Renesis OIL PRESSURE Discussion with Dealer Tech

#26

Midnight here. Heading to bed now.

#28

I'll try to quickly explain the pressure vs viscosity relationship. I work in design and engineering large mud pumps (up to 2200HP) for oil drilling. Our pumps are piston style good up to 7500 psi but we can do plunger style to 15000 psi if necessary. Our pumps are positive displacement style as opposed to a centrifugal style which just can't build the needed pressure. The oil pumps on our rotary engines are positive displacement using what are basically rotors such as a roots blower. Nothing more complex that than. However they don't compress. They just move. That's why they are displacement pumps. They displace. In order to compress, you have to choke off the outlet.

This raises the pressure. However it doesn't do it for free. In order to increase the pressure, we need to decrease the total flow. For a simple example, go play with your garden hose. Take the nozzle off and you have lots of flow but little pressure. It doesn't spray very far. There is no restriction. Now install a nozzle. It is always a restriction. When you open the nozzle all the way, it sprays far. It is a restriction over no nozzle which raises the pressure and causes the water to spray farther. Take 2 empty buckets. Fill one completely with the hose on full but without the nozzle. Time it to see how long it takes. Now fill the other one with the nozzle on and open all the way when it sprays hardest. How long does it take? If they fill at the same rate, there was enough power available in the form of water pressure to maintain flow at the nozzle pressure. Max flow will actually be without the nozzle but this is the least pressure.

On our pumps at work, we can change the piston and liner size. As built the pistons are 6" diameter. We can go down to a 4" on the small size or a 8" on the large size. If we want to run higher pressures, we use smaller pistons and liners. Stroke stays the same. You can probably tell that flow will decrease with smaller pistons as it's the same as reducing the displacement. However if we maintain the same amount of horsepower into the pump, we increase our leverage on our working fluid and we can compress it more.

Here's another test to demonstrate how this works. Let's use Coke cans. We need 2 of them, empty. Put 2 of them on the ground side by side. You can see that you have the top area of 2 cans. Now see if you can stand on them. If you are careful, you can unless you are really heavy! Your weight and the pull of gravity represent a force that is being applied to it. Obviously if you jump on it you can crush them but this is just an example. The area of both of those cans represents a larger piston as we can just pretend it is 1 object. Now lets take those 2 cans and stack one on top of the other. Now assuming you can stand on them without falling off and breaking a leg, you'll notice really quickly that they crush. They same total area was there and the input force was no different. However we increased our leverage and from a can standpoint there was twice the pressure being exerted on them.

Now this assumes we have the same input horsepower. However the chain driven oil pumps on the cars have practically an endless amount of power. If the pump speed is not changed, but the viscosity of the oil is changed, that means the amount of power to move it must also have changed. If we use a thicker oil, the pump having it's speed maintained must have more power being put into it in order to move this oil. That means more power robbed from the engine which is why oil weight is a modern issue.

Now lets take this one step farther. Let's go back to our hose. We know how far water can spray with the nozzle at full blast. How far do you think maple syrup would spray if the pressure were the same? Of course it wouldn't go as far. It would have more pressure but less flow. In order to match the flow level, we'd have to raise the pressure. The only way to do that is to increase the input horsepower. Remember how we just said the pump uses engine power? An interesting side effect of using a thicker oil is that no more of it gets to any parts of the engine and perhaps less of it does. If you aren't completely confused by now then consider yourself lucky. There's actually much more to it but I'll spare you any more for now.

Just as an fyi and I'm sure this will add to the oil debate, in my 1990 n/a RX-7, I run 5W20 synthetic oil.

This raises the pressure. However it doesn't do it for free. In order to increase the pressure, we need to decrease the total flow. For a simple example, go play with your garden hose. Take the nozzle off and you have lots of flow but little pressure. It doesn't spray very far. There is no restriction. Now install a nozzle. It is always a restriction. When you open the nozzle all the way, it sprays far. It is a restriction over no nozzle which raises the pressure and causes the water to spray farther. Take 2 empty buckets. Fill one completely with the hose on full but without the nozzle. Time it to see how long it takes. Now fill the other one with the nozzle on and open all the way when it sprays hardest. How long does it take? If they fill at the same rate, there was enough power available in the form of water pressure to maintain flow at the nozzle pressure. Max flow will actually be without the nozzle but this is the least pressure.

On our pumps at work, we can change the piston and liner size. As built the pistons are 6" diameter. We can go down to a 4" on the small size or a 8" on the large size. If we want to run higher pressures, we use smaller pistons and liners. Stroke stays the same. You can probably tell that flow will decrease with smaller pistons as it's the same as reducing the displacement. However if we maintain the same amount of horsepower into the pump, we increase our leverage on our working fluid and we can compress it more.

Here's another test to demonstrate how this works. Let's use Coke cans. We need 2 of them, empty. Put 2 of them on the ground side by side. You can see that you have the top area of 2 cans. Now see if you can stand on them. If you are careful, you can unless you are really heavy! Your weight and the pull of gravity represent a force that is being applied to it. Obviously if you jump on it you can crush them but this is just an example. The area of both of those cans represents a larger piston as we can just pretend it is 1 object. Now lets take those 2 cans and stack one on top of the other. Now assuming you can stand on them without falling off and breaking a leg, you'll notice really quickly that they crush. They same total area was there and the input force was no different. However we increased our leverage and from a can standpoint there was twice the pressure being exerted on them.

