Help with Rotary Compression Math

#1

Help with Rotary Compression Math

I've been messing around with a few of the Rotary Compression calculators out there, and it didn't take long for me to realize that none of them produce the same results for the same values given.

This took me down the the path of trying to reproduce the numbers myself.

Let me first link you to all the Rotary Compression calculators I'm referencing.

Note: I'm also using the TR-01v2 compression tester. This is important as we need to calculate the dead space for the pressure unit. Also one of the Calculators (App #1) was made especially to work with the RawPSI numbers from the TR-01

1) Foxed.ca Rotary Compression Calculator designed to use the TR-01 RawPSI numbers

http://www.foxed.ca/index.php?page=rotarycalc

2) The Rotary Compression Calculator for the Android

https://www.rx8club.com/series-i-tech-garage-22/rx8-compression-calculator-android-226754/

3) RENESIS Compression adjustment & Rating, Excel Application

https://www.rx8club.com/series-i-do-yourself-forum-73/diy-renesis-compression-adjustment-rating-excel-application-180043/

4) Web based calculator (same dude that makes the Android app)

http://virusakos.freevar.com/web/RX_...alculator.html

To keep the math simple I wanted to use values of 100 psi for all faces for both rotor 1 and 2 and an RPM on Rotor 1 of 250 and Rotor 2 of 200.

So anything on Rotor 1 should return the same PSI value entered after normalizing (I did this as a check)

Like this:

Rotor 1 = 100, 100, 100 @ 250 RPM

Rotor 2 = 100, 100, 100 @ 200 RPM

But to do so you need to calculated for the TR-01's Pressure Units dead space.

Source:https://www.rx8club.com/showthread.p...twisted+rotors

Dead volume has been calculated and the correction factors are listed below. I decided not to code in an automatic correction as the number varies slightly depending on the engine type. For reference the internal volume of the sensor (with adapter) is 2.85cc. To correct for the sensor dead volume just multiply your readings by the correction number appropriate for your engine.

Engine Year Ratio Correction

12A 76-82 9.4 1.042

12A 83-85 9.4 1.042

13B 74-78 9.2 1.035

13B 84-85 9.4 1.036

13B N/T 86-88 9.4 1.036

13B T 86-88 8.5 1.032

13B N/T 89-92 9.7 1.038

13B T 89-92 9.0 1.034

13B T/T 93-95 9.0 1.034

13B Ren 04-on 10.0 1.039 ****

This is where I hit my first wtf, using application #1 Foxed.ca

I entered 100 psi at 250 rpm at 0 feet altitude and expected to see 103.9 psi instead I get 102.68 psi (lets not worry about altitude adjustment right now)

Great, not off to a good start.

**** So for the point of this exercise lets say the Dead Space for the Renny is 1.0268

So that means to get 100 psi

Raw PSI = 97.39 multiply by Dead Space compensation of 1.0268

= 100 psi

Special Note: The only application that excepts Raw PSI values is the Foxed.ca application. The rest of the apps require the dead space value to be calculated.

So for Foxed values enter 97.39 psi for all rotor faces.

Rotor 1 = 97.39, 97.39, 97.39 @ 250 RPM

Rotor 2 = 97.39, 97.39, 97.39 @ 200 RPM

The other applications can use 100 psi

Rotor 1 = 100, 100, 100 @ 250 RPM

Rotor 2 = 100, 100, 100 @ 200 RPM

Rotor 1 results:

Compression APPS #1, #2, #3 and #4 now return same values for Rotor 1

Rotor 2 results:

App #1 = 113.34 PSI

App #2 = 117.08 PSI

App #3 = 116.54 PSI

App #4 = 117.1 PSI

I know the differences are small and rounding values in the code could be causing some deviation but still there seems to be enough of a difference to seed some doubt in the values.

The variances get worse as the normalization delta gets larger ie) 320 rpm or 140 rpm

I am unable to figure out or find exactly how these applications have done the normalization of the PSI to RPM.

My assumption was, if you measured 100psi @ 200rpm the math would look like:

normalization = (100psi*250rpm)/200rpm = 125 psi

Fail sauce apparently <shrug> Help?

Moving on: ---> Altitude compensation

My house is at 1571 feet or 479 meters.

