Increase MOP oil injection by changing hoses?

#26

Wow; and here I thought the OMP oil was there to help ensure [occlusive-] sealing of the rotor apex's and in turn preserve compression.

So, it's really there for evaporative cooling and thereby improving the reliability over time of the seal material itself, which would also help to preserve compression.

'learn sumthin new every day. Thanks MM!

So, it's really there for evaporative cooling and thereby improving the reliability over time of the seal material itself, which would also help to preserve compression.

'learn sumthin new every day. Thanks MM!

There is no need for more oil when you let off the gas.

No load, no heat and no need for additional compression.

Remember, the Renesis is, essentially, a dry-seal motor. The parts that need lube all the time (bearings) get oil all the time.

Injected oil is mainly there to cool the seals, not lube them.

No load, no heat and no need for additional compression.

Remember, the Renesis is, essentially, a dry-seal motor. The parts that need lube all the time (bearings) get oil all the time.

Injected oil is mainly there to cool the seals, not lube them.

#28

Wow; and here I thought the OMP oil was there to help ensure [occlusive-] sealing of the rotor apex's and in turn preserve compression.

So, it's really there for evaporative cooling and thereby improving the reliability over time of the seal material itself, which would also help to preserve compression.

So, it's really there for evaporative cooling and thereby improving the reliability over time of the seal material itself, which would also help to preserve compression.

Which feels cooler?

Probably about the same.

#30

#31

Hmm. "Occlusive"? Not exactly.

It is not a "binding" action.

Fluids become effectively more solid at higher velocities.

Oil being accelerated around the epitrochoid by the apex seal is acting as a semi-solid in the meniscus interface between the adjoining chambers.

It is not a "binding" action.

Fluids become effectively more solid at higher velocities.

Oil being accelerated around the epitrochoid by the apex seal is acting as a semi-solid in the meniscus interface between the adjoining chambers.

#33

Interesting, but I don't see how that would have much effect on cooling at the tiny volumes of oil involved. It takes almost no heat to evaporate the oil itself. Or does it work by wetting the seal and thereby increasing the thermal conductivity to the relatively cool rotor and rotor housing?

#35

Nope.

Came straight from the horse's mouth.

Beside that, think about it for a minute.

If Mazda had intended to "lubricate" the apex seals, why did they make both the seal and the sealing surface out of oleophobic materials?

And why do they apply the oil topically, rather than under pressure from the bearing journals and through the rotors (which would actually lube everything, instead of just the hottest parts of the apex and corner seals)?

Came straight from the horse's mouth.

Beside that, think about it for a minute.

If Mazda had intended to "lubricate" the apex seals, why did they make both the seal and the sealing surface out of oleophobic materials?

And why do they apply the oil topically, rather than under pressure from the bearing journals and through the rotors (which would actually lube everything, instead of just the hottest parts of the apex and corner seals)?

Last edited by MazdaManiac; 05-17-2010 at 05:23 PM.

#37

My S2 Consistently uses 1 litre of Engine OIL per 5000 KMS, that is around a ONE Quart every 3000 miles!...THAT is NOT a lot of Cooling OIL...it is ONLY for Lubrication.

Having covered nearly 30,000 KMS, I fill around 250 mil (cup) Oil per 1200 or so KMS...same as Day one.

Under many different driving modes.

I can not see how 250 Mil over 720 miles is going to cool.

Having covered nearly 30,000 KMS, I fill around 250 mil (cup) Oil per 1200 or so KMS...same as Day one.

Under many different driving modes.

I can not see how 250 Mil over 720 miles is going to cool.

#38

#40

Nope.

There is a lubricating effect and a compression/sealing effect.

It isn't, obviously, ALL about cooling.

That is just its primary function.

No need to go all ignorant and hysterical on us. This isn't day-time TV.

There is a lubricating effect and a compression/sealing effect.

It isn't, obviously, ALL about cooling.

That is just its primary function.

No need to go all ignorant and hysterical on us. This isn't day-time TV.

#41

There is no need for more oil when you let off the gas.

No load, no heat and no need for additional compression.

Remember, the Renesis is, essentially, a dry-seal motor. The parts that need lube all the time (bearings) get oil all the time.

Injected oil is mainly there to cool the seals, not lube them.

No load, no heat and no need for additional compression.

Remember, the Renesis is, essentially, a dry-seal motor. The parts that need lube all the time (bearings) get oil all the time.

Injected oil is mainly there to cool the seals, not lube them.

#43

What might be happening is that the oil film serves as a conduit of heat from the apex seal itself to the adjacent parts. Since the seal is "floating" the contact heat transfer is going to be small without help.

Curious too is that apparently the corner seal is finished is "diamond-like carbon". The authors stated that it was to give a hard surface, but in this context, there may be another reason. Since it's hard for oil to reach and stay in the corner, heat transfer through contact cooling may have been an issue. Diamond has about 4 times the heat conductivity of amorphous carbon or graphite which might help disappate the heat load.

