186000 miles 2007 teardown-for your viewing pleasure

#1

186000 miles original engine 2007 teardown-for your viewing pleasure

Last edited by kevink0000; 04-23-2018 at 12:18 PM. Reason: add to title

#12

more pics

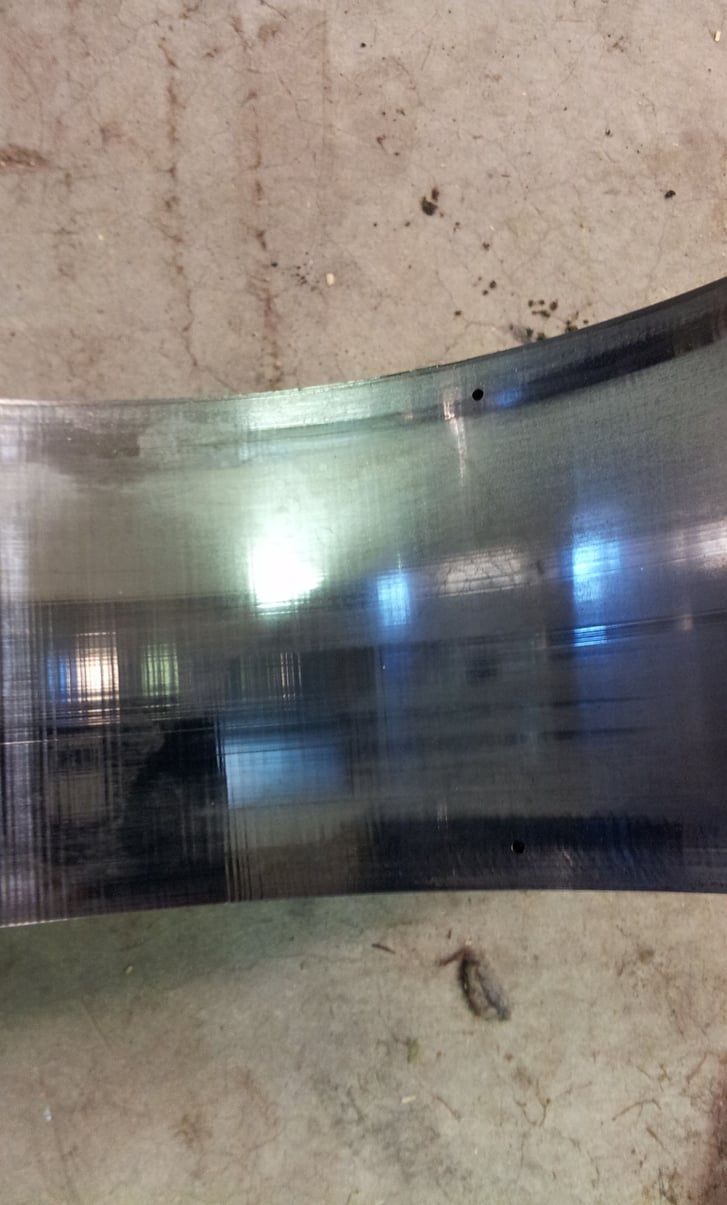

Front rotor. Again very clean. Shows recent damage, which I think came through the intake manifold when the rear rotor's apex seals let go. I found fine pieces of metal in the manifold itself.

#13

more pics

Front rotor showing cleanliness and recent damage. All seals were intact on this one when engine was disassembled. I believe there was distribution of fragments from the rear rotor to the front through the intake manifold. I found lots of metal shards at the rear rotor's intake port, and some further down the port on the way to the front rotor,

#17

PO said he used Castrol gtx5-20, changed oil between 3-5k miles, and the engine used a quart or so between changes. I don't think he premixed, and I have asked him for more info on his driving habits. It was registered in Southern California for its entire life before I got it.

He used FL22 coolant based on what I saw in the engine, which kept the metal corrosion free. Here is a previous post.

I will have more pictures up soon.

Lack of lubrication, yes. I have a 186000 mile DD original 2007 engine taken apart in my garage currently. The PO kept it well, and used GTX 5-20 exclusively, which seems to me based on this engine to be a better oil than I thought it was. The bearings look great, the innards are very clean, but what killed it was lack of lubrication to the apex seals in my opinion. The side seals all had large clearances to the corner seals (.018- .022"), but minimal wear on their faces, and minimal wear on the front irons. The engine ate an apex seal on the rear rotor ultimately, but prior to that compression on both rotors was low, the engine would barely start with a 13t starter, hot or cold. I believe from the wear I see that the apex seal fatigued from excessive "fretting" type wear against the rotor groove and/or the side piece, and then cracked.

The undamaged but worn front rotor housing had evidence of metal to metal contact (very shiny mirror finish in many areas) from the apex seals. No chrome flaking on this engine. The apex seals themselves appear to be the primary wear item as engineered originally, as they are much softer material than what they ride in and against in the engine. They were worn in the middle portion more than the sides, which others have posted, likely from heat related "banana" deforming. Unfortunately, from that fretting wear I described, it looks like the seals are basically kept "dry" in the grooves, with very little in the way of lubrication at that point with the stock injection amounts.

