Wingle's Turbo Install

#32

had an oil leak the first time

2nd time the greddy crapped itself, got an upgrade and rebuild

3rd time I was gonna sell the kit, but did not get much serious interest...it was just getting cobwebs all over it sitting in my garage...so I installed it again

2nd time the greddy crapped itself, got an upgrade and rebuild

3rd time I was gonna sell the kit, but did not get much serious interest...it was just getting cobwebs all over it sitting in my garage...so I installed it again

#33

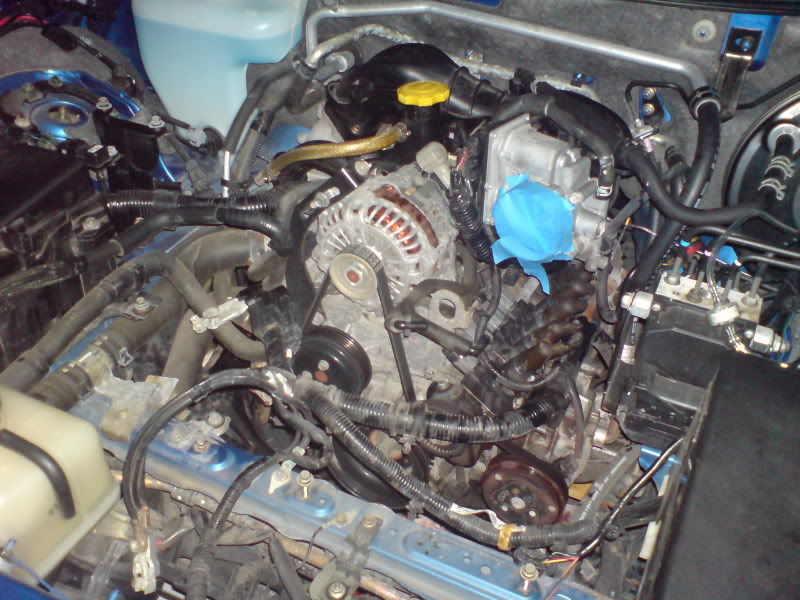

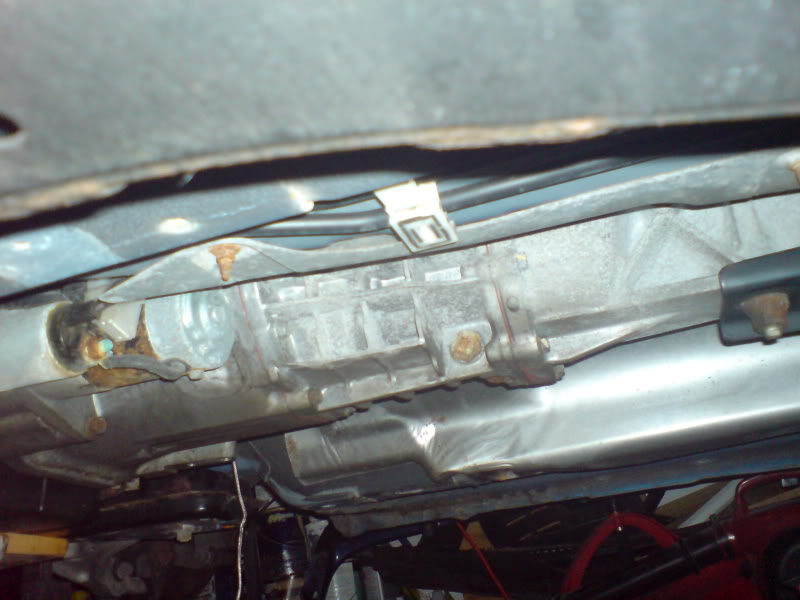

