Rear Toe Control Arm/Link Bent

#1

Rear Toe Control Arm/Link Bent

Hi there, Sorry my first post wasn't an Introduction but I've run into a spot of trouble.

I have been meaning to join these forums a month ago but I have been so busy and now that I ran into a bit of trouble I have few places left to turn.

I ended up bending my driver side rear toe control arm and well I cant seem to get the thing off. I managed to get half of it off but there is still a bolt stuck I cant seem to get out or don't even know if it even comes out.

I managed to get the nut off the bolt with a bit of tug and heave with just a socket and ratchet after spraying some WD-40 on it I pretty much drenched the exposed areas of the bolt and have been working on trying to get it off for about a good 2 hours even took an impact to it on full torque and still cant get this damn bolt off

I even tried to fit an extension bar in there and tried to pound the pin to the control arm out but did not work out so well.

Yes I have the impact on reverse and yes I have been turning the ratchet the right way. Am I doing something wrong or is this thing just really rusted on there. Any suggestions or tips how to get this thing off?

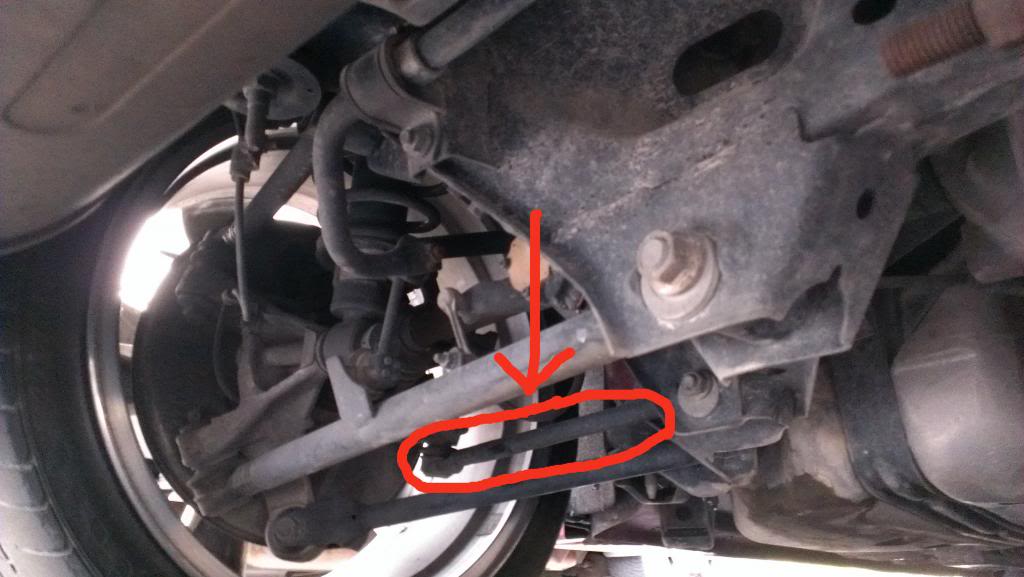

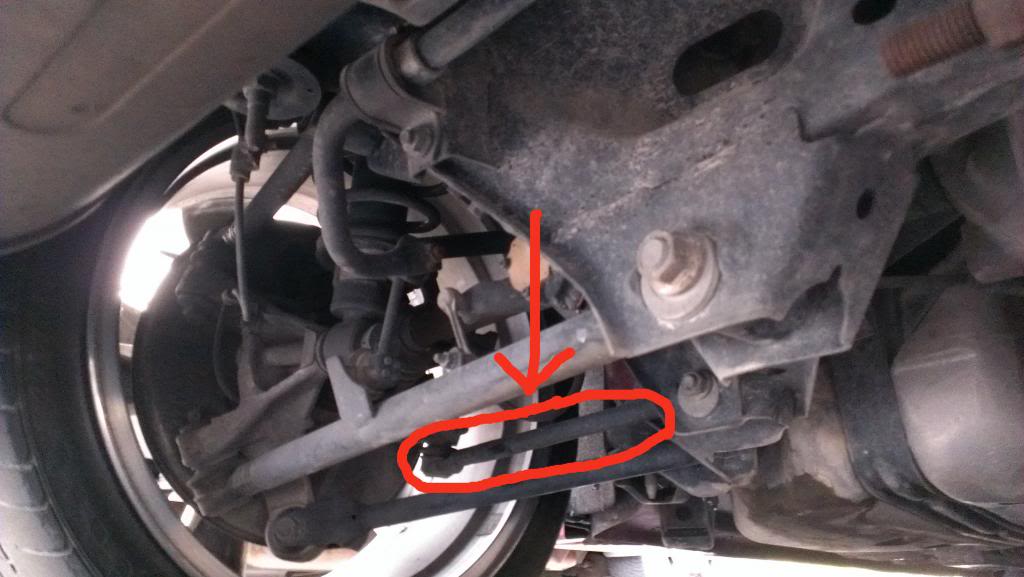

Here are a few pictures I took of the pesky bolt

I have been meaning to join these forums a month ago but I have been so busy and now that I ran into a bit of trouble I have few places left to turn.

I ended up bending my driver side rear toe control arm and well I cant seem to get the thing off. I managed to get half of it off but there is still a bolt stuck I cant seem to get out or don't even know if it even comes out.

I managed to get the nut off the bolt with a bit of tug and heave with just a socket and ratchet after spraying some WD-40 on it I pretty much drenched the exposed areas of the bolt and have been working on trying to get it off for about a good 2 hours even took an impact to it on full torque and still cant get this damn bolt off

I even tried to fit an extension bar in there and tried to pound the pin to the control arm out but did not work out so well.

Yes I have the impact on reverse and yes I have been turning the ratchet the right way. Am I doing something wrong or is this thing just really rusted on there. Any suggestions or tips how to get this thing off?

Here are a few pictures I took of the pesky bolt

#5

