5W30 Oil Don't Cut it, Engine Bearing Pics 58K S1 RX-8 from England.

#401

Registered

iTrader: (3)

i think people are confusing pressure with film strenght(spelling) I never intended to increase my pressure when I went to a heavier oil. i wanted a better film strengh.

We do not run heavier oil to increase the pressure, we run it to better protect the engine -- generally speaking a higher vis oil will have a better film strengh.

This also has been talked about with data support from study of used engine oil analysis.

Once AGAIN--thicker oil will not increase flow, it will not increase oil pump output, BUT, it will help better protect the bearings etc through increased film strengh.

OD

We do not run heavier oil to increase the pressure, we run it to better protect the engine -- generally speaking a higher vis oil will have a better film strengh.

This also has been talked about with data support from study of used engine oil analysis.

Once AGAIN--thicker oil will not increase flow, it will not increase oil pump output, BUT, it will help better protect the bearings etc through increased film strengh.

OD

#402

Super Moderator

Thread Starter

#403

SARX Legend

iTrader: (46)

Question:

When you add extra lines (additional cooler, remote mount, pan etc,) what is the best way to determine how much extra oil to add to the system? Does doing this affect the dipstick reading?

When you add extra lines (additional cooler, remote mount, pan etc,) what is the best way to determine how much extra oil to add to the system? Does doing this affect the dipstick reading?

#404

#406

Out of NYC

iTrader: (1)

I'm not sure, maybe your gauge is broken? Going from 0w-30 to 0w-40 showed 0.5 bar increase under cruise conditions for my pressure. My temperature tends to be at 160F averagely contrast to 150F at 0w-30.

I mentioned performance in regards to better engine efficiency, not power. Sure, 20w-50 is stronger, see how well that works when an engine is trying to turn over which most of us agree that also leads to a lot of wear.

Let's agree that we disagree which oil we want to run. Acting like your choice should be THE choice and the holy grail is delusional. We want to fix the root cause, not compensate for it. The root cause of engine failure is not from the viscosity, but from a lack of oil being fed. Premixing and/or AP helps address this.

I mentioned performance in regards to better engine efficiency, not power. Sure, 20w-50 is stronger, see how well that works when an engine is trying to turn over which most of us agree that also leads to a lot of wear.

Let's agree that we disagree which oil we want to run. Acting like your choice should be THE choice and the holy grail is delusional. We want to fix the root cause, not compensate for it. The root cause of engine failure is not from the viscosity, but from a lack of oil being fed. Premixing and/or AP helps address this.

Premix is the ultimate solution, jet air nozzle will make sure the premix/gas is "everywhere".

We still need protection for the bearings as well, and how do we do that? hmm, Premix? no. We need "stronger" oil.

I think the biggest reason for Mazda to increase the oil pump pressure is for the new EMOP now. (Thx ASH)

there is no doubt that 20w50 offers better "protection" than 5w20. Like I said, all we need to do is to have someone like me, to use nothing but that all the way, take the engine apart after say 50K miles then we'll see whos the winner. sounds fair enough ?

oh one more thing.

Took this tonight.

First picture : Engine Start, Warmed up for maybe 30 seconds, start driving slowly (local) for maybe 7 minutes. At red light :

Second picture : This is about 2-3 minutes of 50 mph, then stuck in traffic for maybe 10 minutes. almost home.

Again you can say my gauges are broken. but Im getting the same readings with 5w20 (when I first got my Reman, it was filled with "o-holy" factory 5w20). and I think Defi is one of the most accurate Racing Gauge maker on the market.

and dont forget, when w20 gets hot. what kind of protection does it have left? compare that to w30, 40, and 50. and you making it sound like the engine will work 100 times harder to try to run with it. If it doesnt work, Mazda wouldnt show it in the oil chart (just not US)

Last edited by nycgps; 10-29-2009 at 08:28 PM.

#408

Out of NYC

iTrader: (1)

well, yeah, I know.

ever since that time my car got pwned front & back, I lost interest to wipe the car clean.

You should see the outside, It hasn't been wash for like close to 2 months and awww it looks really bad.

but that will end soon ... cuz my bumper from Japan is here and Im ready to bring it to a shop to fix it up ...

I was about to say, its not low

yes its in Celsius

ever since that time my car got pwned front & back, I lost interest to wipe the car clean.

You should see the outside, It hasn't been wash for like close to 2 months and awww it looks really bad.

but that will end soon ... cuz my bumper from Japan is here and Im ready to bring it to a shop to fix it up ...

Dude your pressure is very low at cold idle. I will post pics in the morning so you can see.

Edit: Nevermind that is in Celcius?