This is a high enough altitude to have a measurable decrease in compression for a given engine compared to the factory standard, which I've read is typically done at sea level (14.7 psi) at a temperature 59 F

I've found several references, explaining the altitude compensation requirements. However they all address changing the manufactures expected compression value.

Quoted:

Altitude and temperature also affect the compression readings. Manufacturer’s specifications are almost always given at a specific altitude (14.7 psi at sea level), and 59° Fahrenheit. Both temperature and barometric pressure change as you go up in altitude, so you will need to correct your measurements if you wish to compare it with a factory specification. The following chart provides conversion factors for correctly compensating for changes in altitude:

Compression Test Altitude Compensation Factors

Altitude Factor

500 0.987

1500 0.960

2500 0.933

3500 0.907

4500 0.880

5500 0.853

6500 0.826

7500 0.800

8500 0.773

A standard compression reading of about 150 psi at sea level in Los Angeles would measure significantly less in the surrounding mountains. For example, at an elevation of 6000 feet, the expected reading would be 150 psi X .8359 = 125 psi. The cylinders would be reading low if compared to sea level measurements, yet perfectly fine at this altitude.

Right so lets take our value that we received using APP #1 as it is the only application that has a spot for Altitude

App #1 Foxed.ca normalized values

Rotor 1 =100.01 psi @ 250 rpm at sea level.

Rotor 2 =113.34 psi @ 200 rpm at sea level

According to this chart and the example above we would multiply our manufacture spec by 0.96 (for 1500 feet altitude)

Which brings me to another problem of knowing what the specs are, there are several tables. forget I mentioned it.

forget I mentioned it.

Does not matter right now as we want to compensate our reading not our spec.

My math is to take the reciprocal of .96 which is 1.0417 and multiply that by the values given for Rotor 1 and Rotor 2 shown just above

But I can't because that would be compensating for Altitude after I did the normalization to Sea Level and 250 rpm.

So I focused on Rotor 1 at 250 rpm because it doesn't require normalization and I clearly am not using the right formula to do normalization.

Manual Math for Rotor 1 will be RawPSI * DeadSpace * AltitudeComp

Rotor 1 @1500 ft, @250 rpm, @(97.39 * 1.0268 * 1.0417) = 104.17 psi per face

Slightly different value for the Foxed.ca application.

I'm going to compensate for altitude to the RawPSI value and enter those in to the application

App #1 Foxed.ca enter values determined by = RawPSI * AltitudeComp

Rotor 1 @1500 ft, @250 rpm, @(97.39 * 1.0417) = 101.45 psi per face

App #1 Foxed.ca returns = 111.19 psi

OMG what the hell!?!?

Can anyone help me with this please?

I've got myself in to a rabbit hole here, can someone help me out please.

And I still want to compensate for Air Temperature ... ack!

Sources.

http://www.coloradoevo.com/forums/showthread.php?t=4683

http://books.google.ca/books?id=wJvp...20test&f=false

http://books.google.ca/books?id=pGhO...0tests&f=false

http://www.pelicanparts.com/techarti..._rebuild-2.htm

http://www.engineeringtoolbox.com/ai...ure-d_462.html

http://www.engineeringtoolbox.com/ai...ume-d_853.html

http://rotarydiagnostics.com/Model%2...r%20Manual.pdf

This took me down the the path of trying to reproduce the numbers myself.

Let me first link you to all the Rotary Compression calculators I'm referencing.

Note: I'm also using the TR-01v2 compression tester. This is important as we need to calculate the dead space for the pressure unit. Also one of the Calculators (App #1) was made especially to work with the RawPSI numbers from the TR-01

1) Foxed.ca Rotary Compression Calculator designed to use the TR-01 RawPSI numbers

http://www.foxed.ca/index.php?page=rotarycalc

2) The Rotary Compression Calculator for the Android

https://www.rx8club.com/series-i-tech-garage-22/rx8-compression-calculator-android-226754/

3) RENESIS Compression adjustment & Rating, Excel Application

https://www.rx8club.com/series-i-do-yourself-forum-73/diy-renesis-compression-adjustment-rating-excel-application-180043/

4) Web based calculator (same dude that makes the Android app)

http://virusakos.freevar.com/web/RX_...alculator.html

To keep the math simple I wanted to use values of 100 psi for all faces for both rotor 1 and 2 and an RPM on Rotor 1 of 250 and Rotor 2 of 200.