Tap it out with a Hammer...You may want to try using a pry bar in between the notch of the aluminum arm, just slightly pry it apart to help break any corrosion loose. Don't go crazy with the pry bar as it's cast aluminum and you could crack it if you apply too much force.

WD40 is not a good penetrating oil, use Liquid Wrench or PB Blaster.

WD40 is not a good penetrating oil, use Liquid Wrench or PB Blaster.

#6

With the nut off, the bolt in theory will turn either way. The aluminum housing that it is in is not threaded. As JCrane said, use something more powerful than wd40 like pblaster. The thing to do is work the bolt back and forth to loosen up the corrosion.

What I do in those situations is, put the impact gun on, pull the trigger than rapidly switch the rotation back and forward while holding the trigger. This rapidly forces the bolt to try to turn in apposing directions to help free it up. Start first with a lower setting like 2-3 move up to 4-5 only once the bolt is turning. You don't want to break off the head. Then you would have to go at it with a punch.

Do you have access to a torch? That would also help. You need to be careful not to melt the aluminum though. Its a pretty large chunk though. You should be able to get it pretty hot without damaging anything. Heat up the aluminum surrounding the bolt then go at it lightly with the impact gun.

Good luck and welcome to the club.

Edit: One more thing I just remembered you can try also. Reinstall the nut all the way on and use the gun to repeatedly tighten/loosen the nut. In theory that will squeeze the two aluminum "ears" together and apart ever so slightly. While the whole thing is soaked in oil, It may help to loosen the corrosion around the bolt by forcing the oil into the passage that the bolt is in.

Heres a video of an audi VW front tie rod removal. His work methods are a bit crude but It will show you what it looks like inside there. Aside from the bolt on the top in the first 15 seconds, its the same setup you are working with.

What I do in those situations is, put the impact gun on, pull the trigger than rapidly switch the rotation back and forward while holding the trigger. This rapidly forces the bolt to try to turn in apposing directions to help free it up. Start first with a lower setting like 2-3 move up to 4-5 only once the bolt is turning. You don't want to break off the head. Then you would have to go at it with a punch.