It looks like the stock oil amount and "aiming" was adequate to keep the side seals/irons from wearing excessively, but the apex seals suffered. Again when the forum rules allow me to post the engine pics, I will do so. I think they will be interesting given the mileage of the engine.

He used FL22 coolant based on what I saw in the engine, which kept the metal corrosion free. Here is a previous post.

I will have more pictures up soon.

Lack of lubrication, yes. I have a 186000 mile DD original 2007 engine taken apart in my garage currently. The PO kept it well, and used GTX 5-20 exclusively, which seems to me based on this engine to be a better oil than I thought it was. The bearings look great, the innards are very clean, but what killed it was lack of lubrication to the apex seals in my opinion. The side seals all had large clearances to the corner seals (.018- .022"), but minimal wear on their faces, and minimal wear on the front irons. The engine ate an apex seal on the rear rotor ultimately, but prior to that compression on both rotors was low, the engine would barely start with a 13t starter, hot or cold. I believe from the wear I see that the apex seal fatigued from excessive "fretting" type wear against the rotor groove and/or the side piece, and then cracked.

The undamaged but worn front rotor housing had evidence of metal to metal contact (very shiny mirror finish in many areas) from the apex seals. No chrome flaking on this engine. The apex seals themselves appear to be the primary wear item as engineered originally, as they are much softer material than what they ride in and against in the engine. They were worn in the middle portion more than the sides, which others have posted, likely from heat related "banana" deforming. Unfortunately, from that fretting wear I described, it looks like the seals are basically kept "dry" in the grooves, with very little in the way of lubrication at that point with the stock injection amounts.

It looks like the stock oil amount and "aiming" was adequate to keep the side seals/irons from wearing excessively, but the apex seals suffered. Again when the forum rules allow me to post the engine pics, I will do so. I think they will be interesting given the mileage of the engine.

__________________

#21

Many thanks for the information. I'm going to continue more frequent OCI of about 1000-1500 using Wally World's finest 5W30 and continue premixing at > 0.25 oz/gal with a HQ 2-cycle premix that's rated for JASO FC or FD (not TCW3). Currently using Citgo Mystik 2-cycle JASO FD since it's readily available locally for $18/5 qt. bottle.

#24

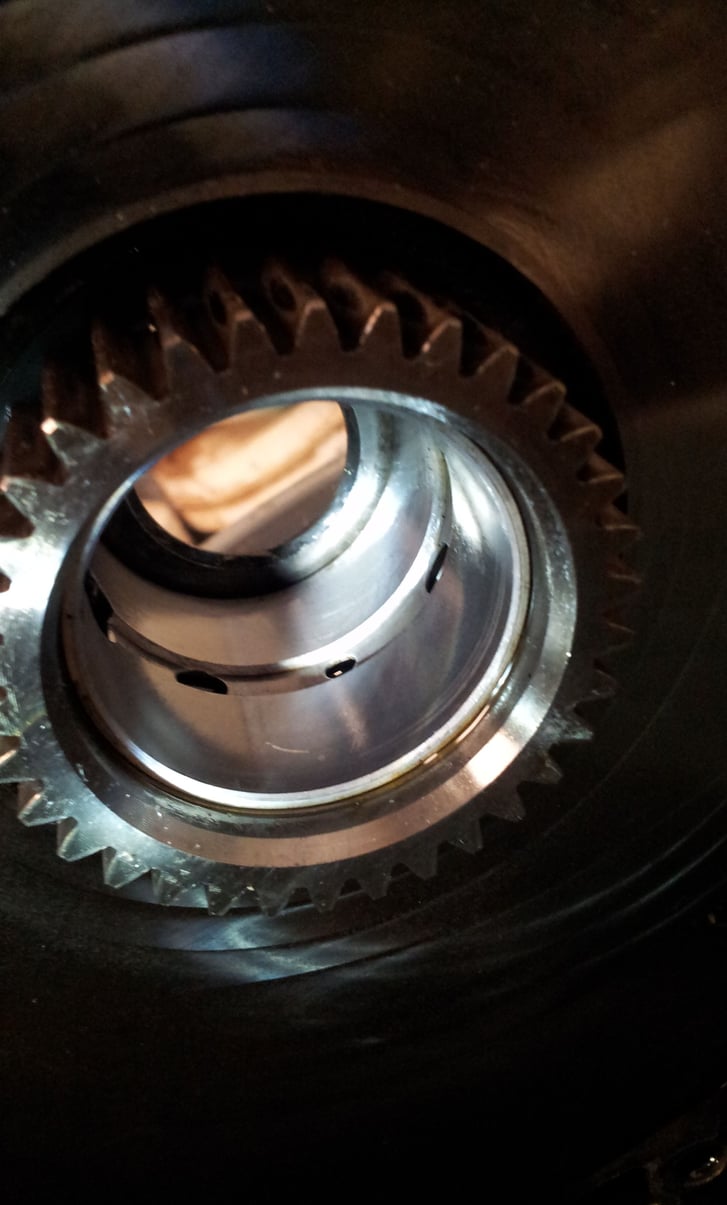

apex seals against a straightedge with light behind

You can see how much the seal center section is worn here. The light is coming through the gap between the seal face and a straightedge.