#45

Might it haze things up a bit if I were to confess that I have accidentally run my OMP tank dry a couple times and did not notice for a few hundred miles each time, even with freeway driving going on?

My engine still starts immediately, has good throttle response, and makes power all the way to a legit 10K rpms.

My engine still starts immediately, has good throttle response, and makes power all the way to a legit 10K rpms.

#46

Might it haze things up a bit if I were to confess that I have accidentally run my OMP tank dry a couple times and did not notice for a few hundred miles each time, even with freeway driving going on?

My engine still starts immediately, has good throttle response, and makes power all the way to a legit 10K rpms.

My engine still starts immediately, has good throttle response, and makes power all the way to a legit 10K rpms.

I did the same thing due to messing with my OMP settings via the AP. I don't know how long I drove without any OMP oil but it was more than just a few miles.

This discussion is making me rethink whether I should be switching to Motul 710 or just keep using the multi-purpose oil I've been using.

#47

I fail to see how a "Dribble/Squirt" of engine oil is going to Cool the Apex and Corner Seals.

IMO it would have the slightest Cooling effect...particularly given the Combustion Temperatures etc that each Rotor and Apex endures.

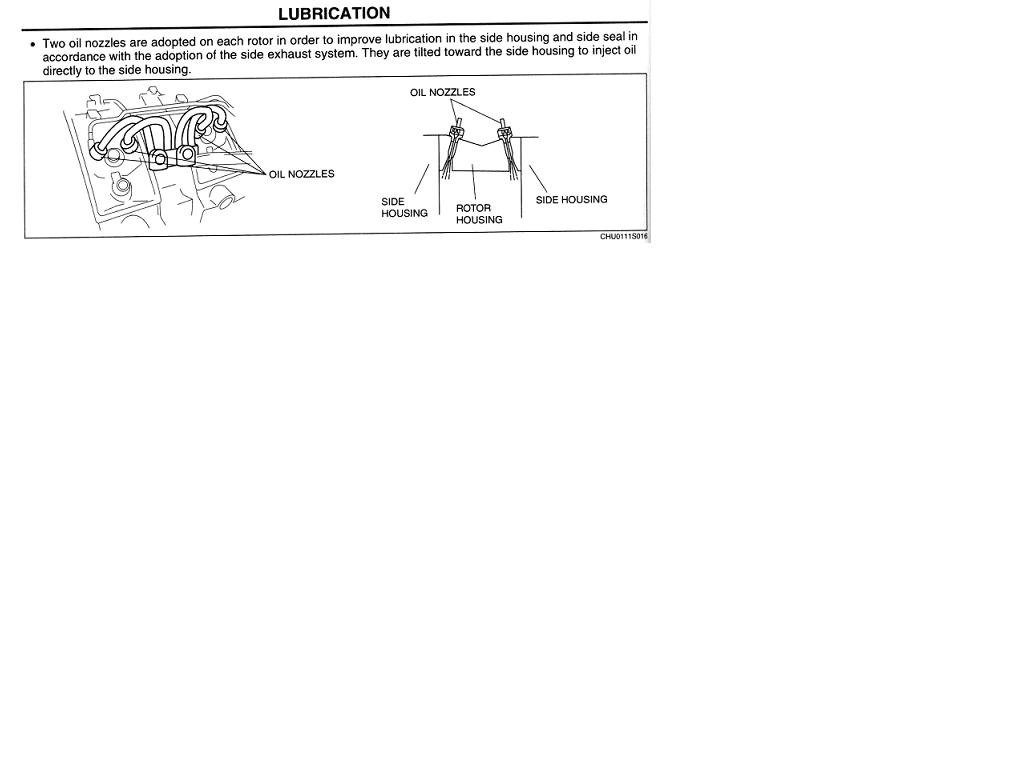

Factory Workshop Service Highlight say the 3RD Nozzle was installed for Apex Seal Lubrication or Lubricity.

Last edited by ASH8; 05-18-2010 at 02:12 AM.

#50

cooling and lubrication is same same guys---come on---it is just sematics.

Does the same thing for the bearings etc etc. If no oil what happens--things seize due to HEAT build up from friction.

Other benefits of the oil film like helping seal etc are present.

It is something to think about when considering different apex etc seals during a rebuild. I think the oem housing and apex seals are made to wear together for example.

Anyway --it does get you to thinking.

OD

Does the same thing for the bearings etc etc. If no oil what happens--things seize due to HEAT build up from friction.

Other benefits of the oil film like helping seal etc are present.

It is something to think about when considering different apex etc seals during a rebuild. I think the oem housing and apex seals are made to wear together for example.

Anyway --it does get you to thinking.

OD