Do you have access to a torch? That would also help. You need to be careful not to melt the aluminum though. Its a pretty large chunk though. You should be able to get it pretty hot without damaging anything. Heat up the aluminum surrounding the bolt then go at it lightly with the impact gun.

Good luck and welcome to the club.

Edit: One more thing I just remembered you can try also. Reinstall the nut all the way on and use the gun to repeatedly tighten/loosen the nut. In theory that will squeeze the two aluminum "ears" together and apart ever so slightly. While the whole thing is soaked in oil, It may help to loosen the corrosion around the bolt by forcing the oil into the passage that the bolt is in.

Heres a video of an audi VW front tie rod removal. His work methods are a bit crude but It will show you what it looks like inside there. Aside from the bolt on the top in the first 15 seconds, its the same setup you are working with.

Last edited by godesshunter; 08-22-2012 at 10:49 PM.

#7

No the bolt doesnt turn but hey thanks for the replys! I will definatly be back later today if not then tomorrow i have another busy day ahead of me looks like im working another 12 hour day then whatever i can get done the rest of the day.

#9

With the nut off, the bolt in theory will turn either way. The aluminum housing that it is in is not threaded. As JCrane said, use something more powerful than wd40 like pblaster. The thing to do is work the bolt back and forth to loosen up the corrosion.

What I do in those situations is, put the impact gun on, pull the trigger than rapidly switch the rotation back and forward while holding the trigger. This rapidly forces the bolt to try to turn in apposing directions to help free it up. Start first with a lower setting like 2-3 move up to 4-5 only once the bolt is turning. You don't want to break off the head. Then you would have to go at it with a punch.

Do you have access to a torch? That would also help. You need to be careful not to melt the aluminum though. Its a pretty large chunk though. You should be able to get it pretty hot without damaging anything. Heat up the aluminum surrounding the bolt then go at it lightly with the impact gun.

Good luck and welcome to the club.

Edit: One more thing I just remembered you can try also. Reinstall the nut all the way on and use the gun to repeatedly tighten/loosen the nut. In theory that will squeeze the two aluminum "ears" together and apart ever so slightly. While the whole thing is soaked in oil, It may help to loosen the corrosion around the bolt by forcing the oil into the passage that the bolt is in.

What I do in those situations is, put the impact gun on, pull the trigger than rapidly switch the rotation back and forward while holding the trigger. This rapidly forces the bolt to try to turn in apposing directions to help free it up. Start first with a lower setting like 2-3 move up to 4-5 only once the bolt is turning. You don't want to break off the head. Then you would have to go at it with a punch.

Do you have access to a torch? That would also help. You need to be careful not to melt the aluminum though. Its a pretty large chunk though. You should be able to get it pretty hot without damaging anything. Heat up the aluminum surrounding the bolt then go at it lightly with the impact gun.

Good luck and welcome to the club.

Edit: One more thing I just remembered you can try also. Reinstall the nut all the way on and use the gun to repeatedly tighten/loosen the nut. In theory that will squeeze the two aluminum "ears" together and apart ever so slightly. While the whole thing is soaked in oil, It may help to loosen the corrosion around the bolt by forcing the oil into the passage that the bolt is in.

the new results are im starting to get pissed off at this thing when i tried to tighten the nut back on with an impact on a low setting number 2 there is now a thread stripped at the very end of the bolt so the nut doesnt tighten any more also tried jogging it back and fourth with the impact 'the bolt not the nut' at a low setting got pissed off and been going at a high setting number 4 and the damn thing still wont budge

I have been drenching it with PB during the entire segment of this two hours so looks like if i even get this bolt off i will have to get a replacement bolt as well now too.

no i did not strip the thread at the end at a high torque i was getting my hopes up thinking i finally broke this bolt from hell loose until i realized it was stripped..

going to wait until the PB drys up a bit and try to go at it again with an impact and then torch the damn thing if that doesn't work

I am really hoping something works soon running low on cash and taking it to a shop is going to be that much more exciting with my busy schedule

#11

after heating it up with a torch now the bolt head is starting gradually strip still no budge so now im afraid to go at it any more i might be looking at taking the whole thing off and smashing it as hard as i can with a hammer im starting to see no other options

#12

well cracked my bit and the bolt still isnt budging.. im going to have to take it to a shop this is unbelievable.. thanks for the tips guys but im out of options i cant get this bolt to move at all and i cant pry the control arm out im thinking its better to leave it the way it is take it to the shop down the street and pray i wont be paying more than $300

#13

With a torch and an air hammer they should be able to get it out in no time. They should just charge you an hour labor at about $85-$100 to get it done. And a few bucks to put in a new nut/bolt.