Edit: Nevermind that is in Celcius?

yes its in Celsius

#411

Out of NYC

iTrader: (1)

Just keep in mind my car is stock. which is about 810 rpm +/- 10 rpm.

if I raise it to say, 900 rpm, the idle pressure will raise to around 250 kPa (36 something psi)

That happened to me when I dont change my oil for more than 3K miles and I was using 10w30 RP under a hot summer days (like 90f+)

if I raise it to say, 900 rpm, the idle pressure will raise to around 250 kPa (36 something psi)

That happened to me when I dont change my oil for more than 3K miles and I was using 10w30 RP under a hot summer days (like 90f+)

#414

#415

#416

Registered User

Join Date: Apr 2009

Location: michigan

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

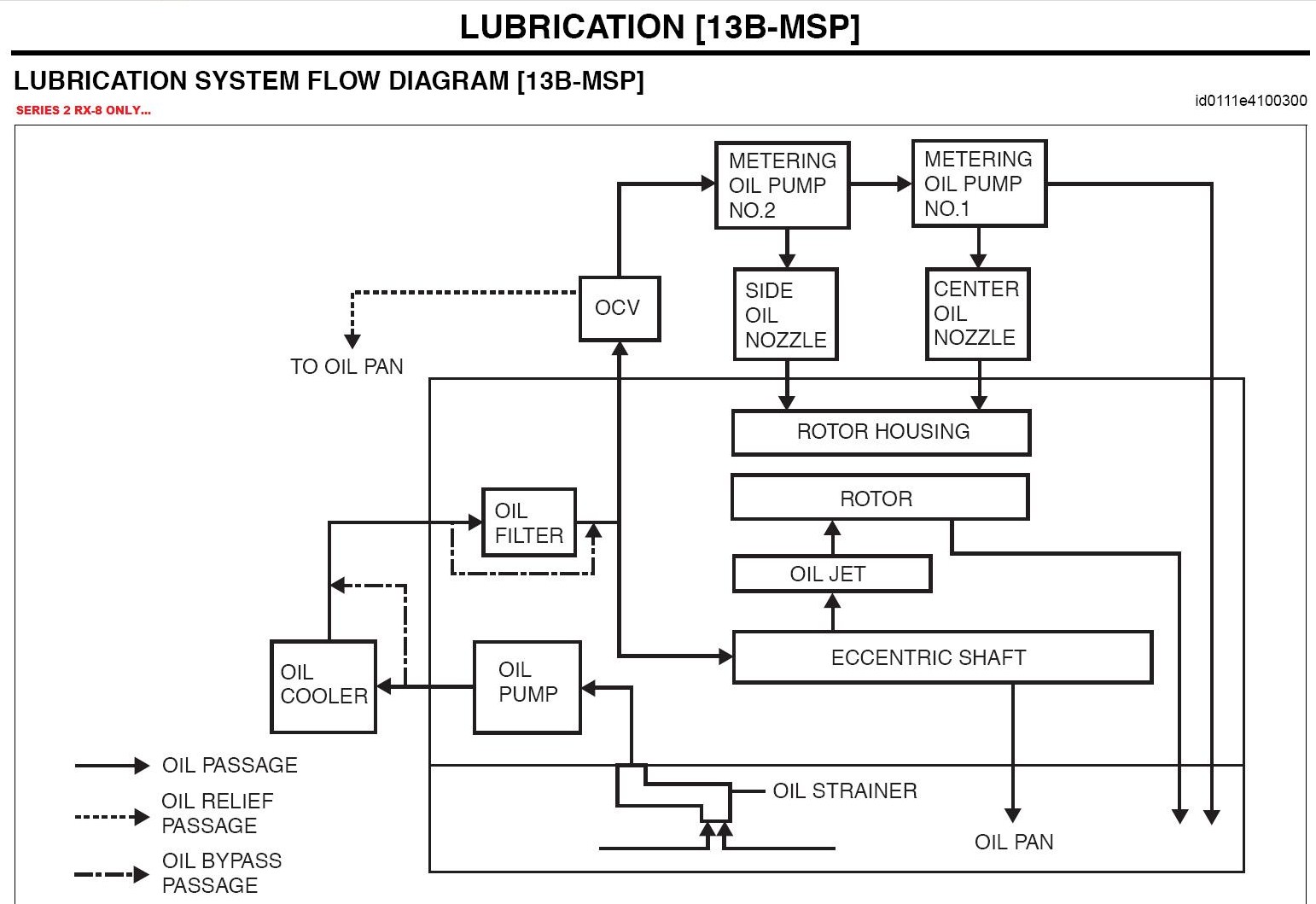

Hmm, it's very possible that the OCV valve drops the localized pressure after the filter to both the MOP and the e-shaft. I wonder what the relief pressure is.

And now onto something a bit unrelated...