Now this assumes we have the same input horsepower. However the chain driven oil pumps on the cars have practically an endless amount of power. If the pump speed is not changed, but the viscosity of the oil is changed, that means the amount of power to move it must also have changed. If we use a thicker oil, the pump having it's speed maintained must have more power being put into it in order to move this oil. That means more power robbed from the engine which is why oil weight is a modern issue.

Now lets take this one step farther. Let's go back to our hose. We know how far water can spray with the nozzle at full blast. How far do you think maple syrup would spray if the pressure were the same? Of course it wouldn't go as far. It would have more pressure but less flow. In order to match the flow level, we'd have to raise the pressure. The only way to do that is to increase the input horsepower. Remember how we just said the pump uses engine power? An interesting side effect of using a thicker oil is that no more of it gets to any parts of the engine and perhaps less of it does. If you aren't completely confused by now then consider yourself lucky. There's actually much more to it but I'll spare you any more for now.

Just as an fyi and I'm sure this will add to the oil debate, in my 1990 n/a RX-7, I run 5W20 synthetic oil.

http://ferrarichat.com/forum/showthread.php?t=136052

Found the RX8 Club link:

https://www.rx8club.com/showthread.p...t=ferrari+chat

#29

Oh I really like that article but It been discussed to death (by me  ) in the other thread. Good read though, learned a lot.

) in the other thread. Good read though, learned a lot.

I am curious what we can find out about the TII pump.

) in the other thread. Good read though, learned a lot.

) in the other thread. Good read though, learned a lot.I am curious what we can find out about the TII pump.

#30

Many guys here have posted that when they increase their oil viscosity they see a Higher Oil Pressure reading, but I also agree with RG and the fact that there really is little difference between all the oils.

The reference I made previously when talking to the Mazda Dealer Tech was all things being equal between S1 RX-8 and the last NA Rotary Mazda made the FC RX-7, is they "coincidently" have the same Oil Pump, and same By Pass Regulator, same Rotor Bearings but as others here who have done many 13B rebuilds have not seen the bearing failures like they have in RENESIS 1, almost every pic I have seen here and in other Forums show the same wear....So Why..

Is it Oil Pressure...same as an NA FC RX-7..

Is it Oil Type or Viscosity, not the same as FC RX-7 (15w40 was the recommended then).

I thought this bearing failure was mainly in the US 5W20, but as seen it appears in the UK also, 5W30. Australia also uses 5W30 but, I have yet to see one apart.

Then you have to look at all the mods done to the RENESIS II, main ones are MOP's which we know, the only other mod is Oil Pressure, with the same 5W20-30 oil recommendation.

There are far greater minds than mine here but, to me the many answers are obvious...I think.

The reference I made previously when talking to the Mazda Dealer Tech was all things being equal between S1 RX-8 and the last NA Rotary Mazda made the FC RX-7, is they "coincidently" have the same Oil Pump, and same By Pass Regulator, same Rotor Bearings but as others here who have done many 13B rebuilds have not seen the bearing failures like they have in RENESIS 1, almost every pic I have seen here and in other Forums show the same wear....So Why..

Is it Oil Pressure...same as an NA FC RX-7..

Is it Oil Type or Viscosity, not the same as FC RX-7 (15w40 was the recommended then).

I thought this bearing failure was mainly in the US 5W20, but as seen it appears in the UK also, 5W30. Australia also uses 5W30 but, I have yet to see one apart.

Then you have to look at all the mods done to the RENESIS II, main ones are MOP's which we know, the only other mod is Oil Pressure, with the same 5W20-30 oil recommendation.

There are far greater minds than mine here but, to me the many answers are obvious...I think.