If you take it to an alignment shop to have it aligned,(you will need to) they may change out the bolt as a courtesy before the alignment. Doesn't hurt to ask.

If you take it to an alignment shop to have it aligned,(you will need to) they may change out the bolt as a courtesy before the alignment. Doesn't hurt to ask.

#15

Thanks guys really appreciate the help and I really dont want someone to have to come out and help me I am still new to the forums and still owe you guys an introduction. I will pay for my own mistakes just sucks but accidents happen.

So here is how it happened pretty much I was being stupid and tried to take a drift around a corner I ended up cutting the wheel too late and I probably should have down shifted to third I ended up smacking into a curb pretty hard it knocked off my side skirt completely smashed up scuffed my rim up a good deal and bent that control arm. I am hoping that is all that is wrong with it I still have a lot of maintenance to put into the car along with paying it off.

I realize it was a pretty stupid thing to do but you have to learn drifting starting somewhere and im paying for it now. The only lesson I learned is I loved the feeling of drifting around a bend and I made a few turns successfully before the accident but on the road is where I am happiest I love my RX8 and I love driving it and I probably will never hear the end of it at work until I actually make that turn haha.

So here is how it happened pretty much I was being stupid and tried to take a drift around a corner I ended up cutting the wheel too late and I probably should have down shifted to third I ended up smacking into a curb pretty hard it knocked off my side skirt completely smashed up scuffed my rim up a good deal and bent that control arm. I am hoping that is all that is wrong with it I still have a lot of maintenance to put into the car along with paying it off.

I realize it was a pretty stupid thing to do but you have to learn drifting starting somewhere and im paying for it now. The only lesson I learned is I loved the feeling of drifting around a bend and I made a few turns successfully before the accident but on the road is where I am happiest I love my RX8 and I love driving it and I probably will never hear the end of it at work until I actually make that turn haha.

Last edited by oldBeggar010; 08-23-2012 at 06:52 PM. Reason: spelling error

#16

Holy crap. How fast were you going!? Kinda had a feeling the bent toe rod was from a failed drifting attempt. That's how most of them happen.

That being said, Here comes the father jargon...You really shouldn't be attempting to learn drifting on public roads. Have you tried looking into a local drifting club? Maybe they rent out a parking lot or something. I've seen them before.

That being said, Here comes the father jargon...You really shouldn't be attempting to learn drifting on public roads. Have you tried looking into a local drifting club? Maybe they rent out a parking lot or something. I've seen them before.

#17

I was going about 55-60 lol like i said i should have cut the wheel sooner down shifted to third and punched it to get those wheels spinning and i would have had it

the reason i cut the wheel too late is because i was checking around the bend making sure no one was coming and if someone was there was a lot i could have went straight into if i had to bail out of it but yeah im going to look into finding some open lots and stick to traffic cones until i can perfect my turns haha

the reason i cut the wheel too late is because i was checking around the bend making sure no one was coming and if someone was there was a lot i could have went straight into if i had to bail out of it but yeah im going to look into finding some open lots and stick to traffic cones until i can perfect my turns haha

#18

There's a lot of helpful people on the forum and many that would be willing to come out and lend a hand if you need help. We understand **** happens, albeit while you were doing something pretty stupid(You shouldn't be trying to learn how to drift on the street).

I would be very surprised if it took me more than 5-10 minutes to get that bolt out with a 2lb Sledge and an Oxyacetylene Torch.

