GReddy strut tower bar installed

#76

You guys have posted such an insane amount of stuff on this topic, I'm not even sure I could respond to all of it.

The E30 link for strut tower theory can't be applied here. That's a MacPherson strut car, the forces at the strut tower are most likely different than our cars.

So I'm a little curious if anyone here as even tried putting a strain gage on the strut tower bar and actually measured the forces it's subjected to. It sounds to me like Mazda's engineers used it purely to triangulate the hood opening.

The vertical forces have nothing to do with the mazda engineers choosing to add a strut tower bar. If there is any effect to the strut tower, it will be minor as I'm willing to bet the spring constant the strut tower contributes to the series of "springs" in the system is far far larger than the rest. Everything in the system is a spring. Go look up the springs in series formulas and tell me that bracing the strut tower for vertical stiffness is going to help, by that theory, swapping any and all rubber bushings out of the system is going to be the biggest improvement you're ever going to see in the car.

Aftermarket vs. OEM. Find me a bent stock bar and I'll believe it. I'm pretty sure it's steel and not aluminum. If anyone made Al flanges that thin, the bar would break through at the bolt holes long before it would bend. And please go look up the modulus of steel vs. aluminum. And this is not counting that we may or may not know the temper of the aluminum used in the aftermarket bar, could be crappy annealed Al in which case you might just be bolting on a block of cheese to your car.

Jointed vs not jointed. Think about it. If you have a .002" clearance to fit a bolt through the hole when you're bolting the bar together, that could be some large amount of allowed deflection when it gets down to the contact patch. Lets say that joing has a lateral motion ratio relation with the contact patch of 100:1, that could be .2" of extra deflection at the contact patch that didn't need to be there. That probably won't affect your grip, as the grip is only directly related with the normal force and Cf at the contact patch. It WILL affect response. So I really want to know how a front strut tower bar could possibly affect the grip of the vehicle, I would HAVE to see a accelerometer reading to believe that. Heck, YOU should demand a accelerometer reading to believe it.

Chassis stiffness is all about response/transient reaction of the car, grip is all in the tires and any possible aero loads. Chassis stiffness will also change a vehicle's response to set-up changes. Change the spring rates on a floppy car and you'll never feel the handling balance change.

Brake master cylinder brace: Lets say the motion ratio between the pedal and where it actuates the master cylinder is 10:1. Lets say you put 120 lbs on it for max braking force. That's 1200 lbs on the master cylinder that's probably bolted at two points on the fire wall. Worse yet, it may not be secured through the booster and the firewall and only the booster by itself. I don't care how strong the firewall is, but load vs. deflection is key. 1200 lb WILL cause any metal to deflect. If the motion ratio is large enough, you're going to feel a lot of mush in your pedal. Doesn't stop the car any faster, but it might help you feel when you're going to lock up your tires. Would that be worth it? Probably. If you need proof, put a dial indicator on the master cylinder and press on the brakes relatively hard and see if it moves, if it does, bracing it can't hurt.

Not saying I have all the answers here, I know I'm vague, I try to be that way unless I have real measured data. I know the Mazda engineers had data. I forget what the article about the Mazdaspeed engineers did to the Mazdaspeed 3, but I believe it said they had somewhere along the lines of 600 channels of data being logged on their test cars down to the temperatures in the ball joints. I would find it VERY hard that ANY aftermarket company does work like this in any way shape or form.

Mazda's engineers know what they're doing, it is the reason why their cars drive the way they do even if they don't put numbers down on paper as good as other cars out there. They KNOW the vehicle dynamics well enough to consistently create cars that to our human perception is fun to drive.

The E30 link for strut tower theory can't be applied here. That's a MacPherson strut car, the forces at the strut tower are most likely different than our cars.

So I'm a little curious if anyone here as even tried putting a strain gage on the strut tower bar and actually measured the forces it's subjected to. It sounds to me like Mazda's engineers used it purely to triangulate the hood opening.

The vertical forces have nothing to do with the mazda engineers choosing to add a strut tower bar. If there is any effect to the strut tower, it will be minor as I'm willing to bet the spring constant the strut tower contributes to the series of "springs" in the system is far far larger than the rest. Everything in the system is a spring. Go look up the springs in series formulas and tell me that bracing the strut tower for vertical stiffness is going to help, by that theory, swapping any and all rubber bushings out of the system is going to be the biggest improvement you're ever going to see in the car.

