Fuel Pump Options for S2

#1

Fuel Pump Options for S2

I've been searching the forums for while trying to get a clean answer and I can't find one. What aftermarket pumps will work with S2? I have a 2010 R3 that I'm pretty sure has a failing fuel pump. I have extreme power loss at 5k, p0171 and p2096.

Its not ignition, just installed BHR coils a month ago (yes I tested for failure)

No misfires, no idle problems, no hot issues.

Its not clogged exhaust, removed OEM cat and it was clean, installed RB DR midpipe anyways.

Clean air filter

Clean ESS sensor and reset profile

VFAD, SSV and VDI all appear to be working (can move freely with fingers, no binding) plus no codes

Checked for vacuum leaks, sprayed electrical cleaner all over engine looking for engine rev, nothing. No hissing sound, or hunting idle.

Cleaned MAF

Is the best way to verify fuel pump failure checking pressure under load? I have a code scanner but it doesn't read in real time.

Its not ignition, just installed BHR coils a month ago (yes I tested for failure)

No misfires, no idle problems, no hot issues.

Its not clogged exhaust, removed OEM cat and it was clean, installed RB DR midpipe anyways.

Clean air filter

Clean ESS sensor and reset profile

VFAD, SSV and VDI all appear to be working (can move freely with fingers, no binding) plus no codes

Checked for vacuum leaks, sprayed electrical cleaner all over engine looking for engine rev, nothing. No hissing sound, or hunting idle.

Cleaned MAF

Is the best way to verify fuel pump failure checking pressure under load? I have a code scanner but it doesn't read in real time.

#2

I dont think the OEM fuel pump has a pressure sender so I am not sure what you would be looking at through obd2, but yes ideally you will want to monitor your fuel pressure. You should be sitting at about 60-65psi (depending on the +/- deviation of the gauge), and you shouldn't drop pressure lower than about 50psi after shutting the car off over night.

If under load your pressure drops below 60psi that is a good sign of a failing pump

If under load your pressure drops below 60psi that is a good sign of a failing pump

#4

I don't have any way of seeing my AFR, I ordered a ELM wifi adapter so I can get some live readings but that wont be here for a week. I ran a bunch of concentrated fuel cleaner through system, the 15$ techron stuff. Same problem, I don't think its losing pressure overnight as it starts right up in the morning. It just falls flat on its face after 5k, it will still rev, slowly not making any power.

BUT I still don't have any answers for replacing the fuel pump (other than OEM which is expensive and apparently prone to failure). Does the DW200 fit? If its not perfect and needs modification thats fine. I can't find a write up or anything, just the long posts about S1 pump options, putting S2 in a S1, S1 options for FI....... nothing for S2!!!!

BUT I still don't have any answers for replacing the fuel pump (other than OEM which is expensive and apparently prone to failure). Does the DW200 fit? If its not perfect and needs modification thats fine. I can't find a write up or anything, just the long posts about S1 pump options, putting S2 in a S1, S1 options for FI....... nothing for S2!!!!

#5

Charles to the rescue! The scanner doesn't give me a timeframe, or timestamp of any kind if thats what you mean. I can tell you what the description of the codes was, I wrote them in my phone for reference.

P0171 - "system too lean"

P2096 - "post catalyst fuel trim system too lean bank 1"

I also had 2 of the P0420 "catalyst efficiency below threshold", which I expected from the midpipe. Thought it was odd there was two though.

#6

From the manual:

2011 - RX-8 - Engine

DTC P0171 [13B-MSP]

DTC P0171 System too lean

DETECTION

CONDITION

The PCM monitors the short term fuel trim (SHRTFT) and long term fuel trim

(LONGFT) when under closed loop fuel control. If the fuel trim is more than

the specification, the PCM determines that the system is too lean.

Diagnostic support note

This is a continuous monitor (fuel system).

The MIL illuminates if the PCM detects the above malfunction condition in

two consecutive drive cycles or in one drive cycle while the DTC for the same

malfunction has been stored in the PCM.

PENDING CODE is available if the PCM detects the above malfunction

condition during the first drive cycle.

FREEZE FRAME DATA (Mode 2/Mode 12) is available.

The DTC is stored in the PCM memory.

