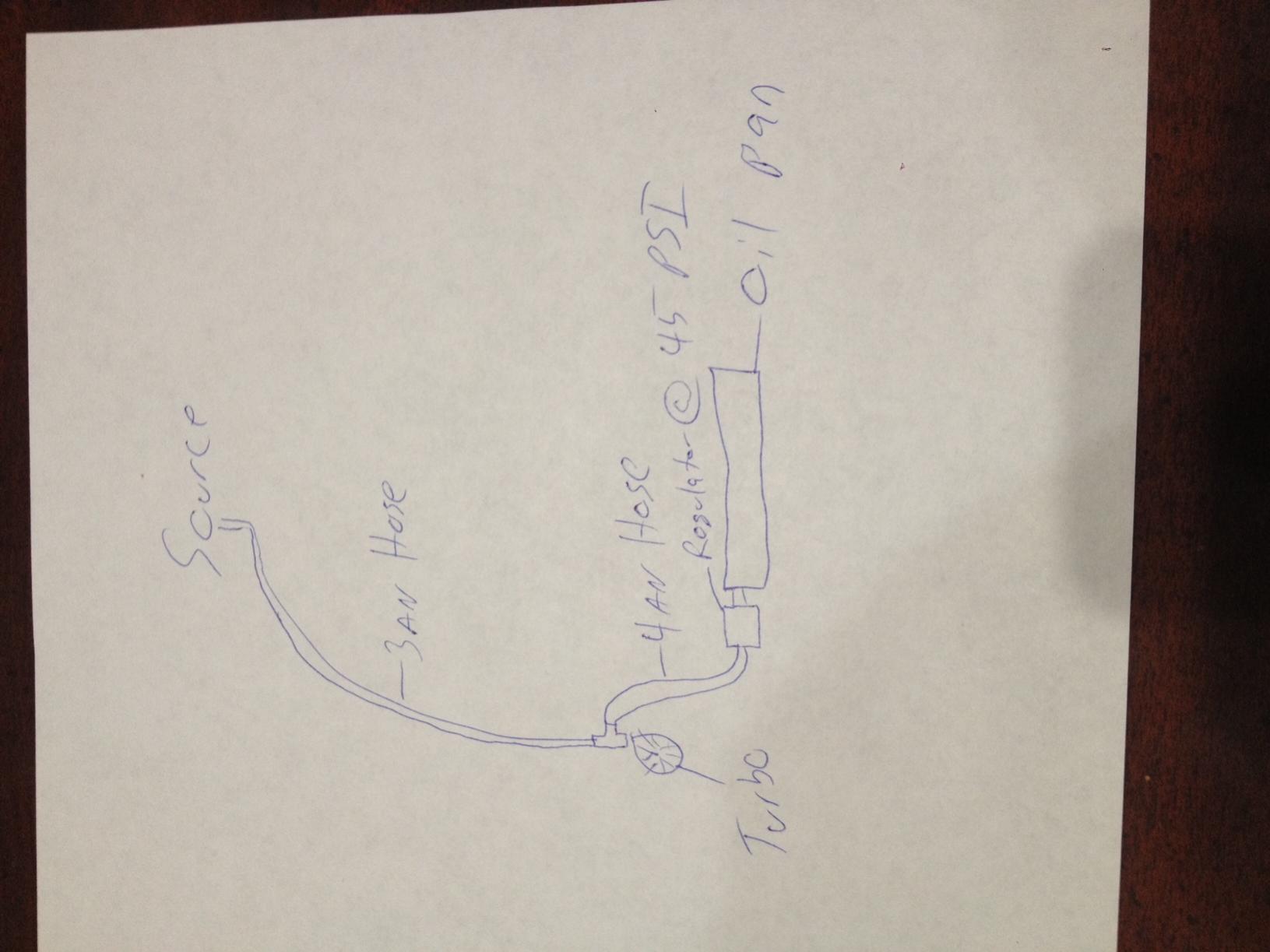

Forgive my crude hand drawing. I don't have an artistic bone in my body.

I'm thinking of running mine something like this. the -3 line should have an ID of 0.125" at a 80 PSI differental and 0.9 SG it will max out around 1.125-1.5 Gallons per minute. So the line should be enough of a restriction.