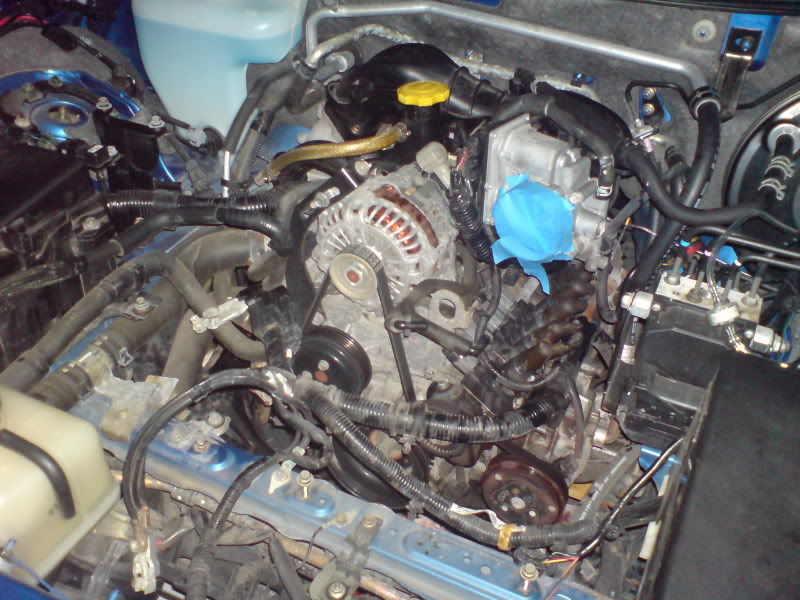

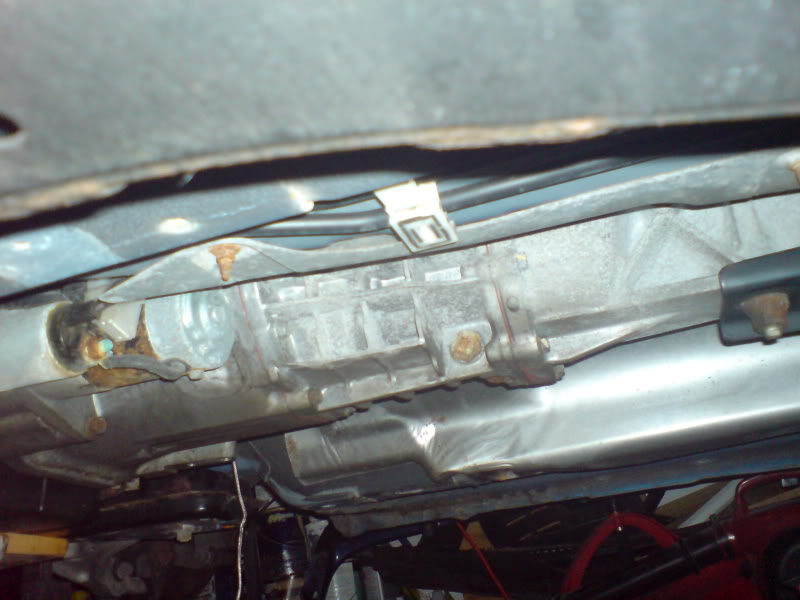

Pics of the car torn apart and ready for install.

Now cutting and sealing all the AN lines and fittings

Any tips rex on not getting any leaks? Im pretty much sealing every fitting with liquid teflon thread sealant.

Now cutting and sealing all the AN lines and fittings

Any tips rex on not getting any leaks? Im pretty much sealing every fitting with liquid teflon thread sealant.

#34

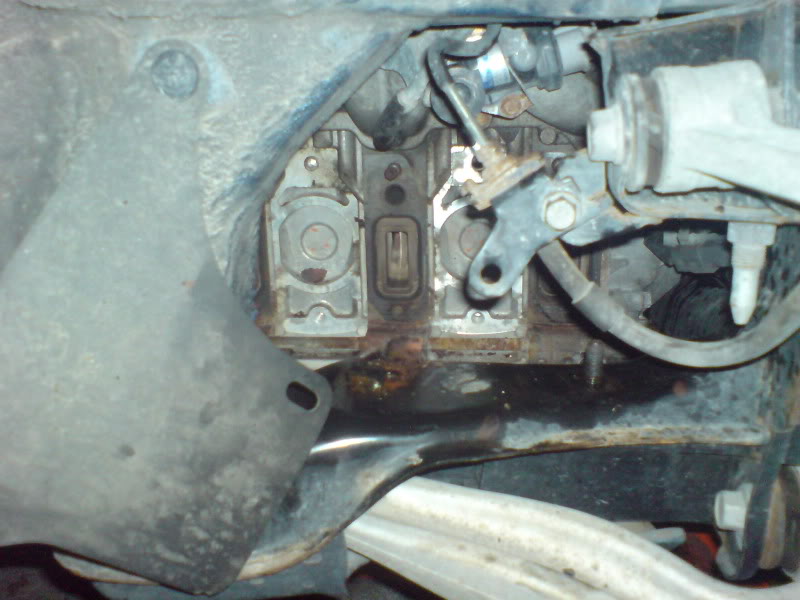

so I was sappose to start the install today before I have to drive to lansing for a bachlor party. Buttt.....