Erratic signal to PCM

APP sensor signal malfunction

ECT sensor signal malfunction

MAF sensor signal malfunction

TP sensor signal malfunction

VSS signal malfunction

Excess air suction in intake-air system

Leakage exhaust gas

A/F sensor malfunction

MAF sensor malfunction

POSSIBLE

CAUSE

Fuel line pressure malfunction

Leakage fuel

Fuel pump unit malfunction

Pressure regulator (built-in fuel pump unit) malfunction

Ignition system malfunction

High-tension lead malfunction

Incorrect power supply to ignition coil

Ignition coil malfunction

AIR system malfunction

Insufficient compression

Metering oil pump malfunction

Engine oil condition malfunction

Increased oil pressure

Oil passage malfunction

Engine malfunction

Fuel injector malfunction

PCM malfunction

Diagnostic procedure

AND

2011 - RX-8 - Engine

DTC P2096 [13B-MSP]

DTC P2096 Target A/F feedback system too lean

DETECTION

CONDITION

The PCM monitors the target A/F fuel trim when under the target A/F

feedback control. If the fuel trim is less than the specification, the PCM

determines that the target A/F feedback system is too lean.

Diagnostic support note

This is a continuous monitor (fuel system).

The MIL illuminates if the PCM detects the above malfunction condition in

two consecutive drive cycles or in one drive cycle while the DTC for the same

malfunction has been stored in the PCM.

PENDING CODE is available if the PCM detects the above malfunction

condition during the first drive cycle.

FREEZE FRAME DATA (Mode 2/Mode 12) is available.

The DTC is stored in the PCM memory.

Leakage exhaust gas

HO2S malfunction

Air suction in intake-air system

Erratic signal to PCM

APP sensor signal malfunction

ECT sensor signal malfunction

MAF sensor signal malfunction

TP sensor signal malfunction

VSS signal malfunction

AIR system malfunction

POSSIBLE

CAUSE

Loose installation of A/F sensor

Leakage exhaust gas

A/F sensor malfunction

MAF sensor malfunction

Air suction in intake-air system

Fuel line pressure malfunction

Leakage fuel

Fuel pump unit malfunction

Pressure regulator (built-in fuel pump unit) malfunction

Ignition system malfunction

High-tension lead malfunction

Incorrect power supply to ignition coil

Ignition coil malfunction

Insufficient compression

Metering oil pump malfunction

Engine oil condition malfunction

Increased oil pressure

Oil passage malfunction

Engine malfunction

Fuel injector malfunction

PCM malfunction

Diagnostic procedure

2011 - RX-8 - Engine

DTC P0171 [13B-MSP]

DTC P0171 System too lean

DETECTION

CONDITION

The PCM monitors the short term fuel trim (SHRTFT) and long term fuel trim

(LONGFT) when under closed loop fuel control. If the fuel trim is more than

the specification, the PCM determines that the system is too lean.

Diagnostic support note

This is a continuous monitor (fuel system).

The MIL illuminates if the PCM detects the above malfunction condition in

two consecutive drive cycles or in one drive cycle while the DTC for the same

malfunction has been stored in the PCM.

PENDING CODE is available if the PCM detects the above malfunction

condition during the first drive cycle.

FREEZE FRAME DATA (Mode 2/Mode 12) is available.

The DTC is stored in the PCM memory.

Erratic signal to PCM

APP sensor signal malfunction

ECT sensor signal malfunction

MAF sensor signal malfunction

TP sensor signal malfunction

VSS signal malfunction

Excess air suction in intake-air system

Leakage exhaust gas

A/F sensor malfunction

MAF sensor malfunction

POSSIBLE

CAUSE

Fuel line pressure malfunction

Leakage fuel

Fuel pump unit malfunction

Pressure regulator (built-in fuel pump unit) malfunction

Ignition system malfunction

High-tension lead malfunction

Incorrect power supply to ignition coil

Ignition coil malfunction

AIR system malfunction

Insufficient compression

Metering oil pump malfunction

Engine oil condition malfunction

Increased oil pressure

Oil passage malfunction

Engine malfunction

Fuel injector malfunction

PCM malfunction

Diagnostic procedure

AND

2011 - RX-8 - Engine

DTC P2096 [13B-MSP]

DTC P2096 Target A/F feedback system too lean

DETECTION

CONDITION

The PCM monitors the target A/F fuel trim when under the target A/F

feedback control. If the fuel trim is less than the specification, the PCM

determines that the target A/F feedback system is too lean.

Diagnostic support note

This is a continuous monitor (fuel system).

The MIL illuminates if the PCM detects the above malfunction condition in

two consecutive drive cycles or in one drive cycle while the DTC for the same

malfunction has been stored in the PCM.