So anything on Rotor 1 should return the same PSI value entered after normalizing (I did this as a check)

Like this:

Rotor 1 = 100, 100, 100 @ 250 RPM

Rotor 2 = 100, 100, 100 @ 200 RPM

But to do so you need to calculated for the TR-01's Pressure Units dead space.

Source:https://www.rx8club.com/showthread.p...twisted+rotors

Dead volume has been calculated and the correction factors are listed below. I decided not to code in an automatic correction as the number varies slightly depending on the engine type. For reference the internal volume of the sensor (with adapter) is 2.85cc. To correct for the sensor dead volume just multiply your readings by the correction number appropriate for your engine.

Engine Year Ratio Correction

12A 76-82 9.4 1.042

12A 83-85 9.4 1.042

13B 74-78 9.2 1.035

13B 84-85 9.4 1.036

13B N/T 86-88 9.4 1.036

13B T 86-88 8.5 1.032

13B N/T 89-92 9.7 1.038

13B T 89-92 9.0 1.034

13B T/T 93-95 9.0 1.034

13B Ren 04-on 10.0 1.039 ****

This is where I hit my first wtf, using application #1 Foxed.ca

I entered 100 psi at 250 rpm at 0 feet altitude and expected to see 103.9 psi instead I get 102.68 psi (lets not worry about altitude adjustment right now)

Great, not off to a good start.

**** So for the point of this exercise lets say the Dead Space for the Renny is 1.0268

So that means to get 100 psi

Raw PSI = 97.39 multiply by Dead Space compensation of 1.0268

= 100 psi

Special Note: The only application that excepts Raw PSI values is the Foxed.ca application. The rest of the apps require the dead space value to be calculated.

So for Foxed values enter 97.39 psi for all rotor faces.

Rotor 1 = 97.39, 97.39, 97.39 @ 250 RPM

Rotor 2 = 97.39, 97.39, 97.39 @ 200 RPM

The other applications can use 100 psi

Rotor 1 = 100, 100, 100 @ 250 RPM

Rotor 2 = 100, 100, 100 @ 200 RPM

Rotor 1 results:

Compression APPS #1, #2, #3 and #4 now return same values for Rotor 1

Rotor 2 results:

App #1 = 113.34 PSI

App #2 = 117.08 PSI

App #3 = 116.54 PSI

App #4 = 117.1 PSI

I know the differences are small and rounding values in the code could be causing some deviation but still there seems to be enough of a difference to seed some doubt in the values.

The variances get worse as the normalization delta gets larger ie) 320 rpm or 140 rpm

I am unable to figure out or find exactly how these applications have done the normalization of the PSI to RPM.

My assumption was, if you measured 100psi @ 200rpm the math would look like:

normalization = (100psi*250rpm)/200rpm = 125 psi

Fail sauce apparently <shrug> Help?

Moving on: ---> Altitude compensation

My house is at 1571 feet or 479 meters.

This is a high enough altitude to have a measurable decrease in compression for a given engine compared to the factory standard, which I've read is typically done at sea level (14.7 psi) at a temperature 59 F

I've found several references, explaining the altitude compensation requirements. However they all address changing the manufactures expected compression value.

Quoted:

Altitude and temperature also affect the compression readings. Manufacturer’s specifications are almost always given at a specific altitude (14.7 psi at sea level), and 59° Fahrenheit. Both temperature and barometric pressure change as you go up in altitude, so you will need to correct your measurements if you wish to compare it with a factory specification. The following chart provides conversion factors for correctly compensating for changes in altitude:

Compression Test Altitude Compensation Factors

Altitude Factor

500 0.987

1500 0.960

2500 0.933

3500 0.907

4500 0.880

5500 0.853

6500 0.826

7500 0.800

8500 0.773

A standard compression reading of about 150 psi at sea level in Los Angeles would measure significantly less in the surrounding mountains. For example, at an elevation of 6000 feet, the expected reading would be 150 psi X .8359 = 125 psi. The cylinders would be reading low if compared to sea level measurements, yet perfectly fine at this altitude.

Right so lets take our value that we received using APP #1 as it is the only application that has a spot for Altitude

App #1 Foxed.ca normalized values

Rotor 1 =100.01 psi @ 250 rpm at sea level.