#31

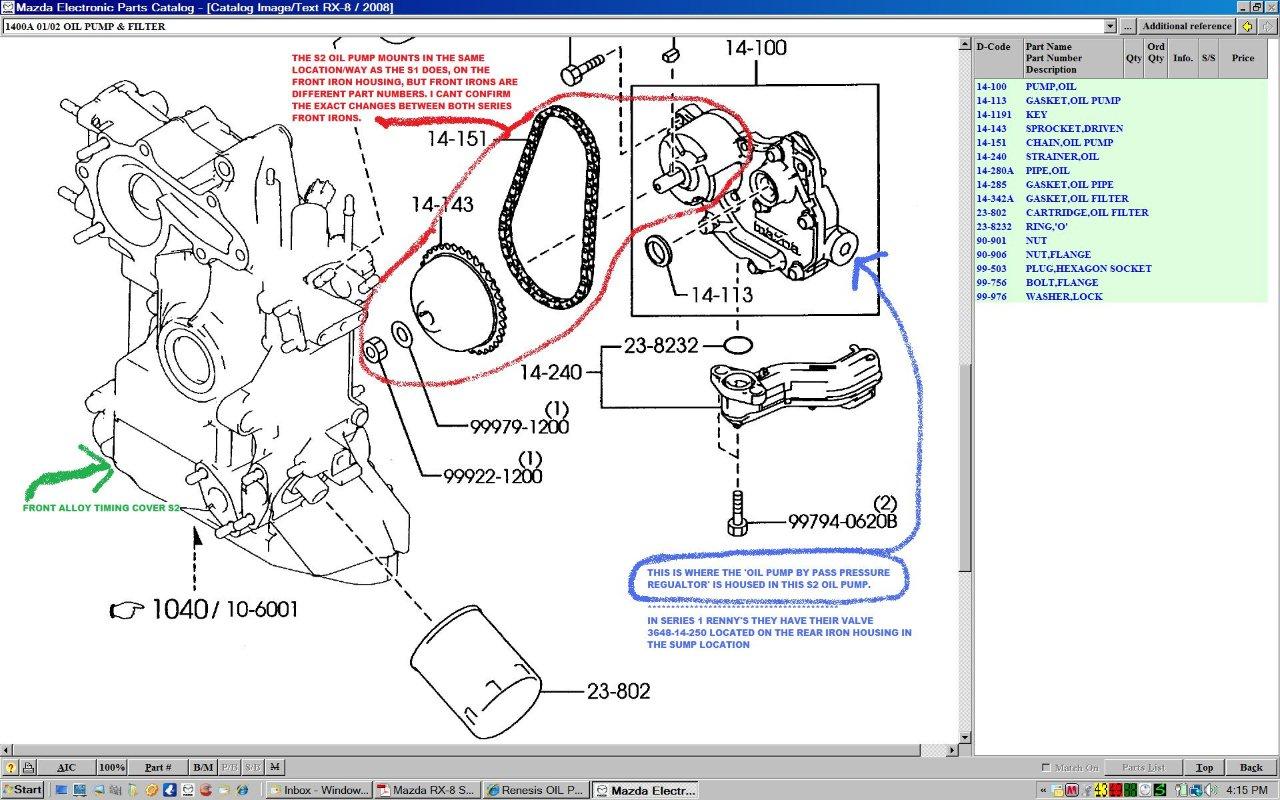

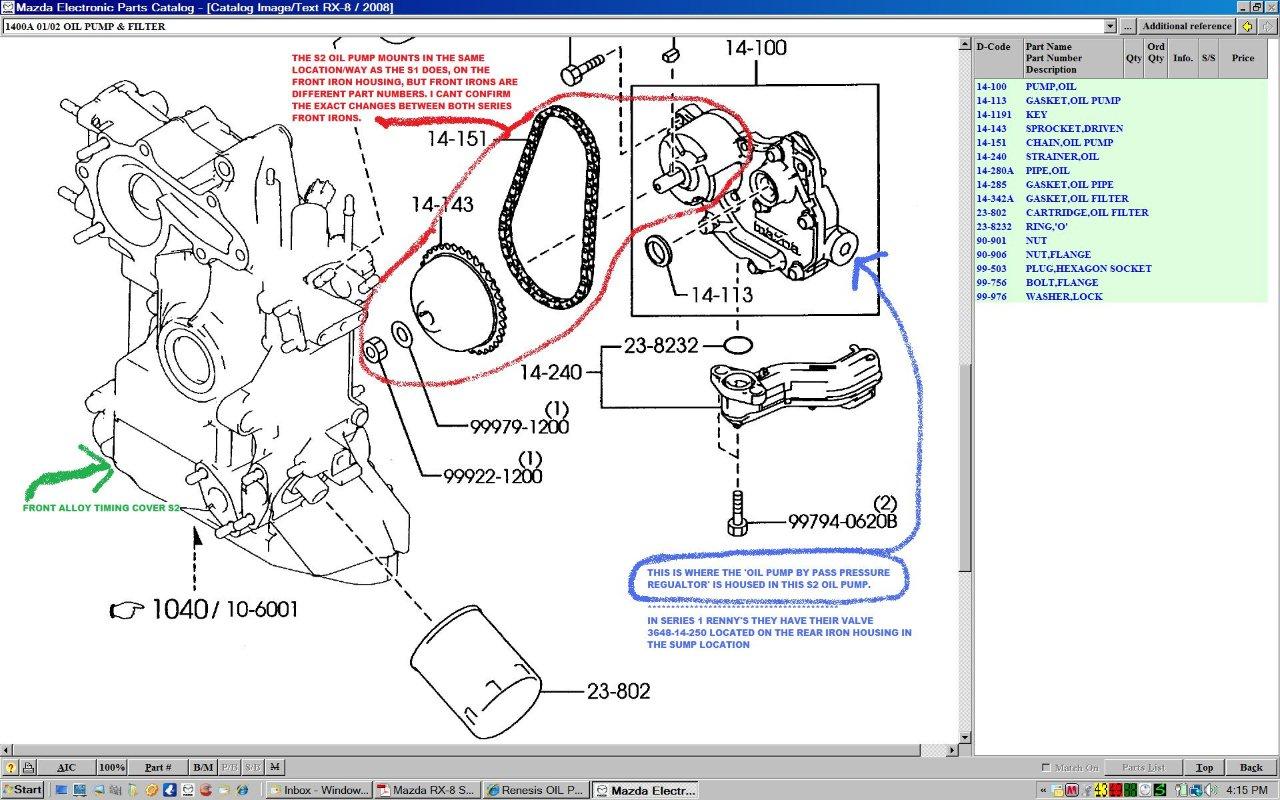

RG, the front Iron housing by Part Number is different in Renny 2, as is the front alloy timing cover surrounding/over the oil pump, the S2 also has the Oil Filter located on the Front Alloy Timing Cover.

