Where did you plumb your boost controller into ? UIM is no good !

#152

Just did.

You guys (like seemingly EVERYONE else around here) keeps using pressure as a reference for everything. Pressure, for our purposes, is just a signal. It says nothing about performance.

When you are screwing around with the WG and the BOV, what you are trying to do is control air mass, but you are using pressure as your reference and it is screwing up your thinking.

If you have turbo over-speed issues while using the pressure signal from the IM as your reference, you simply don't have it set up correctly.

I'm glad that plumbing it to the pre-throttle position "works" for you, but I can assure you that it doesn't work.

You had the flu, you drank a 5th of vodka and you got better 3 days later. That is coincidence, not correlation.

#153

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,606

Likes: 1,535

From: Y-cat-o NZ

Just did.

If you have turbo over-speed issues while using the pressure signal from the IM as your reference, you simply don't have it set up correctly.

I'm glad that plumbing it to the pre-throttle position "works" for you, but I can assure you that it doesn't work.

.

If you have turbo over-speed issues while using the pressure signal from the IM as your reference, you simply don't have it set up correctly.

I'm glad that plumbing it to the pre-throttle position "works" for you, but I can assure you that it doesn't work.

.

And if you are going to say I don't know what I'm doing - remember whose dyno that is that shows the widest power band of any member with any FI system on here to date . Not bad for someone who , according to you, can't set up a boost controller correctly .

Just did.

You guys (like seemingly EVERYONE else around here) keeps using pressure as a reference for everything. Pressure, for our purposes, is just a signal. It says nothing about performance.

When you are screwing around with the WG and the BOV, what you are trying to do is control air mass, but you are using pressure as your reference and it is screwing up your thinking.

You guys (like seemingly EVERYONE else around here) keeps using pressure as a reference for everything. Pressure, for our purposes, is just a signal. It says nothing about performance.

When you are screwing around with the WG and the BOV, what you are trying to do is control air mass, but you are using pressure as your reference and it is screwing up your thinking.

Last edited by Brettus; 09-16-2009 at 11:46 PM.