Rotor 2 =113.34 psi @ 200 rpm at sea level

According to this chart and the example above we would multiply our manufacture spec by 0.96 (for 1500 feet altitude)

Which brings me to another problem of knowing what the specs are, there are several tables.

forget I mentioned it.

forget I mentioned it.Does not matter right now as we want to compensate our reading not our spec.

My math is to take the reciprocal of .96 which is 1.0417 and multiply that by the values given for Rotor 1 and Rotor 2 shown just above

But I can't because that would be compensating for Altitude after I did the normalization to Sea Level and 250 rpm.

So I focused on Rotor 1 at 250 rpm because it doesn't require normalization and I clearly am not using the right formula to do normalization.

Manual Math for Rotor 1 will be RawPSI * DeadSpace * AltitudeComp

Rotor 1 @1500 ft, @250 rpm, @(97.39 * 1.0268 * 1.0417) = 104.17 psi per face

Slightly different value for the Foxed.ca application.

I'm going to compensate for altitude to the RawPSI value and enter those in to the application

App #1 Foxed.ca enter values determined by = RawPSI * AltitudeComp

Rotor 1 @1500 ft, @250 rpm, @(97.39 * 1.0417) = 101.45 psi per face

App #1 Foxed.ca returns = 111.19 psi

OMG what the hell!?!?

Can anyone help me with this please?

I've got myself in to a rabbit hole here, can someone help me out please.

And I still want to compensate for Air Temperature ... ack!

Sources.

http://www.coloradoevo.com/forums/showthread.php?t=4683

http://books.google.ca/books?id=wJvp...20test&f=false

http://books.google.ca/books?id=pGhO...0tests&f=false

http://www.pelicanparts.com/techarti..._rebuild-2.htm

http://www.engineeringtoolbox.com/ai...ure-d_462.html

http://www.engineeringtoolbox.com/ai...ume-d_853.html

http://rotarydiagnostics.com/Model%2...r%20Manual.pdf

Last edited by wcs; 04-09-2012 at 07:11 PM.

#3

lol for what ... the headache lol

So I've decided to go with the Android calculator, even thou the Foxed.ca one gives higher numbers.

I'm not happy with the Foxed.ca due to its dead space adjustment for the Renny Engine at 100 psi and 250 rpm

I thought perhaps that it had something to do with the Sea Level elevation (it may still have) but it took an elevation of 273 feet to get a value of 103.9 PSI

This elevation just didn't click with any of the charts I looked at.

103.9 PSI is what one should get if the RawPSI measurement is 100 psi remember the dead space compensation is 1.039

So with that thought in mind, I've also found many threads in other forum and books using the same chart I have in the first post for altitude compensation.

Altitude compensation for my area in 0.960 or 1.0417

For example

Using the Android Compression calculator my inputs will be

RawPSI * DeadSpace * AltitudeComp

100 * 1.039 * 1.0417 = 108.23 PSI before Normalization

So I've decided to go with the Android calculator, even thou the Foxed.ca one gives higher numbers.

I'm not happy with the Foxed.ca due to its dead space adjustment for the Renny Engine at 100 psi and 250 rpm

I thought perhaps that it had something to do with the Sea Level elevation (it may still have) but it took an elevation of 273 feet to get a value of 103.9 PSI

This elevation just didn't click with any of the charts I looked at.

103.9 PSI is what one should get if the RawPSI measurement is 100 psi remember the dead space compensation is 1.039

So with that thought in mind, I've also found many threads in other forum and books using the same chart I have in the first post for altitude compensation.

Altitude compensation for my area in 0.960 or 1.0417

For example

Using the Android Compression calculator my inputs will be

RawPSI * DeadSpace * AltitudeComp

100 * 1.039 * 1.0417 = 108.23 PSI before Normalization

Last edited by wcs; 04-09-2012 at 07:13 PM.

#4

Bump

Can anyone explain to me the exact math used to normalize your compression reading?