Aftermarket vs. OEM. Find me a bent stock bar and I'll believe it. I'm pretty sure it's steel and not aluminum. If anyone made Al flanges that thin, the bar would break through at the bolt holes long before it would bend. And please go look up the modulus of steel vs. aluminum. And this is not counting that we may or may not know the temper of the aluminum used in the aftermarket bar, could be crappy annealed Al in which case you might just be bolting on a block of cheese to your car.

Jointed vs not jointed. Think about it. If you have a .002" clearance to fit a bolt through the hole when you're bolting the bar together, that could be some large amount of allowed deflection when it gets down to the contact patch. Lets say that joing has a lateral motion ratio relation with the contact patch of 100:1, that could be .2" of extra deflection at the contact patch that didn't need to be there. That probably won't affect your grip, as the grip is only directly related with the normal force and Cf at the contact patch. It WILL affect response. So I really want to know how a front strut tower bar could possibly affect the grip of the vehicle, I would HAVE to see a accelerometer reading to believe that. Heck, YOU should demand a accelerometer reading to believe it.

Chassis stiffness is all about response/transient reaction of the car, grip is all in the tires and any possible aero loads. Chassis stiffness will also change a vehicle's response to set-up changes. Change the spring rates on a floppy car and you'll never feel the handling balance change.

Brake master cylinder brace: Lets say the motion ratio between the pedal and where it actuates the master cylinder is 10:1. Lets say you put 120 lbs on it for max braking force. That's 1200 lbs on the master cylinder that's probably bolted at two points on the fire wall. Worse yet, it may not be secured through the booster and the firewall and only the booster by itself. I don't care how strong the firewall is, but load vs. deflection is key. 1200 lb WILL cause any metal to deflect. If the motion ratio is large enough, you're going to feel a lot of mush in your pedal. Doesn't stop the car any faster, but it might help you feel when you're going to lock up your tires. Would that be worth it? Probably. If you need proof, put a dial indicator on the master cylinder and press on the brakes relatively hard and see if it moves, if it does, bracing it can't hurt.

Not saying I have all the answers here, I know I'm vague, I try to be that way unless I have real measured data. I know the Mazda engineers had data. I forget what the article about the Mazdaspeed engineers did to the Mazdaspeed 3, but I believe it said they had somewhere along the lines of 600 channels of data being logged on their test cars down to the temperatures in the ball joints. I would find it VERY hard that ANY aftermarket company does work like this in any way shape or form.

Mazda's engineers know what they're doing, it is the reason why their cars drive the way they do even if they don't put numbers down on paper as good as other cars out there. They KNOW the vehicle dynamics well enough to consistently create cars that to our human perception is fun to drive.

#77

Mazda's engineers know what they're doing, it is the reason why their cars drive the way they do even if they don't put numbers down on paper as good as other cars out there. They KNOW the vehicle dynamics well enough to consistently create cars that to our human perception is fun to drive.

Yes Mazda's engineers do know what they are doing and have likely more data on just about everything on these cars than any aftermarket company. Just remember that Mazda also has accounants and those are the folks reponsible for comprimises which at times undermine what the engineer intended.

#78

printf("</%i pistons",3);

Joined: Dec 2006

Posts: 654

Likes: 0

From: I'm a yankee trapped in Houston!!

OK, I just read this whole thread and I have a question:

Everyone here as speculated and hypothesised a lot of very probable points, but we still lack any form of definative proof.

Is there anything that *we* - the everyday driver - can do to effectively "measure" the effects of these different braces? I mean, none of us have the high-tech equipment required to get any numerical data, so there's no way for us to actually measure strain or skidpad figures. Is there nothing simple we can do to see our braces at work?

Parking on an uneaven surface and observing shock compression maybe?

Parking on a steep incline to see how much the master cylinder moves?

Measuring stopping distances while turning to see if weight distributes differently (better distribution = faster stopping)?

These are all ideas I thought of just now, so I don't expect any of them to actually work. I'm just trying to give the more analytical/imaginative minds here a running start on DIY strut tower brace testing... (if it's even possible)...

Everyone here as speculated and hypothesised a lot of very probable points, but we still lack any form of definative proof.

Is there anything that *we* - the everyday driver - can do to effectively "measure" the effects of these different braces? I mean, none of us have the high-tech equipment required to get any numerical data, so there's no way for us to actually measure strain or skidpad figures. Is there nothing simple we can do to see our braces at work?