#154

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,606

Likes: 1,535

From: Y-cat-o NZ

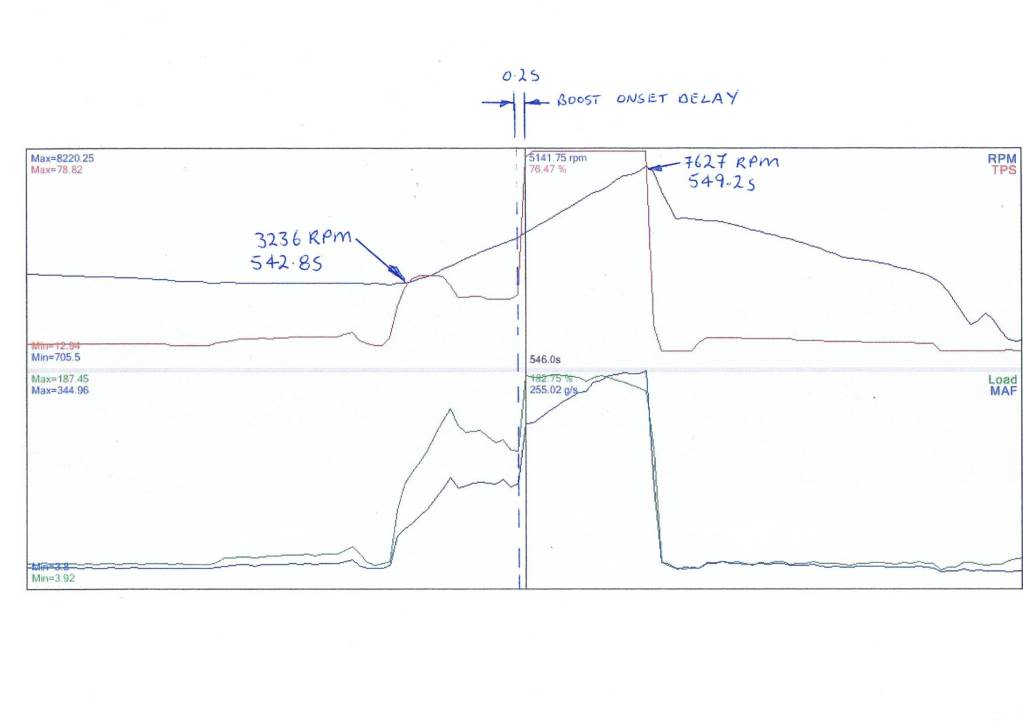

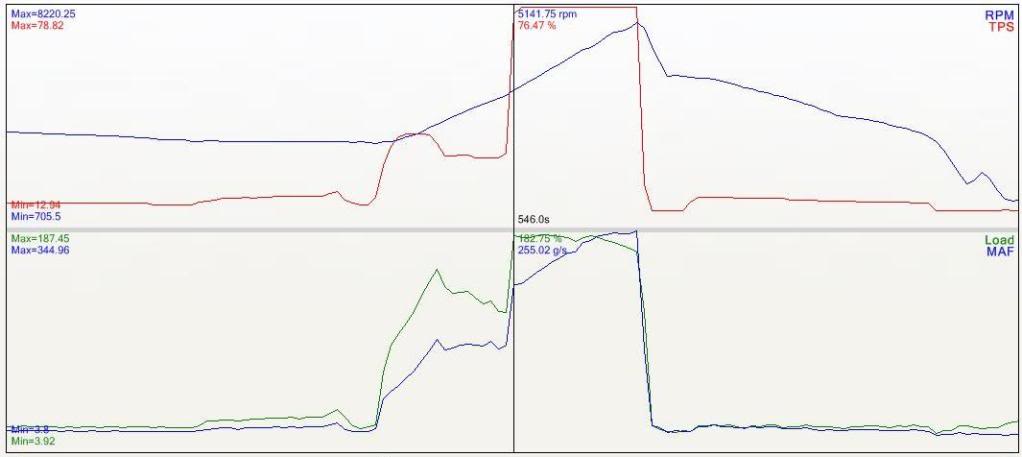

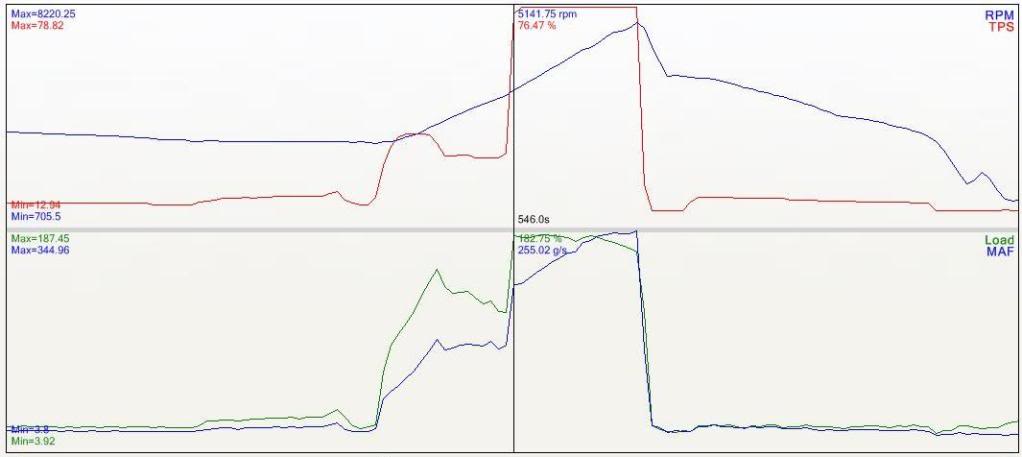

This is an atempt to show what we have been talking about here . In this run I went from about 1/3 throttle acceleration to WOT .

Look at the throttle position (TPS) and compare with load and MAF lines . Note how Maf increases in line with the throttle . In other words the UIM goes from 0psi to 10psi just as quickly as the throttle opens ( 0.2s) .

Does this look like a slow laggy turbo spoolup to anyone ?

Look at the throttle position (TPS) and compare with load and MAF lines . Note how Maf increases in line with the throttle . In other words the UIM goes from 0psi to 10psi just as quickly as the throttle opens ( 0.2s) .

Does this look like a slow laggy turbo spoolup to anyone ?

Last edited by Brettus; 09-17-2009 at 06:24 AM.

#157

I know exactly what you are trying to say. Its wrong. (Or, perhaps I don't know what you are trying to say, just what you are saying.)

When you go WOT, your MAF lags. When you go partial throttle, your MAF lags.

On my car, the MAF moves nearly instantaneously with the throttle.

#159

#160

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,606

Likes: 1,535

From: Y-cat-o NZ

Mama mia !!!!

OK the red line is throttle , the blue line is MAF .

The black vertical line represents a point in time 0.2seconds after I go WOT .

From part throttle to full throttle takes 0.2s on the chart

From approx. 160g/s to 255g/s takes exactly 0.2s also .

So how much more instant than that can you get ?

OK the red line is throttle , the blue line is MAF .

The black vertical line represents a point in time 0.2seconds after I go WOT .

From part throttle to full throttle takes 0.2s on the chart

From approx. 160g/s to 255g/s takes exactly 0.2s also .

So how much more instant than that can you get ?

Last edited by Brettus; 09-17-2009 at 03:13 PM.

#167

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,606

Likes: 1,535

From: Y-cat-o NZ

I can't believe you don't get this MM .

Flow jumps form 160g/s to 255g/s in 0.2s

Boost jumps from 0psi to 10psi in 0.2s

Throttle opens in 0.2s

Load jumps from just over 100% to 180% in 0.2s .

Where is the lag ?

Flow jumps form 160g/s to 255g/s in 0.2s

Boost jumps from 0psi to 10psi in 0.2s

Throttle opens in 0.2s

Load jumps from just over 100% to 180% in 0.2s .

Where is the lag ?

#168

If I have figured out Jeff's point, what he is saying is that you should have a constant (IE non-increasing) MAF reading and since your MAF reading is still increasing even after you are pegging the throttle and getting an initial spike, this is not the ideal behavior.