PENDING CODE is available if the PCM detects the above malfunction

condition during the first drive cycle.

FREEZE FRAME DATA (Mode 2/Mode 12) is available.

The DTC is stored in the PCM memory.

Leakage exhaust gas

HO2S malfunction

Air suction in intake-air system

Erratic signal to PCM

APP sensor signal malfunction

ECT sensor signal malfunction

MAF sensor signal malfunction

TP sensor signal malfunction

VSS signal malfunction

AIR system malfunction

POSSIBLE

CAUSE

Loose installation of A/F sensor

Leakage exhaust gas

A/F sensor malfunction

MAF sensor malfunction

Air suction in intake-air system

Fuel line pressure malfunction

Leakage fuel

Fuel pump unit malfunction

Pressure regulator (built-in fuel pump unit) malfunction

Ignition system malfunction

High-tension lead malfunction

Incorrect power supply to ignition coil

Ignition coil malfunction

Insufficient compression

Metering oil pump malfunction

Engine oil condition malfunction

Increased oil pressure

Oil passage malfunction

Engine malfunction

Fuel injector malfunction

PCM malfunction

Diagnostic procedure

#8

Well, after reading another thread about a gas pump incident I need to purge my fuel system anyways. Pretty sure my tank was pumped full of sludge. So I'll pull the pump assembly, clean the sock and everything that I can get to in the housing. That way I can check the voltage across the pump to see if it's fried. I emailed Deatschwerks and they don't have a specific application for an S2, so I'll have to measure the stock pump so I can compare sizes. Anyone know of a aftermarket pump that does fit the S2?

#10

I haven't checked for exhaust leaks, would an exhaust leak cause that big of a problem? It doesn't sound like I have a leak. I'm at the dealer right now getting a free scan to see if they can get anymore info for me, and a 20$ oil change

#11

Update: I had the dealer flash the computer, not good. They pulled 8 different codes, all of them pertaining to the ABS system..... Wtf? Codes were

C1956-20-ABS

B1318-20-ABS

U0155-20-ABS

U0073-FF-EPS

U1900-FF-IC

U2023-FF-IC

U2064-FF-IC

U2516-FF-IC

U2516-FF-SASM

I never got the pump housing out due to defeat by the ring of death, have to order the tool for that. Also wasn't able to check my fuel pressure as the pressure test kit I rented didn't have the right fittings. Not a very good day. I reset the computer, unhooked the battery, and hold down break. Re-torqued my test pipe bolts. Go for a test drive, it felt a little better, sounded different, but overall not much change.

C1956-20-ABS

B1318-20-ABS

U0155-20-ABS

U0073-FF-EPS

U1900-FF-IC

U2023-FF-IC

U2064-FF-IC

U2516-FF-IC

U2516-FF-SASM

I never got the pump housing out due to defeat by the ring of death, have to order the tool for that. Also wasn't able to check my fuel pressure as the pressure test kit I rented didn't have the right fittings. Not a very good day. I reset the computer, unhooked the battery, and hold down break. Re-torqued my test pipe bolts. Go for a test drive, it felt a little better, sounded different, but overall not much change.

#13

I wasn't going to just blindly change the pump. I wanted to take out the pump assembly to see if my sock was plugged and to test how much voltage was getting through the pump.

There weren't any exhaust leaks, I've checked for vacuum leaks. I sprayed ether all over looking for leaks, nothing.

There weren't any exhaust leaks, I've checked for vacuum leaks. I sprayed ether all over looking for leaks, nothing.

#14

Now why would I have thought that .....

including nothing on S2 pump failures ... maybe you'll be the first, but you need to do a proper pressure check first. Even if you pull it and everything is clean you will still have to do that, but if you do the pressure check first and all is well then theres no need to open it up. Proper analysis and procedures have a purpose.

.

BUT I still don't have any answers for replacing the fuel pump (other than OEM which is expensive and apparently prone to failure). Does the DW200 fit? If its not perfect and needs modification thats fine. I can't find a write up or anything, just the long posts about S1 pump options, putting S2 in a S1, S1 options for FI....... nothing for S2!!!!

including nothing on S2 pump failures ... maybe you'll be the first, but you need to do a proper pressure check first. Even if you pull it and everything is clean you will still have to do that, but if you do the pressure check first and all is well then theres no need to open it up. Proper analysis and procedures have a purpose.

.

Last edited by TeamRX8; 07-04-2014 at 09:24 AM.