I've been thinking about what many people have said (not just on this forum) regarding oil pressure. It's said that a higher oil pressure at the bearings is not providing any more protection than lower pressure oil - as long as the volume of oil is sufficient to fill the gaps. If this is true, then the only reason to try to obtain a higher pressure (and therefore, flow rate - as long as it's not getting bypassed) is to potentially clear debris, and for cooling benefits. It could then also be said that since the oil paths and gaps between bearings and surfaces don't change with RPM, only one flow rate needs to be obtained in order to provide sufficient lubrication.

Once those parameters are determined, it's only important to ensure that the film strength of the oil used will provide enough protection a peak torque (when working pressures during combustion are at their highest). So theoretically, any flow above nominal should not be providing any additional wear protection, but rather just aid in cooling, and removal of contaminants.

Someone please tell me if I'm way off base.

And now onto something a bit unrelated...

I've been thinking about what many people have said (not just on this forum) regarding oil pressure. It's said that a higher oil pressure at the bearings is not providing any more protection than lower pressure oil - as long as the volume of oil is sufficient to fill the gaps. If this is true, then the only reason to try to obtain a higher pressure (and therefore, flow rate - as long as it's not getting bypassed) is to potentially clear debris, and for cooling benefits. It could then also be said that since the oil paths and gaps between bearings and surfaces don't change with RPM, only one flow rate needs to be obtained in order to provide sufficient lubrication.

Once those parameters are determined, it's only important to ensure that the film strength of the oil used will provide enough protection a peak torque (when working pressures during combustion are at their highest). So theoretically, any flow above nominal should not be providing any additional wear protection, but rather just aid in cooling, and removal of contaminants.

Someone please tell me if I'm way off base.

#418

Hmm, it's very possible that the OCV valve drops the localized pressure after the filter to both the MOP and the e-shaft. I wonder what the relief pressure is.

And now onto something a bit unrelated...

I've been thinking about what many people have said (not just on this forum) regarding oil pressure. It's said that a higher oil pressure at the bearings is not providing any more protection than lower pressure oil - as long as the volume of oil is sufficient to fill the gaps. If this is true, then the only reason to try to obtain a higher pressure (and therefore, flow rate - as long as it's not getting bypassed) is to potentially clear debris, and for cooling benefits. It could then also be said that since the oil paths and gaps between bearings and surfaces don't change with RPM, only one flow rate needs to be obtained in order to provide sufficient lubrication.

Once those parameters are determined, it's only important to ensure that the film strength of the oil used will provide enough protection a peak torque (when working pressures during combustion are at their highest). So theoretically, any flow above nominal should not be providing any additional wear protection, but rather just aid in cooling, and removal of contaminants.

Someone please tell me if I'm way off base.

And now onto something a bit unrelated...

I've been thinking about what many people have said (not just on this forum) regarding oil pressure. It's said that a higher oil pressure at the bearings is not providing any more protection than lower pressure oil - as long as the volume of oil is sufficient to fill the gaps. If this is true, then the only reason to try to obtain a higher pressure (and therefore, flow rate - as long as it's not getting bypassed) is to potentially clear debris, and for cooling benefits. It could then also be said that since the oil paths and gaps between bearings and surfaces don't change with RPM, only one flow rate needs to be obtained in order to provide sufficient lubrication.

Once those parameters are determined, it's only important to ensure that the film strength of the oil used will provide enough protection a peak torque (when working pressures during combustion are at their highest). So theoretically, any flow above nominal should not be providing any additional wear protection, but rather just aid in cooling, and removal of contaminants.

Someone please tell me if I'm way off base.

I agree with Philip, it could be compared to what happens in air hockey

Aside from that, nice nick madcows!

#419

Just to add to that, the higher the surface speed of the bearing (rpms), and the more load (also linked with RPM), the more heat will be generated in the oil locally at the bearing, just from the pressure and shearing forces exerted, which causes the oil film to thin, so sufficient flow is needed to keep the localised oil temperatures down.

In extreme cases of too much load and not enough oil flow, the oil can actually experience localised boiling in the bearing, outgas and cause a complete collapse of the bearing film.

In extreme cases of too much load and not enough oil flow, the oil can actually experience localised boiling in the bearing, outgas and cause a complete collapse of the bearing film.

#420

Registered User

Join Date: Apr 2009

Location: michigan

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

Are you referring to thermal expansion of the components? I would hardly imagine that necessitating any significant increase in oil pressure.

Are you referring to thermal expansion of the components? I would hardly imagine that necessitating any significant increase in oil pressure.The only other gap I can see you referring to is that between the e-shaft and bearing at a particular angle (the angle the load is being applied at). If this is what you're talking about, I would have to think lower RPMs (where oil has more time to escape between two surfaces) is more dangerous than the upper limits. Again, I would imagine that the most critical lubrication point is around peak torque and under (since the torque curve is relatively flat). I'm thinking this because besides for oil flowing out of gaps on it's own, oil is also squeezed out between two surfaces at high pressure (rotor bearings on e-shaft). So, the longer a particular event occurs (combustion cycle), the more time there is for the oil to get squeezed out.

bse50, maybe we need to switch avatars. hehe.