#32

IMO...I think it is an area or location that a reference pressure is read, but, where do they read it?, at the bearings , half way down the eccentric shaft, if any of this is possible, or is it an AVERAGE of a few areas?

So in the case of your S1 Renny...you have..

OP Reference Value @3000 RPM 100c of 50.8 PSI

OP at Oil PUMP Relief Valve Opening Pressure 64-71 PSI

OP at Oil Filter By Pass 11.4 - 17.1 PSI

Sorry, no more info there.

#34

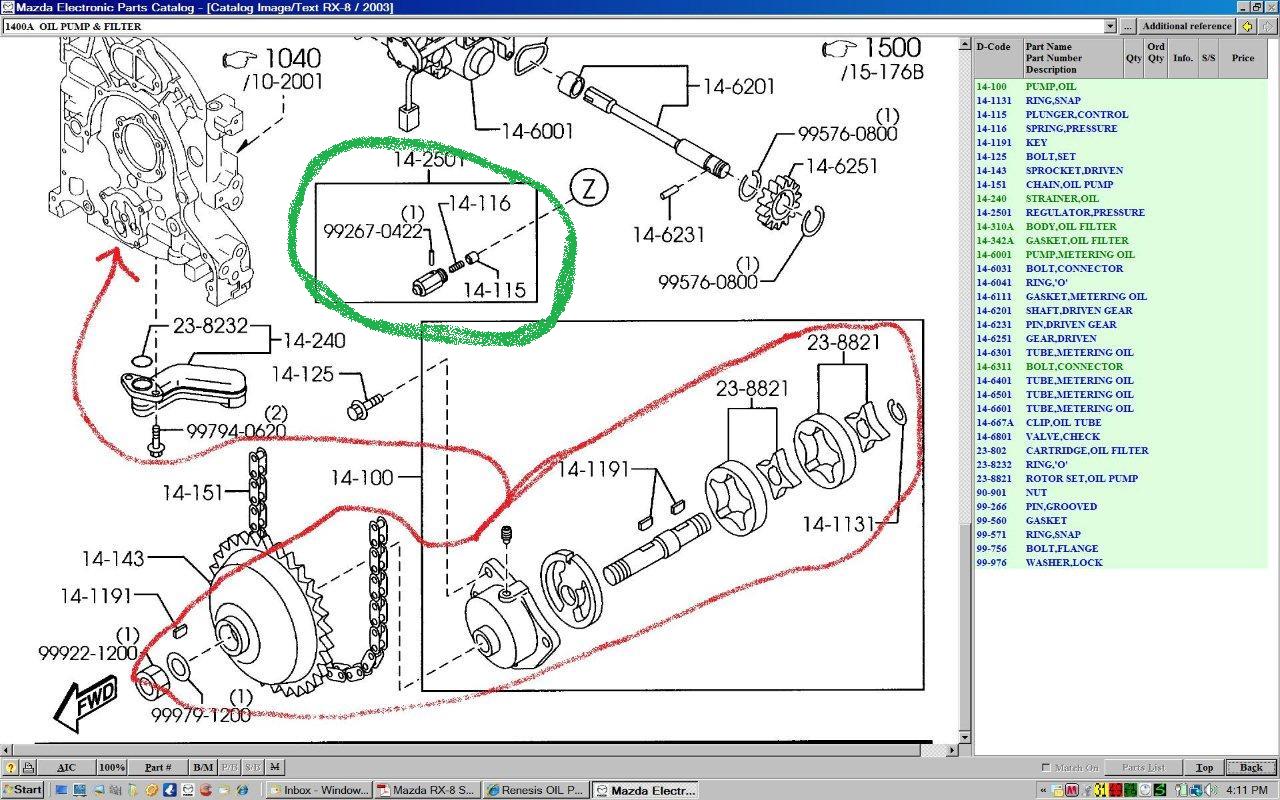

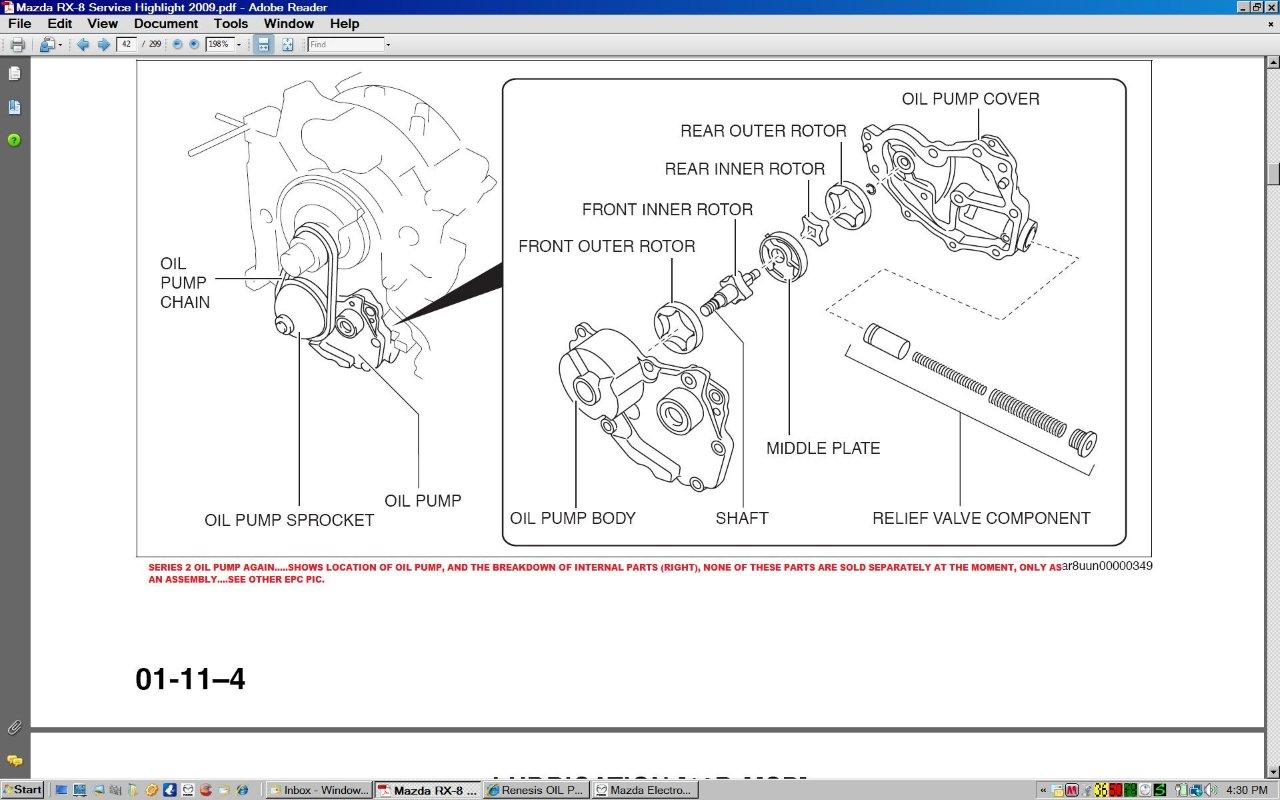

