Wingle's Supercharger Build

#1

Wingle's Supercharger Build

Migrate this from my project teaser to an office build page. Wish me luck!

Hymee Supercharger

Supercharger fixes (port and polish, fittings, spacer, welded dump pipe)

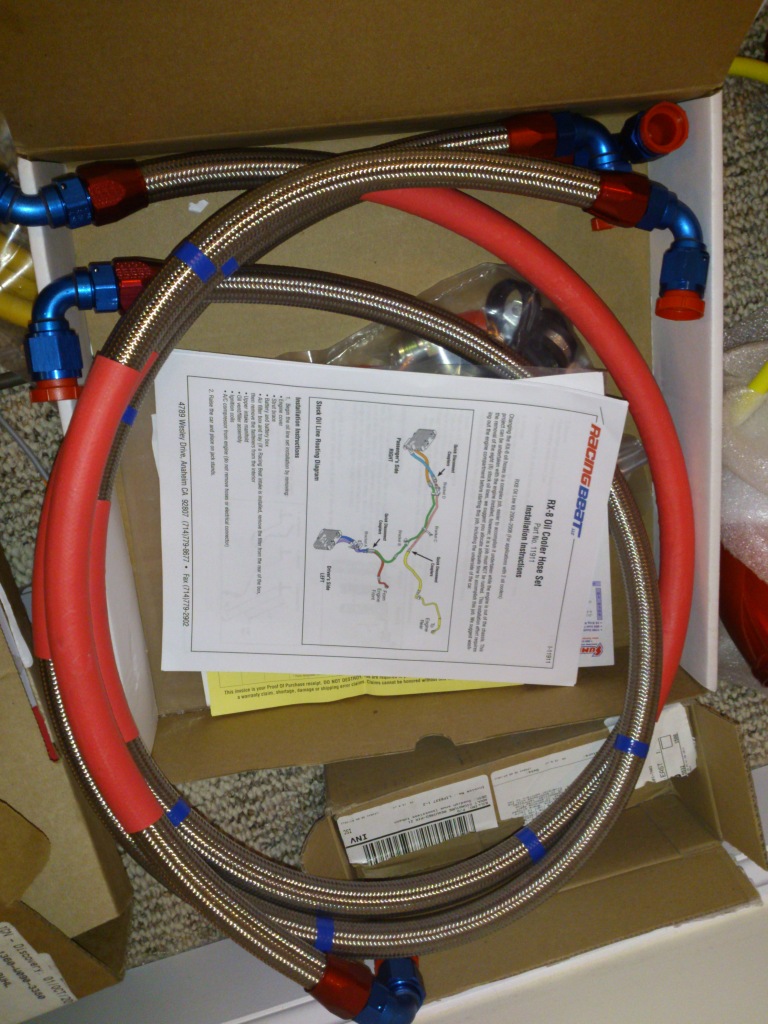

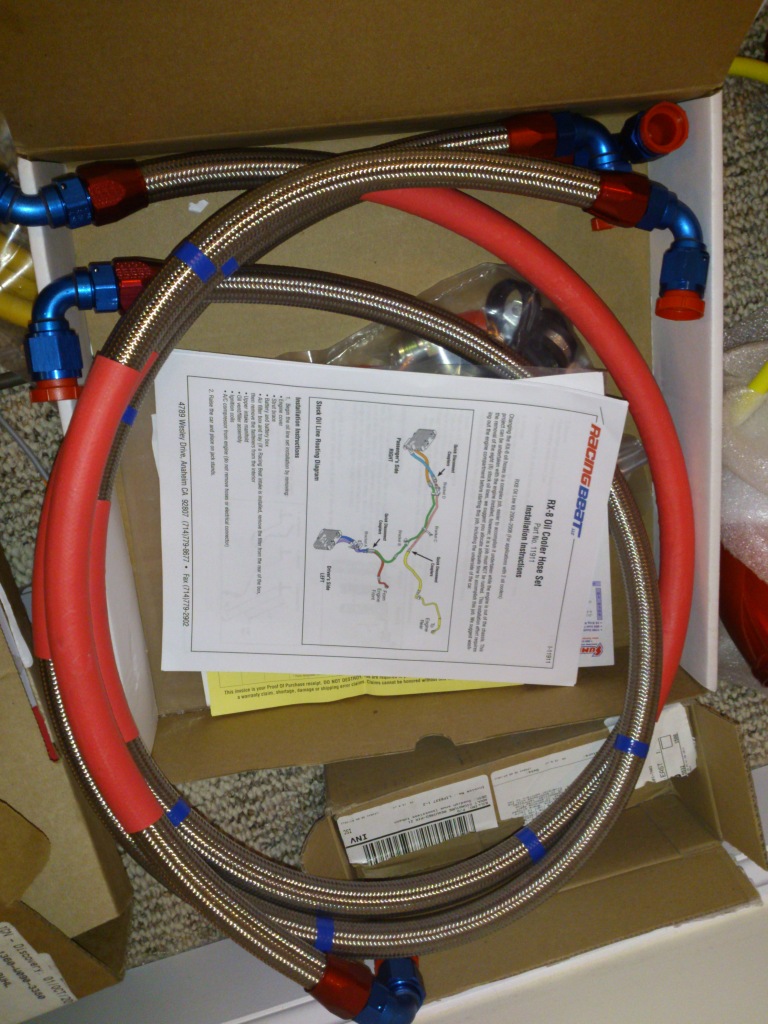

RB Oil Lines

Sohn Adaptor

New Injectors

BHR Fuel Pump

Samco couplers and hose

Photos:

Hymee Supercharger

Supercharger fixes (port and polish, fittings, spacer, welded dump pipe)

RB Oil Lines

Sohn Adaptor

New Injectors

BHR Fuel Pump

Samco couplers and hose

Photos:

Last edited by WingleBeast; 10-03-2012 at 10:16 PM.

#3

I really want to touch up the polish job on the alternator and throttle body, my polisher didnt have any small tools and I could use my dremel, just not sure if the casting is fine enough to do it without sanding

#5

Judging by the look of the parts this is going to look super cool installed . great stuff ! .

#8

Looking good. While you got all the parts out you may as well replace the existing seals with Viton seals as they will last longer as well as polish out all the tooling marks for a better seal. If you are using gear oil then you should be ok.

Get a longer coupler for the first connection pipe after the blower as you will find the pipe may not marry up all that well. The longer coupler will give you room to secure the pipes together without boost leak. I only noticed this boost leak when i removed the battery tray.

I regret not going with upgraded injectors as it now involves removing the supercharger to get to the injectors as the standard pulley now puts out 12psi now that all the boost leaks have been resolved. The power is now in the 300 HP range.

I am looking to change my fuel pump to Aeromotive 11142 for safety as mine is almost 10 yrs old.

Get a longer coupler for the first connection pipe after the blower as you will find the pipe may not marry up all that well. The longer coupler will give you room to secure the pipes together without boost leak. I only noticed this boost leak when i removed the battery tray.

I regret not going with upgraded injectors as it now involves removing the supercharger to get to the injectors as the standard pulley now puts out 12psi now that all the boost leaks have been resolved. The power is now in the 300 HP range.

I am looking to change my fuel pump to Aeromotive 11142 for safety as mine is almost 10 yrs old.

