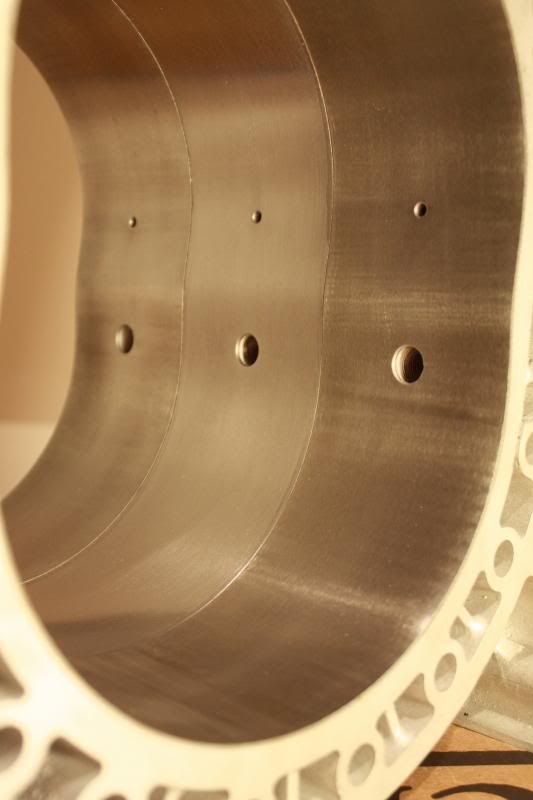

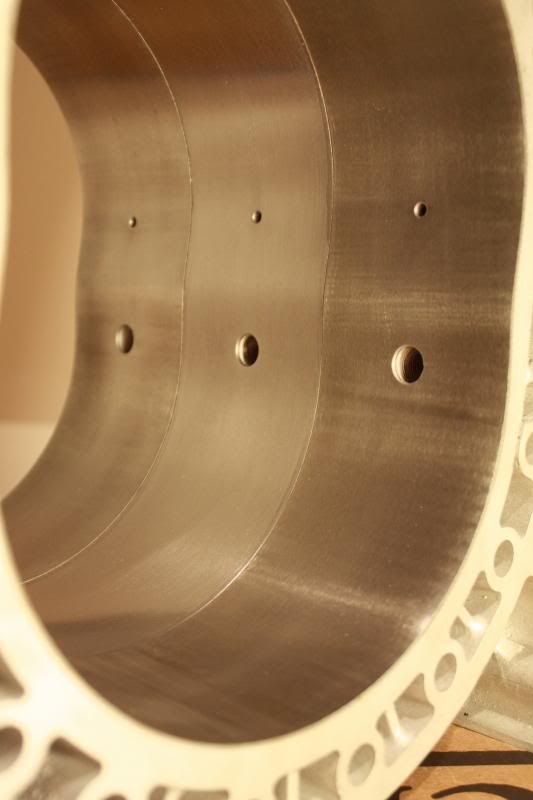

Renesis rotor housing machining/resufacing results

#1

Got some time to program the renesis profile. The parametric formula of the trochoid curve Mazda changed through their revisions. Calculations, blah, blah, blah... you don't want to see the proofing.

Not much to really talk about here other than to show pictures of before and after. The housings weren't in the best shape to begin with. Furthermore, they have to be cleaned before putting them into the machine and after machining they're ultrasonic cleaned due to fragments that end up EVERYWHERE!

Lost the more detailed before pictures so we'll have to just work with the ones I do have...

AFTER the whole process

I'll ask that you respect the fact that I won't go into detail about the programming or tooling involved. The Renesis suffers some of the worst flaking since the 12a engine and you can only remove so much before the integrity is compromised

Anyway, let me know what you think!

Not much to really talk about here other than to show pictures of before and after. The housings weren't in the best shape to begin with. Furthermore, they have to be cleaned before putting them into the machine and after machining they're ultrasonic cleaned due to fragments that end up EVERYWHERE!

Lost the more detailed before pictures so we'll have to just work with the ones I do have...