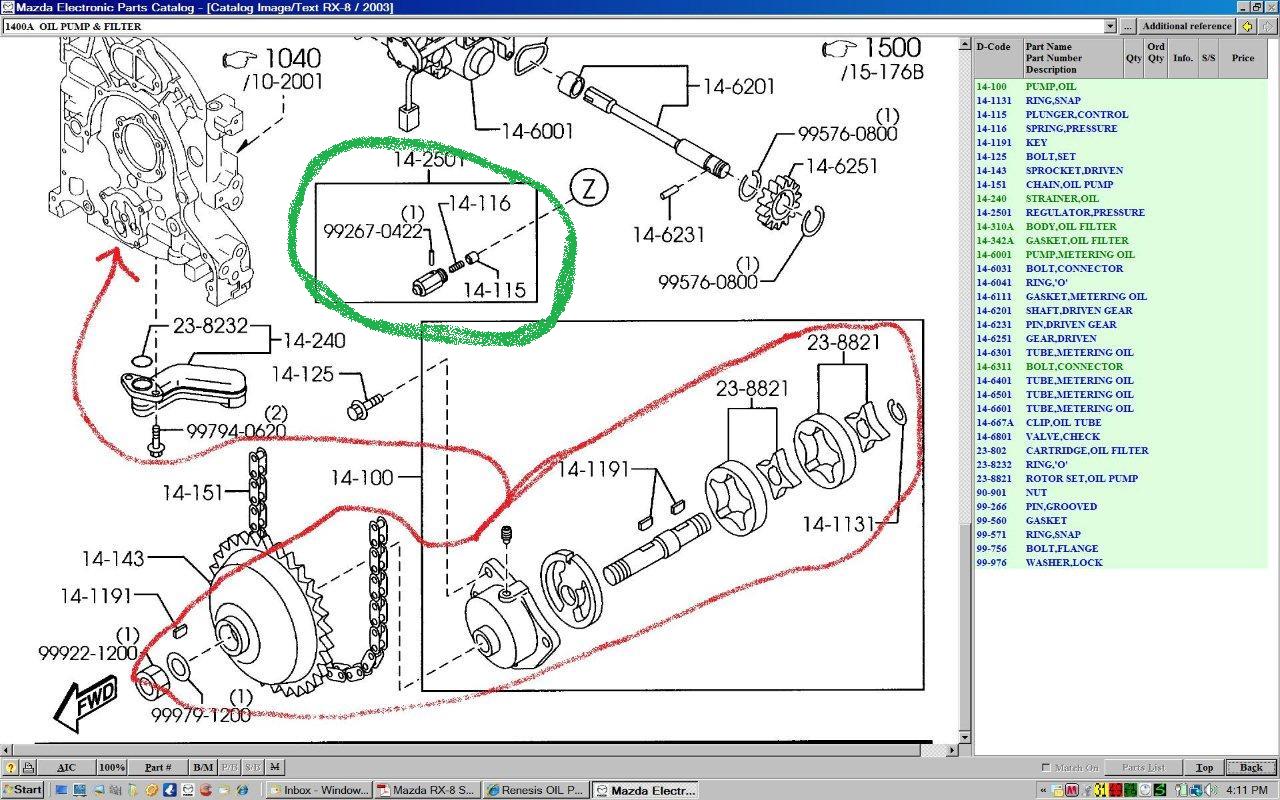

Oil Pump Sketches

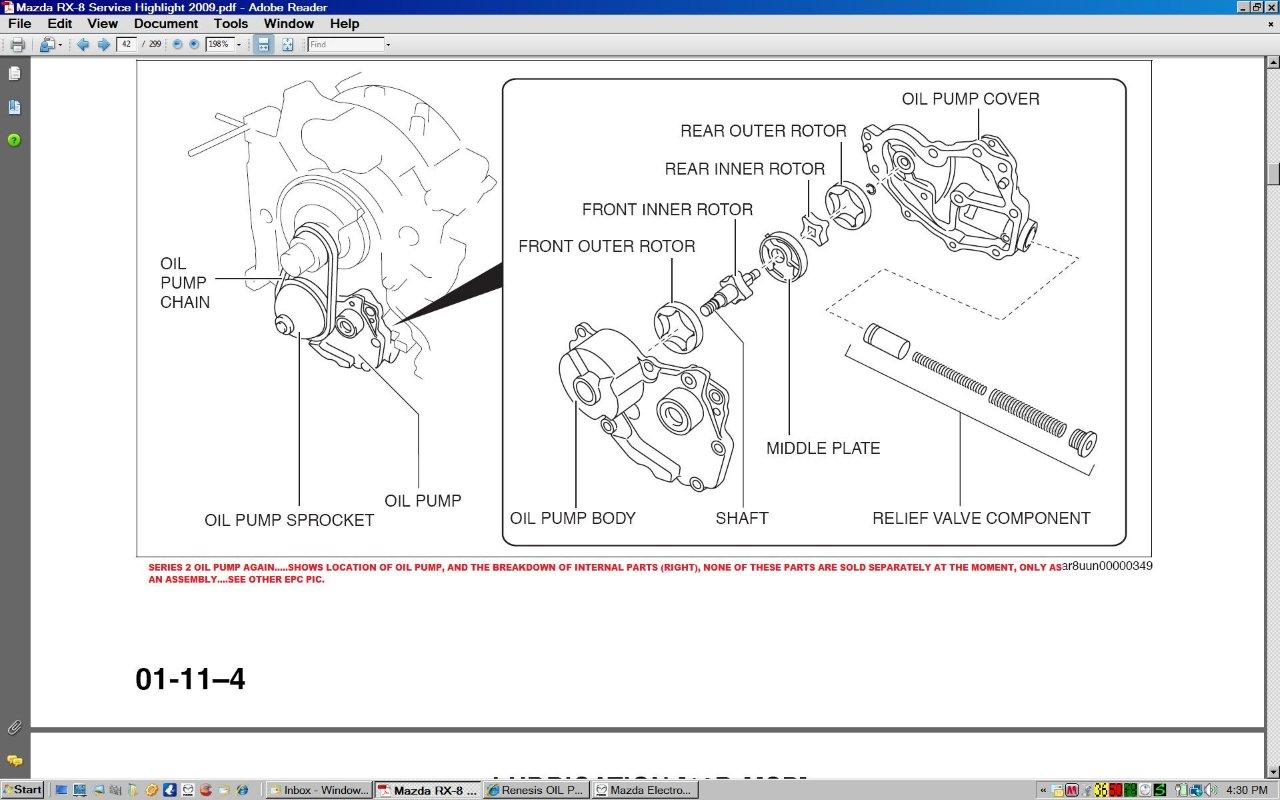

Here are 3 pics of the S1 and S2 Oil Pumps and where they go.

First two are from EPC Parts, last is of S2 oil pump in pieces.

Both of these mount in the same 'way', but the housing they bolt onto are different part numbers, unsure of the exact "design" changes though.

Will an S2 pump fit on an S1, possibly, but as the output pressure of this pump has more than doubled I would have concern about other areas.

Like what do you do with the existing separate By Pass Regulator in rear iron housing?, do you remove it as it would be continually by passing oil, do you blank it off?, you would also have to change Oil Filters, the oil pick up in sump is different..there are a number of issues..

The GREEN Circle shows the 3648-14-250 Oil Pressure By Pass Valve which goes on the Rear Iron Housing in S1 RX-8 (FC RX-7) sump, this type of Pressure Valve is incorporated in the S2 Oil Pump Assembly and Not in the rear iron like S1.