I'm still trying to wrap my head around this, as it seems to me the MAF reading MUST increase with RPM because air consumption increases with RPM

But I think what Jeff is saying is your chart SHOULD look like this (Though I don't know how it could...)

Do I get a cookie Jeff?

I'm still trying to wrap my head around this, as it seems to me the MAF reading MUST increase with RPM because air consumption increases with RPM

But I think what Jeff is saying is your chart SHOULD look like this (Though I don't know how it could...)

Do I get a cookie Jeff?

#170

I agree will you brettus for the upper rpm but down low there seems to be some delay. the first blip of the throttle appears to have spooled the turbo. it seems to me the turbo is spooling round the 3200rpm which sounds about right.

#171

He's being cryptic about it, as always, but what he is trying to say if I understand him correctly, is that while your boost gauge and manifold pressure may be at 10 PSI, your MAF reading is still increasing over time. He's terming this boost lag, I'm not sure if it is or not, as it seems to me that as engine air consumption goes up with RPMs, the MAF will read more air entering the engine.

At the same time, though, if you are "boosting" a constant value (your target 10 PSI), you should have the same amount of air entering the engine, as the MAF is located pre-TB and post-compressor, you should be metering as much air as the turbine is pushing.

Therefore, the turbine is still pushing more air over time, hence the difference between pressure and flow and why, I believe, your turbo is still spooling.

I'm an armchair jockey, I don't pretend to understand this stuff, I'm just trying to. Don't bite my head off

#172

Thread Starter

Boosted Kiwi

iTrader: (2)

Joined: Apr 2006

Posts: 20,606

Likes: 1,535

From: Y-cat-o NZ

Sorry If it seemed that way . That post was more directed at MM not you .

You are quite correct in sayin maf should increase as RPM increases though : I'll run you through what is happening in that log because I have all the numbers in front of me.

1 cruising along at 3200rpm

2 slowly open the throttle to plateu at 37%

3 throttle % dips down to about 30% - boost is about 0psi and flow is 150g/s . At this point still accelerating gently under partial throttle

RPM is at 4941 at this point

4 I slam the throttle down to full WOT

5 0.2 seconds later

flow has gone to 255g/s

load has gone to 182%

boost is at 10 psi

rpm has gone to 5141

6 From 5141 rpm to 7627 rpm at WOT

Maf is gradually increasing as rpm increases

Boost guage is sitting constant at 10psi till about 6500rpm after which point it starts to drop away

You are quite correct in sayin maf should increase as RPM increases though : I'll run you through what is happening in that log because I have all the numbers in front of me.

1 cruising along at 3200rpm

2 slowly open the throttle to plateu at 37%

3 throttle % dips down to about 30% - boost is about 0psi and flow is 150g/s . At this point still accelerating gently under partial throttle

RPM is at 4941 at this point

4 I slam the throttle down to full WOT

5 0.2 seconds later

flow has gone to 255g/s

load has gone to 182%

boost is at 10 psi

rpm has gone to 5141

6 From 5141 rpm to 7627 rpm at WOT

Maf is gradually increasing as rpm increases

Boost guage is sitting constant at 10psi till about 6500rpm after which point it starts to drop away

Last edited by Brettus; 09-17-2009 at 05:34 PM.

#174

I don't want to get in the middle of your argument, I'm trying to point out what I believe Jeff is trying to say.

He's being cryptic about it, as always, but what he is trying to say if I understand him correctly, is that while your boost gauge and manifold pressure may be at 10 PSI, your MAF reading is still increasing over time. He's terming this boost lag, I'm not sure if it is or not, as it seems to me that as engine air consumption goes up with RPMs, the MAF will read more air entering the engine.

At the same time, though, if you are "boosting" a constant value (your target 10 PSI), you should have the same amount of air entering the engine, as the MAF is located pre-TB and post-compressor, you should be metering as much air as the turbine is pushing.

Therefore, the turbine is still pushing more air over time, hence the difference between pressure and flow and why, I believe, your turbo is still spooling.

I'm an armchair jockey, I don't pretend to understand this stuff, I'm just trying to. Don't bite my head off

He's being cryptic about it, as always, but what he is trying to say if I understand him correctly, is that while your boost gauge and manifold pressure may be at 10 PSI, your MAF reading is still increasing over time. He's terming this boost lag, I'm not sure if it is or not, as it seems to me that as engine air consumption goes up with RPMs, the MAF will read more air entering the engine.

At the same time, though, if you are "boosting" a constant value (your target 10 PSI), you should have the same amount of air entering the engine, as the MAF is located pre-TB and post-compressor, you should be metering as much air as the turbine is pushing.

Therefore, the turbine is still pushing more air over time, hence the difference between pressure and flow and why, I believe, your turbo is still spooling.

I'm an armchair jockey, I don't pretend to understand this stuff, I'm just trying to. Don't bite my head off

the MAF only meters what the engine breaths. if it metered all the air the compressor was flowing you could not tune the A/F with it.