AFTER the whole process

I'll ask that you respect the fact that I won't go into detail about the programming or tooling involved. The Renesis suffers some of the worst flaking since the 12a engine and you can only remove so much before the integrity is compromised

Anyway, let me know what you think!

#2

MSP has less chrome than REW, it's known fact, mazda was so naive, they probably think o we don't need to put so much this time cuz this sucker is not gonna make as much power ...

anyway, ur work looks good, but it's still not gonna be a good housing, cuz the edge still done. well, better than nothing I guess. and the process is not exactly new, groopy has been doing stuff lilke this for years

anyway, ur work looks good, but it's still not gonna be a good housing, cuz the edge still done. well, better than nothing I guess. and the process is not exactly new, groopy has been doing stuff lilke this for years

The following users liked this post:

marcjj (07-28-2020)

#4

Unfortunately I don't know of anybody else that does it via a machine. CNC allows us to take off tenths of a thou. .000x". Housings done here have been done for years also this is just the first set of Renesis that have been programmed. Took a customers set of goopy housings next to one here and the difference is night and day. I'll dig up the picture tomorrow

#5

Here's what you can pickup with CNC motion. You can see a much more uniform cutting in the center, goopy is on both sides so you can see no photo trickery was involved. Much less material is removed via CNC machining and the surface is much more smoot/uniform. Again, just two different ways of doing the job...

#7

There's no coating added to the housing. We just machined down the factory chrome. We were successful with applying a new chrome layer on a few housings but the process is dirty, dangerous, and too expensive to continue doing.

As far as strength, as long as you remove a very small amount of material you won't impede strength or longevity. There's also a better "fix" in the works but that's well into next year.

As far as strength, as long as you remove a very small amount of material you won't impede strength or longevity. There's also a better "fix" in the works but that's well into next year.

#8

like mono point out, re-chrome process is just too dangerous to handle for most people. only a few places can do it, and the weird shape of rotor housing just making things even more complicated, Mazda built a machine just for this process and no one else on earth has it.

Anyway, lets see what else you got.

Anyway, lets see what else you got.

#9

There's no coating added to the housing. We just machined down the factory chrome. We were successful with applying a new chrome layer on a few housings but the process is dirty, dangerous, and too expensive to continue doing.

As far as strength, as long as you remove a very small amount of material you won't impede strength or longevity. There's also a better "fix" in the works but that's well into next year.

As far as strength, as long as you remove a very small amount of material you won't impede strength or longevity. There's also a better "fix" in the works but that's well into next year.

If it was filled then is the filler as strong as the original housing?

If the chrome has been ground then would this wear out quicker? If this is the case then it would be false economy to spend thousands on a rebuild and find that your housing has worn prematurely.

#10

One of the photos of the original housing shows that the chrome is chipped and flaking off on the edge. How was this treated to get a even finish?

If it was filled then is the filler as strong as the original housing?

If the chrome has been ground then would this wear out quicker? If this is the case then it would be false economy to spend thousands on a rebuild and find that your housing has worn prematurely.

If it was filled then is the filler as strong as the original housing?

If the chrome has been ground then would this wear out quicker? If this is the case then it would be false economy to spend thousands on a rebuild and find that your housing has worn prematurely.

The machine specifically focuses on a specific X,Y starting coordinate with a fixed Z depth. Cycles are then started that are progressively modified to reduce the chrome in a non-aggressive manner. When the housing is done the hardness is not impacted and is actually better due to the oil-retention finish. We've done this to brand new housings to pickup compression faster and actually wear less over their life.

#11

like mono point out, re-chrome process is just too dangerous to handle for most people. only a few places can do it, and the weird shape of rotor housing just making things even more complicated, Mazda built a machine just for this process and no one else on earth has it.

Anyway, lets see what else you got.

Anyway, lets see what else you got.

. Due to the legality of getting past all the regulations to "make it safe" in our environment I doubt we'll offer it.

. Due to the legality of getting past all the regulations to "make it safe" in our environment I doubt we'll offer it. Resurfacing/machining at this point IMO outweighs the possibility of re-chrome plating the housings. You wouldn't believe what you have to do before you even begin the first tanking process.