Anyway I hope this shows you the difference in oil pumps.

First two are from EPC Parts, last is of S2 oil pump in pieces.

Both of these mount in the same 'way', but the housing they bolt onto are different part numbers, unsure of the exact "design" changes though.

Will an S2 pump fit on an S1, possibly, but as the output pressure of this pump has more than doubled I would have concern about other areas.

Like what do you do with the existing separate By Pass Regulator in rear iron housing?, do you remove it as it would be continually by passing oil, do you blank it off?, you would also have to change Oil Filters, the oil pick up in sump is different..there are a number of issues..

The GREEN Circle shows the 3648-14-250 Oil Pressure By Pass Valve which goes on the Rear Iron Housing in S1 RX-8 (FC RX-7) sump, this type of Pressure Valve is incorporated in the S2 Oil Pump Assembly and Not in the rear iron like S1.

Anyway I hope this shows you the difference in oil pumps.

Last edited by ASH8; 09-30-2009 at 02:31 AM.

The following users liked this post:

e-dub (08-29-2023)

#35

#36

Yeah I think maybe us Renny owners need to be super diligent and do the following things listed below religiously. I just don't think the Series 1 Renny has the margin for error/laziness that most engines have. But even if I get a Series II I will still do a lot of the same. I am thinking my second engine only lasted so much longer than my first because in part because of the OMP update and I was so crazy about oil changes and maintaining it. Had I premixed and ran the GC 0W-30 I am running now, it would probably still be running today. Now if/when my third engine fails prematurely we will tear it apart and really see if we have figured anything out because this engine will have had all of the following done its entire life.

We have to be serious about:

1. Selecting a great synthetic oil.

2. Warm up our cars fully every time before we go anywhere.

3. Change our oil often based on climate/environment.

4. Premix with SOHN Adapter.

5. Do whatever mods lower oil temp (ASH's mod and maybe additional oil coolers).

6. Drive it like it was meant to be driven.

We have to be serious about:

1. Selecting a great synthetic oil.

2. Warm up our cars fully every time before we go anywhere.

3. Change our oil often based on climate/environment.

4. Premix with SOHN Adapter.

5. Do whatever mods lower oil temp (ASH's mod and maybe additional oil coolers).

6. Drive it like it was meant to be driven.

Last edited by 9krpmrx8; 09-30-2009 at 07:33 AM.

#38

If you want to avoid that, you need to be using a full ester synthetic + premix...

#41

#42

Registered User

Joined: Jun 2002

Posts: 3,086

Likes: 1

From: Misinformation Director - Evolv Chicago

Mazmart sells a modified regulator that raises the oil pressure in the system by about 12-13 psi, as I recall. It sells for about $30, and is easy to install. Talk to the guys there and they'll tell you raising the pressure is the only way to go for RX-8s that see track time or are FI.