#421

Registered User

Join Date: Apr 2009

Location: michigan

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

Just to add to that, the higher the surface speed of the bearing (rpms), and the more load (also linked with RPM), the more heat will be generated in the oil locally at the bearing, just from the pressure and shearing forces exerted, which causes the oil film to thin, so sufficient flow is needed to keep the localised oil temperatures down.

In extreme cases of too much load and not enough oil flow, the oil can actually experience localised boiling in the bearing, outgas and cause a complete collapse of the bearing film.

In extreme cases of too much load and not enough oil flow, the oil can actually experience localised boiling in the bearing, outgas and cause a complete collapse of the bearing film.

That's why I suggested that the only realistic benefit (unless I'm gravely mistaking) of higher oil pressure (and thus, flow rate) is better contaminant removal, and cooling properties, but not extra lubrication.

#422

Are you referring to thermal expansion of the components? I would hardly imagine that necessitating any significant increase in oil pressure.

Are you referring to thermal expansion of the components? I would hardly imagine that necessitating any significant increase in oil pressure.The only other gap I can see you referring to is that between the e-shaft and bearing at a particular angle (the angle the load is being applied at). If this is what you're talking about, I would have to think lower RPMs (where oil has more time to escape between two surfaces) is more dangerous than the upper limits. Again, I would imagine that the most critical lubrication point is around peak torque and under (since the torque curve is relatively flat). I'm thinking this because besides for oil flowing out of gaps on it's own, oil is also squeezed out between two surfaces at high pressure (rotor bearings on e-shaft). So, the longer a particular event occurs (combustion cycle), the more time there is for the oil to get squeezed out.

bse50, maybe we need to switch avatars. hehe.

Anyway, bse exactly means mad cow (bovine spongiform encephalopathy), hence the avatar

#423

Registered User

Join Date: Apr 2009

Location: michigan

Posts: 239

Likes: 0

Received 0 Likes

on

0 Posts

It is not just a matter of tolerances the gap PhilipM is talking about. It is the gap where the oil film is fundamental in order to avoid metal to metal contact. That's why friction (rpm related) is a so important factor.

Anyway, bse exactly means mad cow (bovine spongiform encephalopathy), hence the avatar

Anyway, bse exactly means mad cow (bovine spongiform encephalopathy), hence the avatar

However, I can potentially see how higher RPMs increase the "pumping action" between a bearing and shaft surface, and therefore require a higher flow rate to replenish. However, it wouldn't be a linear increase as the duration of each cycle becomes much lower with RPM, thus limiting the amount of oil escaping from it's own pumping action.

This is just leading me to believe there is not a pressure issue with the S1 renesis, but rather just leading me to believe, as many have suggested, it's a combo of low viscosity oil + dino + partial oil evacuation during changes = even lower viscosity oil being too broken down to provide reliable protection. It's possible that even a 20 weight oil under normal driving would be satisfactory as long as all the oil was COMPLETELY changed out during recommended maintenance.

Me thinks it's time for me to get some good 0/5W-40 synthetic, and get a good method to drain as much oil as possible.

bse, that's funny, the original iteration of my user name several years ago was MadCowsDiseased, when the problem was very rampant. Using the american slang word of "mad" to mean "many". On another note we just might be long lost relatives, as my last name is Italian... lol

Last edited by madcows; 10-30-2009 at 02:24 PM.

#424

SARX Legend

iTrader: (46)

Just keep in mind my car is stock. which is about 810 rpm +/- 10 rpm.

if I raise it to say, 900 rpm, the idle pressure will raise to around 250 kPa (36 something psi)

That happened to me when I dont change my oil for more than 3K miles and I was using 10w30 RP under a hot summer days (like 90f+)

if I raise it to say, 900 rpm, the idle pressure will raise to around 250 kPa (36 something psi)

That happened to me when I dont change my oil for more than 3K miles and I was using 10w30 RP under a hot summer days (like 90f+)

What is your cold idle? So your cars is at 30psi at cold idle? At cold idle my car is at like 40-50+psi with 0W-30. I will post some vids tomorrow.

#425

If I'm not mistaking, the oiling system on *any* car doesn't have sufficient pressure to supply oil to those fundamental locations until the external pressure is relieved. Lets take the combustion cycle in the rotary for example: The angle of the e-shaft receiving the pressure from the e-shaft is "floating" on oil that has been supplied to that spot prior to becoming compressed. As the combustion stage progresses, so too does the angle of the e-shaft receiving pressure from the rotor - now the spot that was once under pressure is relieved, and the gap is able to be replenished with oil from the system. While any given spot is being compressed during the combustion stage, even 100psi is far from being enough pressure to push a bearing surface away from a shaft surface.