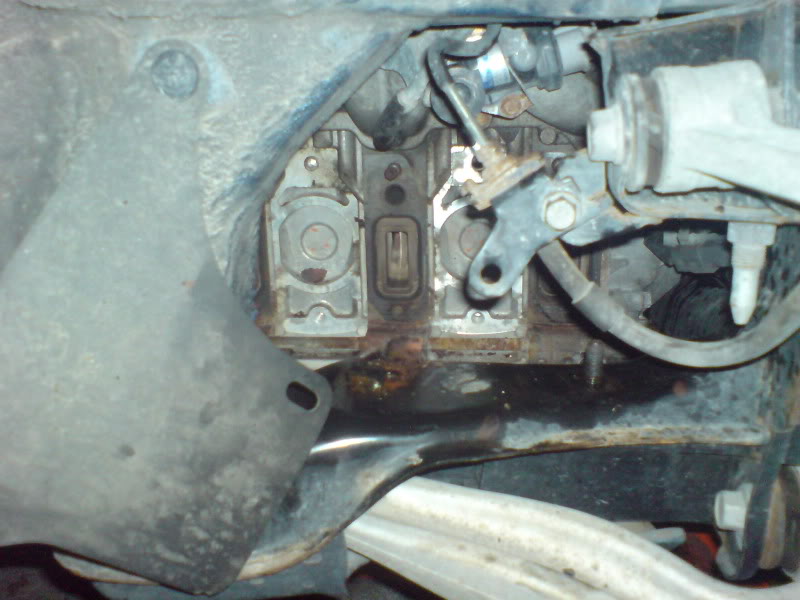

Oil Pressure Switch

.....

so now I have to drive and buy a deep well socket and someone figure how to get a rachet in there. Oh well at least i know that others have been here before and suceeded.

Oil Pressure Switch

.....

so now I have to drive and buy a deep well socket and someone figure how to get a rachet in there. Oh well at least i know that others have been here before and suceeded.

#38

so i bought a 15/16 socket, oil pressure switch came out like a charm.

Put in all my AN fittings and feed lines. Im a little worried about leaks... i tried to tighten as much as possible but I didnt want to tourqe any of the aluminum fittings in half. as i hooked up the feed line to the T-fitting the whole assembly rotaed a little bit, so I hope that doesnt mean its a possible leak and the liquid teflon does its job. Im hopeing as soon as oil is pumped theough there it will compress the sealant on the threads.

Oh well if it does leak at least I can get to that area without ripping the system apart.

Just waiting on some welded fittings then I can get the pipeing underway.

Put in all my AN fittings and feed lines. Im a little worried about leaks... i tried to tighten as much as possible but I didnt want to tourqe any of the aluminum fittings in half. as i hooked up the feed line to the T-fitting the whole assembly rotaed a little bit, so I hope that doesnt mean its a possible leak and the liquid teflon does its job. Im hopeing as soon as oil is pumped theough there it will compress the sealant on the threads.

Oh well if it does leak at least I can get to that area without ripping the system apart.

Just waiting on some welded fittings then I can get the pipeing underway.

#41

i think you are talking to me...lol

I can install the whole kit in about 8 hours now; and that includes removing stock oil pan for greddy one

removing just the turbo takes me about 1 hour

my first time doing it took me forever tho...lol.

I can install the whole kit in about 8 hours now; and that includes removing stock oil pan for greddy one

removing just the turbo takes me about 1 hour

my first time doing it took me forever tho...lol.

#42

#46

sorry for the thread jack Wingle. how's the install?

#47

no prob nuke! its cool to see all this discussion on my install after reading so many other before me for hours. Kinda surreal I am finally installing.

I was in the same boat you are. I bought the kit back in january thinking I would be ready by the time the snow thawed in march. and here I am 5 months later just getting started. I replaced all the couplers and clamps, oil lines are all stainless braided AN fittings (which took me forever to hook up tonight.... my own fault...) Got everything ceramic coated, Bov, all new high grade fasteners plus odds and ends. It definately takes more time and money but I do not regret it knowing the entire setup is going to be top of the line.

As far as why I am up at 2am, I sped the last few hours mounting the manifold and turbo, hooking up all the oil feed lines, and reattaching the engine mount, should have pictures in the morning (or afternoon depending on when I wake up!!!) Now it gets ten times easier with all the pipeing!

I was in the same boat you are. I bought the kit back in january thinking I would be ready by the time the snow thawed in march. and here I am 5 months later just getting started. I replaced all the couplers and clamps, oil lines are all stainless braided AN fittings (which took me forever to hook up tonight.... my own fault...) Got everything ceramic coated, Bov, all new high grade fasteners plus odds and ends. It definately takes more time and money but I do not regret it knowing the entire setup is going to be top of the line.

As far as why I am up at 2am, I sped the last few hours mounting the manifold and turbo, hooking up all the oil feed lines, and reattaching the engine mount, should have pictures in the morning (or afternoon depending on when I wake up!!!) Now it gets ten times easier with all the pipeing!

#49

intercooler is mounted, all the pipeing is in. All that is left is get my oil drain from the welder, air pump back in, midpipe, and figure out how to put the damn BOV on.

PROMISE to have pics tomorrow

PROMISE to have pics tomorrow

#50

you should leave the air pump off and use a blocking plate on the downpipe.

which BOV do you have, HKS? i'm having trouble with mine too. can't figure out how to get the c-clip in.

which BOV do you have, HKS? i'm having trouble with mine too. can't figure out how to get the c-clip in.

good luck on the install

good luck on the install