I would be very surprised if it took me more than 5-10 minutes to get that bolt out with a 2lb Sledge and an Oxyacetylene Torch.

#19

that it hit a curb was obvious, it is designed to bend for just that reason. The issue with doing this on the street is you can end up making other people pay for your mistakes. It is your mistake to make though.

put the nut on so there is a gap to the seating surface, put a socket on an extension and place it on the nut, then drive it out by pounding on the extension end with a 2 lb hammer, slowly back the nut off as you pound it out

put the nut on so there is a gap to the seating surface, put a socket on an extension and place it on the nut, then drive it out by pounding on the extension end with a 2 lb hammer, slowly back the nut off as you pound it out

#20

you need a pickle fork to remove, don't just smack it with a sledge. Stick the pickle fork in the there and smack that instead. If you want to save the boot use a **** ton of greece. It'll come out super easy.

#22

That wont work till the bolt is out. The post has a recess that the bolt slides through. I think you are confusing a taper seat with a pinch bolt setup.

#23

Hello, very sorry to revive an old thread, but for some reason I am no longer able to post new threads.

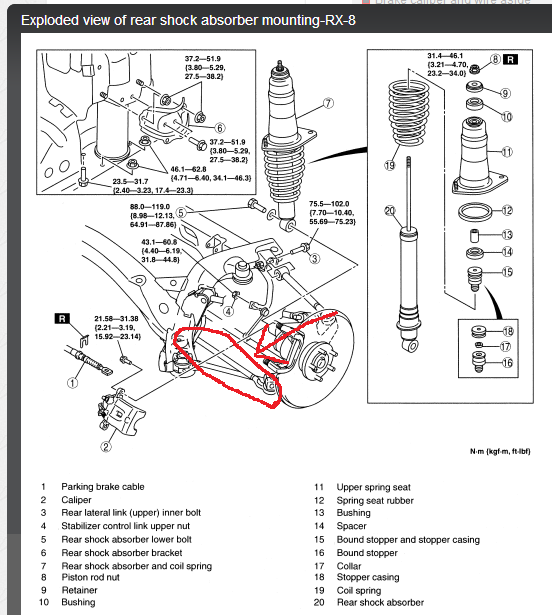

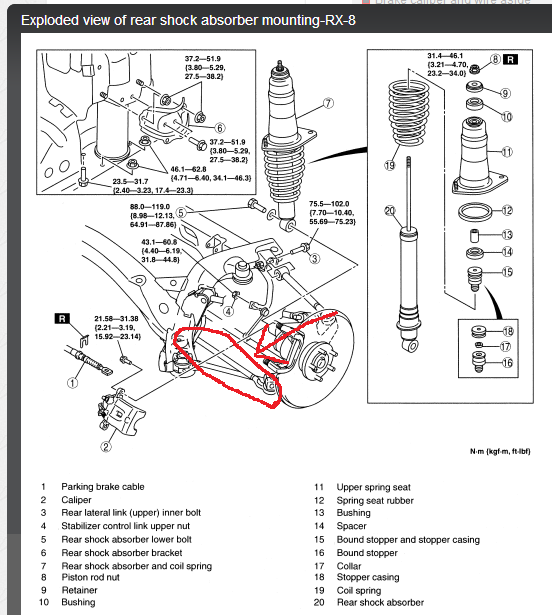

I believe my rear toe control arm is bent as well. Before I ordered the new part, I just wanted to make sure I was correct. The pictures below highlight the arm that is bent. That is the rear toe control arm correct? Part number F1512845XC for 2004 RX8 correct? Thank You.

I believe my rear toe control arm is bent as well. Before I ordered the new part, I just wanted to make sure I was correct. The pictures below highlight the arm that is bent. That is the rear toe control arm correct? Part number F1512845XC for 2004 RX8 correct? Thank You.

Thread

Thread Starter

Forum

Replies

Last Post

projectr13b

Series I Do It Yourself Forum

1

09-06-2015 01:04 PM

nivong

Europe For Sale/Wanted

0

09-02-2015 07:54 AM