#12

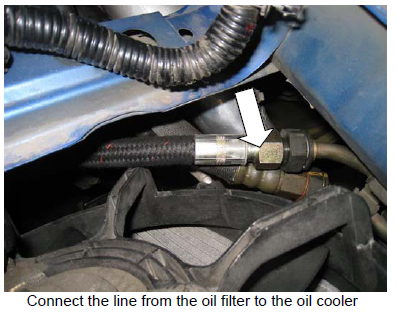

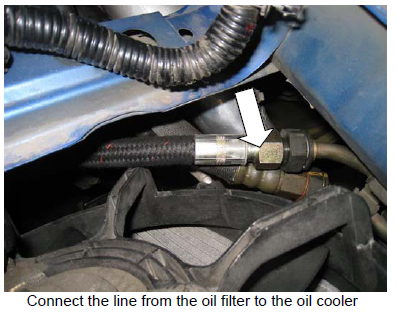

Running into an issue, looking in Hymee's instructions it appears that he runs the oil filter to cooler oil line to the left (drivers side in US) oil cooler. But in my car that oil line runs to the passenger side and mounts differently. Here is the page I am talking about. Curious to hear from our friends from down under whats up.

#14

Running into an issue, looking in Hymee's instructions it appears that he runs the oil filter to cooler oil line to the left (drivers side in US) oil cooler. But in my car that oil line runs to the passenger side and mounts differently. Here is the page I am talking about. Curious to hear from our friends from down under whats up.

#15

Unfortunately, I did not get to replace the seals within the compressor. The only Viton seals I used was for the dog bone.

You should be able to source replacement seal from your local bearing shop. take your original seals for measurement

You should be able to source replacement seal from your local bearing shop. take your original seals for measurement

#17

OK, so to make things easier I am just going to buy RB oil line kit and add the Hymee extension to it. Spent all today cutting the lines out with a pocket knife since the fittings were so rusted in the wheel well. Also took out the air pump to make room for both Sohn Adapter Tank, and Oil Catch Can.

Also any ideas on what weight gear oil to use in the blower?

Also any ideas on what weight gear oil to use in the blower?

#21

I sent an e-mail to Hymee and Sprintex regarding the oil. We will see what turns up in the inbox.

#22

Ordered my RB oil line kit, as well as extensions that should cover eveything, pics on wednesday.

Got on a stainless steel kick as far as fasteners, and am a little concerned about their lack of tensile and load strength compared to Hymees 12.9 grade galvanized. I have been assured by my mechanic it will not be a problem except for rotational clamping loads (inside the blower, pulley/idler bolts.) But just to be sure I ordered ARP high strength stainless bolts for the large M8 bolts that withstand the weight and vibrations of the blower.

My general view is that the 800,000 Kpa that would shear a stainless bolt would be more likely to bend the aluminum plate first, but I am no physicist (or mechanic).

Just seeing if any of you have any opinions on that matter.

Got on a stainless steel kick as far as fasteners, and am a little concerned about their lack of tensile and load strength compared to Hymees 12.9 grade galvanized. I have been assured by my mechanic it will not be a problem except for rotational clamping loads (inside the blower, pulley/idler bolts.) But just to be sure I ordered ARP high strength stainless bolts for the large M8 bolts that withstand the weight and vibrations of the blower.

My general view is that the 800,000 Kpa that would shear a stainless bolt would be more likely to bend the aluminum plate first, but I am no physicist (or mechanic).

Just seeing if any of you have any opinions on that matter.

#23

Just got my injectors back from cleaning,

Before (Flow@ 43.5psi):

Used S1 Blues

1 612cc

2 624cc

3 624cc

4 600cc

New S2 Green

5 492cc

6 492cc

After (Flow@ 43.5psi):

Used S1 Blues

1 612cc

2 612cc

3 612cc

4 612cc

New S2 Green

5 492cc

6 492cc

Before (Flow@ 43.5psi):

Used S1 Blues

1 612cc

2 624cc

3 624cc

4 600cc

New S2 Green

5 492cc

6 492cc

After (Flow@ 43.5psi):

Used S1 Blues

1 612cc

2 612cc

3 612cc

4 612cc

New S2 Green

5 492cc

6 492cc

I have one of these kits sitting in my garage. Hopefully someone will make Hoss-05 happy and buy it.

I have one of these kits sitting in my garage. Hopefully someone will make Hoss-05 happy and buy it.