Mazda's machine for the final bore finishing isn't anymore special than the machine I use. Technically that machine can't be used for anything else and the geometry is fixed for that specific housing "generation"; why do you think the 12a housings are no longer made

.

.The 12a housings that have been resurfaced actually benefit more due to the poor adhesion process to begin with and the softer chrome of the time. I'll get some before and after pictures of some 12a housings that were done some months ago and shipped to Australia.

Does rx8club.com allow facebook links to photo albums without any trouble?

#14

MSP has less chrome than REW, it's known fact, mazda was so naive, they probably think o we don't need to put so much this time cuz this sucker is not gonna make as much power ...

anyway, ur work looks good, but it's still not gonna be a good housing, cuz the edge still done. well, better than nothing I guess. and the process is not exactly new, groopy has been doing stuff lilke this for years

anyway, ur work looks good, but it's still not gonna be a good housing, cuz the edge still done. well, better than nothing I guess. and the process is not exactly new, groopy has been doing stuff lilke this for years

the fact that they are still even allowed to chrome plate anything on that densely populated island is confusing. in most countries all chrome plating is outlawed due to the high toxicity of the process.

if they could make a ceramic sleeve most of these problems wouldn't even be here. apex seals would have almost an indefinite lifespan as would the housings, but the seals would still be brittle and breakable and susceptible to carbon buildup. if it weren't for the side seals the oil injection could probably even be done away with. ceramic is the future for many friction surfaces but it is also quite a bit more expensive.

i don't even much care for resurfacing housings due to the above and i have to wear a respirator when doing so. (note for mono4lamar if using a dry cutter)

Last edited by Karack; 11-08-2013 at 03:25 PM.

#15

Whenever a housing is sent in with flaking with will come back with that same area missing. As I stated, the pictures with more detail were lost and these are quick cellphone pictures that were taken before shipping. I'll see if I can get the guy who owns the housings to get some pictures.

The machine specifically focuses on a specific X,Y starting coordinate with a fixed Z depth. Cycles are then started that are progressively modified to reduce the chrome in a non-aggressive manner. When the housing is done the hardness is not impacted and is actually better due to the oil-retention finish. We've done this to brand new housings to pickup compression faster and actually wear less over their life.

The machine specifically focuses on a specific X,Y starting coordinate with a fixed Z depth. Cycles are then started that are progressively modified to reduce the chrome in a non-aggressive manner. When the housing is done the hardness is not impacted and is actually better due to the oil-retention finish. We've done this to brand new housings to pickup compression faster and actually wear less over their life.

#16

chroming is a single step bonding process as you can't bond chrome to chrome, it has to all be removed and completely redone.

#20

it's also why i usually won't even bother opening an engine with over 80k on it, they just look trashed. you can also tell who follows the "redline a day" myth.

Last edited by Karack; 11-08-2013 at 04:33 PM.

#21

The price is now the exact same as goopy charges (when you buy their apex seals). I was told it's more if you don't purchase their seals.

The easy way to show a whole process from start to finish is here in an album on facebook of some 12a housings. If linking to facebook is not allowed please accept my apologies in advance...

https://www.facebook.com/media/set/?...2694493&type=1

#22

Japan is still waist deep in chroming shops. Their EPA rules aren't much more than china's. infact where I live there is a chrome shop about 6 blocks from the city center. They mostly do racks like in refrigerators.

Housings look amazing. Also if not ceramic, could another material be used to sleeve the housings. If someone figured that out they would be on to something.

Housings look amazing. Also if not ceramic, could another material be used to sleeve the housings. If someone figured that out they would be on to something.

#23

Someday, they will outlaw it and Mazda (anyone who still uses chrome) will have to find alternatives. Ceramic is the future, it's just that it's gonna be a whole different level, both in technology and price of the final product

#24

Mazda needs items that can be rapidly produced; like every manufacture out there. Chrome is very flexible and is ideal to the flexibility of their manufacturing process. Rechroming is a good alternative but it's very difficult. The selection process for the ideal candidates for rechroming is a rigorous detail-oriented process. Mainly the reason we're putting it well on the backburner for now...

#25