I'm going to run -4 from the turbo to the regulator so it should not provide a flow restriction and be able to relive any excess pressure down to 45 PSI.

With this setup and the regulator line pointing upward from the turbo the oil flow should go to the turbo first then once pressure backs up in the system it will relive the excess pressure. If the regulator is before the turbo then it might open and starve the turbo for oil.

I am keeping my eyes open for a flow control valve, but I'm not going to buy 3 just to have them made. If anyone a couple of people want to go in on them I'll order a set.

I'm thinking of running mine something like this. the -3 line should have an ID of 0.125" at a 80 PSI differental and 0.9 SG it will max out around 1.125-1.5 Gallons per minute. So the line should be enough of a restriction.

I'm going to run -4 from the turbo to the regulator so it should not provide a flow restriction and be able to relive any excess pressure down to 45 PSI.

With this setup and the regulator line pointing upward from the turbo the oil flow should go to the turbo first then once pressure backs up in the system it will relive the excess pressure. If the regulator is before the turbo then it might open and starve the turbo for oil.

I am keeping my eyes open for a flow control valve, but I'm not going to buy 3 just to have them made. If anyone a couple of people want to go in on them I'll order a set.

#90

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

My only issue with this setup would be the packaging. With the greddy setup it is very tight down there. I have been thinking about mounting and the affects that the placement might have on how this all works. i am just waiting on one fitting that was back ordered.

#93

If anyone is intrested I have a extra 1302L-.075gpm flow controler on the way. I had to order a minimum of 2 so I have an extra. the cost will be about 35 dollars. I haven't found out the shipping cost yet.

#94

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

Well it looks like a cluster **** but we tested it with air today and it works perfectly. Adjusting it we got a minimum of 20psi at the gauge and a maximum of about 65PSI at varying pressures on the feed side up to 100PSI. I am not sure how that will change with engine oil. Don't mind how long the -4 lines are I just had them laying around already. Now I just need to get this contraption simplified instead of using all these fittings and adapters,  I can also put a sending unit on it instead of a gauge and just connect my dash mounted oil pressure gauge to it when I want to get readings or make adjustments. I will post details of how I plan to return it to the sump soon.

I can also put a sending unit on it instead of a gauge and just connect my dash mounted oil pressure gauge to it when I want to get readings or make adjustments. I will post details of how I plan to return it to the sump soon.

I can also put a sending unit on it instead of a gauge and just connect my dash mounted oil pressure gauge to it when I want to get readings or make adjustments. I will post details of how I plan to return it to the sump soon.

I can also put a sending unit on it instead of a gauge and just connect my dash mounted oil pressure gauge to it when I want to get readings or make adjustments. I will post details of how I plan to return it to the sump soon.

Last edited by 9krpmrx8; 06-14-2014 at 11:48 AM.

#95

It will likely indicate much higher on oil due to the higher viscosity and density

Hooking it up to the engine with an on-off valve, catch pan, and graduated cylinder or cup would allow you to test it under actual conditions and measure flow.

Hooking it up to the engine with an on-off valve, catch pan, and graduated cylinder or cup would allow you to test it under actual conditions and measure flow.

#97

Im attempting one close but a little different. 0.75gpm flow control. I figured i would mount the flow control, tee and pressure sensor to the underside of the intake manifold then run 3 hoses. -3 hoses.

Im going to weld a pipe fitting into the oil pan and Install the regulator there.

I will run it without a turbo to get the pressure adjusted.

Im thinking 45 psi max pressure to the turbo.

Im going to weld a pipe fitting into the oil pan and Install the regulator there.

I will run it without a turbo to get the pressure adjusted.

Im thinking 45 psi max pressure to the turbo.

#100

Thread Starter

SARX Legend

iTrader: (46)

Joined: Jan 2007

Posts: 33,786

Likes: 455

From: San Antonio, Texas

I finally got the setup somewhat finalized. I am still missing the bypass line in this picture but i just need to make this weekend and that will be it.

Pay no mind to the cut oil filler tube assembly, it is just extra junk that I just used it to test everything. This will be the return to the sump from the bypass valve.

Pay no mind to the cut oil filler tube assembly, it is just extra junk that I just used it to test everything. This will be the return to the sump from the bypass valve.

Last edited by 9krpmrx8; 07-10-2014 at 03:10 PM.