#15

Well I don't know what to say, I cant get a mechanical pressure reading of fuel pressure although I really doubt it is that at this point. I decarbed the intake, and did a seafoam treatment. The lean codes haven't come back (its been over a week) and I have some top end power, although I have the damn flutter issue. I've read three other LONG post about flutter issues and power loss in higher rpms. So I'm back to square one, idle - 4.5k feels perfectly normal, responsive. I get the flutter around 5-5.5k and lasts untill roughly 6.5k, after that it seems to get its groove back until redline. I've ordered a wifi adapter so I run a diagnostic via my phone (torque) so I don't have any datalogs yet. Feels like the engine hears the flutter and pulls timing, then adds it back in after it goes away. 7-9k feels better and no flutter. I know this points to SSV or VFAD, my SSV moves easily by hand, and I've unplugged my VFAD with no change. So tired of chasing this problem, I just want it to feel like it did after the BHR ignition. For like a 2 week period it just WENT, felt amazing. Then the slow decay to where I am now. I'll post some datalogs soon as I get my adapter in the mail. To all that have offered feedback, thank you.

#16

mind posting pics of your spark plugs? You never know, might show us something out of the norm.

Also, how did you test the coils? Although the HEI spark tester is a good way to test spark, it isn't a end-all test. I wonder if the coils are failing to fire properly at the higher RPM band?

Try this as well (was true when i had my flutter issue)

1. WOT causes flutter

2. slowly climbing towards redline causes no flutter at all (no wot, just gentle progression to redline)

interested to see the results.

Lastly. my flutter was caused by my own failure to adhere to proper torque specs on the spark plugs. Unfortunately I didn't torque well enough and the plugs managed to slowly back themselves out causing fluttering (engine would lean out hard at higher rpms due to the poor spark). Dead giveaway was when i removed the plugs, realized they came out real easy, and realized the crush washer on the plugs didn't crush

Also, how did you test the coils? Although the HEI spark tester is a good way to test spark, it isn't a end-all test. I wonder if the coils are failing to fire properly at the higher RPM band?

Try this as well (was true when i had my flutter issue)

1. WOT causes flutter

2. slowly climbing towards redline causes no flutter at all (no wot, just gentle progression to redline)

interested to see the results.

Lastly. my flutter was caused by my own failure to adhere to proper torque specs on the spark plugs. Unfortunately I didn't torque well enough and the plugs managed to slowly back themselves out causing fluttering (engine would lean out hard at higher rpms due to the poor spark). Dead giveaway was when i removed the plugs, realized they came out real easy, and realized the crush washer on the plugs didn't crush

#18

Call it what you will but it happened. It was interesting because I actually had some oil come out of the plug hole as well which is what made me look in the first place.