Parking on an uneaven surface and observing shock compression maybe?

Parking on a steep incline to see how much the master cylinder moves?

Measuring stopping distances while turning to see if weight distributes differently (better distribution = faster stopping)?

These are all ideas I thought of just now, so I don't expect any of them to actually work. I'm just trying to give the more analytical/imaginative minds here a running start on DIY strut tower brace testing... (if it's even possible)...

#80

LabDad, you're absolutely right. But also realize that aftermarket companies have accountants as well. They are surely more interested in marketing and taking your money than to give you the best possible product that can be made. Afterall, if they don't make money they can't even offer you any products. I just think that since the Mazda engineers have the data they can cut right to the problem and fix it.

To tune a car without the data is a shot in the dark. You could be spending a lot of unecessary cash. From what I see on the aftermarket you could be doing a lot of harm based on people's technical hunches and not real data. I know of many many examples of aftermarket butchery of automotive engineering (not necessarily with rx-8 products).

To tune a car without the data is a shot in the dark. You could be spending a lot of unecessary cash. From what I see on the aftermarket you could be doing a lot of harm based on people's technical hunches and not real data. I know of many many examples of aftermarket butchery of automotive engineering (not necessarily with rx-8 products).

#81

LabDad, you're absolutely right. But also realize that aftermarket companies have accountants as well. They are surely more interested in marketing and taking your money than to give you the best possible product that can be made. Afterall, if they don't make money they can't even offer you any products. I just think that since the Mazda engineers have the data they can cut right to the problem and fix it.

To tune a car without the data is a shot in the dark. You could be spending a lot of unecessary cash. From what I see on the aftermarket you could be doing a lot of harm based on people's technical hunches and not real data. I know of many many examples of aftermarket butchery of automotive engineering (not necessarily with rx-8 products).

To tune a car without the data is a shot in the dark. You could be spending a lot of unecessary cash. From what I see on the aftermarket you could be doing a lot of harm based on people's technical hunches and not real data. I know of many many examples of aftermarket butchery of automotive engineering (not necessarily with rx-8 products).

But the best way to find out if there is chassis flex is pretty simple.

1 remove strut tower bar.

2 make hard candy

3 make a pencil thin section of hard candy that will attach to each side of the strut tower assemblies.

4 drive your car

if the candy breaks that means there was chassis flex. If it doesnt, then there is no chassis flex.

feel free to use any hard setting brittle substance that you want.

But hard candy is just sugar and corn syrup heated up.

#84

I like that AutoExe bar, just by looking at it design wise. I just like to play devil's advocate. I learned a lot of stuff in the last couple of years that pretty much blew everything else I learned in the last 6 years wrong. It's really tough knowing how much is unknown and seeing people just bolting all kinds of stuff on to their cars.

#85

I like that AutoExe bar, just by looking at it design wise. I just like to play devil's advocate. I learned a lot of stuff in the last couple of years that pretty much blew everything else I learned in the last 6 years wrong. It's really tough knowing how much is unknown and seeing people just bolting all kinds of stuff on to their cars.

#86

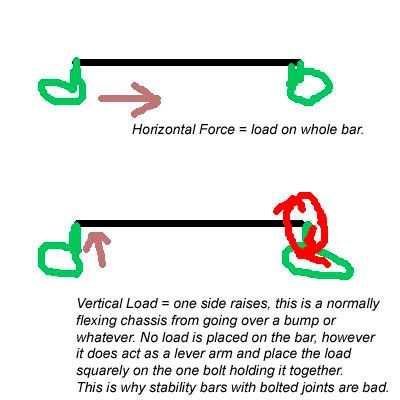

So as long as the shock tower bars only receive forces in the horizontal direction, pushing toward each other or pulling away from each other, they will do their job well.

But once any vertical force is encountered, the bolted sides become the sole bearer of the entire stress. I don't think that one bolt torqued to maybe 35 ft/lbs is going to hold a candle to half the weight of the car being thrown around.

IMHO, any bar that has a bolted joint is only able to do half its job. greddy * 2 = autoexe bar. Now the price is reasonable in comparison!

Last edited by staticlag; 07-26-2007 at 11:10 PM.

Thread

Thread Starter

Forum

Replies

Last Post

JimmyBlack

Series I Major Horsepower Upgrades

273

02-10-2020 11:23 PM

projectr13b

Series I Do It Yourself Forum

1

09-06-2015 02:04 PM