#44

Registered User

Joined: Jun 2002

Posts: 3,086

Likes: 1

From: Misinformation Director - Evolv Chicago

#47

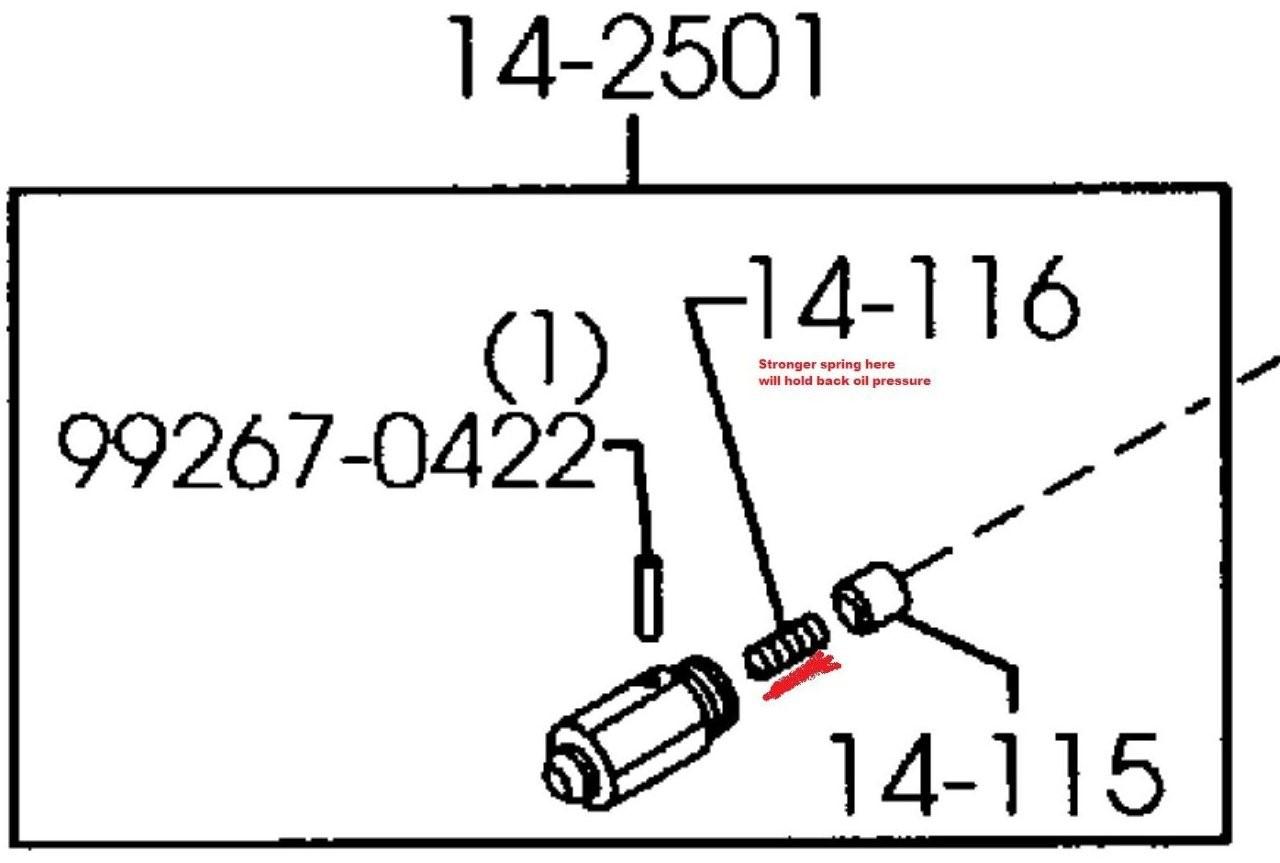

The Regulator Red Devil is talking about is located on the Rear Iron Housing,

the original is the 3648-14-250 see Green Circle above in pic.

The modification is to put a slightly stronger spring behind the 0221-14-115 Plunger (Piston) so your oil won't by pass as early it will hold back oil increasing OP.

To remove unit as R Devil says you have to drop your sump pan and use a shifter, the regulator body is about 20 mm bolt head for memory.

BTW...Trivia. This 0221 Parts Model code is a part from the 1966 Mazda 800 4 cyl.

This By Pass Plunger and Spring is the exact same one used in dozens of Mazda cars from Rotary and Piston...Like Mazda 1500, Capella, RX-2,3,4,5,7,8.

Mazda 626,929,MX-5,6.

the original is the 3648-14-250 see Green Circle above in pic.

The modification is to put a slightly stronger spring behind the 0221-14-115 Plunger (Piston) so your oil won't by pass as early it will hold back oil increasing OP.

To remove unit as R Devil says you have to drop your sump pan and use a shifter, the regulator body is about 20 mm bolt head for memory.

BTW...Trivia. This 0221 Parts Model code is a part from the 1966 Mazda 800 4 cyl.

This By Pass Plunger and Spring is the exact same one used in dozens of Mazda cars from Rotary and Piston...Like Mazda 1500, Capella, RX-2,3,4,5,7,8.

Mazda 626,929,MX-5,6.

Last edited by ASH8; 09-30-2009 at 12:30 PM.

#48

I keep coming back to the same basic thought based on Mazda Spare Parts facts, that is the parts that are original by Mazda Part Numbers.

ALL By Pass Plunger/Piston and Springs are the same for ALL NA Rotaries, from 1969 R100 to 2008 RX-8 S1. #0221-14-115 and 0221-14-116., so therefore the BY Pass Pressures are ALL the same...Right.

The variations in the OIL Pumps themselves are so small they are so close to being all the same...Right.

There is the Eccentric Shaft By Pass Valve (really a Pellet) is there to warm up engine oil faster...you can leave this one out.

And then the Oil Filter By Pass, all Rotary oil filters are the same for NA's including RX-8 S1...Right.

The ONLY variable that could change Oil Pressure between rotary models are the Location or Position or Distance of the Oil Cooler (s) and Lines/Hoses.

So, the very last Difference which can have an effect on Oil Pressure is the ENGINE OIL.

In other words the ONLY thing that has changed in NA rotaries over the past 38 years is the Engine OIL...Not the Oil Pressure (Leaving out S2 RX-8), not the Oil Filter Valves, not the By Pass Valves.

ALL By Pass Plunger/Piston and Springs are the same for ALL NA Rotaries, from 1969 R100 to 2008 RX-8 S1. #0221-14-115 and 0221-14-116., so therefore the BY Pass Pressures are ALL the same...Right.

The variations in the OIL Pumps themselves are so small they are so close to being all the same...Right.

There is the Eccentric Shaft By Pass Valve (really a Pellet) is there to warm up engine oil faster...you can leave this one out.

And then the Oil Filter By Pass, all Rotary oil filters are the same for NA's including RX-8 S1...Right.

The ONLY variable that could change Oil Pressure between rotary models are the Location or Position or Distance of the Oil Cooler (s) and Lines/Hoses.

So, the very last Difference which can have an effect on Oil Pressure is the ENGINE OIL.

In other words the ONLY thing that has changed in NA rotaries over the past 38 years is the Engine OIL...Not the Oil Pressure (Leaving out S2 RX-8), not the Oil Filter Valves, not the By Pass Valves.

Last edited by ASH8; 09-30-2009 at 01:18 PM.