#19

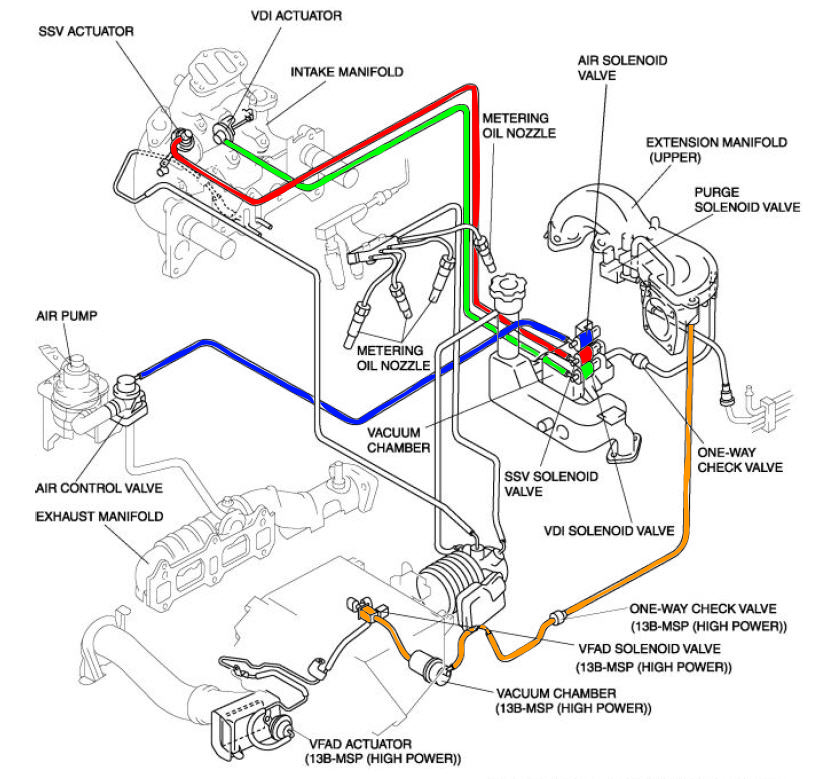

An exciting development! My idle crept up today, and all my pedals felt firmer than normal, so this reinforced the vacuum leak idea. When I got home I popped the hood for the daily "WTF is wrong with you conversation" and I could definitely hear a vacuum leak. I was poking around and the small vacuum hose going into the air pump had ZERO vacuum. I followed it into the bowels of the UIM and the sound looks like its coming from the bank of three vacuum nipple underneath. The blue wire in the picture is the one that had zero vacuum. I'm not a pro to know whether that line should have vac or not at idle, but the leak is defenitely one of those three, red, green or blue. Not sure when I'll be able to take the UIM to get to it, Sat at the latest.

In reference to the spark plugs Paimon, I checked them less than two weeks ago and all were tight. Double checked wires, re snapped everything down just to be safe. I tested with an HEI tester and coils seemed fine, no issues.

In reference to the spark plugs Paimon, I checked them less than two weeks ago and all were tight. Double checked wires, re snapped everything down just to be safe. I tested with an HEI tester and coils seemed fine, no issues.

#20

The air control valve vacuum line should only present a vacuum when the pump is activated - for a minute or so on stone cold starts. If your car was warm then you would have been right to find no vacuum here.

#22

A spark plug would have to be literally falling out to otherwise leak that much past all that fine thread length. The only way for it to happen is somebody forgot to fully install them properly since it obviously can't unthread itself very far with a spark wire attached. In that extreme case maybe, but just off-the-seat loose is not going to happen past 3/4" depth of fine thread. That's why the plug is built as such. It would be a microscopic vacuum leak on the intake cycle and maybe slight psi loss under compression at the most. Oil leaking past it is a progression over time factor.

To the OP: I thought you said it was ether checked for vacuum leaks? The fuel trim values at idle will tell the tale.

To the OP: I thought you said it was ether checked for vacuum leaks? The fuel trim values at idle will tell the tale.

#23

TeamRx8: I did ether test last week with no results, but I didn't have a vacuum hiss sound then either. I can't get to where I need to spray without taking the UIM off. As for idle STFT, I have freeze frame data from a p0420 code yesterday that was at 2240 rpm. It was 3.1, LTFT was at 6.3.

I don't have a real time data logger. None of the good ones talk with iPhones, stupid Bluetooth. I'd order a nice one from scan tool but the wifi one doesn't come out till sometime in August

Edit: I had those backwards, the STFT was 6.3, LTFT was 3.1

I don't have a real time data logger. None of the good ones talk with iPhones, stupid Bluetooth. I'd order a nice one from scan tool but the wifi one doesn't come out till sometime in August

Edit: I had those backwards, the STFT was 6.3, LTFT was 3.1

Last edited by noredline; 07-08-2014 at 07:26 PM.

#24

UPDATE: Well I found my intake leak, it wasn't at all what I expected though. I thought that the seal between the middle manifold(APV runners) and the upper manifold was bad. Or that I had a bad hose going to the vacuum chamber for the SSV and VDI actuators. I pulled the manifold off ( few different steps for S2 than S1, for another post..) and looked at everything and scratched my head. Everything looked fine, no tears or holes, I vacuum tested each of the SSV and VDI and everything was good there. Inside of the lower mani looked clean, all the rubber gaskets looked good. So I decided to clean everything while I had it out, and while cleaning the APV runners I noticed that the cleaner I sprayed in the runners could run right out the seam at the back of the housing. I couldn't believe it, I tested it a few times to be sure I wasn't crazy. There was maybe an 1/8th" gap between the two pieces of plastic and the cleaner could run right through it. So I filled it with some 1 minute gasket maker and put everything back together. Reset the computer, and I've put 65miles on it since then (sat), it feels great!! It feels like the car I bought 3 months ago. Steady even build of power, 5-7k feels great, no bogging like before. Below is a picture of where I filled, the light grey is the size of the gap.

In hindsight, I wish I would have filled the whole manifold. There were a few other spots were the gaps were larger as well.

In hindsight, I wish I would have filled the whole manifold. There were a few other spots were the gaps were larger as well.