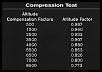

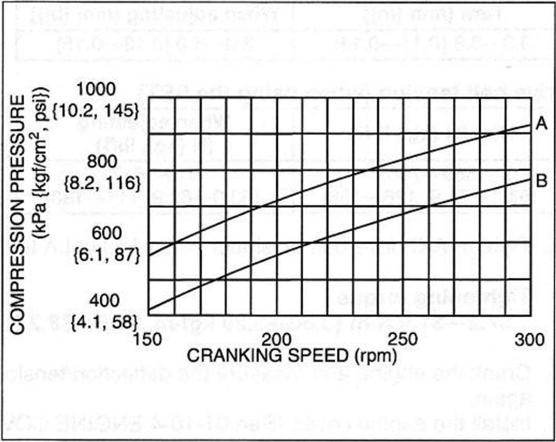

All the charts I've seen only show the adjusted minimum acceptable limit for RPM not how to normalize your PSI at X RPM to X PSI at 250 RPM

I've tried the following but none of my results even come close to any of the compression apps out there.

(100psi/300rpm)=(Xpsi/250rpm)

100*250/300=83.3 psi

Using the Android app I get 86.85psi

Yes its a small amount but to me its enough to investigate

Can anyone explain to me the exact math used to normalize your compression reading?

All the charts I've seen only show the adjusted minimum acceptable limit for RPM not how to normalize your PSI at X RPM to X PSI at 250 RPM

I've tried the following but none of my results even come close to any of the compression apps out there.

(100psi/300rpm)=(Xpsi/250rpm)

100*250/300=83.3 psi

Using the Android app I get 86.85psi

Yes its a small amount but to me its enough to investigate

#6

Bump

Can anyone explain to me the exact math used to normalize your compression reading?

All the charts I've seen only show the adjusted minimum acceptable limit for RPM not how to normalize your PSI at X RPM to X PSI at 250 RPM

I've tried the following but none of my results even come close to any of the compression apps out there.

(100psi/300rpm)=(Xpsi/250rpm)

100*250/300=83.3 psi

Using the Android app I get 86.85psi

Yes its a small amount but to me its enough to investigate

Can anyone explain to me the exact math used to normalize your compression reading?

All the charts I've seen only show the adjusted minimum acceptable limit for RPM not how to normalize your PSI at X RPM to X PSI at 250 RPM

I've tried the following but none of my results even come close to any of the compression apps out there.

(100psi/300rpm)=(Xpsi/250rpm)

100*250/300=83.3 psi

Using the Android app I get 86.85psi

Yes its a small amount but to me its enough to investigate

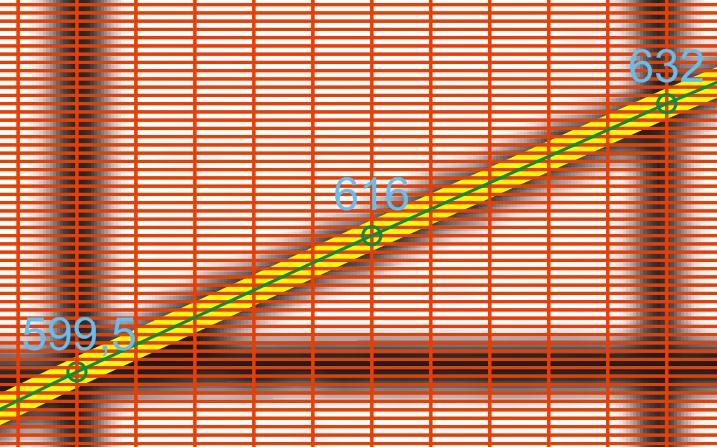

… i made some correction to the photo of the diagram on the two axis, RPM and PRESSURE, and the cropped (zoomed) picture below show how I “read” the values after putting specific gridlines over the compression diagram picture

I put both readings Values (RPM and PRESSURE in kPa) in an Excel table as below

The relationships are :

Minimum Value + Adjust Value= 680 kPa

Standard Value + Adjust Value= 830 kPa

Standard Value - Minimum Value=150 kPa

Example

If Face 1 Rotor 1 measurement is 520 kPa at 154 RPM the Adjust Value is 251 so the compression at 250 RPM is 520+251=771 kPa

Thread

Thread Starter

Forum

Replies

Last Post

gwailo

New Member Forum

38

05-14-2024 07:57 AM

TeslaMSI

New Member Forum

11

12-10-2015 02:10 AM

Silver_Excalibur

Series I Trouble Shooting

0

08-25-2015 10:09 PM